Page 1

Time Electronics

1048 Current / Voltage / Loop Calibrator

Technical Manual

V1.2 30/12/10 Time Electronics Ltd

Botany Industrial Estate, Tonbridge, Kent, TN9 1RH

Tel: +44(0)1732 355993 Fax: +44(0)1732 770312

Email: mail@timeelectronics.co.uk

Web Site: www.timeelectronics.com

Page 2

2

Contents

1. Introduction .................................................................................................... 3

2. F ront panel controls and operating modes ................................................. 4

2.1. Operating Mode: NORMAL ............................................................................ 5

2.2. Operating Mode: STEP .................................................................................. 5

2.3. Operating Mode: RAMP ................................................................................. 5

3. Normal Operating Mode ................................................................................ 6

3.1.1. Resolution high/low ............................................................................................ 6

3.1.2. Output polarity switch ......................................................................................... 6

3.2. Measure – Voltage ......................................................................................... 7

3.3. Measure – Current ......................................................................................... 8

3.4. Power and calibrate - transmitters/sensors ................................................. 8

3.5. Source – Voltage............................................................................................ 9

3.6. Source – Current............................................................................................ 9

3.7. Sink - transmitter simulator (TX SIM) ..........................................................10

4. Additional Operating Modes ....................................................................... 11

4.1. STEP - Manual ...............................................................................................11

4.2. STEP – Automatic .........................................................................................12

4.3. RAMP .............................................................................................................12

5. Operating Precautions ................................................................................. 13

5.1. Display ...........................................................................................................13

5.2. Usage & Storage ...........................................................................................13

5.3. Automatic power down disable ...................................................................13

6. Power S upplies ............................................................................................ 14

6.1. Auto-power down .........................................................................................14

6.2. Battery Life ....................................................................................................14

6.3. Battery Replacement ....................................................................................14

6.4. Mains Power Supply Adapter .......................................................................14

6.5. Fuse Replacement ........................................................................................14

7. Maintenance ................................................................................................. 15

7.1. Recalibration .................................................................................................15

7.2. Dis-Assembling the Unit ..............................................................................16

7.3. Trimmer Locations .......................................................................................17

7.4. Measure Function Calibration ......................................................................18

7.5. Step Mode Calibration ..................................................................................19

7.6. Current Shunt Calibration ............................................................................19

7.7. Re-Assembling the Unit ...............................................................................20

7.8. Calibration Certificates.................................................................................20

7.9. Front Panel Keypad and Connections ........................................................20

8. S pecifications ............................................................................................... 21

9. Guarantee & S ervicing ................................................................................. 23

All Time Electronics' instruments are subject to continuous development and improvement and in

consequence may incorporate minor detail changes from the information contained herein.

