Page 1

Time Electronic s

1044 Voltage and Current Calibrator

Technical Manual

V1.1 09/01/11 Time Electronics Ltd

Botany Industrial Estate, Tonbridge, Kent, TN9 1RH

Tel: +44(0)1732 355993 Fax: +44(0)1732 770312

Email: mail@TimeElectronics.co.uk

Web Site: www.TimeElectronic s .com

Page 2

2

Contents

1. Introduction ........................................................................................................ 3

2. S pecifications ..................................................................................................... 4

3. Opera tion of the 1044 ........................................................................................ 6

3.1. Preliminary .......................................................................................................... 7

3.2. Setting a voltage output ..................................................................................... 7

3.3. Setting a current output ..................................................................................... 7

3.4. Measuring a voltage input .................................................................................. 8

3.5. Measuring a current input .................................................................................. 8

4. Opera tion of the 4-20mA S ys tem ...................................................................... 9

5. B attery Replacement ....................................................................................... 10

6. R ecalibration .................................................................................................... 11

7. F ault Diagnos tic s ............................................................................................. 12

8. Guarantee & S ervicing ..................................................................................... 13

Manuel Technique (Francais) ................................................................................. 14

Technis ches Handbuch (Deutsch)......................................................................... 28

All Time Electronics' instruments are subject to continuous development and improvement and in

consequence may incorporate minor detail changes from the information contained herein.

V1.1 09/01/11 Page | 2 1044 Technical Manual

Page 3

1. Introduction

3

The 1044 has been designed to offer solutions in many applications from the R&D lab to the

service engineer; in fact anywhere an accurate and low cost calibrator is needed.

We have used our experience in designing instrumentation to bring you the most versatile

and practical calibrator yet. The 1044 can source and measure voltage and current in one

compact unit and the 0.05% accuracy is ideal for simulation and calibration in most

engineering applications.

Being virtually foolproof in operation, the 1044 combines the advantages of digital accuracy

with analog controls. Progressing from the familiar functions of our popular 1030 calibrator,

the 1044 offers more ranges, better accuracy and the ability to measure as well as source,

making it even more of an asset.

The large, easy to read LCD display shows the actual output, even if the connected load

exceeds the specifications. This important feature eliminates the risk of large errors when

connecting to unknown loads. The display even shows if the battery becomes low.

In the source mode, voltage up to 20v and current up to 20mA may be generated in three

ranges, whilst in current source mode; the 1044 has a high 24V compliance voltage which is

ideal powering process control loops.

In the measurement mode, the range and function can be easily selected and will operate

as a multimeter. The measured input is accurately shown on the LCD display.

The 1044 is housed in a pocket sized, rugged ABS case and comes with a leatherette carry

case containing a compartment for storing test leads. Connections are by standard 4mm

plugs or by simply clamping the wires under the terminals.

The instrument is powered from an internal 9V alkaline battery (see page 10). Alternatively

the 1044 can be powered from an optional external linear AC/DC power supply (Time

Electronics code 7643). If power is supplied via other means, such as an in-vehicle 12V DC

socket, a 200mA fuse must be fitted to the socket adaptor.

