Time TT100 User Manual

General description

1

1.1 Scope of applications

The handheld microprocessor-controlled thickness gauge is designed for

measuring the thickness of metals, and non-metallic materials e.g. aluminum,

titanium, plastics, ceramics, glass and any other good ultrasonic wave-conductor

as far as it has two parallel surfaces on the top and bottom.

The TT100 can be used in industrial applications to perform precise

measurements on various kinds of new materials, parts and components, and it

can also be used to monitor various kinds of pipes and pressure vessels for the

decrease of their thickness due to corrosion and/or erosion.

1.2 Basic working principle

The principle of ultrasonic wave in the thickness measurement is similar to that of

optical wave. The ultrasonic wave pulses transmitted by the probe will be reflected

back, while they reach the interfaces. The thickness of the object is determined by

precisely measuring the time the ultrasonic wave travels in the object.

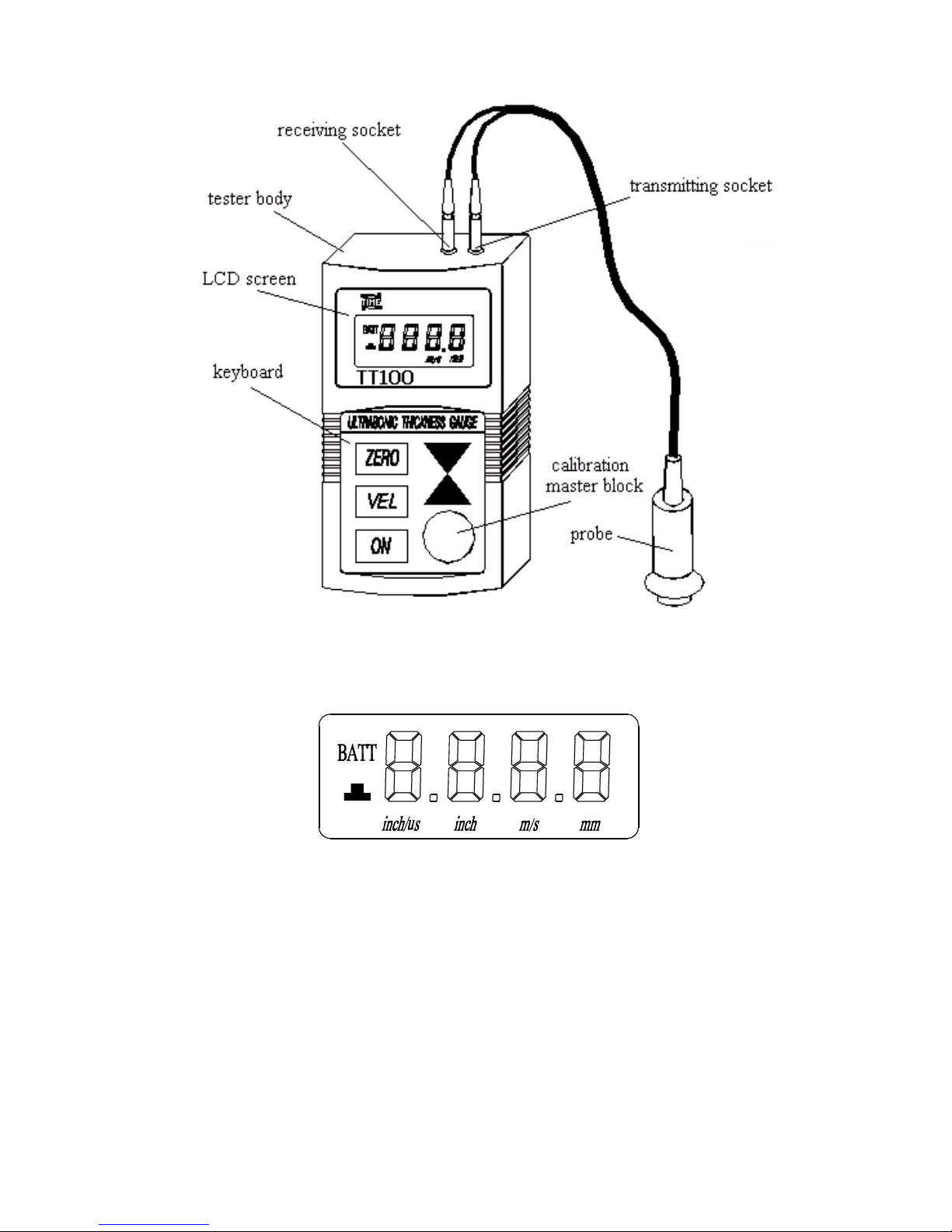

1.3 Basic configuration and each part description of the tester

1.3.1 Basic configuration:

main processor: 1 piece

probe: 1 piece

coupling agent: 1 bottle

1.3.3 The name of each part of the testing meter (see figure below):

1

LCD screen display:

