Operating Manual

Keyboard Control Unit

Copyright 1995

All Rights Reserved

Manual No. 73A005-B

Preface

Assistance and Information

TimeLine Technical Support

1755 La Costa Meadows Drive: Phone:(760) 761-4440

Suite B Fax: (760) 761-4449

San Marcos, CA 92069 SUPPORT@TIMELINEVISTA.COM

Software Version Serial Number

Technical Assistance is available ONLY if the Keyboard Control

Unit (KCU) is registered. Mail in your Warranty Card

immediately to register the KCU.

Remember, when calling for technical support, you must provide

the software version and KCU serial number so that we can give

you accurate and prompt assistance.

Printing History

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form, or by any means electronically, mechanical,

photocopying, recording or otherwise, without the prior written permission of TimeLine

Vista, Inc.

Each revision will cause the letter to the right of the manual part number to change.

The purpose for each revision will be listed below. Events such as the addition of a

feature or functional test will cause the revision number to change.

Internal Document Number: 73K005 Revision B

Revision Date Serial No. Affected Changes Made

A All First Edition

B 8/11/95 All Complete Rewrite

Printed in the United States of America.

ii Keyboard Control Unit

09/08/00

Limited Warranty

Labor and Parts

Preface

TimeLine Vista, Inc. (TimeLine) warrants this product against

defects in material or workmanship as follows:

1. For a period of ninety (90) days from the date of purchase

TimeLine will at it’s option, either perform necessary repairs

at it’s expense or pay the labor charges of others it authorizes

to repair the defective product. After the initial 90 day period

labor charges are the responsibility of the purchaser.

2. In addition TimeLine will supply at no charge, new or rebuilt

replacements for defective parts for a period of one (1) year

from the date of purchase.

To obtain warranty service, the purchaser must notify TimeLine

in writing during the initial ninety (90) day period. TimeLine will

then authorize the purchaser to take or deliver, prepaid, the

product to TimeLine or it’s authorized Service Center.

Parts Only

During the remainder of the warranty period, any defective part

will be replaced if the purchaser will take or deliver the product,

prepaid to TimeLine. Labor incurred in the repair is at the

purchaser’s expense.

This Warranty does not cover any damage due to accident, misuse,

abuse, or negligence.

We suggest that the purchaser retain the dated sales receipt as

evidence of the original date of purchase. This warranty is not

transferable and applies only to the original, registered purchaser.

REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS

WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER. TIMELINE SHALL NOT BE LIABLE FOR BREACH OF

ANY EXPRESS OR IMPLIED WARRANTY ON THIS PRODUCT,

EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW,

AND EXCEPT FOR THE LIMITED WARRANTY DESCRIBED

ABOVE. TIMELINE EXPRESSLY DISCLAIMS ANY WARRANTY,

EXPRESS OR IMPLIED, OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

Keyboard Control Unit iii

09/08/00

USA: Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on how long

an implied warranty lasts, so the above limitation and exclusions

may not apply to you. This warranty gives you specific legal rights

and you may also have other rights that vary from state to state.

Preface

Safety

To assist identification of potentially hazardous circumstances or

procedures, warnings and cautions will be displayed with the

appropriate text. Occasionally, information that provides an

enhanced understanding of the text will be provided as a Note.

Note: A Note provides information about or an explanation of a

topic related to the subject being discussed.

Warnings describe a procedure that if not followed as specified could potentially

cause damage to the equipment, a loss of data, or create an error condition.

Manual Contents and Use

Warning

Introduction

Applications

Installation

This manual starts with information that is used most frequently

and moves to less frequently used information. To use the manual

effectively, first review the applications and system configurations

presented in the Applications chapter to determine your

requirements and preferences.

Then use the Installation chapter to install the Keyboard Control

Unit and make the correct equipment connections. Follow the

initialization and start up tutorial described in the Getting

Started chapter to get a “hands-on” demonstration of the KCU’s

capabilities.

If you experience any difficulties, refer to the Troubleshooting

chapter to analyze the problem. Refer to the subsequent chapters

for detailed information about each of the KCU functions.

Provides KCU features, a system overview, system

configurations, and specifications.

Illustrates some of the most common KCU applications.

Describes KCU installation and interface procedures.

Getting Started

Troubleshooting

Features and Controls

Advanced Features

iv Keyboard Control Unit

Describes KCU basic operating procedures.

List the most common KCU messages, prompts, and warnings.

Describes the key functions of the KCU.

Describes those functions available uniquely in non-080 series

09/08/00

KCU software configurations.

Preface

Appendix

SMPTE Made Simple

Provides basic information and various applications using

SMPTE time code.

Key Combination Guide

Provides Key and Key Combination Identification Numbers for

"stuck key" errors.

Glossary

An alphabetic list of terms used during the discussion of the

KCU.

Quick Reference Guide

Graphical charts of the KCU Setup options.

Conventions Used for Examples

This manual uses the following conventions.

Press

Press a key, generally a movement key or function key such as

[CLR].

Select

You see

[CLR]

LED

Key

Press or adjust the indicated key or wheel to obtain a result or

display

A key word, indicator, or number that you can see on the front

panel or display.

This indicates a particular key on the KCU, such as the clear key

in this example.

This is one of the lights on the KCU.

Each of the buttons, switches or keys on the KCU that you press

to cause something to happen.

Keyboard Control Unit v

09/08/00

Preface

vi Keyboard Control Unit

09/08/00

Table of Contents

CHAPTER 1 INTRODUCTION

Keyboard Control Unit Features .......................................................................................... 1-2

System Overview................................................................................................................... 1-4

Keyboard Control Unit (KCU)......................................................................................... 1-5

Lynx-2 and Lynx Time Code Modules ............................................................................ 1-6

Lynx System Supervisor Unit (SSU) .............................................................................. 1-7

Lynx Console Control Unit (CCU) .................................................................................. 1-8

Remote Motion Controller ............................................................................................... 1-9

Jog/Shuttle Wheel Assembly Kit....................................................................................1-10

System Configurations .........................................................................................................1-11

Specifications........................................................................................................................1-12

Keyboard .........................................................................................................................1-12

Jog/Shuttle Wheel...........................................................................................................1-12

Power Supply ..................................................................................................................1-12

Physical...........................................................................................................................1-12

Software Versions...........................................................................................................1-12

CHAPTER 2 APPLICATIONS

Stand-alone KCU Operation ................................................................................................. 2-2

Typical Uses..................................................................................................................... 2-2

Considerations ................................................................................................................. 2-2

Stand-alone KCU with a VTR............................................................................................... 2-3

Typical Uses..................................................................................................................... 2-3

Considerations ................................................................................................................. 2-3

Varispeed and Gearbox Operations with the KCU .............................................................. 2-4

KCU and System Supervisor Unit (SSU) Operation ........................................................... 2-5

CHAPTER 3 INSTALLATION

Hardware Supplied ............................................................................................................... 3-1

System Setup Planning ......................................................................................................... 3-2

Power ............................................................................................................................... 3-2

Cabling ............................................................................................................................. 3-2