V1.1 09/01/11 Page | 3 1044 Technical Manual

Page 4

2. Specifications

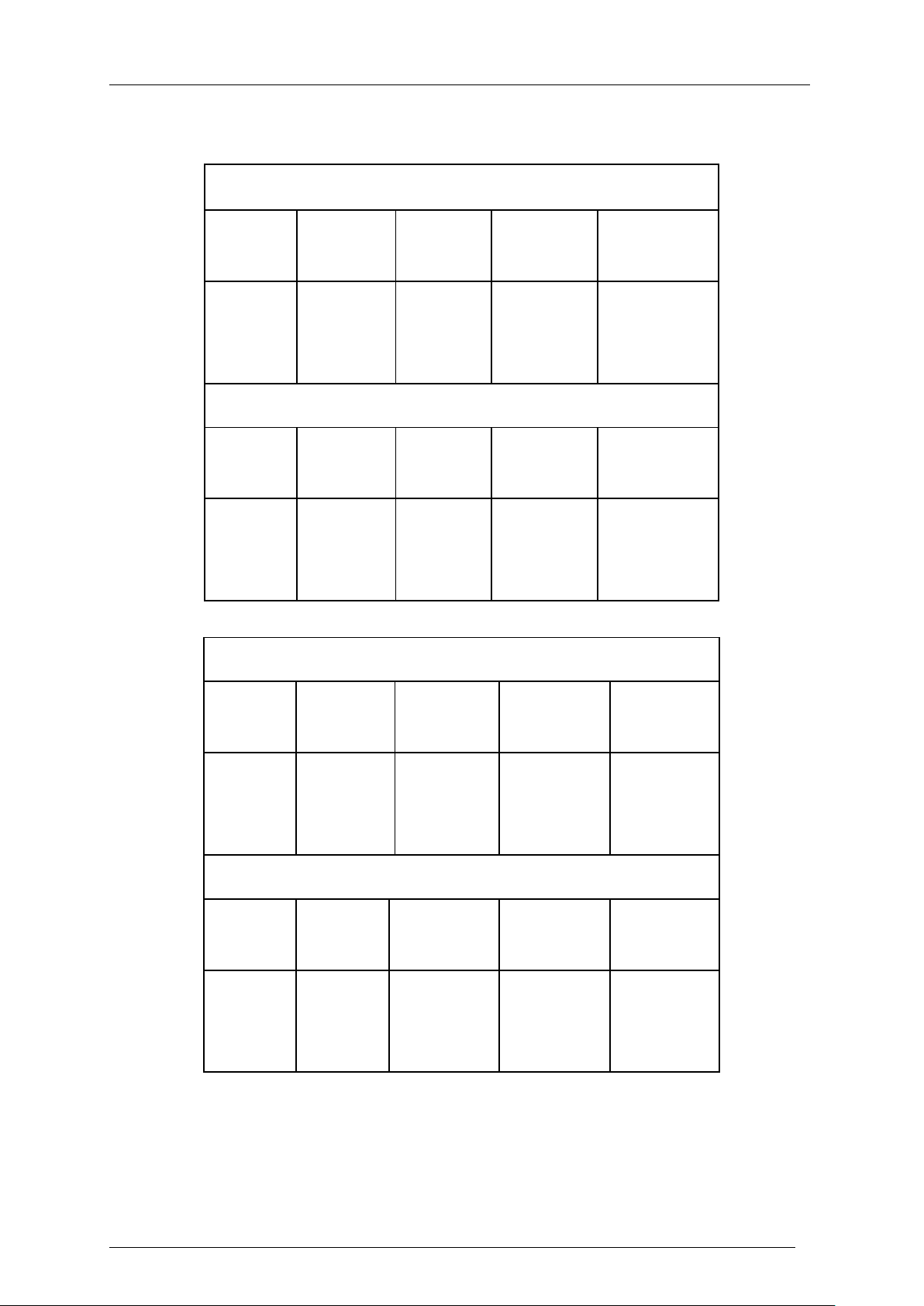

RANGES

Range Resolution Accuracy O/P Current T/C per °C

4

Voltage Source

0 - 200mV

0 - 2V

0 - 20V

100uV

1mV

10mV

± 0.05%

+

± 2 Counts

20mA

± 150ppm

Voltage Measure

Range Resolution Accuracy O/P Voltage T/C per °C

0 - 200mV

0 - 2V

0 - 20V

100uV

1mV

10mV

± 0.05%

+

± 2 Counts

<2V = 1MΩ

<20V =

10MΩ

± 150ppm

Current Source

Range Resolution Accuracy O/P Voltage T/C per °C

0 - 200uA

0 - 2mA

0 - 20mA

100nA

1uA

10uA

± 0.05%

+

± 3 Counts

24V Max

± 200ppm

Current Measure

Range Resolution Accuracy Impedance T/C per °C

0 - 200uA

0 - 2mA

0 - 20mA

100nA

1uA

10uA

± 0.05%

+

± 3 Counts

10Ω

± 200ppm

V1.1 09/01/11 Page | 4 1044 Technical Manual

Page 5

5

OUTPUT NOISE

<30ppm of f.s. on voltage, <50ppm of f.s. on current

CONNECTIONS

Connections are made by 4mm banana type connectors or may be clamped using the wire

compression feature.

