Page 1

INSTALLATION & OPERATING

PROGRAM

DAY 1 2 3 4 5 6 7

CHANGE

ON OFF TIMED

ON

PROGRAM

DAY 1 2 3 4

CHANGE

ON OFF TIMED

ON

INSTRUCTIONS

Panel

MASTER

Models

EL11 (24 hour)

EL17 (7 day)

Page 2

PROGRAM

DAY 1 2 3 4

CHANGE

ON OFF TIMED

ON

PROGRAM

DAY 1 2 3 4 5 6 7

CHANGE

ON OFF TIMED

ON

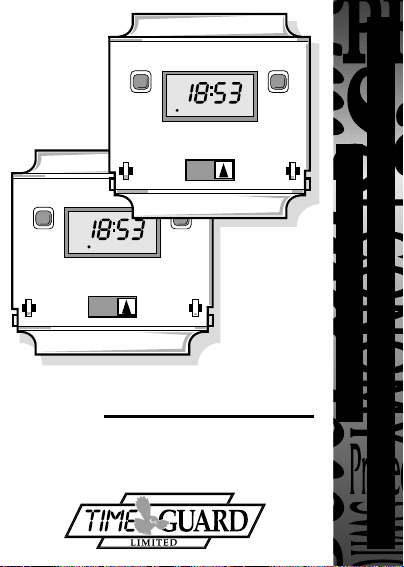

Figure 1

N

NOC

NC

L

Override button

(also used in

conjunction with the

programme button

to programme clock

and times/days for

ON periods

24 hour clock

display

Slide switch provides

Contents

1 EL11 (24 hour) or EL17 (7 day)

1 Panel mount bezel

1 Tamper proof cover

4 Surface mount stand offs (length 10mm)

2 Panel mount bolts

2 Self-tapping screws (No. 4 x 5/8 in) for panel mount bolts

2 Self-tapping screws (No.6 x 3/8 in) for attaching bezel to EL11/17

General

The EL11 (24 hour) or EL17 (7 day) is primarily a panel mounted timeswitch

rated at 240V, 16A resistive at T40. It can also be surface mounted within

cubicles if required.

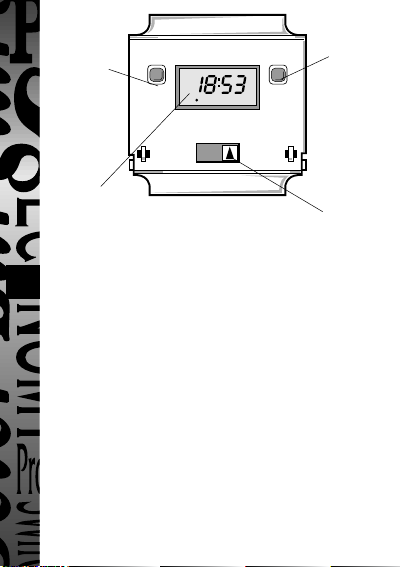

The contacts are single pole change over and are fully voltage free. The front of

the unit is shown in figure 1. The rear of the unit showing wiring connections

and the internal circuit is shown in figure 2.

Connections are made to the EL11/17 by 1/4 in receptacles. The unit can be

made tamper proof by wiring the cover supplied in place which still leaves the

display visible.

Programme button

used to programme

clock and times/days

for ON periods

continuous ON,

continuous OFF or

normal programme

operation

Page 3

PROGRAM

DAY 1 2 3 4

CHANGE

ON OFF TIMED

ON

Installation - Panel Mounting

N

NOC

NC

L

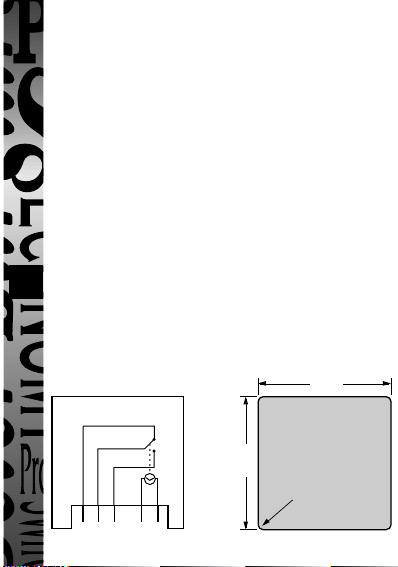

For panel mounting (in panels up to 7.0mm thick with the cut-out as shown in

figure 3) the EL11/17 should be snapped into the bezel supplied and secured

in place by the use of the 2 No. 6 x 3/8in self-tapping screws provided as

shown in figure 4.

When selecting a position for the unit it should be born in mind that a

clearance behind the front panel surface of 26.0mm is required over the full

area of the panel cut-out.