Power On Initialization ................................................................................................... 3-2

vii 2/6/95

Keyboard Control Unit

Table of Contents

Installing the KCU.................................................................................................................3-2

Cabling..............................................................................................................................3-2

Connecting the KCU and Power Supply Unit .................................................................3-4

Power Supply....................................................................................................................3-5

Connecting the Lynx-2 Modules ......................................................................................3-6

GPIs ..................................................................................................................................3-7

System Supervisor Unit ...................................................................................................3-8

Quick Test and Initialization.................................................................................................3-9

Testing the Lynx-2 Modules.............................................................................................3-9

Setting Up the KCU .......................................................................................................3-10

Verifying Communications.............................................................................................3-10

Interface Diagrams ..............................................................................................................3-10

KCU Stand-Alone ...........................................................................................................3-11

Post-Production System–System Supervisor Unit........................................................3-12

CHAPTER 4 GETTING STARTED

Initializing and Configuring the KCU...................................................................................4-2

Turning on the KCU.........................................................................................................4-2

Resetting the KCU ...........................................................................................................4-2

Setting the System Reference ..........................................................................................4-3

Initializing Lynx Communication ....................................................................................4-3

Using KCU Memory...............................................................................................................4-4

Capturing a Time Code Value..........................................................................................4-4

Retrieving a Time Code Value .........................................................................................4-5

Changing Memory Size ....................................................................................................4-5

Using Time Code Registers....................................................................................................4-6

Local Zero Register...........................................................................................................4-6

Time Register ...................................................................................................................4-7

Preroll Register ................................................................................................................4-7

Postroll Register ...............................................................................................................4-7

Reference Sync Point Register .........................................................................................4-8

Source Sync Point Register ..............................................................................................4-8

Offset Register..................................................................................................................4-9

Error Register...................................................................................................................4-9

In Point Register ..............................................................................................................4-9

Out Point Register.......................................................................................................... 4-10

Duration Register...........................................................................................................4-11

Cue Point Register..........................................................................................................4-12

viii 09/08/00

Keyboard Control Unit

Table of Contents

Grouping Machines with the KCU ......................................................................................4-12

Machine Modes ...............................................................................................................4-12

Changing the Master Machine.......................................................................................4-15

Separating the Master and Reference Machines...........................................................4-15

Using Offsets ........................................................................................................................4-16

Setting an Offset.............................................................................................................4-16

Calculating Offsets Using Sync Points ..........................................................................4-17

Trimming an Offset ........................................................................................................4-18

Editing with the KCU ..........................................................................................................4-20

Editing Example .............................................................................................................4-20

Setting a Sync Point .......................................................................................................4-21

Clearing a Sync Point .....................................................................................................4-22

KCU Messages and Errors...................................................................................................4-22

Displaying System Error Messages ...............................................................................4-22

Displaying Version Numbers .........................................................................................4-23

Accessing Status Mode ...................................................................................................4-23

Setup [SETUP] Options .......................................................................................................4-23

Setup Options .................................................................................................................4-24

Setup Example................................................................................................................4-25

KCU Options Menus ............................................................................................................4-26

Editing [EDIT] Options Menu........................................................................................4-26

Event Select GPI [EVNT] Options Menu.......................................................................4-27

Film [FILM] Options Menu............................................................................................4-27

SSU List [LIST] Options Menu......................................................................................4-27

Edit Looping [LOOP] Options Menu..............................................................................4-28

System [SYS] Options Menu ..........................................................................................4-28

Track Select [TRKS] Options Menu...............................................................................4-28

Transport [TRAN] Options Menu ..................................................................................4-29

CHAPTER 5 TROUBLESHOOTING

Keyboard Power-Up Messages.............................................................................................. 5-2

Prompts.................................................................................................................................. 5-2

Self Test Messages ................................................................................................................ 5-4

System Error Messages......................................................................................................... 5-5

Warnings ............................................................................................................................... 5-6

Keyboard Control Unit

09/08/00 ix

Table of Contents

CHAPTER 6 FEATURES AND CONTROLS

KCU Display Screen ..............................................................................................................6-2

Machine Information........................................................................................................6-2

Time Code Information ....................................................................................................6-3

Machine Status.................................................................................................................6-3

Calculator Scratch Pad ....................................................................................................6-4

Transport Controls.................................................................................................................6-5

LOC (Locate) Key .............................................................................................................6-5

CUE Key ...........................................................................................................................6-5

ALL STOP Key .................................................................................................................6-5

ROLLBACK Key...............................................................................................................6-6

REPLAY Key ....................................................................................................................6-6

EDIT Key ..........................................................................................................................6-6

<< (Rewind) Key ...............................................................................................................6-7

>> (Fast Forward) Key .....................................................................................................6-7

■ (Stop) Key......................................................................................................................6-7

> (Play) Key ......................................................................................................................6-7

REH Key ...........................................................................................................................6-8

REC Key ...........................................................................................................................6-8

Using the Jog/Shuttle Wheel and Controls ...........................................................................6-9

TRIM Key .........................................................................................................................6-9

JOG Key..........................................................................................................................6-10

NEXT Key.......................................................................................................................6-10

SHUTTLE Key ...............................................................................................................6-10

ENTR Key.......................................................................................................................6-10

Device Select Keys ...............................................................................................................6-11

SYS Key .......................................................................................................................... 6-11

GEN Key.........................................................................................................................6-11

FILM Key........................................................................................................................6-11

SETUP Key.....................................................................................................................6-11

TRKS Key .......................................................................................................................6-12

TRAN Key.......................................................................................................................6-12

EVNT Key.......................................................................................................................6-12

LIST Key.........................................................................................................................6-13

MEM Key........................................................................................................................6-13

