Ultrasonic Thickness Gauge

TT130

Content

TIME Group Inc.

Beijing TIME High Technology Ltd.

2

1. GENERAL DESCRIPTION ................................................................................................... 3

1.1 SCOPE OF APPLICATION........................................................................................................ 4

1.2 BASIC WORKING PRINCIPLE.................................................................................................. 4

1.3 BASIC CONFIGURATION AND EACH PART DESCRIPTION OF THE TESTER ................................ 4

2. PERFORMANCE PARAMETERS........................................................................................ 6

3. MAIN FUNCTIONS...............................................................................................................7

4. MEASURING STEPS..............................................................................................................7

4.1 PREPARATIONS FOR MEASUREMENT..................................................................................... 7

4.2 THE ADJUSTMENT OF SOUND VELOCITY ............................................................................... 8

4.3 CALIBRATION ...................................................................................................................... 8

4.4 MEASUREMENT OF THICKNESS:............................................................................................ 9

5. SWITCH BETWEEN METER AND INCH........................................................................ 10

6. SOUND VELOCITY MEASUREMENT ............................................................................. 10

7. MEMORY OF THICKNESS VALUES............................................................................... 11

7.1 MEMORY STATE................................................................................................................. 11

7.2 REVIEWING THE MEMORY UNIT.......................................................................................... 11

8. AUTOMATIC TURN OFF ................................................................................................... 13

9. MEASURING TECHNOLOGY...........................................................................................13

9.1 CLEANING THE SURFACE.................................................................................................... 13

9.2 LESSENING THE ROUGHNESS.............................................................................................. 13

9.3 ROUGHLY MACHINED SURFACE.......................................................................................... 13

9.4 CYLINDRICAL SURFACE ..................................................................................................... 13

9.5 COMPOUND CONTOUR........................................................................................................ 14

9.6 NON-PARALLEL SURFACE .................................................................................................. 14

9.7 TEMPERATURE EFFECT OF TEST MATERIAL ........................................................................ 14

9.8 HIGH ATTENUATION MATERIALS........................................................................................ 14

9.9 REFERENCE TEST BLOCK.................................................................................................... 14

9.10 A FEW MEASURING METHODS .......................................................................................... 15

9.11 SELECTION OF THE PROBE................................................................................................ 15

PROBE TYPE............................................................................................................................. 15

9.12 THE WEAR OF PROBE CROSS TALK ISOLATION BOARD MAY AFFECT THE RESULTS OF

MEASUREMENT

, PROBE SHOULD BE REPLACED WHEN THE FOLLOWING PHENOMENA OCCUR:..16

10. PREVENTION OF MEASURING ERRORS .................................................................. 16

10.1 SUPER-THIN MATERIALS .................................................................................................. 16

10.2 RUSTY SPOTS AND ERODED PITS....................................................................................... 16

10.3 ERROR IN MATERIALS IDENTIFICATION ............................................................................ 16

10.4 WEAR OF THE PROBE........................................................................................................ 16

10.5 USE OF THE ZERO-KEY ................................................................................................... 17

10.6 LAMINATED AND COMPOUND MATERIALS........................................................................ 17

10.7 THE EFFECT OF THE METAL OXIDE LAYER ........................................................................ 17

10.8 ABNORMAL READING....................................................................................................... 17

10.9 USE AND CHOICE OF COUPLING AGENTS........................................................................... 17

3

10.10 PROTECTIVE SHEATH OF PROBE...................................................................................... 17

11. PRECAUTIONS................................................................................................................... 18

11.1 AUTOMATIC TURN OFF..................................................................................................... 18

11.2 CLEANING OF TEST BLOCKS ............................................................................................. 18

11.3 CLEANING OF THE SHELL OF THE INSTRUMENT ................................................................ 18

11.4 PROTECTION OF THE PROBE.............................................................................................. 18

11.5 REPLACEMENT OF BATTERIES .......................................................................................... 19

11.6 STRICTLY AVOID ANY COLLISION OR DAMP ENVIRONMENT, ETC...................................... 19

12. MAINTENANCE.................................................................................................................19

13. NON-WARRANTY PARTS................................................................................................ 20

1. General description

4

1.1 Scope of application

Adopting the theory of ultrasonic wave measurement, TIME TT130 intelligent

Ultrasonic Thickness Gauge possesses the capability of thickness measurement for

various kinds of materials in which ultrasonic wave pulses propagate with a constant

velocity and reflect on the back interface.