The unit is designed to be mounted from the front of the panel by the

following procedure:

a. Insert the 2 bolts provided in the locations shown in figure 5.

b. Then insert the 2 No. 4 x 5/8 in self-tapping screws into the bolts and

engage thread.

c. Make connections to the unit by wires terminated in 1/4 in receptacles

from behind the panel. Ensure that the wiring is adequate for the load to

be carried.

d. Insert the EL11/17 complete with bezel into the panel and tighten up the

2 No. 4 self-tapping screws. The ears on the bolts will rotate under the

tightening action to clamp the unit to the panel.

67mm

Figure 2

67mm

R 3.5mm

Figure 3

Page 4

PROGRAM

DAY 1 2 3 4

CHANGE

ON OFF TIMED

ON

Use No. 6 x 3/8in selftapping screws to fully

secure bezel to EL11/17

(fixed from rear)

Bezel

No. 4 x 5/8in selftapping screw

Figure 4

Surface Mounting

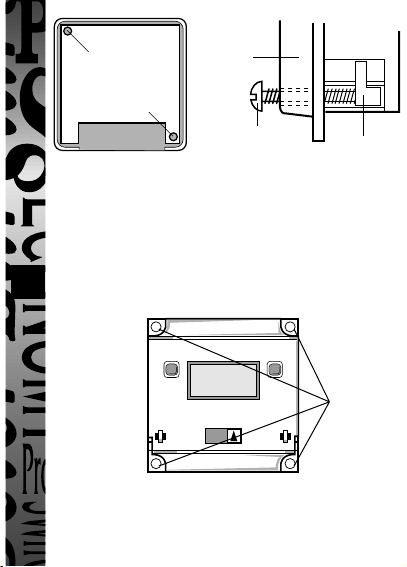

The EL11/17 without bezel can be surface mounted using the 4 securing holes

as shown in figure 6. The unit can be stood off from the mounting surface by

10mm using the 4 spacers if required. Screws are not provided and it must be

remembered that if used in this way the EL11/17 must be installed within a

housing or cubicle to prevent access to the mains terminations.

Figure 6

On/Off/Timed Slide Switch

The three position slide switch allows continuously ON, continuously OFF or

normal programmed operation.

Figure 5

Bolt

4 fixing holes

for surface

mounting

Page 5

PROGRAM

DAY 1 2 3 4

CHANGE

ON OFF TIMED

ON

EL11 Programming Instructions

Change Button

sets Hours and

Minute times and

self cancelling

override

Easy view 24

hour digital

clock/timer

display

Battery

This product has a factory fitted rechargeable battery. If the time controller is left with

its mains power switched off for more than 1 month the display may go blank. In this

case switch mains on, wait 30 minutes, and apply reset - see 1 before programming.

Programming

Only two setting buttons are provided <Change> and <Program>. During the

programme mode the <Change> button is used to set the hour and minute times.

Holding this button down achieves rapid selection of the hr and minute times. It is

also used for changing the output status during normal operation. The <Program>

button is used to select the clock time and 4 ON/OFF programmes and to review

them once set. Holding this button down achieves rapid selection of the next

programmes or can be used as a quick exit from programme mode or programme

review.

Normal Operating Mode

In normal operation the PanelMaster will display the

correct time with the colon flashing. The output

status will be shown by either ON or OFF on the display.

1 To Reset Display

To clear programmes from memory and reset the time controller press and hold

down both buttons until the display goes blank.

Release buttons and display will fill with its complete

range of characters and then clear to show clock and

hour digit flashing.

You are now in the clock setting mode

at the beginning of the programme sequence

Programme Button

used to select the

clock time and the 4

ON/OFF

programme times

and to review them

once set

Output Status

showing unit

either ON or OFF

OFF

1 2 3 4

1 2 3 4

Page 6

Programming sequence

....

......

➔

Programme 3 ON

:

:

Programme 3 OFF

:

Programme 4 ON

:

Programme 4 OFF

:

:

Operating Mode

hour setting.

Setting clock

Programme 1 ON

Programme 1 OFF

Programme 2 ON

Programme 2 OFF

Note: Button pauses greater than 1 minute during programming will result in

automatic return to the operating mode.

2 Setting Clock (after reset)

i Hour Setting - Press the <Change> button to advance

the hour setting.Note: For rapid hour selections press

and hold down <Change> button.

ii Minute Setting - Press the <Program> button once to

select the minutes - display shows clock symbol

and minute digits flashing. Press the <Change>

54321

button to advance the minutes setting. Note: For rapid

minute selection press and hold down <Change>

button. (Note: 16 hrs shown as example of hrs set)

iii Press <Program> button once - clock is now set and

display shows ready for the first ON programme time

with ON and hours digits flashing.