x 09/08/00

Keyboard Control Unit

Table of Contents

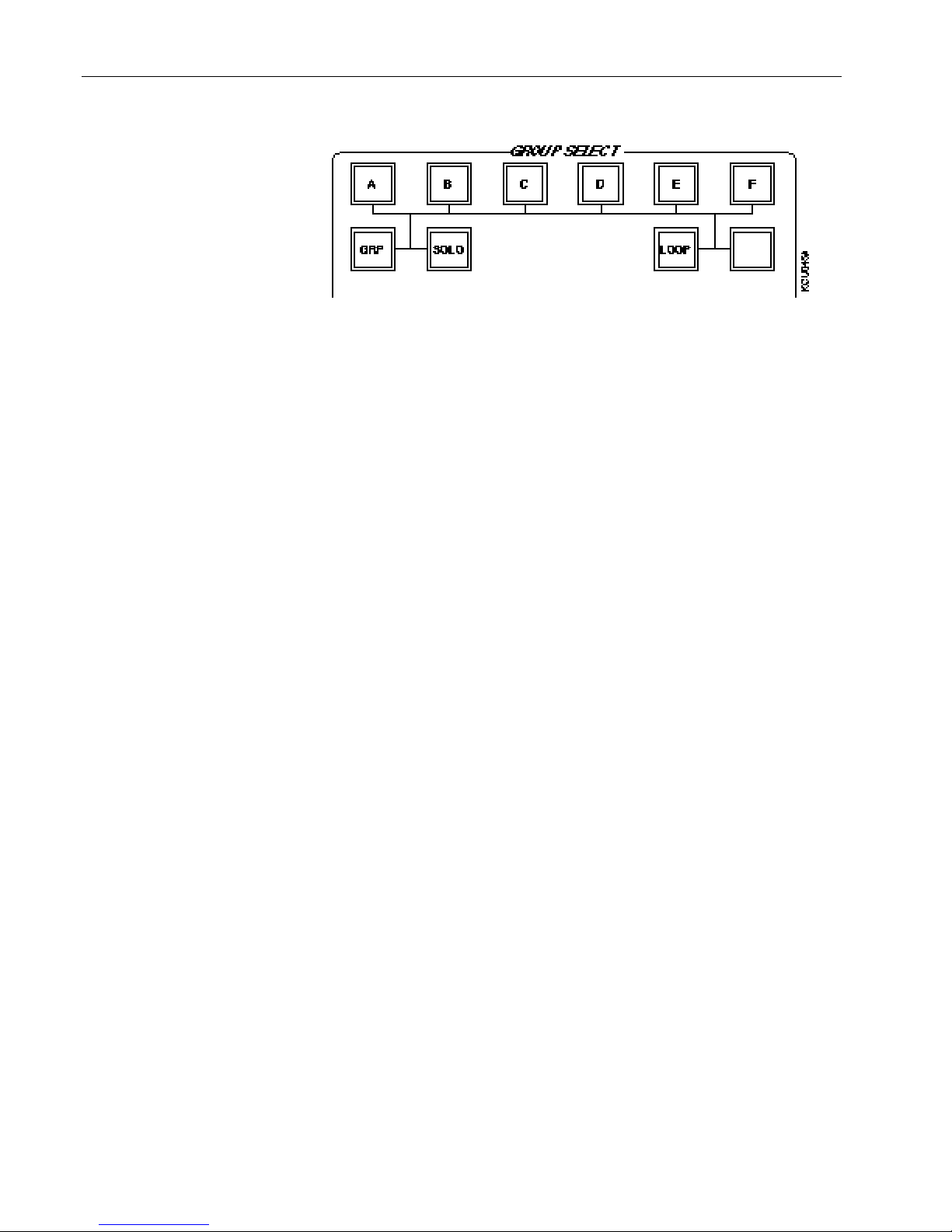

Machine (Group) Select Keys...............................................................................................6-14

A-F Machine (Group) Select Keys ..................................................................................6-14

GRP (GROUP) Key .........................................................................................................6-14

SOLO Key .......................................................................................................................6-14

LOOP Key .......................................................................................................................6-14

BANK Key.......................................................................................................................6-15

Calculator Keys ....................................................................................................................6-15

Accessing Time Code Registers ......................................................................................6-16

00–ZERO Key .................................................................................................................6-16

CLR Key..........................................................................................................................6-16

0–TIME/VID Key ............................................................................................................6-17

1–PRE/A1 Key ................................................................................................................6-17

2–POST/A2 Key ..............................................................................................................6-17

3–REF/A3 Key ................................................................................................................6-18

4–SYNCP/A4 Key ...........................................................................................................6-18

5–OFST/CUE Key...........................................................................................................6-18

6–ERR/TC Key................................................................................................................6-18

7–IN Key .........................................................................................................................6-18

8–OUT Key .....................................................................................................................6-18

9–DUR/ASM Key ............................................................................................................6-19

= (EQUAL) Key..............................................................................................................6-19

+ (PLUS) Key .................................................................................................................6-19

– (MINUS) Key ..............................................................................................................6-19

KCU Auxiliary Function Keys .............................................................................................6-20

RCL Key..........................................................................................................................6-20

STO Key..........................................................................................................................6-20

CAPT Key .......................................................................................................................6-21

SUBFR Key.....................................................................................................................6-21

KCU Status Keys and LED Indicators ................................................................................6-22

ON LINE (Poll) Key and LEDs ......................................................................................6-22

Busy LEDs ......................................................................................................................6-22

REC (Record Enable) Key and LEDs .............................................................................6-23

AUX LEDs ......................................................................................................................6-23

Special Function Keys ..........................................................................................................6-24

IN Key .............................................................................................................................6-24

OUT Key .........................................................................................................................6-24

REF SYNC Key...............................................................................................................6-24

SRC SYNC Key...............................................................................................................6-25

CUE PT Key....................................................................................................................6-25

END PT Key ...................................................................................................................6-25

Keyboard Control Unit

09/08/00 xi

Table of Contents

Macros ..................................................................................................................................6-25

CHAPTER 7 ADVANCED FEATURES

Varispeed (KCU 600 Series Software)...................................................................................7-2

Varispeed Configuration Requirements ..........................................................................7-2

X-Frame Synchronization ................................................................................................7-2

Varispeed Operation with KCU.......................................................................................7-3

Varispeed Pivot Points and Offsets .................................................................................7-3

Varispeed Options Menu Differences ..............................................................................7-6

Calculating with Varispeed..............................................................................................7-8

Displaying Varispeed Status............................................................................................7-9

Varispeed Error Messages .............................................................................................7-10

System Supervisor Unit (KCU 300 Series Software)..........................................................7-10

Installing the SSU..........................................................................................................7-10

KCU Options Menus with the SSU ...............................................................................7-12

Event [EVNT] Select GPI Options Menu ......................................................................7-12

Group [GRP] Options Menu...........................................................................................7-14

Record Enable [REC] Options Menu .............................................................................7-14

System Options Menu ....................................................................................................7-15

Time Code Generators....................................................................................................7-15

xii 09/08/00

Keyboard Control Unit

Chapter 1 Introduction

The Lynx Keyboard Control Unit (KCU) is a versatile, powerful

machine controller and editor, encompassing a wide spectrum of

multiple machine synchronization and audio editing applications.

Because the operating environment of the KCU incorporates

multiple microprocessors, there are several versions of software

available. Features vary with each software version. This manual

describes the KCU features and functions when fitted with the

following series of operating software:

• KCU080 Stand-alone KCU operation

• KCU300 System Supervisor Unit, multiple controller operation

• KCU600 Stand-alone Varispeed synchronization

This chapter introduces the KCU in the following categories:

• KCU features

• System overview

• System configurations

• Specifications

Keyboard Control Unit

09/08/00 1-1

Introduction

Keyboard Control Unit Features

The KCU provides comprehensive control of up to six tape or film

transports and two programmable GPI (General Purpose

Interface) relay closures. Machines may be operated individually,

or any selection of available machines may be operated as a

synchronized group. Any machine may be operated as the master

transport for group operations.

Figure Chapter 1 -1. Keyboard Control Unit

Keyboard Control Unit

1-2 09/08/00

Introduction

The following is a partial list of features of the Keyboard Control

Unit (KCU):

• User panel with lighted keys.

• Two-row alphanumeric display with large (.25" high), blue-

green characters.

• Programmable macro keys to execute complex operations with

a single keystroke.

• Special function keys for single keystroke time code capture

and store-to-key data registers.

• Calculator keypad for direct entry of time code numbers.

• Calculator keypad for track enable.

• Calculator keypad to control data access in system register

store and recall operations.