V1.2 30/12/10 Page | 2 1048 Technical Manual

Page 3

3

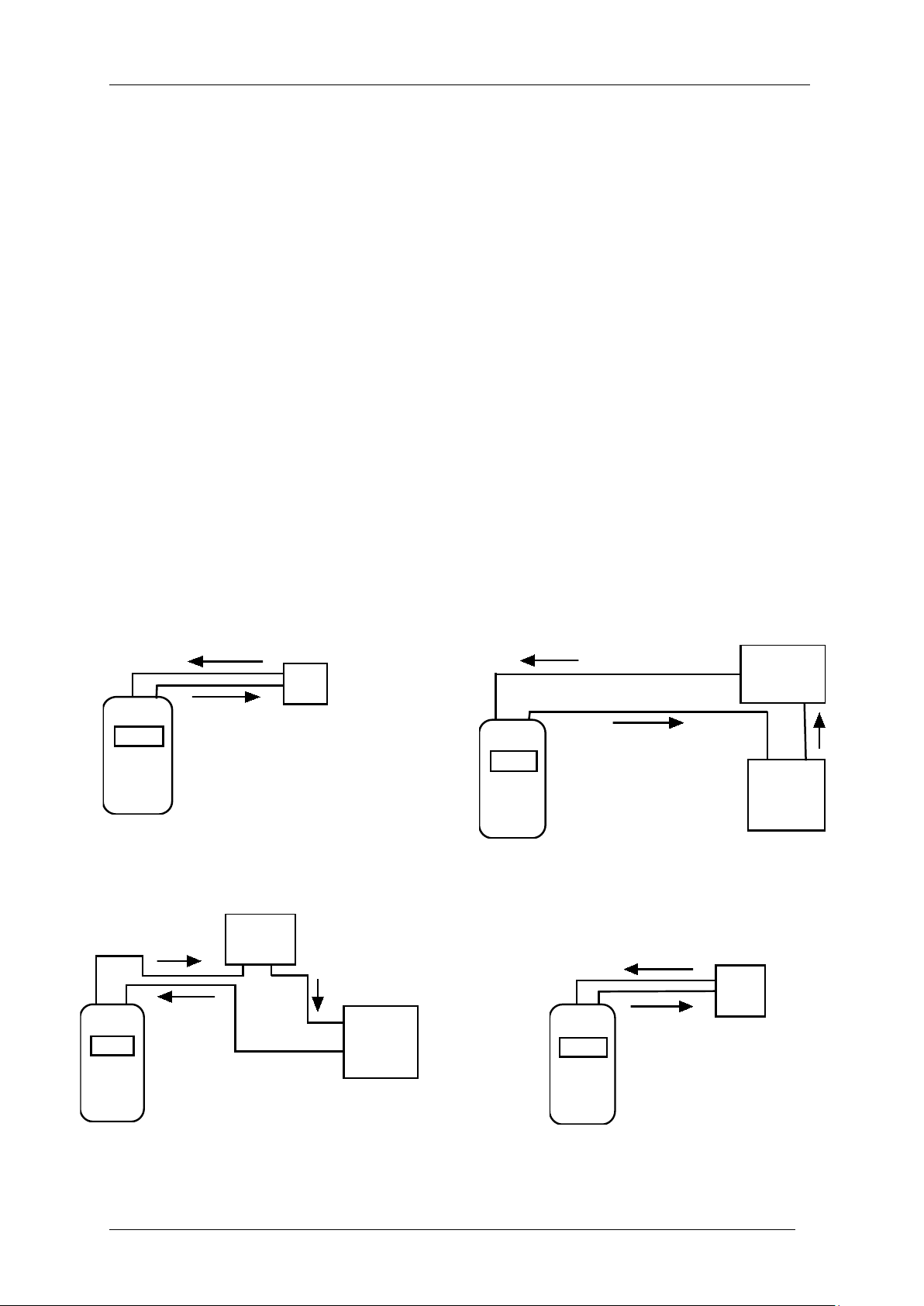

-

+

Source Mode

Receiving instrument

+

Measure Mode

-

+

Sensor

- +

- +

Pow er Suppl

y

2 wire transducer/transmitter

-

+

_

P ower

+ Supply

Sink Mode (transmi tter simulator)

Controller

+ -

-

+

+

Sensor

Measure & Power Mode

2 wire transducer/transmitter

1. Introduction

The 1048 is a current, voltage, and loop calibrator that meets the needs of R&D labs and

process control engineers. It provides source and measure functions in three current and

voltage ranges, plus a transmitter simulator/sink function. Accuracy is 0.02% of span and it

has 4.5 digit (0.005% of span) resolution.

Output m odes include steps and ramps. No menus to learn, just switches and buttons. A

multi-turn potentiometer controls coarse output adjustment while increment/decrement

buttons are provided for fine control. The source output can be reversed (+/ -) and zeroed at

the flick of a switch. The front panel features a large easy-to-read 4.5 Digit LCD display that

auto-ranges to allow the ranges to be extended by 10% above the normal 0.2/ 2.0/20 full

scale. Manual reset of the ramp function is also provided for quick restore.

The unit is powered by a PP3 (Alkaline) battery that lasts approximately 15 hours.

Continuous operation in the current mode will shorten the battery life. The unit will indicate

‘Low Battery’ when the battery needs changing.

When used as a source the output can be zeroed and reversed to enable the calibration of

centre-zero type voltage or current instruments e.g. –10V to 0 to +10V.

If the unit is not operated for approximately 15 minutes, it will automatically power down to

conserve battery life. If required this feature can be disabled in the user set-up.

The unit is constructed in a rugged pocket size hard ABS case and supplied with leatherette

carrying pouch. Leads can be stored in the pouch.

V1.2 30/12/10 Page | 3 1048 Technical Manual

Page 4

4

G. Range switch

2. Front panel controls and operating modes

A. Terminals

B. Display

C. OFF/V/mA switch

D. Decrement (DEC)

H. Increment (INC)

E. Multi-Turn

Output Control

I. Function switch

F. Output switch

A. Input/Output terminals

B. 4.5 Digit LCD Display.

C. 3 position switch for ON/OFF( OFF), Vol ts (V), Current (mA).

D. Push button for fine decreasing (DEC) of the output.

E. 10 turn control for coarse output adjustment

F. 3 position switch, normal (NORM), zero (OFF), reverse (REV) output. Also used to

restore high resolution display.

G. 3 position range switch (22, 2.2, 0.22).

H. Push button for fine increasing (INC) of the output. Also used in conjunction with the

I. 3 posit ion function switch for source (SRC), measure (MEAS), and transmitter

V1.2 30/12/10 Page | 4 1048 Technical Manual

DEC button to select the modes of operation i.e. Normal, Step, and Ramp. When in

Step mode, it initiates automatic stepping. When in Ramp mode, it re-starts the ramp.

simulation (TX SIM).

Page 5

5

The unit has three principal operating modes:

2.1. Operating Mode: NORMAL

Provides manual operation of the standard measure and source functions for both

voltage and current. A transmitter simulation/sink (TX SIM) function is also included for

loop test and calibration. The internal power supply can also be used to provide the drive

voltage to passive process control transmitters and sensors. This allows them to be

calibrated without the need for the loop power to be connected.

2.2. Operating Mode: STEP

Provides output steps of fixed value. Three options are available:

a) 5 point calibration: 4, 8 ,12, 16, 20 mA.

b) 11 point calibration: 1,2,3,4,5,6,7,8,9,10 mA or V.

c) 21 point calibration: 1,2,3,4,5…18,19,20 mA or V.

