Page 1

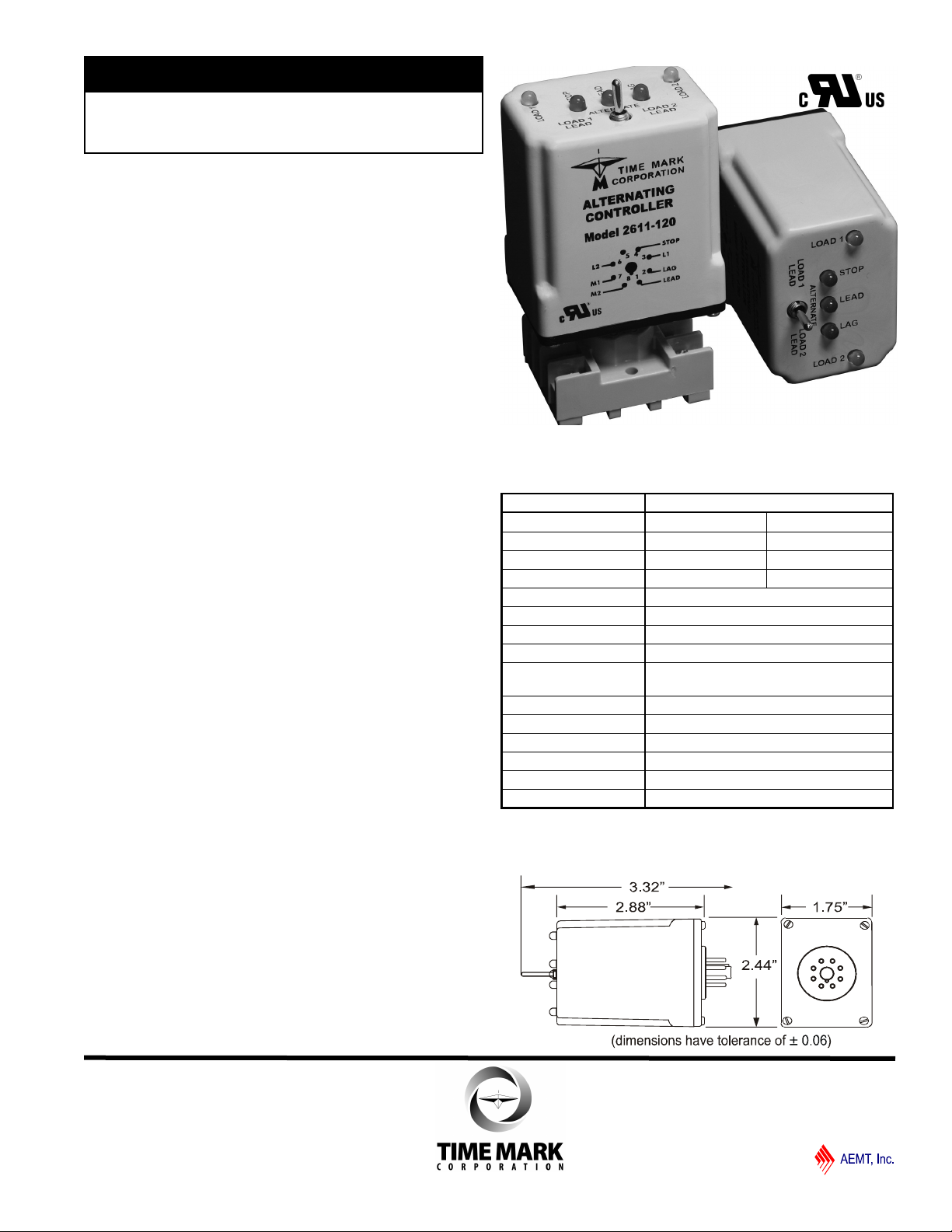

MODEL 2611

TIME MARK is a division of

Alternating Controller

Alternate Two Loads or Lock Sequence

with Lead Select Switch

Sequence On-Simultaneous off

(S.O.S.O.) Operation

Works with 3 Switches - STOP, LEAD & LAG

5 LEDs Indicate Switch and Relay Status

Control Switch Fault Detection

Replaces Multiple Components

Saving Space and Labor

DESCRIPTION

The Model 2611 Alternating Controller is a

microprocessor based controller designed for use

where two loads are required to alternate to provide

equal run time on the loads. LED indicators show the

status of the unit’s three control switch inputs and 2 load

outputs. A lead select switch allows the loads to

alternate normally in the center position, or disable

automatic sequencing and lock in a 1-2 or 2-1

sequence.

When a Stop, Lead or Lag switch closes, the

corresponding LED on top of the unit will illuminate.