• Jog wheel for shuttle and frame jog functions with VTRs and

many ATRs.

• Jog wheel for trimming of data register values in frames and

subframes.

• Intuitive, prompting environment to minimize the need for

operator training.

• All time code and system setup data retained when powered

down, due to independent CPU with battery backed-up RAM.

• Two GPI relays, including dialog beep mode with menu

selections for three or four beeps, beep spacing, and beep

duration.

• System lock tally.

• Supervisor Port communicates with Lynx System Supervisor

Unit.

• Large illuminated transport keys operate single transports

(Solo mode) or all selected transports (Group mode).

• 25-foot RS422 cable provided to connect KCU power supply

and the first Lynx-2 module.

Keyboard Control Unit

09/08/00 1-3

Introduction

System Overview

This section describes the following components of the KCU

system (shown in the following figure):

• Keyboard Controller Unit (KCU)

• Lynx-2 and Lynx Time Code Modules

• Lynx System Supervisor Unit (SSU)

• Lynx Console Control Unit (CCU)

• Remote Motion Controller (RMC)

• Jog/Shuttle Wheel

See the Applications chapter of this manual for examples of

configurations to meet specific needs.

1-4 09/08/00

Figure Chapter 1 -2. System Overview

Keyboard Control Unit

Keyboard Control Unit (KCU)

The Keyboard Control Unit (KCU) allows remote control of up to

six machines. Editing and control commands are entered on the

keyboard. Time code status and register contents appear on the

40-character fluorescent display that is hinged above the keyboard.

The control panel is designed with separate key banks for ease of

operation for the following:

• Motion control

• Device selection

• Function macros

• Special functions

A numeric calculator keypad addresses specific devices and

associated memory registers, performs time code calculations, and

allows direct input of time and numeric data.

The KCU keypad jog/shuttle wheel allows jog operations and

shuttle operations. The wheel can be used for convenient

trimming of numeric data.

Introduction

Using the KCU is described in the Getting Started and the

Features and Controls chapters of this manual.

Keyboard Control Unit

09/08/00 1-5

Introduction

Lynx-2 and Lynx Time Code Modules

Each Lynx-2 and Lynx Time Code Module features a SMPTE/EBU

time code generator, a wide-band time code reader, and a

comprehensive machine controller and synchronizer.

Figure Chapter 1 -3. Lynx-2 Module

Each time code module is daisy-chained through a 9-pin RS422

connector to the KCU. The Lynx modules issue Record, Record

Stop and Rehearse commands to machines controlled by the KCU.

The Lynx modules can also be used to control the record-enable

status for serially controlled machines.

Film Modules

Gearbox Processor

TimeLine offers Lynx-2 and Lynx Film Modules. Film modules

integrate sprocketed film transports controlled from a biphase bus

into a Lynx-synchronized system.

Lynx-2 Modules and Lynx Modules fitted with the Gearbox

Processor can handle X-Frame and Varispeed synchronization.

Synchronization is conveniently addressed from the KCU keypad.

1-6 09/08/00

Keyboard Control Unit

Lynx System Supervisor Unit (SSU)

The Lynx System Supervisor Unit (SSU) is a sophisticated

communications interface unit. The SSU provides integrated

control of a variety of devices used in audio and sound postproduction environments.

Introduction

Figure Chapter 1 -4. System Supervisor Unit

The SSU simplifies external computer control of a complex postproduction system. The SSU assumes the workload of all highspeed data communications necessary to control and synchronize

tape machines and film transports, via Lynx-2 and Lynx Time

Code and Film Modules.

The SSU provides a variety of additional control facilities

including, but not limited to, eight GPI relays, two annunciator

outputs, three externally controllable time code outputs, multiple

remote controller connections, and MIDI Time Code output.

Using the Lynx SSU is described in detail in the Advanced

Features chapter of this manual.

Keyboard Control Unit

09/08/00 1-7

Introduction

Lynx Console Control Unit (CCU)

The Console Control Unit (CCU) is a keyboard input accessory for

the System Supervisor Unit. A CCU may be used in conjunction

with a KCU. The optional Jog/Shuttle wheel assembly is available

for console mounting.

Figure Chapter 1 -5. Console Control Unit

The miniature CCU keyboard mounts in the faceplate of Neve,

SSL, and other consoles. The CCU handles up to six transports.

Multiple CCUs can be connected to the System Supervisor Unit to

provide expanded configurations for film dubbing multiconsoles.

Each operator has individual control of machine transport

functions.

1-8 09/08/00

Keyboard Control Unit

Remote Motion Controller

The Remote Motion Controller (RMC) mirrors the motion control

switches of the KCU.

The RMC may be added to the System Supervisor Unit to provide

an additional remote transport controller, or to provide machine

control and editing features for a CCU/SSU installation. The

RMC provides LED indications for ADR beep countdown, group

lock, and loop. The RMC is available as a kit for mounting into a

console or other remote location.

Introduction

Figure Chapter 1 -6. Remote Motion Controller

Keyboard Control Unit

09/08/00 1-9

Introduction

Jog/Shuttle Wheel Assembly Kit

A Jog/Shuttle Wheel assembly kit is available for customer

installation into several System Supervisor Unit applications. The

Logic I/O connector on the back of the SSU provides for a

connection to the Jog/Shuttle Wheel outputs. Please refer to the

System Supervisor Unit (SSU) manual for wiring information.

Figure Chapter 1 -7. Jog/Shuttle Wheel

The Jog/Shuttle Wheel assembly provides console-top mounting

for CCU or KCU applications, and allows expansion of the Remote

Motion Controller. The RMC and Jog/Shuttle Wheel may be

configured as a single unit for ease of installation.

1-10 09/08/00

Keyboard Control Unit

System Configurations

In stand-alone operation, the KCU provides control of up to six

Lynx-2 or Lynx Time Code or Film modules, two programmable

GPIs (General Purpose Interface), and a system lock tally. The

KCU handles all the real-time communications with the Lynx

Modules via RS422 serial communication.

Lynx modules are daisy-chained to each other with their supplied

RS422 connectors, and continue to the KCUs power supply Lynx

Port. The 15-pin GPI/Supervisor port on the KCU power supply

provides two GPI relay closures to control turntables, CD players,

cart machines, and ADR beep outputs. The KCU is connected to

its power supply with a supplied 25-pin to 25-pin, 25-foot cable.

When connected to the SSU, the SSU assumes all high speed

communication and cabling to centralize operation and

installation. The KCU connects to the SSU Computer Control

Port, while the Lynx modules connect to SSU Trib Port 1. This

configuration provides a total of eight available GPIs, three

programmable time code generators, annunciator countdown

outputs, a MIDI interface, and system tally status.

Introduction

See the Applications chapter of this manual for examples of

configurations to meet specific needs.

Keyboard Control Unit

09/08/00 1-11

Introduction

Specifications

Keyboard

Jog/Shuttle Wheel

Power Supply

This section describes specifications for the KCU.

Display Type 40 character fluorescent, pivot tilting

Keys 57 numeric, function keys

12 transport control keys

Communications RS422, 38.4 k baud asynchronous

A remote power supply unit connects to the KCU via a supplied

single multi-conductor cable, 20 feet long.