The stepping between the calibration points can be done manually (see Section 4.1), or

can be set to proceed automatically at an adjustable rate (see Section 4.2)

2.3. Operating Mode: RAMP

Provides a continuous ramp up/down with dwell periods at the top and bottom. Both

voltage and current are available for ramping (see Section 4.3)

SELECTING THE OPERATING MODE:

The above operating modes are selected by simultaneously pressing the INC and

DEC buttons.

Every time they are pressed the next mode will be selected.

The mode at power up is NORMAL.

This is followed by STEP, which is indicated by the ‘CONTINUITY’ legend

appearing in the top right section of the display.

The final mode is RAMP, which is indicated by the ‘CONTINUITY’ legend flashing

V1.2 30/12/10 Page | 5 1048 Technical Manual

Page 6

6

3. Normal Operating Mode

3.1.1. Resolution high/low

The unit has a unique method of changing the display resolution when values greater than

the conventional 19999 (4.5 digit) display are used. This feature allows the units ranges to

be extended by 10% above the commonly used 0.2/2.0/20 full scales. Calibration of values

just above these figures is now possible. This will be found particularly useful with 4 - 20mA

transducers where they are slightly over scale but are still within specification.

For both measure and source functions, high resolution (4.5 digit, e.g. 1.9999) will apply for

all values below:

• 0.20 on the 0.22 range

• 2.0 on the 2.2 range

• 20 on the 22 range

All values above those above will be displayed to 3.5 digit resolution e.g. 21.05.

The change-over from high to low resolution is automatic. However, if the value increases

and the resolution changes from high to low, it will not return to high resolution until the

value is reduced to:

• 0.1on the 0.22 range

• 1.0 on the 2.2 range

• 10 on the 22 range

To force the display back into high resolution the output polarity switch, should be operated

from Hi to Lo to Hi. There is a marking on the front panel below the switch to indicate this.

3.1.2. Output polarity switch

It is important for the user to understand the operation of the output polarity switch (‘F’ on

the front panel diagram section 2.). The switch has three positions, NORM/OFF/REV, and

its function depends on the operating mode being used.

Measure function (V & mA)

In the NORM position the unit will measure inputs connected in the same polarity as the

terminals i.e. red is positive and black negative.

The OFF (centre) position, when measuring voltage, disconnects the signal internally and

leaves the input terminals still providing 1M ohm input resistance. The display should read

zero but occasionally the last digit may show ‘1’, this is normal and is within the

specification.

The OFF position, when measuring current, disconnects the signal internally and leaves the

input terminals still providing the current shunt input resistance. The display should read

zero but occasionally the last digit may show ‘1’, this is normal and is within the

specification.

The REV position is not used since the unit’s measuring capability is bi-polar i.e. it can

accept both +ve and –ve input signals. The –ve inputs are displayed with a ’-’ sign in front of

the value.

V1.2 30/12/10 Page | 6 1048 Technical Manual

Page 7

7

-

+

Measure Mode

+

Source function (V & mA)

The NORM position outputs signals in the polarity indicated by the terminals.

The REV position reverses the polarity.

When outputting voltage or current, the OFF position disconnects the output signal and

places an open circuit on the output terminals. The display will read zero.

PS When the switch is in the REV position it should be noted that the display does not place

a – annunciator before the value.

TX SIM function

The switch is not used for this function and has no effect at all.

STEP and RAMP modes

In both these modes the function switch is in the source (SCR) position and the

NORM/OFF/REV switch performs in the same way as in the NORMAL operating mode i.e.

conventional V and I measure/source.

3.2. Measure – Voltage

The unit measures dc voltage in three selectable ranges, 0 to 0.22V (displayed in mV), 0 to

2.2V and 0 to 22V (plus over-range to 50V).

SPECIAL NOTE: Although the top range is nominally 22V it can be safely used to measure

voltages up to 50V.

• Set Function switch to MEAS

• Set OFF/V/I switch to V

• Set Range switch to the desired range

• Set Output switch to NO RM

• Connect the unit to the signal source observing correct polarity, the voltage will be

displayed with 3.5 or 4.5 resolution - see section 3.1.1.

V1.2 30/12/10 Page | 7 1048 Technical Manual

Page 8

8

Measure Mode

-

+

Sensor

- +

- +

Power Suppl

y

2 wire transducer/transmitter

-

+

+

Sensor

Measure & Power Mode

2 wire transducer/transmitter

3.3. Measure – Current

The unit measures current in three selectable ranges, 0 to 0.22mA (displayed in uA), 0 to

2.2mA and 0 to 22mA (plus over-range to 70mA).

SPECIAL NOTE: Although the top range is nominally 22mA span, it can be safely

used to measure current up to 70mA.

• Set Function switch to MEAS

• Set OFF/V/mA switch to mA

• Set Range switch to the desired range

• Set Output switch to NORM

• Connect the unit to the signal source observing correct polarity, the current will be

displayed with 3.5 or 4.5 resolution - see Section 3.1.1.

Connect the unit to the sensor or

transmitter observing the correct polarity.

The current drawn is displayed.

3.4. Power and calibrate - transmitters/sensors

If the loop’s power supply is not available it is possible to use the unit’s internal 22V supply

to power the loop. Set up the unit as described below.

