Page 1

MODEL 252

L1

L2

L3

M

M

M

M

MOTOR

O/L's

Start

Remote

Indicator

Lamp

Stop

Control

Voltage

Model

252

M

3 4

5

6 1

2

8

7

TIME MARK is a division of

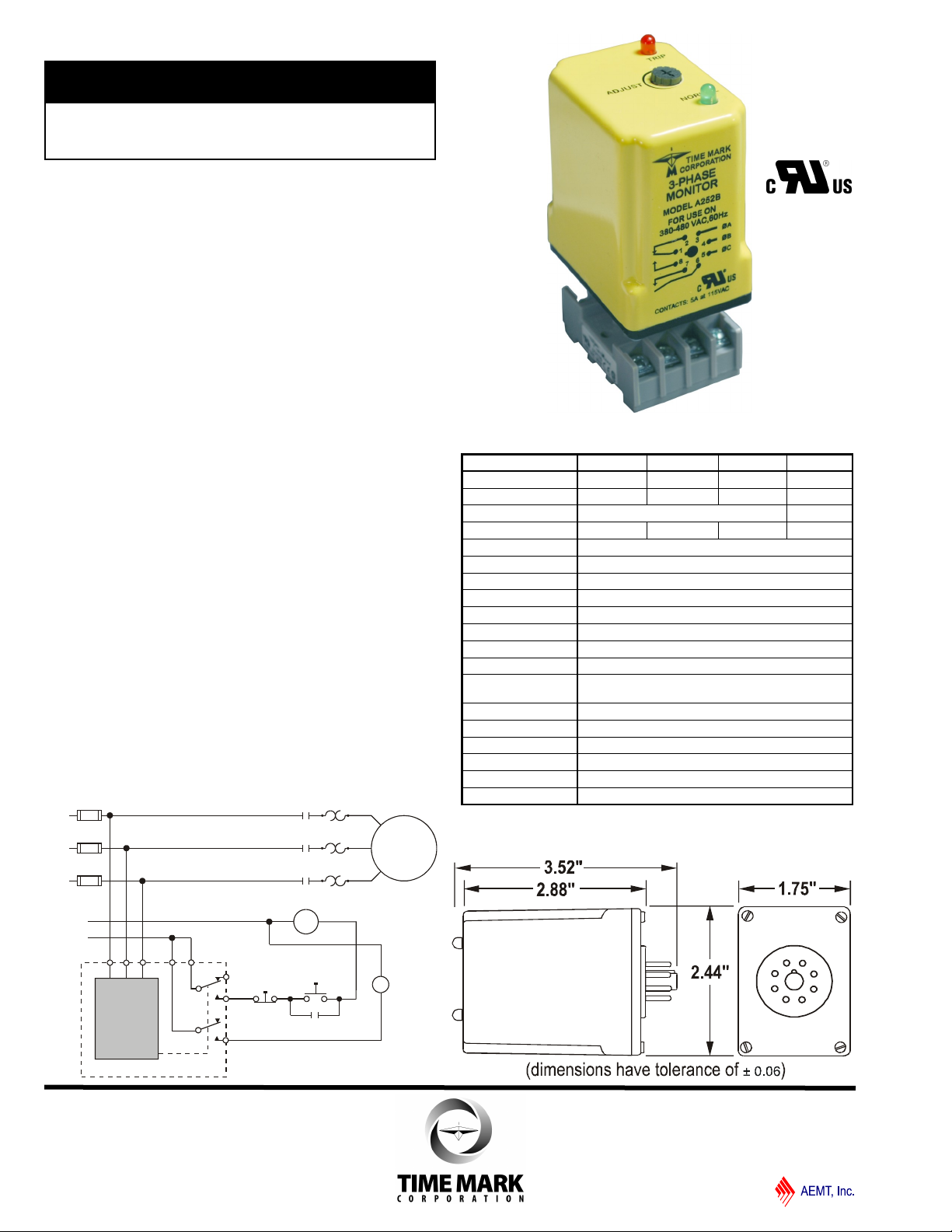

3-Phase Monitor

Detects Phase Loss, Low Voltage

and Phase Reversal

50Hz and 60Hz versions

Automatic Reset

DESCRIPTION

The Model 252 3-Phase Monitor continuously monitors

3-phase power lines for abnormal conditions. When

properly adjusted, the Model 252 will detect phase loss

on a loaded motor even when regenerated voltage is

present.

This device consists of a solid-state voltage and phaseangle sensing circuit, driving an electromechanical relay

with one SPDT and one SPST contact. When correct

voltage and phase rotation are applied, the internal

relay will energize. A fault condition will de-energize the

relay. When the fault is corrected the Model 252 will

automatically reset.