Power Supply Mains Input 100-250 VAC at 50/60 Hz W nominal

30 W max.

Physical

Software Versions

Output +5V, 3A max.

Keyboard Size 5 1/8 " high, 12" wide, 8 1/3" deep

Weight 7 lbs., 5 oz.

Mounting Freestanding

KCU080 Stand-alone KCU operation

KCU300 System Supervisor Unit, multiple

controller operation

KCU600 Stand-alone Varispeed

synchronization

When the KCU operating software is updated, functional and

operational changes are covered in an addendum to this manual.

The information on the title page of this manual indicates the date

and designation of the latest software version covered by the

manual and any included addenda.

TimeLine Vista, Inc. reserves the right to change the design and specification of equipment without notice.

1-12 09/08/00

Keyboard Control Unit

Chapter 2 Applications

Before you configure the Lynx Keyboard Control Unit (KCU),

decide what equipment is needed and how you will set up the

system.

This chapter illustrates some of the most common KCU

applications. Please use these guides in configuring your system

to accommodate your specific application:

• Stand-alone KCU operation

• Stand-alone KCU with a VTR

• Varispeed and Gearbox operations with the KCU

• KCU and System Supervisor Unit (SSU) operation

Any combination of Lynx-2 and Lynx modules, fitted with gearbox

processor cards and V500 software, can be used with the KCU.

When looking through this chapter, keep in mind that other

TimeLine equipment will be configured along with the KCU.

Lynx-2 and Lynx Time Code Modules provide the building block

starting point for any Lynx Editing System. Install with the

greatest attention to detail, as the performance of the entire

system depends on their reliability. Please refer to the Lynx-2

manual for system application examples.

Keyboard Control Unit

09/08/00 2-1

Applications

Stand-alone KCU Operation

Figure Chapter 2 -1. Stand-alone Keyboard Control Unit

Typical Uses

The KCU adds editing control to multiple machine

synchronization systems. The KCU provides a fast and convenient

way to perform time code reading and synchronization. It can

easily control frequently performed activities such as locating,

entering offsets, slipping one tape machine against another, and

doing automated edits.

Considerations

The KCU automatically calculates offsets based on machine

positioning or register stored time code numbers. You may trim

machine offsets with the Jog wheel trim function.

2-2 09/08/00

Keyboard Control Unit

Stand-alone KCU with a VTR

Figure Chapter 2 -2. Stand-alone Keyboard Control Unit with VTR

Typical Uses

TimeLine synchronizers are compatible with numerous video

transports including standard 3/4" U-matic, Beta, S-VHS, open

reel, and digital VTRs. With the KCU, video machines are always

resolved, so they can be selected as master or slave in group

machine operations. Track select for serial video machines,

including video assembly modes, is available from the KCU

calculator keypad.

Applications

Considerations

Use an external video sync source as a speed reference source for

the Lynx modules and VTRs.

Keyboard Control Unit

09/08/00 2-3

Applications

Varispeed and Gearbox Operations with the KCU

Typical Uses

Figure Chapter 2 -3. KCU with Varispeed and Gearbox

With the KCU, complicated varispeed and time code gearboxing

can be controlled from the Keyboard Controller. Preset standard

NTSC and PAL pull-ups and pull-downs are included, as well as a

varispeed synchronizing range of ±15%.

When the Gearbox is used, 30, DF, 25 and 24 time codes can run

concurrently, while simultaneously using the Varispeed feature.

All operations are accessed from the KCU status display, with

multiple methods for entering varispeed and gearbox calculations

available.

2-4 09/08/00

Keyboard Control Unit

KCU and System Supervisor Unit (SSU) Operation

Applications

Figure Chapter 2 -4. Keyboard Control Unit and System Supervisor Unit Operation

Typical Uses

Use the KCU with the SSU for unparalleled control of audio,

video, MIDI, and console automation systems. Because of the

integrated system approach that TimeLine employs, everything

can be controlled from the Keyboard Control Unit.

Keyboard Control Unit

09/08/00 2-5

Applications

2-6 09/08/00

Keyboard Control Unit

Chapter 3 Installation

This chapter describes installation and interface procedures for

the TimeLine Keyboard Control Unit (KCU). It also includes a

quick software verification that shows the KCU is operational.

This chapter contains the following information:

• Hardware supplied

• System setup planning

• Installing the KCU

• Quick test and initialization

• Interface diagram

Sections of this chapter assume some prior working knowledge of

the Lynx-2 Time Code Module. Correct operation requires that

each module be properly installed and initialized. The Installation

chapter of the Lynx-2 manual provides detailed information on

initialization and installation.

Hardware Supplied

Note: Please save the original factory packaging. It is specially

designed to protect your KCU, should it require reshipment.

The KCU includes the following items:

1 Keyboard Controller Unit

1 KCU Power Supply

1 KCU to Power Supply Cable

1 KCU to Lynx-2 Cable

1 IEC AC Power Cord

1 HEX key wrench (to tighten display swivel)

Keyboard Control Unit

09/08/00 3-1

Installation

System Setup Planning

Before you install and configure the KCU, there are several

fundamental issues to consider.

Power

An AC outlet is required for the KCU. If more than one piece of

equipment will be connected to the AC outlet, use a surgeprotected power distribution strip as an adequate extension cable.

Cabling

The KCU requires communication and power cabling. Careful

connection and routing of cables will ensure a quick and successful

installation. Power supply and Lynx-2 cables are included with

the KCU.

Power On Initialization

Installing the KCU

Cabling

The KCU is supplied from the factory ready for initialization. All

parameters of the KCU are stored in RAM, and are restored on

subsequent power ups.

On power-up, the KCU will automatically poll any Lynx-2 module

that is communicating on the RS422 serial bus. At this point, the

KCU is ready to address each module within a group, or

individually, for machine control.

Because the KCU is a free-standing controller, installation offers

configuration choices. The KCU and its power supply have been

designed with the utmost in versatility, which provides a simple

path for any future upgrade requirements your facility might

require.

Cable connections are critical. Bad or poorly routed cables are

often the cause of installation problems. It is essential that the

correct, high quality cables are used to ensure reliable, troublefree operation.

3-2 09/08/00

Keyboard Control Unit

Installation

Cabling harnesses for the power supply and Lynx-2 modules are

provided from the factory with every KCU. The KCU power

supply also provides outputs for GPI relays and the SSU. Use the

following cable requirements diagram to determine what

equipment will be connected to the KCU and to verify that the

correct cables are available.

Keyboard Control Unit

09/08/00 3-3

Figure Chapter 3 -1. Cable Requirements

Installation

Connecting the KCU and Power Supply Unit

Verify that the KCU power supply is set for the correct AC mains

voltage as indicated by a small white button showing through one

of the four holes at the right of the IEC power cord receptacle. If

the voltage setting is not correct for your facility, please refer to

the section Changing the Mains Voltage Setting.

Figure Chapter 3 -2. KCU with Power Supply Connected

Connect the supplied 25-pin cable between the KCU connector on

the power supply and the Keyboard Unit. Secure both connections

with the retaining screws and secure the cable to the KCU with

the supplied cable clamp.