BATTERIES

1 off PP3, 6AM6, MN1604 or 6LR61 type battery.

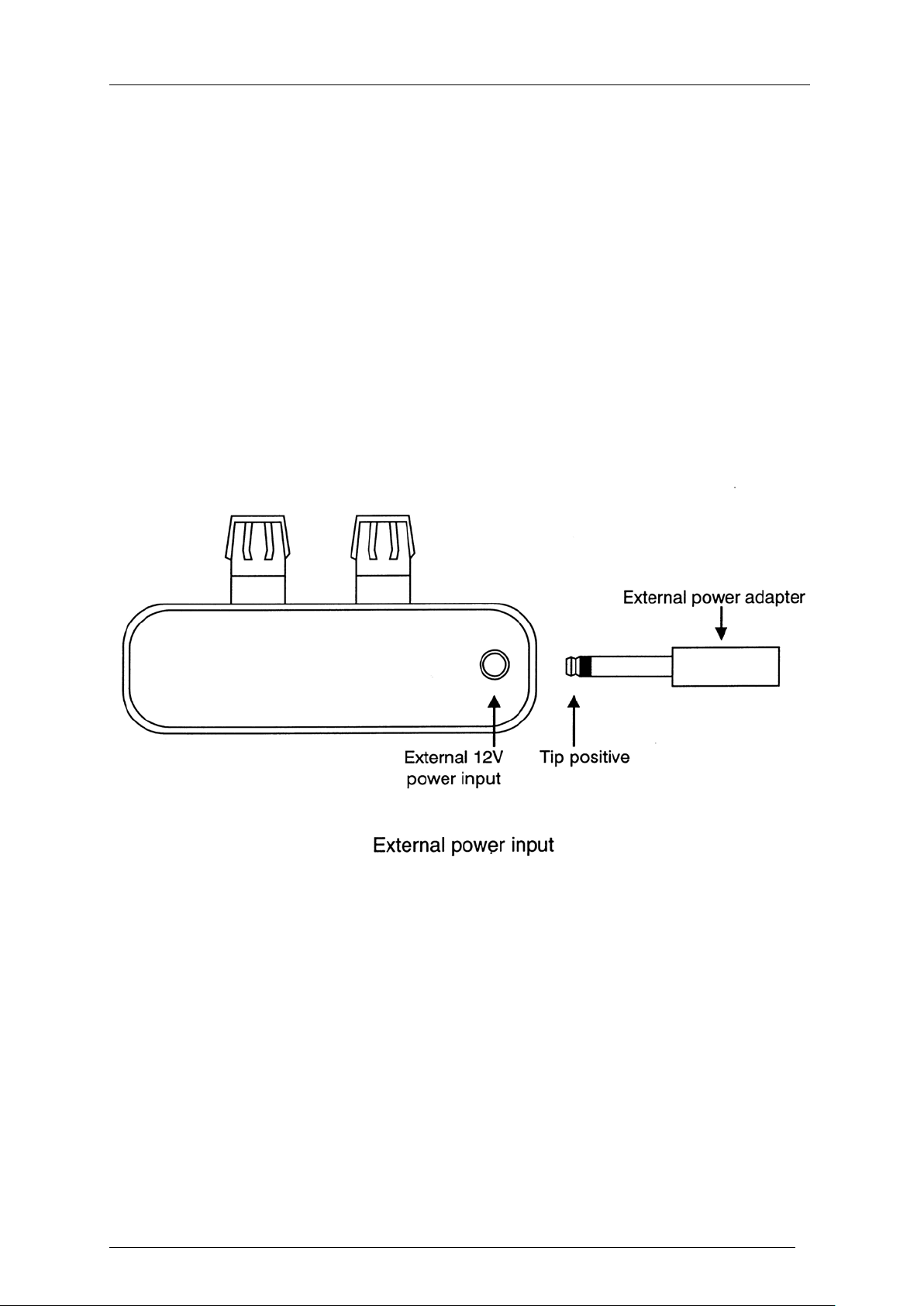

Battery life is approximately 30 Hours depending on the current sourced. Alternatively an

optional 12V power supply can be plugged into the 2.5mm socket located on the end of the

unit, the tip of the plug should be positive.