The Model 252 does not require a neutral connection

and can be used with WYE or DELTA configured

systems. Four versions cover 120V, 208/240V and

480V, 60Hz, and 380V, 50Hz. Adjustment ranges are

sufficiently wide to allow for proper adjustment to

existing conditions. Two LED indicators are provided to

aid in adjustment and system troubleshooting.

TYPICAL APPLICATION

SPECIFICATIONS

Model B252B 252B A252B EX252B

Nominal AC Voltage 120VAC 208/240VAC 480VAC 380VAC

Adjustment Range 85-120VAC 160-240VAC 380-480VAC 300-380VAC

Frequency 60Hz 50Hz

Power Consumption

Transient Protection 2500V for 10ms

Repeat Accuracy

Response Time

Reset Time

Reset Type Automatic

Dead Band 2%

Output Contacts 1 - SPDT 1 - SPST (N.O.)

Contact Rating 5A at 115VAC resistive

Expected Relay Life Mech: 10 million operations

Operating Temp - 20º to 131º F

Humidity Tolerance 97% w/o condensation

Enclosure Material ABS plastic

Mounting 8-pin socket (*order separately)

Weight 5 oz.

Agency Approvals UL Recognized (U.S. & Canadian)

0.25W 0.50W 1.5W 1.25W

0.1% of set point (fixed conditions)

0.05 seconds

0.05 seconds

Elec: 100,000 at rated load

*Order 8-pin socket number 51X120

Shows No Power Applied

DIMENSIONS

11/2011

© 2011 TIME MARK CORPORATION

Page 2

A

B

C

MODEL 252

TIME MARK is a division of

3-Phase Monitor

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

GENERAL SAFETY

POTENTIALLY HAZARDOUS VOLTAGES ARE PRESENT AT THE TERMINALS OF THE MODEL 252.

ALL ELECTRICAL POWER SHOULD BE REMOVED WHEN CONNECTING OR DISCONNECTING WIRING.

THIS DEVICE SHOULD BE INSTALLED AND SERVICED BY QUALIFIED PERSONNEL.

Installation Instructions

INSTALLATION

Mount the socket in a suitable enclosure. A NEMA approved

enclosure, designed for socket-mounted relays, is available

from Time Mark Corporation.

Connect the 3-phase power to terminals 3, 4 and 5 on the

socket. Phase rotation may be verified using a Time Mark

Model 108A or 108B Phase Sequence Detector.

Connect the load control wiring to the appropriate terminals on

the socket. The SPST contacts (pins 6 and 7) are electrically

isolated from the SPDT contacts.

For motor control and phase loss alarm applications; use

the SPDT contacts.

For auxiliary indicator applications; use the appropriate

SPST contacts.

Insert the Model 252 into the socket.

Apply power. If the contacts do not transfer, (TRIP indicatorOn ), check that all phases are present and of the correct

voltage. If power is correct, rotate the level adjustment counter

-clockwise.

If the contact still does not transfer, remove power and reverse

two of the three phase wires at the socket (phase rotation is

reversed). Re-apply power. The contact should transfer to

provide a signal path between both sets of normally-open

contacts. The green LED (NORMAL) should be lit.

Note: When installing the Model 252 in areas of high humidity

or contamination, it is recommended that the base area and all

exposed metal parts of the socket be coated liberally with a

good quality silicone grease, such as Dow Corning DC-4 or

DC-4X. Insert the unit into the socket and wipe off excess

grease around the base. This will prevent the entrance of

moisture and other contaminants into the base and socket

area.

PIN DIAGRAM

ADJUSTMENT

The following procedure will adjust the Model 252 to trip below

the nominal voltage.

Rotate the level adjustment clockwise, until the relay contact

transfers (TRIP indicator On). Slowly turn the adjustment

counter-clockwise, until the contact resets. This setting will be

correct for most applications.

Should nuisance tripping occur, turn the adjustment slightly

farther counter-clockwise, lowering the trip level. A more

accurate adjustment procedure requires a 3-phase variac,

allowing the voltage to be lowered to a specific voltage. The

Model 252 can then be set to trip at this precise voltage level,

when installed in the motor control circuit. Factory set

versions are also available.

TROUBLESHOOTING

Should the Model 252 fail to operate properly, check that all

three voltages are present and are of the correct level and

phase rotation (a Model 108A or 108B Phase Sequence

Detector may be used to verify phase rotation). Check all

fuses and verify that all wiring connections are correct. Should

problems persist, contact the manufacturer at 800-862-2875.

WARRANTY

This product is warranted to be free from defects in materials

and workmanship, and is covered by our exclusive 5-year

Unconditional Warranty. Should this device fail to operate

for any reason, we will repair it for five years from the date of

manufacture. For complete warranty details, see the Terms

and Conditions of Sales page in the front section of the Time

Mark catalog or contact Time Mark at 1-800-862-2875.

11/2011

© 2011 TIME MARK CORPORATION

Loading...

Loading...