3-4 09/08/00

Figure Chapter 3 -3. KCU Cable Clamp

Keyboard Control Unit

Power Supply

The KCU has an external DC power supply that can be switched

to the correct AC voltage for your site. It is suitable for operation

at any voltage in any country.

Changing the Mains Voltage Setting

Installation

Figure Chapter 3 -4. KCU Power Supply, Rear Panel

1. Remove the AC mains cord from the power supply.

2. With a small slotted screwdriver, gently pry the fuse holder

cover off the power supply.

3. Use long-nosed pliers to remove the small printed circuit board

from the right side of the compartment.

4. Locate the edge of the circuit board that has the correct AC

mains voltage rating printed on it. Manipulate the white

nylon tab to position it on the edge opposite the desired mains

voltage. This tab position provides the external indication of

the voltage selection.

5. Re-insert the circuit board into its compartment in the power

supply.

6. Verify that the fuse is the correct type and rating for the new

operating voltage. See the Fuses section following this

procedure.

7. Replace the fuse holder in the power supply and confirm that

the tip of the white nylon tab is located in the correct hole in

the fuse holder cover.

Keyboard Control Unit

09/08/00 3-5

8. Replace the AC mains cord.

9. Turn on the power switch. Confirm that the POWER LED

lights up and the KCU itself powers on.

Installation

Fuses

Replacing a Fuse

The correct fuse is installed in the power supply by the factory. In

the event that the fuse in the KCU power supply needs to be

changed, replace it only with the same type and rating fuse. The

normal fuse types for the KCU power supply are listed in the

following table:

Table Chapter 3 -1. KCU Power Supply Fuse Specifications

100-120 volt AC mains 1/2 ampere, 250 volt, type MDL

(slow blow)

220-240 volt AC mains 1/4 ampere, 250 volt, type MDL

(slow blow)

1. With a small slotted screwdriver, pry the fuse holder cover off

the power supply.

2. Pull the fuse out of its holder.

3. Use 250V fuses only.

Connecting the Lynx-2 Modules

Connect the supplied 9-pin cable between the LYNX connector on

the KCU power supply and either RS422 connector on any Lynx-2

Module in the system. The order in which the modules are

connected is arbitrary and does not affect operations. Secure both

connections with the retaining screws.

Figure Chapter 3 -5. KCU with Power Supply and Lynx-2 Time Code Module

3-6 09/08/00

Keyboard Control Unit

GPIs

Installation

To daisy-chain the first Lynx-2 Module to the next module,

connect a 9-pin jumper cable from the second RS422 connector on

the first Lynx-2 Module to either RS422 connector on the next

module.

Connect the KCU power supply to a convenient AC mains outlet of

the correct voltage. Turn on the power and confirm that the

POWER LED indicator on the power supply lights up and the

KCU itself powers up.

The KCU power supply contains two relays which are used as GPI

(General Purpose Interface) closures to trigger a wide variety of

external events when the Lynx system doesn’t include a System

Supervisor Unit. The GPIs in the KCU power supply are

presented as a pair of normally-open relay closures on four pins of

the GPI/SUPERVISOR connector. The pair of annunciator LEDs

on the power supply light simultaneously with each relay closure.

The GPI connector on the KCU power supply is a standard female

15-pin D-subminiature connector.

Table Chapter 3 -2. GPI Pinout

Pin Signal Pin Signal

1 9

2 10

3 GPI 2 N/O 11 GPI 2 COM

4 GPI 1 N/O 12 GPI 1 COM

5 +5V 13 Ground

6 14

7 15

8

The GPI relays are rated at 2 Amperes maximum in low voltage

DC applications (up to 30 volts DC), or at 0.6 Amperes maximum

in higher voltage DC or AC applications.

Keyboard Control Unit

09/08/00 3-7

Installation

System Supervisor Unit

In addition to the steps detailed above, connect the cable supplied

with the System Supervisor Unit between the GPI/SUPERVISOR

connector on the KCU power supply and the COMPUTER/

KEYBOARD CONTROL PORT 1 connector on the back panel of

the SSU.

When the KCU is connected to the SSU, the Lynx-2 RS422

connections are made directly to the SSU Trip Port 1. The

modules are not connected to the KCU. See the System

Supervisor Unit manual, Installation chapter for complete details.

Figure Chapter 3 -6. KCU with Power Supply, Lynx-2 and System Supervisor Unit

Keyboard Control Unit

3-8 09/08/00

Quick Test and Initialization

Follow this procedure to test the communication of different

equipment and initialize the KCU. You will be able to operate the

system when this procedure is complete.

Specific questions regarding initialization for the SSU and Lynx-2

modules can be addressed from their respective owner’s manuals.

Testing the Lynx-2 Modules

To verify that the Lynx-2 modules are communicating to the KCU:

1. Press [POWER] (Lynx-2 module)

Module turns on.

Turn on each Lynx-2 module. Confirm the setup

parameters of each Lynx-2.

2. Press [TRAN MODE]

Online LED on

Put all modules online.

Installation

Each module must have a unique address. If the KCU detects

that the modules have the same address, the KCU will not poll

correctly. The message Press the ‘Poll’ key to establish

communications is displayed on the KCU.

The Lynx-2 power-on sequence displays the serial address of

each module. If you need to review or change the address of a

module, press [SHIFT] + [MSTR] simultaneously, then [GEN

CODE] to access the address menu. Use the [↑] and [↓] arrow

keys to make changes. Press [SHIFT] + [MSTR] to exit setup.

3. Press[PLAY] (Transport)

Time code reader display increments, VID LED on

Lets the Lynx-2 modules read time code for ten seconds.

4. Press [STOP] (Transport)

Display stops incrementing

The Lynx-2 modules are ready to be controlled by the KCU.

Keyboard Control Unit

09/08/00 3-9

Installation

Setting Up the KCU

Turn on the KCU power supply unit. The KCU automatically

polls the Lynx-2 RS422 Control bus to establish communications

with the modules. The LEDs in the KCU STATUS/ON LINE

display light, corresponding to the addresses previously set on the

modules. The 422 LEDs on each module come on.

Verifying Communications

To verify that the KCU and Lynx-2 modules are communicating

correctly,

1. Press [SOLO] then [A] (KCU)

2. Press [PLAY] (KCU)

SOLO : a* displayed

This solos the transport assigned to the [A] key.

SOLO:A>L displayed on the KCU

Play the transport for ten seconds to allow the Lynx-2 to

read the time code and lock. If you don’t get a lock

indication, refer to the Troubleshooting chapter of the

Lynx-2 manual.

Interface Diagrams

3. Press [STOP] (KCU)

4. Repeat steps 1-3 for each transport.

This section presents a variety of interface diagrams. Refer to the

diagram that most closely represents your system setup and

application. Remember, slight differences in equipment may

require small configuration modifications.