PROTECTION

The 1044 can withstand open circuits, short circuits and reverse polarity up to 25V.

Additional protection is by an 20mm F100mA internal fuse.

CONSTRUCTION

Construction is in a durable plastic case with sliding cover for battery storage. Internally the

circuit is built on a single compact PCB with plug in display module. A carry case is also

supplied for moderate protection.

DIMENSIONS AND WEIGHT

Length 142mm (5.6”) x Width 75mm (2.9”) x Height 50mm (2.0”)

Weight 280g (0.6 lbs)

V1.1 09/01/11 Page | 5 1044 Technical Manual

Page 6

6

3. Operation of the 1044

CONTROLS

All the operator controls are located on the front panel with calibration adjustments located

inside the unit along with the input/output protection fuse. Refer to the Fault Diagnosis

section for more information.

V1.1 09/01/11 Page | 6 1044 Technical Manual

Page 7

7

3.1. Preliminary

Operation of the 1044 can be defined as four different procedures; voltage source, current

source, voltage measure and current measure.

For correct operation ensure that the battery low indicator is not showing in the display. The

output will only be indicated when the polarity switch is in either ‘normal’ or ‘reverse’

positions, not in the ‘off’ position. Be certain to check the polarity settings before connecting

the unit under test. The display will show a negative sign ‘-’ if the output is in reverse polarity

mode.

The display will show the actual applied output in source mode so if the value alters when

the unit under test is connected, the loading specifications might be exceeded. This is also

useful because it eliminates potential errors when connecting to an unknown U.U.T.

Always check the mode of operation and range values before connecting to the unit under

test or to the circuit being measured. If the 1044 will not source or measure the protection

fuse has probably blown due to an excessive current being applied to the unit. This can be

found inside the 1044 - refer to section 7, page 12 for more details.

3.2. Setting a voltage output

To set a voltage output, set the function switch to V and set the appropriate voltage

range.Set to the desired voltage by turning the output adjust multiturn potentiometer, the

output voltage shown in the display will alter. The unit under test may now be connected

observing the polarity.

3.3. Setting a current output

To set a current output, set the function switch to mA and set the appropriate current range

ensuring that the output adjust potentiometer is set to zero. Connect the unit under test. The

desired current can be set by turning the output adjust multiturn potentiometer where the

output current shown in the display will alter. To obtain a current reading, a load must be

connected to the output of the 1044.

Note that if the current output is set to its maximum but is not indicated on the display, the

output load is probably too high or the battery is low. Therefore reduce the loop resistance

or replace the battery.

V1.1 09/01/11 Page | 7 1044 Technical Manual

Page 8

8

3.4. Measuring a voltage input

To measure a voltage input select the V function and select the appropriate range. If the

input is unknown then choose the highest range. Select the measure mode and ensure that

the polarity switch is set to normal. The reading should now be displayed. If the display

shows the digit 1 with a blank character then the unit has over-ranged and must be switched

to the next highest range.

3.5. Measuring a current input

To measure a current input select the mA function and select the appropriate range. If the

input is unknown then choose the highest current range. Select the measure mode and

ensure that the polarity switch is set to normal. The reading should now be displayed. If the

display shows the digit 1 with a blank character then the unit has over-ranged and must be

switched to the next highest range.

V1.1 09/01/11 Page | 8 1044 Technical Manual

Page 9

9

4. Operation of the 4-20mA S ys tem

Introduction

A common use of the 1044 would be to simulate a transducer or measure the current flow in

a transducer loop. The following brief explanation, which is intended as a guideline only,

may help when operating the 1044 in a 4-20mA system.

The 4-20mA System

The basic requirement for any transducer with remote display is:

A) To use as few wires as possible.

B) That errors are not introduced into the signal from the transducer by the effects of

interference due to lead resistance.