• Set Function switch to SRC

• Set t he Multi-Turn Output Control fully clockwise.

• Set OFF/V/mA Switch to mA

• Set Range switch to the desired range

• Set Output switch to NORM

Connect the unit to the sensor or transmitter

observing the correct polarity.

The current drawn is displayed.

V1.2 30/12/10 Page | 8 1048 Technical Manual

Page 9

9

-

+

Source Mode

Receiving instrument

+

-

+

Source Mode

Receiving instrument

+

3.5. Source – Voltage

The unit outputs voltage from 0 to 22V in three ranges, 0 to 0.22V (displayed in mV); 0 to

2.2V and, 0 to 22V.

Set function switch to SRC

Set OFF/V/mA switch to V

Set range switch to the desired range

Set output switch to NORM

Set multi-turn output control to minimum (anticlockwise)

Connect the unit to the process instrument

observing correct polarity and adjust the

multi-turn output control for coarse control and

INC and DEC buttons for fine control.

NOTE:

1) The maximum output current is limited to approx 50mA.

2) The units output resistance is approx 2.5 ohms. Therefore the user should be aware of the loading

implications - a load of 2.5K ohms will produce a 0.1% error in the output voltage. To maintain full

accuracy the maximum load should be restricted to 1.1K ohms.

3.6. Source – Current

The unit outputs current from 0-22mA in three selectable ranges, 0 to 0.22mA (displayed in

uA), 0 to 2.2mA and 0 to 22mA.

• Set function switch to SRC

• Set OFF/V/mA switch to mA

• Set range switch to the desired range

• Set output switch to NORM

• Set multi-t urn output control to minimum (anticlockwise)

Connect the unit to the process instrument

observing correct polarity and adjust the

multi-turn output control for coarse control and

INC and DEC buttons for fine control.

V1.2 30/12/10 Page | 9 1048 Technical Manual

Page 10

10

3.7. Sink - transmitter simulator (TX SIM)

In the Sink function, the unit simulates a process field transmitter as part of a loop testing

and calibration operation. The unit takes its excitation power from the loop and acts as a

variable resistance to adjust the loop current to the value shown on the units display. The

excitation voltage must be in the range 3 to 50 volts dc.

The NORM/OFF/REV switch in not functional in the SINK mode.

• Set function switch to TX SIM

• Set OFF/V/mA switch to mA

• Se t range s wi tch to t he 22 position

• Set output switch to NORM

• Set multi-t urn output control to minimum (anticlockwise)

Connect the unit in the loop

observing correct polarity. Set the

current in the loop by adjusting the

multi-turn control (coarse) and the

INC/DEC buttons (fine)

V1.2 30/12/10 Page | 10 1048 Technical Manual

Page 11

11

4. Additional Operating Modes

These modes are designed to automate and speed up the process of testing and calibration.

The STEP mode allows simplified calibration. It provides output steps of fixed value.

Three choices are available,

a) 5 point calibration; 4, 8 ,12, 16, 20 mA

b) 11 point calibration; 1,2,3,4,5,6,7,8,9,10 V

c) 21 point calibration; 1,2,3,4,5…18,19,20 mA or V

The a) and b) choices are the defaults. The c) choice is obtained by powering up the unit

while pressing the DEC button.

The RAMP mode provides a continuous ramp up/down with dwell periods at the top and

bottom. Both voltage and current are available for ramping and the ramp limits can be

selected as shown above i.e. for 5, 11 or 21 point calibrations.

SELECTING THE OPERATING MODE:

The above operating modes are selected by simultaneously pressing the INC and DEC

buttons.

Every time they are pressed the next mode will be selected.

The mode at power up is NORMAL.

This is followed by STEP, which is indicated by the ‘CONTINUITY’ legend appearing in the

top right section of the display.

The final mode is RAMP, which is indicated by the ‘CONTINUITY’ legend flashing

.

4.1. STEP - Manual

Considerably speeds up the calibration process as a simple push of a button enables the

unit to manually step through standard calibration points, 5 points in 4-20, 11 points in 0-10,

or 21 points in 0-20.

• Set function switch to SRC

• Set OFF/V/mA switch to the desired units (V or mA)

• Set r ange switch to the desired range

• Set output switch to NORM

Simultaneously press INC and DEC buttons and the word “CONTINUITY” will appear on the

display and the reading will go to zero.

The unit is now ready to manually step through the preset values determined by the switchon mode stated in section 4.0 a), b) or c).

Press the INC to step to the next output value.

Press the DEC button to step back to the previous output value.

NOTES:

a) When choosing the 4 - 20 steps the initial value will be zero. It will move to 4 at the first press and

subsequently cycle between 4 and 20 in the regular 5 point pattern.

b)

The output switch will operate in the same way as for source (V & mA) function.

V1.2 30/12/10 Page | 11 1048 Technical Manual

Page 12

12

4.2. STEP – Automatic

This function provides a method of automatically stepping through the fixed output values.

• Set function switch to SRC

• Set OFF/V/mA switch to the desired units (V or mA)

• Set range switch to the desired range.

• Set output switch to NORM

• Simultaneously press INC and DEC buttons. The word “CONTINUITY” will appear on

the display and the reading will go to zero.