BATT : low voltage indication

凸 : coupling indication for satisfactory acoustic

coupling between probe and test piece

m/s : measurement unit of sound velocity

mm : measurement unit of thickness

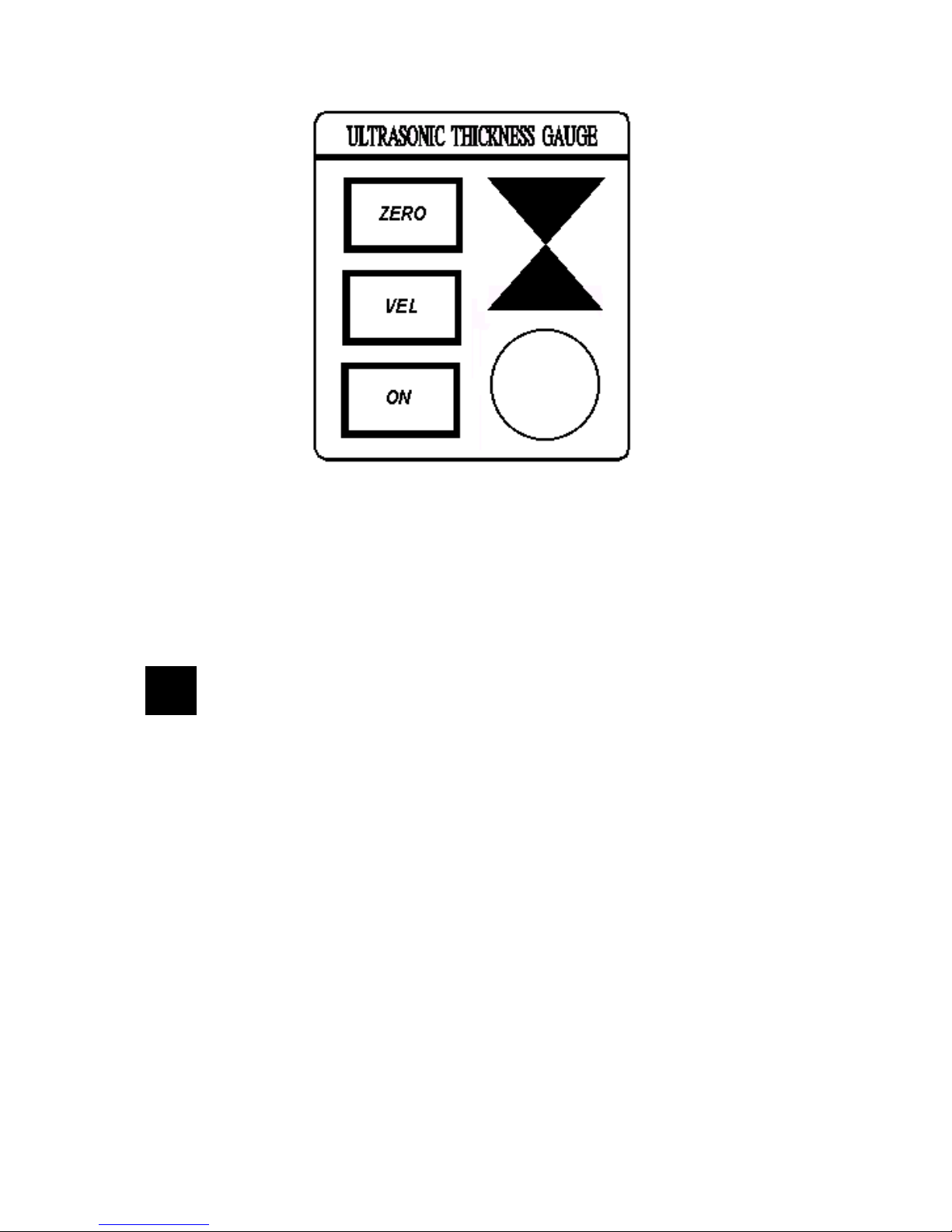

Keyboard:

2

ON : power

ZERO: probe zero procedure

VEL : sound velocity value / 5 velocity are stored

▲-▼: adjustment keys for sound velocity, thickness, 10

memory units for thickness storage

2

Performance parameters

Display type: 4-digit LCD

Minimum display unit: 0.1 mm

Measuring range: 1.0mm – 225.0mm in steel (with standard

probe) (other maximum values depending

on material)

Lower limit for steel pipes: 20 mm × 3.0 mm

Display accuracy: ±0.1mm

Sound velocity range: 1000 – 9999 m/s

Coupling check: satisfactory / no probe coupling

Range of operating temperature: 0℃~40℃

Working frequency 5 MHz

Update rate: 4 Hz

Power supply: two AA alkaline cells 1.5V

Battery life: 250 hours with one battery set

Dimensions: 126×68×23mm

Weight: 170 g

3

Loading...

Loading...