C) To supply power to the transducer to enable amplifiers to be built into the transducer

when the signal produced by the sensing element is too small to be transmitted without

amplification.

In the 4-20mA system the transducer is supplied with D.C. power from the 2 wire line. The

transducer takes the current from the line proportional to the stimulus (i.e. pressure,

temperature, etc.). By measuring the current flowing in the line, the output of the transducer

can be monitored.

Since the signal is transmitted as a current, lead resistance and voltage drop do not affect

the accuracy. The basic requirements are therefore fulfilled using just two wires - the

minimum possible.

To enable a certain amount of standardisation, and to compensate for voltage drop or

variation in the supply, transducers are designed to operate over a wide voltage range,

usually between 15 and 30 volts, and to take a ‘zero’ current of 4mA and a full scale current

of 20mA .

The simplest 4-20mA current loop system consists of 3 parts, although often 2 parts are

incorporated into the same unit. The 3 main parts are -

1) D.C. Power supply usually 24V.

2) 4 - 20mA current meter/recorder.

3) The transducer.

The D.C. power supply generates the drive power for the system and can be considered as

a battery.

The 4-20mA meter/recorder can be a passive moving coil mA meter with a zero offset. To

obtain a reading, current must be applied.

The transducer completes the loop and allows a current flow around the loop dependent on

the level of stimulus to the transducer. It can be considered as a potentiometer changing in

resistance to let between 4 and 20 mA to flow.

The 1044 can be used to check this system in either source or measure modes of operation

and has a 24V compliance voltage when set to current source mode that will power a loop.

V1.1 09/01/11 Page | 9 1044 Technical Manual

Page 10

10

5. Battery R eplacement

Battery life is primarily dependent on the output currents drawn. With low output currents,

battery life can exceed 50 hours, but with high currents battery life may be reduced to less

than 5 hours. If a short battery life is experienced, rechargeable batteries may be used but

the battery must be charged externally.

Battery replacement is by sliding the rear panel up to its stopping point revealing the battery

compartment (see page 12 for diagram). The battery may now be replaced. Only use high

quality PP3, 6AM6, MN1604 or 6LR61 batteries that will not leak.

An optional mains power supply Time Electronics order code 7643 may be used to power

the instrument via the 2.5mm jack socket at the end of the instrument. This will cut out the

internal battery and power the 1044. Note that the tip of the 2.5mm jack plug should be

positive. The 1044 is protected against reverse polarity and will not function in this state.

If an external power supply other than the above is used it must be 12V supply and up to

200mA capability.

V1.1 09/01/11 Page | 10 1044 Technical Manual

Page 11

11

6. R ecalibration

Introduction

Recalibration of the 1044 is essential to ensure both correct operation and maintain

accuracy. Recalibration is recommended annually.

This chapter gives calibration information.

Recalibration

This instrument is calibrated before it leaves the factory and the calibration controls will not

normally need adjustment, although periodic annual re-calibration is recommended. If recalibration is found to be necessary then follow this calibration procedure and adjust the

outputs to the published specifications.

All readings are taken from the front panel LCD display. Once calibrated, the 1044 would

only need verification that these readings are accurate. Equipment required for verification is

a digital multimeter with accuracy of at least 0.01% and a voltage and current source of

similar accuracy. Suggested items would be the Time Electronics 5075 High Resolution

Digital Multimeter and the Time Electronics 5018 Voltage and Current calibrator.

The calibrator procedure is as follows To adjust the trim pots follow the procedure described in fuse replacement.

The zero is factory set and should not require adjustment. Set the Output Adjust

potentiometer to full scale. All adjustments are to be within 0.05% ± 1 count and are taken

from the front panel LCD display.

1) Locate the 200mV trimmer pot on the rear of the LCD display. This can be reached via a

hole in the PCB. Set the 1044 to the 200mV range and adjust the trimmer to give 200mV.

2) Locate VR7 - 20V adjust. Select the 20V range and adjust VR7 for reading of 20V.

3) Locate VR6 - 2V adjust. Select the 2V range and adjust VR6 for a reading of 2V.

4) Locate VR5 - 20mA adjust. Select the 20mA current range and adjust VR5 for a reading

of 20mA .