There are two interface diagrams:

• KCU stand-alone

• Post-production system–System Supervisor Unit

3-10 09/08/00

Keyboard Control Unit

KCU Stand-Alone

Installation

Figure Chapter 3 -7. KCU Stand-Alone Production System

Keyboard Control Unit

09/08/00 3-11

Installation

Post-Production System–System Supervisor Unit

Figure Chapter 3 -8. Post Production System - Audio

3-12 09/08/00

Keyboard Control Unit

Chapter 4 Getting Started

This chapter describes the basic operating procedures to use the

Keyboard Control Unit (KCU).

Keyboard Control Unit

09/08/00 4-1

Figure Chapter 4 -1. Keyboard Control Unit

This chapter presents the following topics:

• Initializing and configuring the KCU (to be performed after

installation is complete)

• Using KCU memory

• Using time code registers

• Grouping machines with the KCU

• Using offsets

• Editing with the KCU

• KCU messages and errors

• KCU options menu

Getting Started

Initializing and Configuring the KCU

Perform the procedures in this section after the installation is

complete, but before you begin using the KCU.

Turning on the KCU

The KCU has a battery backed-up memory system. Each time the

KCU is turned on, it powers up in exactly the same condition in

which it was powered down. All the setup and transport

information previously entered is immediately operational.

When first turned on, the KCU does a quick lamp test and

displays the software version(s) installed. The power-on sequence

also indicates if the System Supervisor Unit (SSU) is enabled, and

the amount of memory locations available (0-9 or 00-99).

At this point, the KCU has finished its sign-on and displays Press

the Poll Key to Establish Communication. Turn on the Lynx-2

modules and put them on line with the [TRAN MODE] key. Press

the yellow status key ([POLL] key) on the KCU to establish RS422

communication.

Resetting the KCU

If the Lynx-2 modules are powered on and placed online prior to

the KCU being turned on, the KCU automatically polls the Lynx-2

modules and displays Hold the GRP Key and add Groups in Order

of Priority.

If it becomes necessary to clear or reset the KCU, use the

calculator [CLR] key and the [POLL] key to re-initialize the KCU.

All KCU parameters are set to their default settings and the group

is erased, with a prompt displayed to re-establish the group at the

end of the reset.

To reset the KCU, press and hold the [CLR] key while pressing

the [POLL] key. Continue to hold the [CLR] key momentarily

after releasing the [POLL] key. The prompt Lamp Test, Clearing

Memory is displayed while the KCU initializes a lamp and LED

test. When the initialization is complete, the KCU prompts you to

re-establish the group.

4-2 09/08/00

Keyboard Control Unit

Setting the System Reference

Before using the KCU, determine the system speed reference your

machines will be locked to. When a system reference is selected,

the KCU synchronizes all Lynx-2 modules, including the master, as

slaves to this timing reference. This provides fast and stable locking because each machine is independently controlled and locked.

When a system reference is selected at the KCU, verify that the

selected reference is properly connected to every Lynx-2 module in

the chain.

There are four reference selections available:

Int Xtal Lynx-2 Module internal crystal

Ext Vid External composite or black burst video sync signal

Mains AC mains frequency

VSO Variable speed, determined by varispeeding the master

Getting Started

transport

The KCU reference defaults to External Video. The system speed

or rate is determined by the video source applied to the Lynx-2

modules, either 29.97 Hz for NTSC or 25 Hz for PAL/SECAM.

Unless you use a different frame rate, for example 30 Hz, use this

reference to get started.

System reference parameters may be changed in the SYS options

menu. See KCU Options Menus in this chapter for details.

Initializing Lynx Communication

Turn on the Lynx-2 modules and put the modules on line with the

[TRAN MODE] key. Make sure each Lynx-2 module is set to a

unique address, and has the correct external video sync signal

connected (if needed).

1. Press the KCU [POLL] key and confirm that the 422 LED

illuminates on each Lynx-2 module. The corresponding

STATUS LEDs on the KCU should also illuminate.

2. Press the [SOLO] key

The [SOLO] key will light.

Keyboard Control Unit

09/08/00 4-3

Getting Started

3. Press the [A] key.

The [A] key will light

This solos the corresponding A machine. The current time

code position of the A machine is shown in the display.

“SOLO:A” appears in the display with the “.” indicating the

machine is stopped. Other soloed machine indicators are

“>“ for play, “>>“ for fast forward, “<<“ for rewind, REC for

record, and REH for rehearse.

The “Err: 0.–” display shows the offset error, in frames and

subframes, to lock. When the machine is played, the offset

error value is counted down to .00 to indicate that the

machine has been properly synchronized.

4. Press the [>] (Play) key.

The [>] key lights. Time code display updates.

“SOLO : A > L” indicates the soloed machine is in play and

locked.

5. Press the [■] (Stop) key.

The [■] key lights and the time code display stops.

6. Repeat steps 3 through 5 for each Lynx-2 module.

Using KCU Memory

This section describes the use of KCU memory functions.

The KCU can capture and store in memory up to 100 time code

values. Time code values can be retrieved and used as auto-locate

positions or for other time code operations.

Capturing a Time Code Value

Capture and locate a time code value in either solo or group mode.

The machine in this example is in solo mode.

1. Press the [A] key.

2. Press [>].

Play to the time code that you want to capture and save.

This solos the corresponding A transport.

3. Press the [CAPT] key.

4-4 09/08/00

[CAPT] key flashes, [STO] key flashes

The KCU has captured a time code and is ready to store the

value.

Keyboard Control Unit

4. Press the [MEM] key.

[MEM] key flashes

5. Press [1].

6. Press [CLR].

Retrieving a Time Code Value

1. Press the [MEM] key.

[MEM] key flashes

2. Press [1].

Mem1 xx:xx:xx is displayed

Getting Started

“Store Memory” is displayed, prompting you to choose a

memory location.

The KCU stores the data into memory location 1.

Clears the display.

The KCU is ready to recall a time code value stored in a

memory location.

The value stored in memory 1 is retrieved.

Changing Memory Size

3. Press [LOC] to locate using the value in the Calculator Entry

register (lower right of display) as the locate point.

The [LOC] key lights, “SOLO : A Loc xx:xx:xx” is displayed.

The transport locates to the time code value retrieved from

memory location 1, displayed in the Calculator register

plus the preroll amount.

Memory size determines the number of memory spaces that will

be available for storing values. Press [SETUP], then [MEM], to

change memory size.

See Using KCU Memory in this chapter for more information.

Keyboard Control Unit

09/08/00 4-5

Getting Started

Using Time Code Registers

Values may be stored to or recalled from any of the time code

registers.

The calculator keys provide access to the time code register values.

The registers correspond to the numbered (00-9) calculator keys:

• 00/ZERO for the Local Zero register

• 0/TIME for the Time register

• 1/PRE for the Preroll register

• 2/POST for the Postroll register

• 3/REF for the Reference Sync Point register

• 4/SYNCP for the Source Sync Point register

• 5/OFST for the Offset register

• 6/ERR for the Error register

• 7/IN for the In Point register

Local Zero Register

• 8/OUT for the Out Point register

• 9/DUR for the Duration register

The following special function keys provide additional access to

registers:

• IN for the In Point register

• OUT for the Out Point register

• REF SYNC for the Reference Sync Point register

• SRC SYNC for the Source Sync Point register

• CUE PT for the Cue Point register

The calculator [00/ZERO] key provides access to the Local Zero

register, which is used to store an offset value that will be

subtracted from values stored to memory registers. This function

is used mainly for film applications.