The device can be used to perform accurate measurement for various kinds of

plates and parts. Another prominent characteristic of it is to monitor various kinds of

pipes and pressure vessels for the decrease of their thickness during the use

because of corrosion and erosion. TT130 enjoys a wide range applications in many

areas, such as petroleum, chemical engineering, metallurgy, shipbuilding, aviation

and spaceflight, etc.

1.2 Basic working principle

The principle of ultrasonic wave in the thickness measurement is similar to that of

optical wave. The ultrasonic wave pulses transmitted by the probe will be reflected

back, while they reach the interfaces. The thickness of the object is determined by

precisely measuring the time the ultrasonic wave travels in the object.

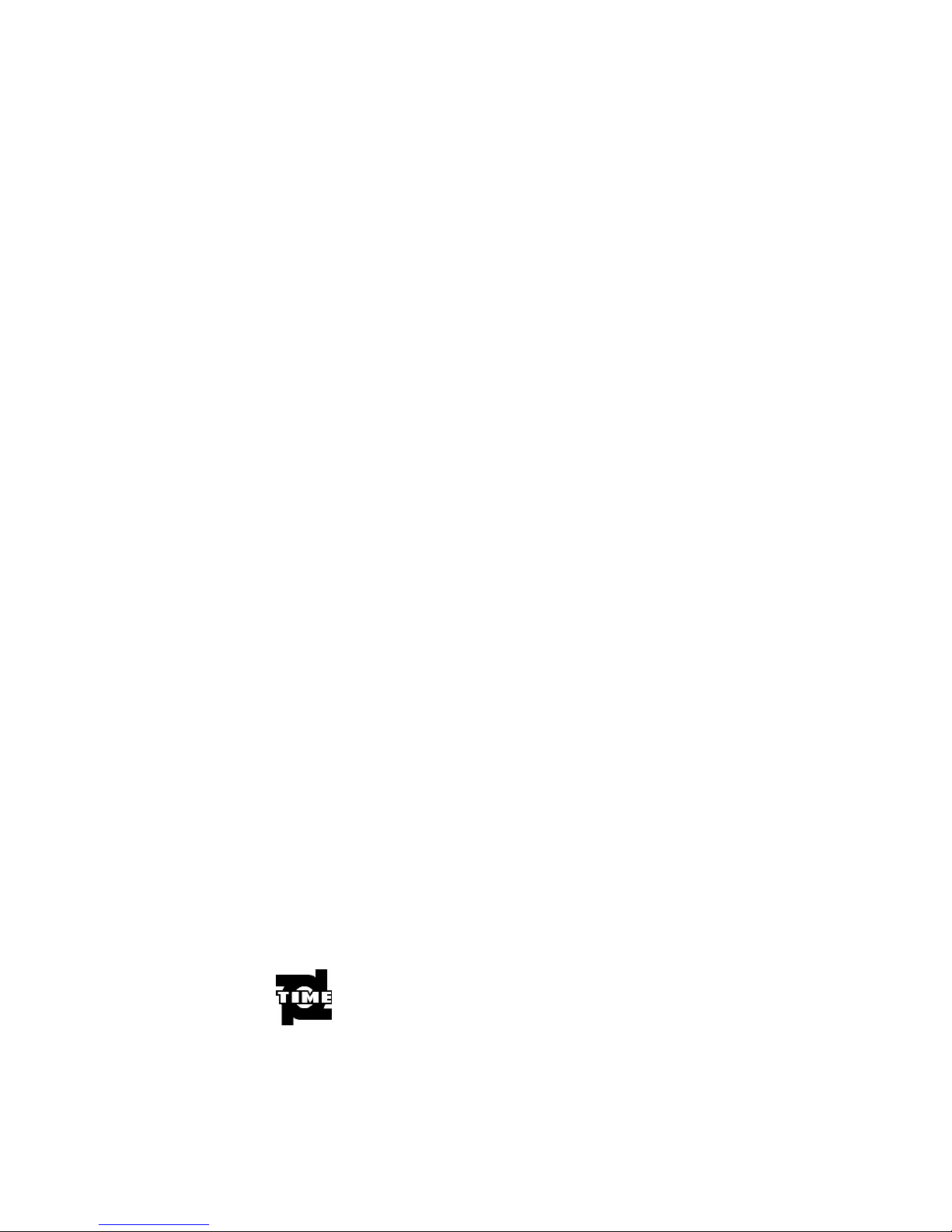

1.3 Basic configuration and each part description of the tester

1.3.1 Basic configuration:

main processor: 1 piece

5P10 probe: 1 piece

coupling agent: 1 bottle

1.3.2 Optional probes: 5P10/90 probe 1 piece

SZ2.5P probe 1 piece

7P6 probe 1 piece

1.3.3 The name of each part of the testing meter (see figure below):

5

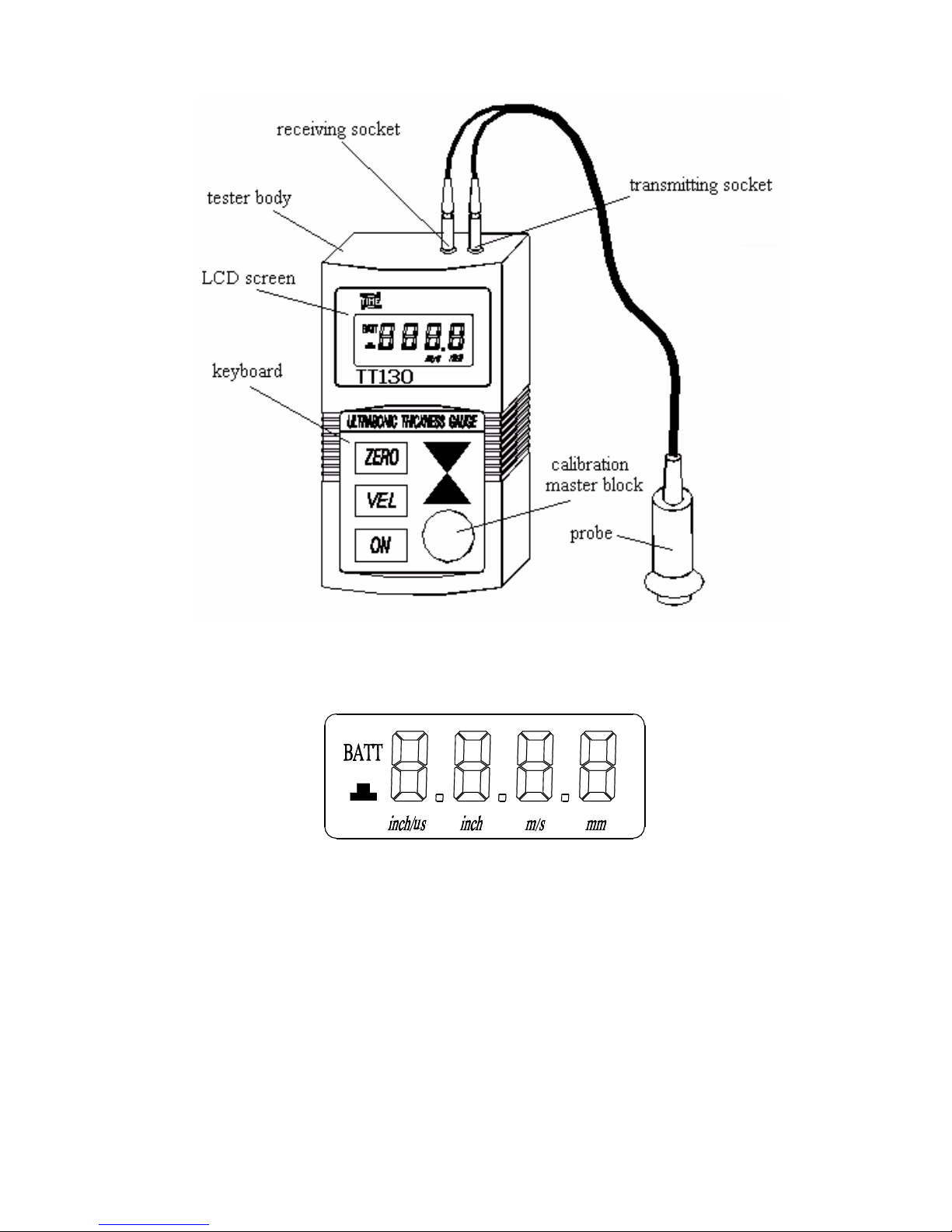

LCD screen display:

BATT : low voltage indication

凸 : coupling indication

m/s : metric unit of sound velocity

mm : metric unit of thickness

inch/μs: imperial unit of sound velocity

inch : imperial unit of thickness

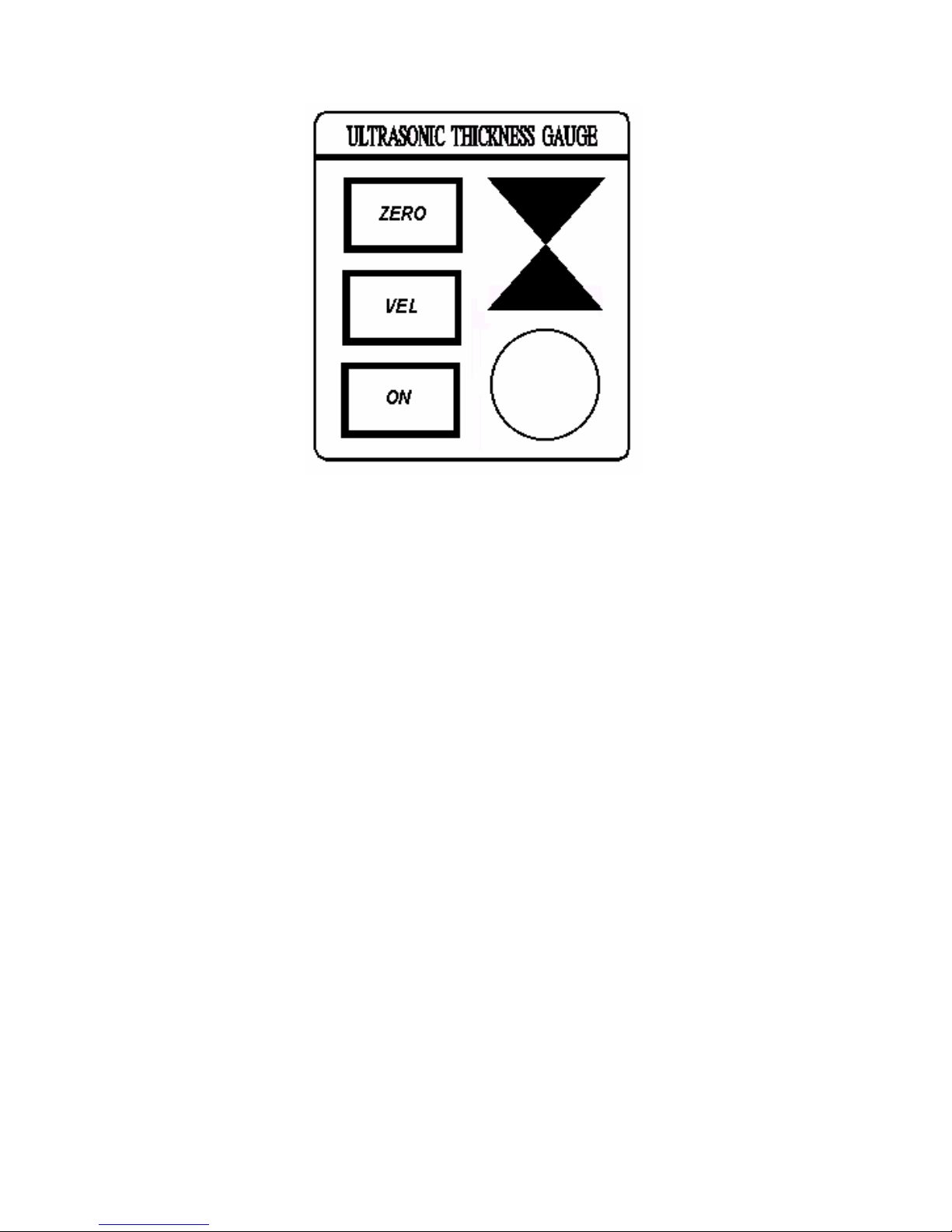

Keyboard:

6

ON : power

ZERO : calibration

VEL : sound velocity

▲ : adjustment key for sound velocity, thickness and thickness

unit

▼ : adjustment key for sound velocity, thickness and thickness

unit

VEL+ZERO : keys for thickness memory

2. Performance parameters

Display type: 4-digit LCD

Minimum display unit: 0.01 mm

Working frequency: 5 MHz

Measuring range: 1.2 mm~225.0 mm (steel)

Lower limit for steel pipes: Ф20 mm × 3.0 mm

Measuring error: ±(1%H+0.1) mm, H is the actual thickness

of the object to be measured.