The unit is now ready to enter the Auto-Step function and automatically output the preset

values determined by the switch-on mode stated in section 4.0 a), b), or c)

• Press the INC button and hold for 1 second. The display decimal point will start to

flash and the output will cycle up and down through the fixed values. The time step

on each value may be varied from 1 to 9 seconds by adjusting the multi-turn output

control.

• To return to the Manual Step Function press the INC button. The decimal point will

stop flashing.

4.3. RAMP

When using either the Source or Sink functions, RAMP provides a method of continuously

increasing and then decreasing the output in a continuous fashion. The output ramps up

from 0% (4 in the 4-20 selection) to the full scale where it stays (dwells) for a fixed period

before ramping down again to its starting value. It dwells here again for a fixed period before

restarting the cycle. The ramp times are approx 7 secs and the dwell times approx 5 secs.

Ramp operation is available for both voltage and mA output.

• Set function switch to SRC or TX SIM

• Set OFF/V/mA switch to desired units

• Set range switch to the desired range

• Set output switch to NORM

• Simultaneously press INC and DEC buttons twice. The CONTINUITY legend will

appear flashing on the display.

The unit will now ramp up and down automatically between the range limits as determined

by the range and V/mA selected. The alternative limits can also be used and are as

determined by the switch-on conditions as stated at the start of section 4.

Note

When the unit initially enters RAMP mode the first dwell period will be shorter than 5 secs.

To reverse the direction of the ramp at any time press the INC button once. To restart the ramp

immediately when it is waiting in the dwell period, press the INC button once.

V1.2 30/12/10 Page | 12 1048 Technical Manual

Page 13

13

5. Operating Precautions

5.1. Display

The LCD display should not be exposed to strong sunlight for prolonged periods.

5.2. Usage & Storage

Temperature

Operating: -10 to +50 degC (14 to 120 degF)

Storage: -30 to +70 degC (-22 to 160 degF)

Humidity

The operating and storage relative humidity limits are 10 to 90%

non-condensing at 25 deg C (77 deg F)

5.3. Automatic power dow n disable

If the unit is not operated for 15 minutes it will automatically power down to conserve the

battery life.

This feature can be inhibited by pressing the INC button when switching on the unit. It

should be noted that the operation is indicated by flashing the decimal point at the switch on

time.

V1.2 30/12/10 Page | 13 1048 Technical Manual

Page 14

14

6. Power S upplies

6.1. Auto-power down

If the unit is not used for 15 minutes, it will automatically power down to conserve the battery

life. This feature can be disabled by holding down the INC button whilst switching on the

unit.

6.2. Battery Life

The unit is powered by a PP3 (Alkaline) battery that lasts approximately 15 hours of normal

operation. Continuous operation on current will shorten the battery life. The unit will indicate

‘Low Battery’ when the battery needs changing. A short period of operation is possible when

‘Low Battery’ is showing but no more than a few mA will be available at the output.

6.3. Battery Replacement

Slide off the back cover of the case and remove

the battery from its compartment. Unclip the

battery and replace it with a new PP3 (Alkaline).

The NiCad / NiMH rechargeable version of this

battery may be used. However it should be

noted that if the optional mains power supply

adapter (see below) is used to power the unit,

the battery will not

necessary to remove the battery and re-charge

it externally.

be re-charged. It is

6.4. Mains Power Supply Adapter

The unit can be operated from an external 12V dc

(100 mA) mains power supply unit. This is available

as an optional extra. Connection is via the small

jack plug socket on the terminal end of the unit.

6.5. Fuse Replacement

The unit is fitted with a F100 mA fuse. Switch off the unit and disconnect the battery. Slide

off the back cover to access the fuse. The fuse is located adjacent to the battery. Fuse

length 20mm x 5mm, TE code: 6107.

V1.2 30/12/10 Page | 14 1048 Technical Manual

Page 15

15

7. Maintenance

7.1. Recalibration

Calibration equipment required:

A) A precision DC voltage calibrator with an accuracy of 0.01% or better. Examples of

suitable instruments are Time Electronics’ 1017, 5018, 5025 or 5051.

B) DMM with accuracy of 0.01% or better. Examples of suitable instruments are Time

Electronics’ 5075, or 5065.

Note: It is advisable to use leads with low thermal emf connections. This will ensure that

stray thermal emfs do not cause errors when calibrating the low voltage range (.22V) which

has a setting resolution of 10uV.