5) Locate VR4 - 2mA adjust. Select the 2mA current range and adjust VR4 for a reading of

2mA.

6) Locate VR3 - 200uA adjust. Select the 200uA current range and adjust VR3 for a reading

of 200uA.

Once these readings have been completed, verification that the LCD display is reading

correctly is necessary. This is performed by injecting a known 200mV signal into the 1044

whilst in measure mode and set to the 200mV range. If the reading is out of specification,

the unit is faulty and must be repaired.

V1.1 09/01/11 Page | 11 1044 Technical Manual

Page 12

12

7. F ault Diagnos tics

Introduction

This section gives details of some possible problems and how to correct them.

Fault Check List

If the 1044 is completely dead without any indication of the display working, check

the following

1) Battery condition - replace battery.

2) Polarity of external power unit - reverse connections.

The 1044 indicates an output but there is not an output at the terminals.

1) The output protection fuse has blown. Check why this might have blown, commonly

caused by a signal being applied while still in the source mode. Replace with the correct

fuse.

Current output is not available.

Is there a load connected to the output? If not, current will not flow through the circuit.

The value selected on the display drops when the unit under test is connected.

This is a feature of the 1044 where the ‘actual’ value is indicated. This is probably

insufficient current drive from the 1044 because the unit under test is loading the output

beyond its 20mA drive capability. Check the unit under test for faults.

It might be due to a low battery condition. Check to see if ‘BAT’ is showing on the LCD

display.

Fuse replacement

To replace the output fuse slide the rear panel up to its stopping point revealing the battery

and fuse compartment. Carefully remove the old fuse and replace with a 100mA fuse.

Always replace with a 100mA fuse or serious damage to the 1044 could result. Slide the

rear panel firmly closed.

V1.1 09/01/11 Page | 12 1044 Technical Manual

Page 13

13

8. Guarantee & S ervicing

Guarantee Period.

This unit is guaranteed against defects in materials and workmanship for a period of one

year from it s delivery to the cust omer.

We maintain comprehensive after sales facilities and the unit can, if necessary be returned

to us for servicing. During this period, Time Electronics Ltd will, at its discretion, repair or

replace the defective items. For servicing under guarantee, the instrument type and serial

number must always be quoted, together with details of any fault and the service required.

The purchaser of the instrument must prepay all shipping charges. Time Electronics Ltd will

pay return shipping charges.

This guarantee is void if servicing has been attempted by an unauthorised person or agent

If, during the guarantee period, failure is due to misuse or abuse of the unit, the repair will

be put in hand without delay and charged unless other instructions are received.

Please note that if you require a new UKAS Certificate during the warranty period, this will

be charged at the current rate on our price list.

Service after Guarantee Period.

Even after the guarantee period has expired, Time Electronics Ltd., can still service your

instrument. As the manufacturer, we have the specialised knowledge needed to keep your

instrument in peak condition and we also maintain a comprehensive spare parts service.

Please enclose details of the service required and your full company details including a

contact name when returning for servicing.

Returning Instruments

when returning instruments please ensure that they have been adequately packed,

preferably in the original packing supplied. Time Electronics Ltd will not accept

responsibility for units returned damaged. Please ensure that all units have details of the

service required and all relevant paperwork.

Send the instrument, shipping charges paid to:-

Time Electronics Ltd

Botany Industrial Estate, Tonbridge, Kent, TN9 1RH

Tel: +44(0)1732 355993 Fax: +44(0)1732 770312

Email: mail@TimeElectronics.co.uk

Web Site: www.TimeElectronics.com

V1.1 09/01/11 Page | 13 1044 Technical Manual

Disposal of your old equipment

1. When this crossed-out wheeled bin symbol is attached to a product it means the

product is covered by the European Directive 2002/96/EC.

2. All electrical and electronic products should be disposed of separately from the

municipal waste stream via designated collection facilities appointed by the

government or the local authorities.

3. The correct disposal of your old appliance will help prevent potential negative

consequences for the environment and human health.

4. For more detailed information about disposal of your old appliance, please contact

your city office, waste disposal service or return to Time Electronics.

Loading...

Loading...