Sound velocity range: 1000m/s~9999m/s

Velocity measurement according to a known thickness: measurement range is

1000m/s~9999m/s, the sound velocity measurement precision is 1mm/HX100 when

master block is 20mm thick and 5% precision with thickness of 20mm.

Range of operating temperature: 0℃~40℃

Power supply: two AA alkaline cells 1.5V

Power consumption: working current is smaller than 20mA (3V)

Dimensions: 126×68×23 mm

Weight: 170 g

7

3. Main functions

1) Automatic calibration to zero: automatically correct the system errors

2) Automatic non-linear compensation: within the full range, computer software

is used to correct the non-linear errors of the probe for the purpose of

improving the accuracy

3) The upward and downward adjustment keys enable prompt selection of

sound velocity, thickness, and check the thickness memory units

4) Prompt for coupling state: provide coupling indication and the observation of

the stability of the indication can tell if the coupling is normal

5) Ten thickness values can be stored without loss after turn-off, which is very

convenient for measuring in field and high platform

6) Measuring sound velocity: according to the test block’s thickness, sound

velocity can be measured directly needless to search in the conversion table

7) Sound velocity of five different materials can be stored

8) Low voltage indication

9) Automatic turn-off

10) All keys enclosed----oil proof for longer service life

4. Measuring steps

4.1 Preparations for measurement

Put the probe into the probe socket of the unit. Push ON-key to turn on the unit. As it

is shown in the figure below, sound velocity of last turn-off will be shown after the full

screen displays for a few seconds. The measurement can start now.

Full display screen

8

Sound velocity of last turnoff

4.2 The adjustment of sound velocity

If the screen currently displays the thickness values, then push the VEL-key to enter

into sound velocity state. The screen will display the content of the current memory

unit of sound velocity. Each time the VEL-key is pushed the sound velocity memory

unit will change. Five different sound velocity values will be displayed in turn. If the

current displayed sound velocity is desired to be changed, the keys △-▽ can be

used to adjust the display the desired value. This value will be stored automatically

as one out of five stored velocities.

Push VEL-key to enter into state of sound velocity

Value after adjustment by △-▽ key

4.3 Calibration

Each time the probe or battery is changed, calibration should be performed. This

step is rather critical to secure the measuring accuracy. If necessary, calibration can

be repeated several times.

Set the sound velocity to 5900m/s then push the ZERO-key and enter into the state

of calibration and then the screen display:

9

Put the coupling agent on the testing block supplied with the unit and couple the

probe with the testing block. At this time, the bar lines displayed on the screen will

disappear one after the other until the screen display 4.0mm (0.158inch). This

indicates that the calibration is over. Then enter the measurement state and

measure a random test block. If the measuring value error exceeds the

measurement error range, the calibration should be operated again until the

measuring value lies within the measurement error.

4.4 Measurement of thickness:

Put the coupling agent in the place to be measured and then couple the probe with

the material to be measured. The measurement can thus start. The screen will

display the thickness of the material measured. See the figure below:

Take the probe away, the thickness value will remain and coupling indication will

disappear. See the figure below:

10

5. Switch between meter and inch

5.1 When the power is off, press and hold ZERO button, press ON to

toggle between meter and inch.

5.2 When the power is on, if the current display is inch, press ZERO

for more than 5 seconds to toggle between meter and inch. Release

the button to end setting. If you hit the ZERO quickly, the calibrate

mode is on.

6. Sound velocity measurement

If the sound velocity in a certain kind of material is to be measured, a test block with

a known thickness is employed to measure the sound velocity. At first the accurate

thickness value should be obtained by using vernier calipers or micrometer. By

coupling the probe with the test block of known thickness, the screen will display a

thickness value, then remove the probe and adjust the shown value to the actual

one using the keys △-▽. Push VEL-key to get the desired sound velocity, at the

same time this sound velocity will be stored in the current memory unit. In sound

velocity measurement, the test block is required to be thick enough. The

recommended minimum thickness is 20mm.

Example: Measuring the sound velocity of material with the thickness of 25mm, the

operation procedure is as follows:

1. enter sound velocity state, a thickness value is displayed as:

2. Use keys

△-▽ to adjust the displayed thickness value to 25mm, just as the

following display:

11

3. Push the VEL-key, the sound velocity measured for this materials will be

displayed.