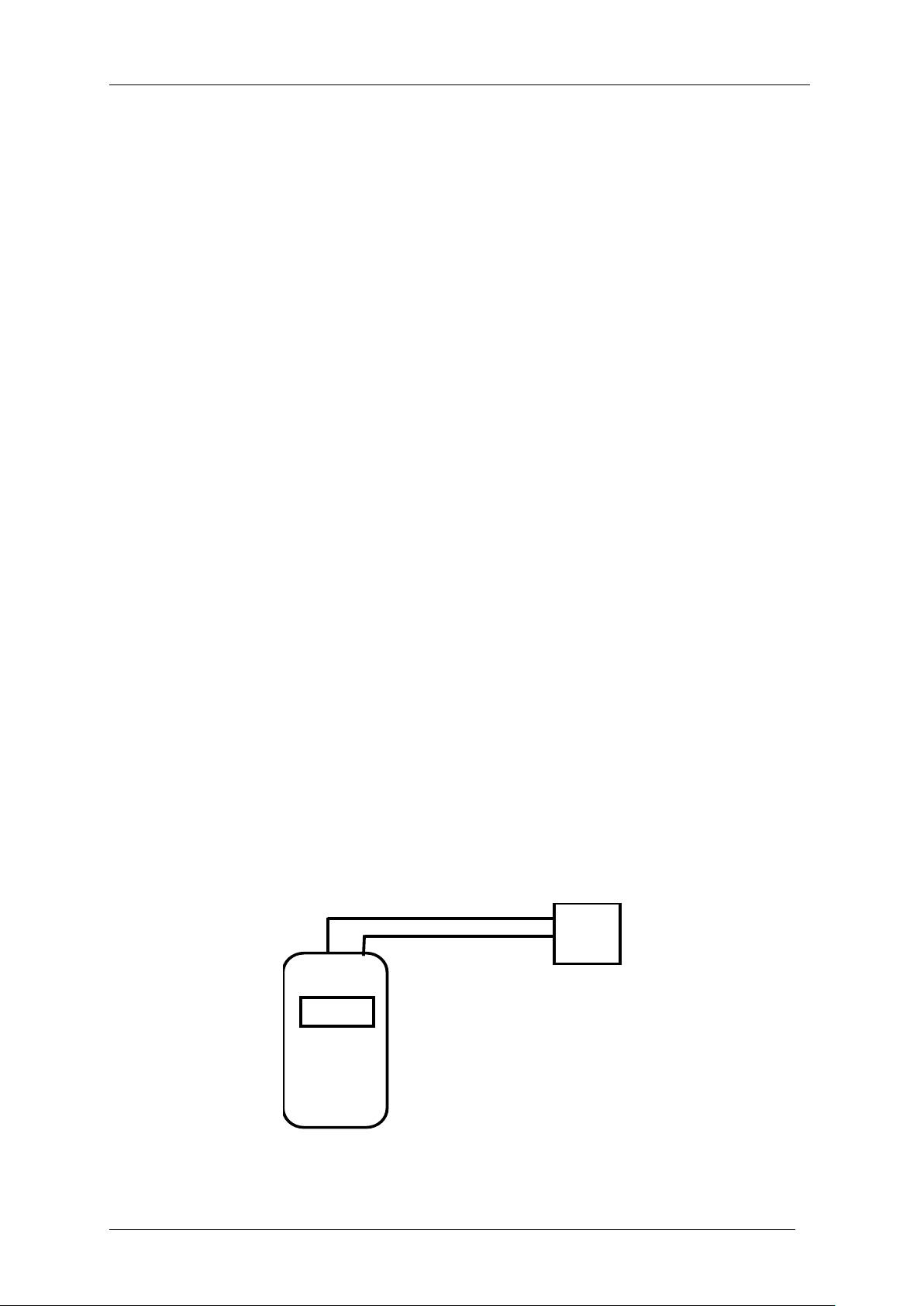

The unit connected to a Time

Electronics’ 1017 Precision

0.005% DC V & I calibrator.

The unit connected to a Time

Electronics 5065 6.5 digit

Precision DMM

V1.2 30/12/10 Page | 15 1048 Technical Manual

Page 16

16

7.2. Dis-Assembling the Unit

A. Ensure that the unit is switched off before removing

the rear panel which slides out.

Note: The plastic cover retaining clip will need to be

removed prior to sliding cover off, refit when

reassembled.

B. Remove the cap on the multi-turn control knob by levering it off

with a fine bladed screwdriver or similar tool.

C. Remove the collet nut (inside the knob). Use a suitable split

head screwdriver or small long nosed pliers.

D. Remove the knob and then the hexagon nut below it, use

the correct sized spanner or pliers. Take care not to

damage the front panel label.

E. Gently press on the shaft of the multi-turn control to

release the printed circuit assembly and battery from the

case. Do not attempt to remove it completely - leave the

case sitting vertical and the assembly flat horizontal.

V1.2 30/12/10 Page | 16 1048 Technical Manual

Page 17

7.3. Trimmer Locations

P7

P5

P9

P2

P6

17

P3

P8

P4

V1.2 30/12/10 Page | 17 1048 Technical Manual

Page 18

18

7.4. Measure Function Calibration

1) a) Switch on the unit while holding down the ‘Decrement-DEC’ button (left side). Select

the ‘V’ position.

b) Select ‘MEAS’ on the Function switch.

c) Select ‘0.22’ on the Range switch.

d) Select ‘NORM’ on the Output switch.

Note: It may be necessary to check the required switch positions by looking at the markings

on the front panel.

2) Connect the precision DC voltage calibrator to the unit’s terminals and select zero

output. Check that the unit is displaying 00.00. Note that it may take a short while for

the connection leads to stabilize thermally and settle down.

3) Inject 190.00 mV from the calibrator and adjust P3 for the correct reading on the

display.

4) Select ‘2.2’ on the Range switch and inject 1.9000 V from the calibrator. Adjust P5 for

the correct reading on the display.

5) Select ‘22’ on the Range switch and inject 19.000 V from the calibrator and adjust P7

for the correct reading on the display.