When the Stop switch and Lead switch closes, Load 1

or Load 2 will come on and the corresponding green

LED will illuminate. If fluid levels continue to rise and

the Lag switch closes, the 2nd load will energize.

Loads remain energized until the Stop switch opens or

a fault condition is detected. See Typical Pump Down

Application - SOSO Operation on page 3 for details.

FAULT DETECTION

If any control switches open or close out of order, the

faulty switch is bypassed by the fault detection logic.

STOP, LEAD and LAG switch inputs are reassigned to

maintain safe operation. Should a faulty or fouled

switch begin operating normally, the fault detection logic

will restore STOP, LEAD and LAG assignments to their

proper designation.

SPECIFICATIONS

MODEL 2611

Supply Voltage 24V AC/DC 120V AC/DC

Voltage Range 20 - 28V 90 - 130V

Max Voltage 30V 140V

Supply Current

Control Current

Operating Duty Continuous

Min. Cycle Time 100ms

Contacts 10A at 120VAC resistive

Expected Relay Life

Operating Temp +32ºF to +140º F

Humidity Tolerance 0 - 97% w/o condensation

Mounting 8-pin socket*

Enclosure Material ABS plastic

Weight 4.3 oz.

Agency Approvals UL Recognized (U.S. & Canadian)

0.05A 0.01A

0.001 amp

Mech: 10 million operations

Elec: 100,000 operations at rated load

* Order with 8-Pin Socket 51X120

DIMENSIONS - Model 2611

Page 1 of 3 11/2011

© 2011 TIME MARK CORPORATION

Page 2

LAG

LEAD

STO P

MO D EL 2 611

2

1

4

LOA D CO M M O N TO L 2

3

6

8

7

M2

M1

L

O

A

D

1

L

O

A

D

2

uC

MODEL 2611

TIME MARK is a division of

Alternating Controller

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

GENERAL SAFETY

POTENTIALLY HAZARDOUS VOLTAGES ARE PRESENT AT THE TERMINALS OF THE MODEL 2611.

ALL ELECTRICAL POWER SHOULD BE REMOVED WHEN CONNECTING OR DISCONNECTING WIRING.

THIS DEVICE SHOULD BE INSTALLED AND SERVICED BY QUALIFIED PERSONNEL.