7. Memory of thickness values

7.1 Memory state

Push VEL-key and then ZERO-key to enter into thickness memory state and the

screen will show a memory unit of a certain thickness. Use keys △-▽ to set required

unit (use upward or downward keys can display unit0 to unit9 in turn). While

measuring the thickness, the value measured can be stored in the chosen unit.

Each time when a new value is measured, the old one in this unit will be

automatically replaced. The stored value in this memory unit is the latest

measurement value. Push VEL-key to leave the thickness state.

7.2 Reviewing the memory unit

Push and hold VEL-key and then push the ZERO-key to show current memory unit

number. Use keys △-▽ to look for required unit(using keys △-▽ can to display

unit0~unit9 in turn). Operate again to show the content of the memory. A new

measurement value can also be stored in this unit. Push VEL-key to exit thickness

memory state.

Example: Check the thickness value in memory unit 3

12

1. Push and hold VEL-key and then push ZERO-key, the display is as follows:

2. Use keys

△-▽ to find memory unit 3, the display is as follows:

3. Push and hold VEL-key and then push ZERO-key, the thickness value in

memory in unit 3 will be displayed:

4. Push VEL-key to exit. If leaving the thickness memory state without pushing

VEL-key, the new measurement value will replace the content of this memory

unit.

Low voltage indication

If BATT is displayed on the screen, it shows that the battery voltage is running low

and the batteries should be replaced in time before the unit can be used again.

7

13

8. Automatic turn off

If within two minutes no operation is performed, the unit turns off automatically.

9. Measuring technology

9.1 Cleaning the surface

Before measurement, it is necessary to clean the dust, dirt or rusty matters and

coatings of the surface off the test object.

9.2 Lessening the roughness

Too rough a surface may cause errors or no reading. Before measurement starts,

measures should be taken to keep the test surface smooth by way of grinding,

polishing and filing. High viscosity coupling agent may also be used.

9.3 Roughly machined surface

The regular fine furrows of roughly machined surface (such as machined by lathe or

planer) may also cause errors. The remedy method is similar to 9.2. Better result

can also be achieved by adjusting the intersectional angle between the probe cross

talk isolating board (the thin metal layer on the bottom center of the probe) and the

fine furrows of test materials (vertical or parallel). And select the minimum of the

readings as the accurate thickness of the materials.

9.4 Cylindrical surface

It is essential to select the right intersectional angle between the probe cross talk

isolating board and the axial line of the test materials in measuring materials with

Cylindrical surface, such as tubes or barrels. Simply speaking, make the probe

coupled with test materials and the probe cross talk isolating board and the axial line

of the test materials parallel or perpendicular and then gently shake the probe

vertically along the direct of the axial line of the test material, the reading will change

regularly. Select the minimum of the readings as the accurate thickness of the

materials.

14

The standard for the intersectional angle is determined by the curvature of the

material. For tubular material with bigger diameters, make the cross talk isolating

board perpendicular to the axial line of the tube; for tubes with a smaller diameters,

select two methods (making the intersectional angle parallel with and perpendicular

to the axial line) and select the minimum value of the readings as the thickness

measured.

9.5 Compound contour

In measuring materials with compound contour (such as elbows), the method

introduced in 7.4 may be used. The difference is that there is the need to measure

the second time to obtain two readings and take the smaller reading as the thickness

of the point measured.

9.6 Non-parallel surface

In order to obtain a satisfactory ultrasonic response, the other side of the test

materials must be parallel or on the same axial with the test surface. Otherwise,

there will be errors or no reading at all.

9.7 Temperature effect of test material

The thickness and ultrasonic wave transmission speed are all affected by

temperature. If a high accuracy is required, test block comparison method should be

employed. This method is to correct the measurement value by temperature

compensation coefficient obtained by measuring test blocks of the same materials

at the same temperature.

9.8 High attenuation materials

In the fiber, porous, large-grained materials, the ultrasonic wave will be scattered

and got energy attenuation, the above phenomena will cause abnormal display and

even no display (generally the abnormal displayed value is less than the actual one).

In this case, it’s not suitable to apply the gauge to this material.

9.9 Reference test block

For the calibration of the instrument, a test block with the thickness of 4.00mm is

configured on the TT130 cabinet, calibration method is scheduled in figure 4.3. The

attached test blocks are not enough for calibration while measuring different

materials on various conditions. The more similar the test block materials are to the

tested materials, the more accurate the measurement is. The ideal one is a series of

test blocks with different thickness. This series can offer device compensation

calibration coefficient (such as material microstructure, heat treatment condition,

grain orientation, surface roughness). It’s very important to possess a series of test

blocks to guarantee the maximum accuracy.