6) Reduce the output from the calibrator to 1.9000 V and reading on the display. Return

to test above and re-check the 22V range. There is a small amount of interaction of P5

and P7.

7) Finally re-check the 2.2V range to ensure that it has not changed.

8) Over-Range check: The unit allows measurement up to 50V on the 22V range. This

can be checked by injecting 30, 40, 50V.

This completes the calibration of the measure function and the precision DC calibrator can

be disconnected.

V1.2 30/12/10 Page | 18 1048 Technical Manual

Page 19

19

7.5. Step Mode Calibration

1) a) Select ‘SRC’ on the Mode select switch.

b) Select 0.22 on range switch.

c) Select ‘Norm’ on output switch.

2) Enter the step mode by pressing the ‘Inc’ and ‘Dec’ buttons simultaneously. The

‘CONTINUITY’ legend will then show on the top of the right side of the display. Press the

‘DEC’ button twice. Note: Make sure that the unit was switched on with the ‘DEC’ button

held down.

3) Adjust P9 for 100.0 on the display.

4) Press ‘Inc’ 20 times until the display shows approximately 200. Adjust P2 for 200.0 on

the display.

This completes the ‘Step Mode’ calibration.

7.6. Current Shunt Calibra ti on

1) a) Select normal mode operation by pressing the ‘Increment’ and ‘Decrement’ buttons

simultaneously. The ‘CONTINUITY’ legend will then show on the top of the right side

of the display

b) Select ‘SRC’ on the Mode select switch.

c) Select .22 on range switch.

d) Select ‘Norm’ on output switch.

e) Select ‘mA’ on the OFF/V/I switch.

2) Connect a precision DMM to the output terminal and set it to 30 or

100 mA DC current range.

3) Adjust the multi-turn control until the display shows 19.000 (use the INC/DEC buttons

for fine adjustment). Make sure the unit is in high resolution mode, i.e. 5 digit display. If

it has dropped back to low resolution (4 digit), move output switch to ‘Lo’ position and

then back to ‘Hi’.

4) Adjust P8 until DMM reads exactly 19.000 mA.

5) Select ‘2.2’ on the range switch, select 3 or 10 mA range on DMM.

6) Use similar procedure to 3) and 4) to calibrate at 1.9000 mA (P6)

7) Select ‘.22’ on the range switch. Select 0.3 or 1 mA on DMM and use similar procedure

to 3) & 4) to calibrate at 190.00 uA. (P4)

This completes the calibration of the ‘current shunts’.

V1.2 30/12/10 Page | 19 1048 Technical Manual

Page 20

20

7.7. Re-Assembling the Unit

Re-assemble the unit in the reverse order as in

5) through to 1).

Please note that there is some difficulty in returning

the printed circuit board assembly to its correct

position in the case. It is important to initially

position it so that the external supply socket (the

terminal end) is adjacent to its hole in the case.

The whole assembly should then be lowered into

position as far as it will go - it is important to have

the ‘OFF/V/mA’ and range switches to the ‘OFF’ and

‘22’ positions and the ‘OUTPUT’ and ‘MODE’

switches in ‘OFF’ and ‘MEAS’ positions.

It is then necessary to lever the multi-turn shaft

(with a small screw driver) towards the terminals.

This will ease the output and mode switches forward

enough to allow them to spring into their slots. At

the same time the ‘INC/DEC’ buttons may need to

be re-positioned slightly to allow them to go back

into their holes.

7.8. Calibration Certific a t e s

It should be noted that the previously listed procedures are used to set up the adjust

trimmers that ensure that the unit will be within the manufacturer’s specification.

To produce a full set of calibration results and a ‘Certificate of Calibration’, the unit must be

checked on all its ranges. Good practice requires a minimum of 5 calibration points per

range.

Time Electronics can supply calibration certificates for the unit either NPL (National Physical

Laboratories, UK) traceable, or to UKAS standard. Equivalent certificates will be available

from calibration houses throughout the world.

Time Electronics EasyCal Calibration System

It should be noted that users who have access to the above system can obtain on request,

free of charge, a copy of the manufacturers recommended calibration procedure. Please

specify either floppy disc or e-mail for the delivery media.

7.9. Front Panel Keypad and Connecti ons

The Front Panel should be cleaned by wiping with a damp cloth. Solvents must not be used

as damage may result.

When connecting cables the screwed terminals should be hand tightened only.

V1.2 30/12/10 Page | 20 1048 Technical Manual

Page 21

21

8. Specifications

DC Current -Source and Measure

Span: 0 - 22mA (Source), 0 - 22mA and 22-70mA (Measure)

Source Accuracy: 0.02% of range

Measure Accuracy: as source 0-22mA, above 22mA 0.05%

Resolution: 1uA (0 - 19.999mA), 10uA (above 20mA)

Span: 0 - 2.2mA

Accuracy: 0.02% of range

Resolution: 0.1uA (0 - 1.9999mA), 1uA (above 2mA)

Span: 0 - 220uA

Accuracy: 0.05% of range

Resolution: 0.01uA (0 - 199.99uA), 0.1uA (above 200uA)