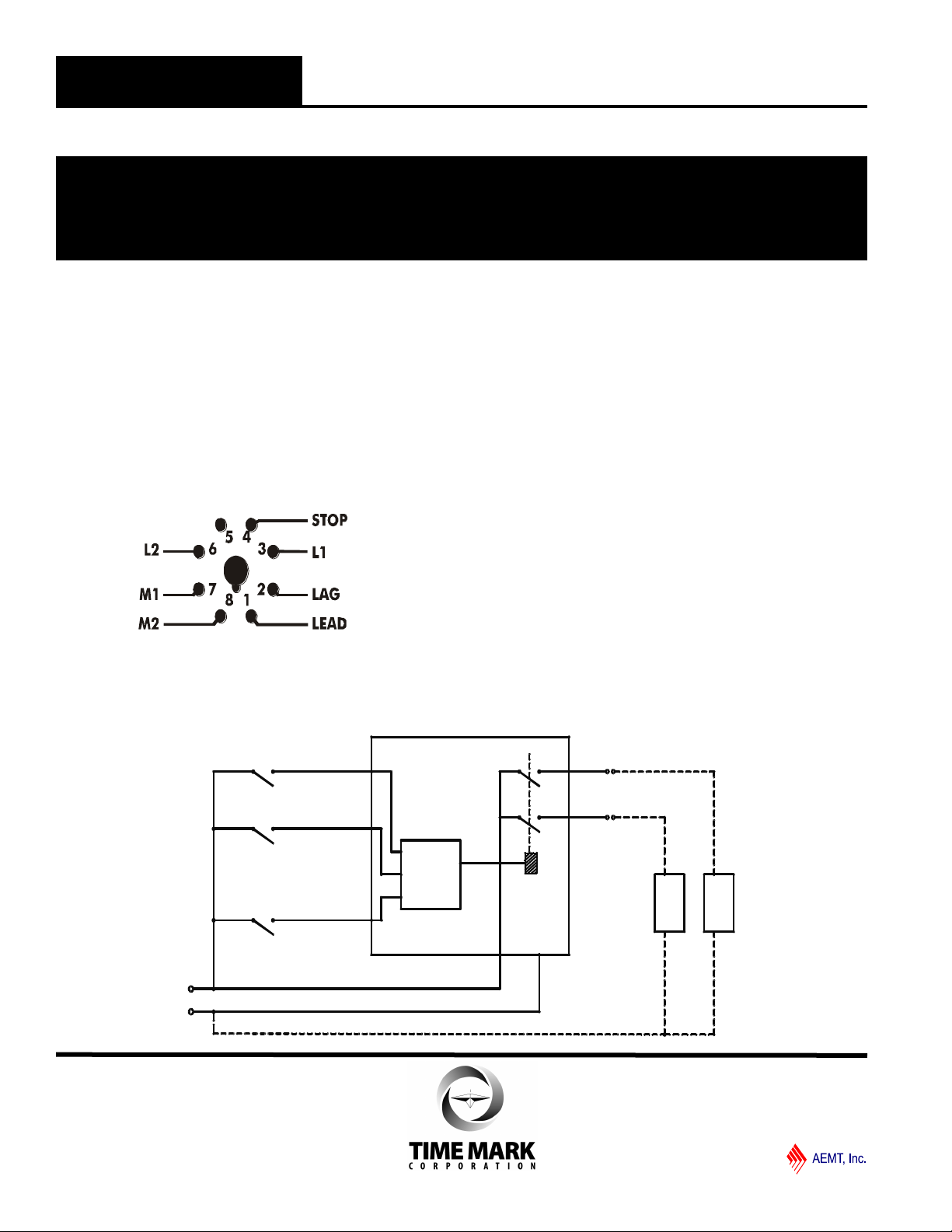

INSTALLATION

Connect wiring to the socket as indicated in the

following examples.

The Model 2611 Alternating Controller is extremely

versatile and can be used in many other configurations

besides those shown. Any type of switches (float,

TROUBLESHOOTING

Should the Model 2611 fail to operate properly, check

to see that voltage level and connections are correct

and securely attached to equipment. Should problems

persist, contact the factory at 800-862-2875 for

assistance.

pressure, etc.) can be used as a control switch;

however, it must be connected as shown (from L1 to the

control input) or the alternator will not function properly.

WARRANTY

This product is warranted to be free from defects in

materials and workmanship, and is covered by our

exclusive 5-year Unconditional Warranty. Should this

device fail to operate for any reason, we will repair it for

five years from the date of manufacture. For complete

warranty details, see the Terms and Conditions of Sales

page in the front section of the Time Mark catalog or

contact Time Mark at 1-800-862-2875.

APPLICATION DIAGRAM - 2611

NOTE: All drawings shown with no power applied.

Page 2 of 3 11/2011

© 2011 TIME MARK CORPORATION

Page 3

EXTE RNAL REL AY

E-S TOP

ALA RM

L2

L1

NC

NO

LAG

LEA D

STO P

MO DEL 2 611

2

1

4

LOAD COMM ON TO L2

3

6

8

7

M2

M1

L

O

A

D

1

L

O

A

D

2

uC

MODEL 2611

EXTE RNAL R ELAY

E-S TOP

ALAR M

L2

L1

NC

NO

LAG

LEA D

STOP

MOD EL 261 1

2

1

4

LOAD COMM ON TO L2

3

6

8

7

M2

M1

L

O

A

D

1

L

O

A

D

2

uC

Alternating Controller Page 3 of 3 11/2011

TYPICAL PUMP DOWN APPLICATION - SOSO Operation

Step 1

In this example, the three normally open

dry float switches are designated Stop,

Lead and Lag. All switches begin open

and Load 1 and Load 2 are deenergized. The lead select switch

begins in the center (alternate) position.

Step 2

Fluid levels begin rising. STOP switch

closes, red STOP LED lights indicating

switch closure. No loads are

energized.

Step 3

Fluid levels continue to rise, LEAD

switch closes and energizes 1st load.

Red LED lights indicating LEAD switch

closure and a green LOAD 1 or LOAD 2

LED lights indicating which load is

currently LEAD.

Step 4

Fluid levels continue to rise, LAG switch

closes, energizes 2nd load, and lights

red LAG switch LED and remaining

green LOAD LED.

Step 5

As fluid levels fall, LEAD and LAG

switches open, loads remain energized

until the STOP switch opens. Red

switch status LEDs turn off as

corresponding switches open.

Step 6

Fluid levels fall below the STOP switch,

de-energizing all loads and turning off

green load status LEDs. Control logic

alternates LEAD load, unless automatic

sequencing is disabled by the Lead

Select switch.

OPTIONAL APPLICATION DIAGRAMS NOTE: All drawings shown with no power applied.

Using emergency STOP float switch (E-Stop) and SPDT relay to trigger alarm & cut power to LOAD 1 and LOAD 2.

As above, but wired with a high alarm float switch

Page 4

TIME MARK is a division of

Have Questions? Call us at (800) 862-2875 and talk to a real live person.

Main (918) 438-1220

11/2011

© 2011 TIME MARK CORPORATION

Loading...

Loading...