The Local Zero register is available with KCU 600 and KCU 300

series software.

4-6 09/08/00

Keyboard Control Unit

Time Register

Preroll Register

Getting Started

The calculator [TIME] key provides access to the Time register.

The Time register is used to store a time code value to the Lynx-2

or Lynx-2 Film Module.

Press [STO], then [TIME], to store a new value in the Time

register. The current time code of the selected machine is

displayed.

Press [RCL], then [TIME], to recall the current in the Time

register. The current time code of the selected machine is

displayed.

To display the current time code of a different machine, press the

appropriate machine select key, then [RCL], then [TIME].

The calculator [PRE] key provides access to the Preroll register.

The preroll position is the time code location that the KCU uses to

cue the master machine during locate and edit functions.

Postroll Register

The value in the Preroll register is used to calculate the preroll

position using the following equation:

Preroll position = In Point – Preroll value

The default value for the Preroll register is 5 seconds.

The Preroll register may be accessed during store, recall, and trim

operations.

The calculator [POST] key provides access to the Postroll register.

The value in the Postroll register is used by the KCU to calculate

the postroll time code position at the end of an edit sequence.

The postroll position is the time code location to which the KCU

rolls the transports at the end of an edit. The postroll position is

calculated using the following equation:

Postroll position = Out Point + Postroll value

The default value for the Postroll register is 5 seconds.

Keyboard Control Unit

09/08/00 4-7

The Postroll register may be accessed during store, recall, and

trim operations.

Getting Started

Reference Sync Point Register

The KCU uses the time code value in the Reference Sync Point

register to calculate offsets for any source machines with source

sync points. Offsets are calculated using the following equation:

Offset = Source Sync Point - Reference Sync Point

If you change the reference sync point value (either in Trim mode

or by entering a new value), the KCU recalculates and stores the

correct offset for all source machines with active source sync point

values.

Accessing the Reference Sync Point Register

The calculator [REF] key provides access to the Reference Sync

Point register during store, recall, and trim operations.

The special function [REF SYNC] key provides access to the

Reference Sync Point register.

Clearing the Reference Sync Point Register

Press [CLR] and [REF] simultaneously to clear the Reference Sync

Point register.

Press and hold [CLR] and press special function [REF SYNC] key

to deactivate the value in the Reference Sync Point register

without actually clearing the value. The [REF SYNC] key is no

longer lighted.

Source Sync Point Register

The [SYNCP] key provides access to the Source Sync Point

register for a specified machine. The KCU uses the time code

value in the Source Sync Point register of each machine to

calculate an offset for a source machine relative to the reference

sync point. Each source machine in the system has a separate

sync point register. The reference machine can not have a Source

Sync Point register.

The offset is displayed as a positive or negative number with an

absolute value of 12:00:00:00 (12 hours) or less. The offset is

calculated using the following equation:

If the source sync point has a higher time code value than the

source sync point, the keyboard displays the offset as a small

negative number. For example, -1:10:00:00 is displayed rather

than the equivalent large positive number 22:50:00:00.

4-8 09/08/00

Offset = Source Sync Point - Reference Sync Point.

Keyboard Control Unit

If you change the source sync point value (either in Trim mode or

by entering a new source sync point value), the KCU recalculates

and stores the correct offset for that machine.

Accessing the Source Sync Point Register

The calculator [SYNCP] key provides access to the Source Sync

Point register during store, recall, and trim operations.

The special function [REF SYNC] key provides access to the

Reference Sync Point register.

Clearing the Source Sync Point Register

Solo a machine, then press [CLR] and [SYNCP] simultaneously to

clear the Source Sync Point register.

Press and hold [CLR] and press the special function [SRC SYNC]

key to deactivate the value in the Source Sync Point register

without actually clearing the value. The [SRC SYNC] key is no

longer lighted.

Getting Started

Offset Register

Error Register

In Point Register

The [OFST] key provides access to the Offset register for a

specified machine. This register may be accessed during store,

recall, and trim operations. Each slave machine in the system has

a separate Offset register. The reference machine cannot have an

offset.

Offsets are discussed in detail in the Using Offsets section of this

chapter.

The [ERR] key provides access to the machine offset Error

register. The Error register does not store any values, but

provides a display of the positional error of a machine.

Press [RCL], then [ERR], to display the Error register for a

selected machine. The error is displayed in status mode.

Keyboard Control Unit

09/08/00 4-9

The In Point register stores the time code value of the current

programmed edit. The value is expressed in terms of the master

machine time code. The edit in point is used to calculate source

machine offsets if no reference sync point is entered.

Getting Started

The special function [IN] key is illuminated whenever there is an

active value in the In Point register.

If no in point is set, it will be calculated automatically when you

enter an out point and a duration. The equation for calculating an

in point is:

In Point = Out Point – Duration

The KCU calculates an in point value based on the current

position of the source machine and the source machine offset

value. This occurs if a source or slave transport is soloed when

you press the special function [IN] key (the reference machine

time code is not running at the time). The in point value is

calculated in the reference time code type.

If there is no active value in the In Point register when you select

an edit mode, the error message Set an “in” point is displayed and

the edit command is canceled.

The value in the In Point register is also used as the Reference

Sync Point in any automatic offset calculations if there is no value

in the Reference Sync Point register.

Accessing the In Point Register

The calculator [IN] key provides access to the In Point register

during store, recall, and trim operations.

Press the special function [IN] key at any time to store the current

reference machine time code value into the In Point register.

Clearing the In Point Register

Press [CLR] and calculator [IN] simultaneously to clear the In

Point register.

Press and hold [CLR], then press special function [IN], to

deactivate the value in the In Point register without actually

clearing the value. The [IN] key is no longer lighted.

Out Point Register

The value stored in the Out Point register is the record out point

of the current programmed edit. The value is expressed in terms

of the master machine time code.

4-10 09/08/00

Keyboard Control Unit

Getting Started

The out point is calculated and stored automatically when you

enter an in point and a duration. The equation for calculating an

out point is

Out Point = In Point + Duration

The special function [OUT] key is illuminated whenever there is

an active value in the Out Point register.

If there is no active value in the Out Point register when you

select an edit mode, the message Warning: open end is displayed

and the KCU performs an open-ended edit. In an open-ended edit,

the duration shows as open during the preroll, and is incremented

a single frame at a time during the actual edit period.

If a source or slave transport is soloed when you press the special

function [OUT] key (the reference machine time code is not

running at the time), the KCU calculates an Out Point value in

the reference machine’s time code based on the current position of

the source, or slave, machine and its offset value.

Altering the value of the duration also causes the out point to be

recalculated. Altering the out point causes the duration to be

recalculated.

Accessing the Out Point Register

The calculator [OUT] key provides access to the Out Point register

during store, recall, and trim operations.

Press the special function [OUT] key to store the current reference

machine time code value in the Out Point register.

Clearing the Out Point Register

Press the [CLR] and calculator [OUT] keys simultaneously to clear

the Out Point register.