3. To Set Programme ON/OFF Times

(after clock setting)

Programme 1 ON time

i Press <Change> button to advance the

1 2 3 4

1 2 3 4

ON

1 2 3 4

ii Press <Program> button once to select minute time -

display shows minute digits and ON flashing. Press

<Change> button to advance minute setting.

(Note: 16 hrs shown as example of hours set).

ON

1 2 3 4

Page 7

iii Press <Program> button once - the first ON time is

now set and display shows ready for the first OFF

programme time.

iv Now set the hrs and minutes as before.

v Repeat steps i to iv to set the remainder of the 3 ON/OFF times as required.

Note: Any unused ON/OFF programme should be skipped until the display

shows normal operating mode. Do not programme ‘0’s into unused

programmes.

IMPORTANT After setting a clock time which falls within a programmed ON

period, the unit will not switch ON. Use the override facility to switch unit ON.

After this the unit will operate normally to the programmes set.

4. Programme Review

To fast review the set programmes or for quick exit to normal operating mode press and hold the <Program> button.

5. Initiating Programme Mode

This can be initiated any time during the normal operating mode. Press

6

<Program> button and the Clock symbol, hrs and minutes symbols on the

display will flash - this is review mode. If any change to programmes is

required press <Change> button to initiate programme mode and then follow

steps 2 and 3.

6. Cancelling Programmes

Any ON/OFF programme can be cancelled by clearing its ON and OFF time.

Follow step 5 and when into the ON or OFF programme to be cancelled press

the <Change> button until the hour digits show -- :

then press the <Program> button to clear the

programme. The display will show the hour

and minute digits and ON or OFF flashing.

Self Cancelling Override

To change the output status from ON to OFF or vice versa during normal operation

press the <Change> button. The output status will change and indicate override is in

operation by flashing.

1 2 3 4

1 2 3 4

OFF

ON

Page 8

PROGRAM

DAY 1 2 3 4 5 6 7

CHANGE

ON OFF TIMED

ON

EL17 Programming Instructions

PROGRAM

DAY 1 2 3 4 5 6 7

CHANGE

ON OFF TIMED

ON

PROGRAM

DAY 1 2 3 4

CHANGE

ON OFF TIMED

ON

Change Button

sets Day(s), Hours

and Minute times

and self cancelling

override

Easy view 24

hour digital

clock/timer

display

Battery

This product has a factory fitted rechargeable battery. If the time controller is left with

its mains power switched off for more than 1 month the display may go blank. In

this case switch mains on, wait 30 mins, and apply reset - see 1 before programming.

Programming

Only two setting buttons are provided <Change> and <Program>. During the

programme mode the <Change> button is used to set days and the hour and

minute times. Holding this button down achieves rapid selection of the day and

the hour and minute times. During normal operation it is used for changing the

output status. The <Program> button is used to select the clock time and 6

ON/OFF programmes and to review them once set. Holding this button down

achieves rapid selection of the next programmes or can be used as a quick exit

from programme mode.

Normal Operating Mode

In normal operation the PanelMaster will display the

correct day and its time with the colon flashing. The output

status will be shown by either ON or OFF on the display.

1 To Reset Display

To clear programmes from memory and reset the time controller press and hold

down both buttons until the display goes blank.

Release buttons and display will fill with its complete

range of characters and then clear to show clock and

day 1 symbol flashing.

You are now in the clock setting mode

at the beginning of the programme sequence

Programme Button

used to select the

clock time and the 6

ON/OFF

programme times

and to review them

once set

Output Status

showing unit

either ON or OFF

Day indicator

1 = Monday

7 = Sunday

OFF

1 2 3 4 5 6 7

1 2 3 4 5 6 7

Page 9

Programming sequence

PROGRAM

DAY 1 2 3 4 5 6 7

CHANGE

ON OFF TIMED

ON

PROGRAM

DAY 1 2 3 4

CHANGE

ON OFF TIMED

ON

....

......

➔

Programme 4 ON

:

:

Programme 4 OFF

:

Programme 5 ON

:

Programme 5 OFF

:

Programme 6 ON

:

:

Programme 6 OFF

:

Operating Mode

Setting clock

Programme 1 ON

Programme 1 OFF

Programme 2 ON

Programme 2 OFF

Programme 3 ON

Programme 3 OFF

Note: Button pauses greater than 1 minute during programming will result in

automatic return to the operating mode.

2 Setting Clock (after reset)

i Day Setting - Press <Change> button to advance to the day required.