In most cases, only one test block is enough to get satisfactory measurement

precision. This test block should be of the same material and similar thickness to the

15

testing material. Select the testing material whose thickness is well-distributed and

measured by micrometer as a reference test block.

When the thickness of a thin material is close to the lower testing limit of the probe,

a test block can be employed to determine the exact lower limit (1.2mm for steel). Do

not measure the materials whose thickness is lower than the low limit. If the

thickness range can be estimated, the upper limit of the thickness of the test block

should be selected.

When the material is thick, especially alloys with complex microstructure, a similar

test block in the series should be employed for proper correction.

Most of the casting and forging are directional in internal structure. The speed of

sound may have a little change along different directions. In order to solve this

problem, the test block should have similar structure to the testing material. The

direction of the spread of sound in the test block should also be the same as the

testing material.

In some cases, look up the sound velocity of known materials for replacement of the

test block, but this can only approximately replace some of the test blocks. In some

cases, there are differences between the two values in the sound velocity table and

the actual one because of the difference in the physical and chemical properties of

material. This method is often used to test low carbon steel only for approximate

measurement.

Since TT130 ultrasonic wave gauge possesses the capability to measure sound

velocity, sound velocity can be obtained at first and then measurement of the part

can be undertaken according to this velocity.

9.10 A few measuring methods

a) single measuring method: measuring on one point

b) double measuring method: measuring two times on one point, make the cross

talk isolating board perpendicular to each other. Select the minimum display as

the exact thickness for the materials.

c) multi-point measuring method: measuring many times at a range of

measurement, select the minimum as the thickness of the material

9.11 Selection of the probe

Probe type

5PФ10 5PФ10/90 7PФ6 SZ2.5P

Frequency

(MHz)

5 5 7 2.5

Working

temperature

range

-10~60℃ -10~60℃ -10~60℃ -10~60℃

Measurement

range

1.2~225.0mm 1.2~225.0mm 0.75~60mm 3.0~300.0mm

16

9.12 The wear of probe cross talk isolation board may affect the results of

measurement, probe should be replaced when the following phenomena

occur:

1. The screen always displays the same measurement value while measuring

different thickness.

2. There is echo wave indication or measurement value displayed when the probe

has been inserted without measurement.

10. Prevention of measuring errors

10.1 Super-thin materials

Any material whose thickness is lower than the low limit of the probe will cause

measurement errors. Instrument should be connected again for measuring the

same material in order to obtain the result of the minimum thickness.

In measuring super-thin materials, there might be such erroneous results as “dual

deflection” sometimes. That means that the displayed reading is twice as big as the

actual thickness. Another error is known as “pulse envelope, cyclic jumping”. The

result is bigger than the actual thickness. To prevent these errors, the critical thin

materials should be measured repeatedly for verification.

10.2 Rusty spots and eroded pits

Rusty spots and eroded pits may cause the readings to change irregularly. Under

extreme circumstances, there is even no reading. It is hard to discover a small rusty

spot. When a eroded pit is found or in suspicion, care is needed to measure the

area. Different positions of angles of the probe cross talk isolating board may be

selected to carry measurements for many times.

10.3 Error in materials identification

Though the device has been corrected by one material, there is still mistake

when measuring another materials, so proper sound velocity should be

selected.

10.4 Wear of the probe

The probe surface is made of acrylic resin. After using for a long times, the

roughness may increase, thus causing the sensitivity declines. If it has been

determined that the error is caused by roughness, the sand paper or oil grinding

stone may be used to grind the surface of the probe so that it will become smooth

and parallel. If the reading is still unstable, the probe must be replaced.

17

10.5 Use of the ZERO-key

The key is used only for correction by coupling the probe onto the standard test

block on the instrument panel. It is not to be used on any other kinds of test blocks.

Otherwise it will cause measurement errors.

10.6 Laminated and compound materials

It is impossible to measure the uncoupled laminated materials, because the

ultrasonic wave cannot penetrate the spaces that have not been coupled. As the

ultrasonic waves can not spread in a uniform speed in compound materials, the

instruments measuring thickness according to the ultrasonic deflection theories are

not applicable to measuring laminated or compound materials.