Max source load: 1100ohms@20mA. Max drive, 22V

Max measure load: 0.22, 2.2, 22 mA ranges are 1K, 110, 16 ohms

DC Volts - Source and Measure

Span: 0 - 22V (Source) and 0 - 22V and 22 - 50V (Measure)

Source Accuracy: 0.02% of span

Measure Accuracy: as source 0-22V, above 22V 0.05%

Resolution: 1mV (0 - 19.999V), 10mV (above 20V)

Span: 0 - 2.2V

Accuracy: 0.02% of span

Resolution: 0.1mV (0 - 1.9999V), 1mV (above 2V)

Span: 0 - 220mV

Accuracy: 0.05% of span

Resolution: 10uV (0 - 199.99mV), 0.1mV (above 200mV)

Source output resistance: Less than 2 ohms. Max current 50mA

Measure input resistance: 1M ohm on all ranges

Note: Accuracies for all measure modes are +/- 1 digit

V1.2 30/12/10 Page | 21 1048 Technical Manual

Page 22

22

Sink (TX SIM)

2 wire transmitter simulation: External excitation voltage, 3V min, 50V max. The current sink

levels are adjustable with accuracies as in the three mA source ranges shown on page 21.

Output Steps

5 fixed steps for I output 4, 8, 12, 16 & 20 mA

11 fixed steps for V output 0,1,2...10V

21 fixed steps for V & I output 0,1,2…...20

Stepping can be done manually or can be set to run automatically up and down

continuously with adjustable speed control (1-10 sec/step). Dwell time (top and bottom) 1

step period. The resolution of the display is 3.5 digits and accuracy as source specification.

Output Ramp

Current Ramp 4 to 20, or 0 to 20 on all ranges.

Voltage Ramp 0 to 10, or 0 to 20 on all ranges.

Ramp time 7 sec. Dwell (top & bottom) 5 sec. Manual restart.

Ramp operation is also available in Sink(TX SIM) function.

Source Output Adjustment

A ten turn potentiometer is provided for quick positioning with fine adjustment using up/down

incrementing buttons.

Power

A single internal 9V PP3 size battery or an optional external mains power supply. Battery

life: Typically about 15 hrs use.

A 15 minutes inactivity auto-power down feature is also included to conserve the battery,

see page 13, section 5.3.

Operating temperature: -10 to 50 degC (0 to 120 degF)

Operating Humility: 10-90% non-condensing 25 degC(77 degF)

Dimensions: 14 x 8 x 5 cm, 280 gm (5.5 x 3 x 2in, 10oz)

Housing

The 1048 is supplied in a rugged pocket size hard ABS case. It comes complete with a

leatherette carrying case. Test leads (not supplied) can be stored inside the leatherette

case.

Ordering Information

Voltage/Current/Loop Calibrator 1048

Mains power supply 230V AC 7643

Mains power supply 115V AC 7652

NPL traceable calibration certificate C176

UKAS calibration certificate C138

V1.2 30/12/10 Page | 22 1048 Technical Manual

Page 23

23

9. Guarantee & Servicing

Guarantee Period

This unit is guaranteed against defects in materials and workmanship for a period of one

year from its delivery to the customer.

We maintain comprehensive after sales facilities and the unit can, if necessary be returned

to us for servicing. During this period, Time Electronics Ltd will, at its discretion, repair or

replace the defective items. For servicing under guarantee, the instrument type and serial

number must always be quoted, together with details of any fault and the service required.

The purchaser of the instrument must prepay all shipping charges. Time Electronics Ltd will

pay return shipping charges.

This guarantee is void if servicing has been attempted by an unauthorised person or agent.

If, during the guarantee period, failure is due to misuse or abuse of the unit, the repair will

be put in hand without delay and charged unless other instructions are received.

Please note that if you require a new UKAS Certificate during the warranty period, this will

be charged at the current rate on our price list.

Service After Guarantee Period

Even after the guarantee period has expired, Time Electronics Ltd., can still service your

instrument. As the manufacturer, we have the specialised knowledge needed to keep your

instrument in peak condition and we also maintain a comprehensive spare parts service.

Please enclose details of the service required and your full company details including a

contact name when returning for servicing.

Returning Instruments

When returning instruments, please ensure that they have been adequately packed,

preferably in the original packing supplied. Time Electronics Ltd will not accept responsibility

for units returned damaged. Please ensure that all units have details of the service required

and all relevant paperwork.

Send the instrument, shipping charges paid to:-

Time Electronics Ltd

Botany Industrial Estate, Tonbridge, Kent, TN9 1RH

Tel: +44(0)1732 355993 Fax: +44(0)1732 770312

Email: mail@TimeElectronics.co.uk

Web Site : www.TimeElectronics.com

Disposal of your old equipment

1. When this crossed-out wheeled bin symbol is attached to a product it means the

product is covered by the European Directive 2002/96/EC.

2. All electrical and electronic products should be disposed of separately from the

municipal waste stream via designated collection facilities appointed by the

government or the local authorities.

3. The correct disposal of your old appliance will help prevent potential negative

consequences for the environment and human health.

4. For more detailed information about disposal of your old appliance, please contact

your city office, waste disposal service or return to Time Electronics.

V1.2 30/12/10 Page | 23 1048 Technical Manual

Loading...

Loading...