Day 1 = Monday and Day 7 = Sunday.

ii Hour Setting - Press the <Program>

button once to select the hour - display

shows clock symbol and the hrs

digit flashing.

Press the <Change> button to advance

the hour setting.Note: For rapid hour selections press

and hold down <Change> button.

iii Minute Setting - Press the <Program> button once to

select the minutes - display shows with clock symbol

and minute digits flashing. Press the <Change>

button to advance the minutes setting. Note: For rapid

minute selection press and hold down <Change>

button. (Note: 16 hrs shown as example of hrs set)

iv Press <Program> button once - clock is now set and

display shows ready for the first ON programme time.

3. To Set Programme ON/OFF Times (after clock setting)

Programme 1 ON time

i Press <Change> button to advance the day flag to the required day(s) settings

which are:

1 2 3 4 5 6 7

1 2 3 4 5 6 7

ON

1 2 3 4 5 6 7

Page 10

1234567

PROGRAM

DAY 1 2 3 4 5 6 7

CHANGE

ON OFF TIMED

ON

PROGRAM

DAY 1 2 3 4

CHANGE

ON OFF TIMED

ON

●●●●●

●●●●●●●

●

ii

Once day option selected press <Program>

button once to select hour time - display

shows hour digits and ON flashing. Press

<Change> button to advance hour setting.

(Note: Monday shown as an example of days set).

iii Press <Program> button once to select minute time -

display shows minute digits and ON flashing. Press

<Change> button to advance minute setting.

(Note: 16 hrs shown as example of hours set).

iv Press <Program> button once - the first ON time is

now set and display shows ready for the first OFF

programme time.

v Now set the hrs and minutes as before.

The day(s) selected remains the same.

vi Repeat steps i to v to set the remainder of the 5 ON/OFF times as required. Note:

Any unused ON/OFF programme should be skipped until the display shows

normal operating mode. Do not programme ‘0’s into unused programmes.

IMPORTANT After setting a clock time which falls within a programmed ON

period, the unit will not switch ON. Use the override facility to switch unit ON.

After this the unit will operate normally to the programmes set.

4. Programme Review

To fast review the set programmes or for quick exit to normal operating mode press and hold the <Program> button.

5. Initiating Programme Mode

This can be initiated any time during the normal operating mode. Press

<Program> button and the Clock symbol, day flag, hrs and minutes symbols

on the display will flash - this is review mode. If any change to programmes is

required press <Change> button to initiate programme mode and then follow

steps 2 and 3.

●●

=

5 days (Weekdays)

=

2 days (Weekend)

=

7 days (Everyday)

=

Individual days

Mo Tu We Th Fr

Sa Su

Mo Tu We Th Fr Sa Su

Starting with Monday through to Sunday

●

1 2 3 4 5 6 7

●

1 2 3 4 5 6 7

●

1 2 3 4 5 6 7

ON

ON

OFF

Page 11

6. Cancelling Programmes

PROGRAM

DAY 1 2 3 4 5 6 7

CHANGE

ON OFF TIMED

ON

PROGRAM

DAY 1 2 3 4

CHANGE

ON OFF TIMED

ON

Any ON/OFF programme can be cancelled by clearing its ON and OFF time.

Follow step 5 and when into the ON or OFF programme to be cancelled press

the <Change> button until the hour digits show -- :

then press the <Program> button to clear the

programme. The display will show the hour and

minute digits and ON or OFF flashing.

(Note: Monday shown as an example of days set).

Self Cancelling Override

To change the output status from ON to OFF or vice versa during normal operation

press the <Change> button. The output status will change and indicate override is in

operation by flashing.

Specifications

1. A fully CE marked product conforming to BS EN 60730-2-7 for function and

safety as a control to be incorporated in other equipment.

2. Complies with EMC standards EN50081-1 for emission and EN50082-1 for

immunity as a control to be incorporated in other equipment.

10987

3. Contacts: Silver Cadmium Oxide. Single pole change over.

4. Permissible Loads: 16A Resistive

For other loads refer to Technical Service on 020 8450 0515

*This load with power factor correction capacitors is not recommended for

normally closed contacts.

5. Panel Cut Out: 67mm square with 2.5mm radius corners.

6. Battery Back-up: 1000 hours by factory fitted rechargeable battery.

7. Operating abmient temperature: -10°C to 40°C. Upper limit can be

8. Operating Voltage: 220 - 240V AC 50Hz.

6A At 0.4 power factor inductive

10A Filament lamps

*500W Fluorescent lighting with or without power factor

correction capacitors (4µF per 65W tube)

1h.p. Motor

increased for loads less than 16A - refer to

Technical Service.

ON

●

1 2 3 4 5 6 7

Loading...

Loading...