10.7 The effect of the metal oxide layer

Dense oxide layer may be found in some metals, such as aluminum etc. This oxide

layer contacts with the substrate tightly without clear interface. But ultrasonic wave

transmits with different velocities in these two materials, which will cause

measurement error. Different thickness of oxide layer will result in different

measurement errors. It should be cautious to deal with this kind of situation. It’s

applicable to select one block of testing material as sample, measure its thickness

by vernier caliper or micrometer and use this sample to calibrate the gauge.

10.8 Abnormal reading

Operators should have the ability of identifying abnormal readings. Usually, rusty

sports, corroded pits and the interior flaws of the test materials can all cause

abnormal readings. For solution, see chapter 9 and 10 of this manual.

10.9 Use and choice of coupling agents

Coupling agent is used for transmitting high frequency ultrasonic energy between

the probe and the test material. Incorrect selection of the types of coupling agents or

improper usage may cause errors or flashing of the coupling sign, making it unable

to measure the thickness. Coupling agent should be used in proper amount and

coated evenly.

It is important to select the proper type of coupling agents. When the surface of the

test material is smooth, low viscosity coupling agent should be used (coupling

agents and light machine oil are provided with the instrument). High viscosity

coupling agents (such as glycerin paste and lubricating fat,etc.) may be chosen for

rough surface or vertical surface or peak surface.

10.10 Protective sheath of probe

18

When measuring curved surface, curved surface probe sheath should be used so as

to gauge the thickness more accurately. Probe protective sheath is optional in

purchasing.

11. Precautions

11.1 Automatic turn off

There are two AA (5) alkaline batteries and a lithium cell in TT130 ultrasonic wave

gauge to supply uninterrupted power for the ROM memory units. If the two batteries

have been taken out before the automatic turnoff, the device will be forced to use

lithium cell. When the lithium cell runs out of energy, the device can’t restore the

measurement data and can’t be used any more. Please note to replace batteries

only when the gauge automatically turns off.

11.2 Cleaning of test blocks

As the correction of the instrument by using the test block provided needs coupling

agents, it is necessary to take measures against rusting. After usage, the test blocks

must be cleaned. When the temperature is high, caution must be taken not to stain it

with sweat. When not used for a long time, the test block should be coated with a

thin layer of fat to prevent rusting. To use again, clean the fat, the instrument will

work normally.

11.3 Cleaning of the shell of the instrument

The shell of the instrument should be cleaned with a little amount of clean water

instead of alcohol or dilution liquid which are corrosive to the shell, especially the

window.

11.4 Protection of the probe

The surface of the probe is made of acrylic resin, sensitive to rough surface. It must

be handled gently. When measuring rough surface, the sliding of the probe over the

surface should be prevented as far as possible.

At the ambient condition, the temperature of the test surface should not exceed

60°C. Otherwise, the probe cannot be used any more.

The collection of grease and dust will make the probe wire aging fast or fracture.

After usage, please clean the cable.

19

11.5 Replacement of batteries

When the low voltage indicator flashes, the batteries should be replaced in time. The

method of replacement is shown in below:

a) Wait for the automatic turnoff

b) Open the battery chamber (use the thumb to press down the chamber and slide it

out)

c) Take off the batteries and put in the new batteries. Note the polarity of the battery.

When the instrument lies idle for a long time, take out the batteries to prevent leaking

that will corrode the battery chamber and the poles.

11.6 Strictly avoid any collision or damp environment, etc.

12. Maintenance

12.1 When the measured value is too big, please consult chapter 10

and 11.

12.2 If the following problems occur, please contact the company.

a) Components of the instruments are damaged and there is no output.

b) The display is abnormal.

c) Errors are too big in normal use.

d) Keyboard failure or disorder.

12.3 As the TIME TT130 Ultrasonic Thickness Gauge is a high-tech

product, repairs and services must be undertaken by well-trained

person. No unqualified person is allowed to dismantle it for repairs.

Table: Sound velocities of different materials

Materials Sound velocity (m/s)

Aluminum

6320

Zinc

4170

Silver

3600

Gold

3240

Tin

3320

Iron

5900

Brass

4430

Copper

4700

SUS

5970

Acrylic resin

2730

20

Water(20℃)

1480

Glycerine

1920

Sodium siliate

2350

13. Non-warranty Parts

1. Window, 2. Battery, 3. Probe. 4.Test block. 5. Sheath of gauge. 6. Couplant

Loading...

Loading...