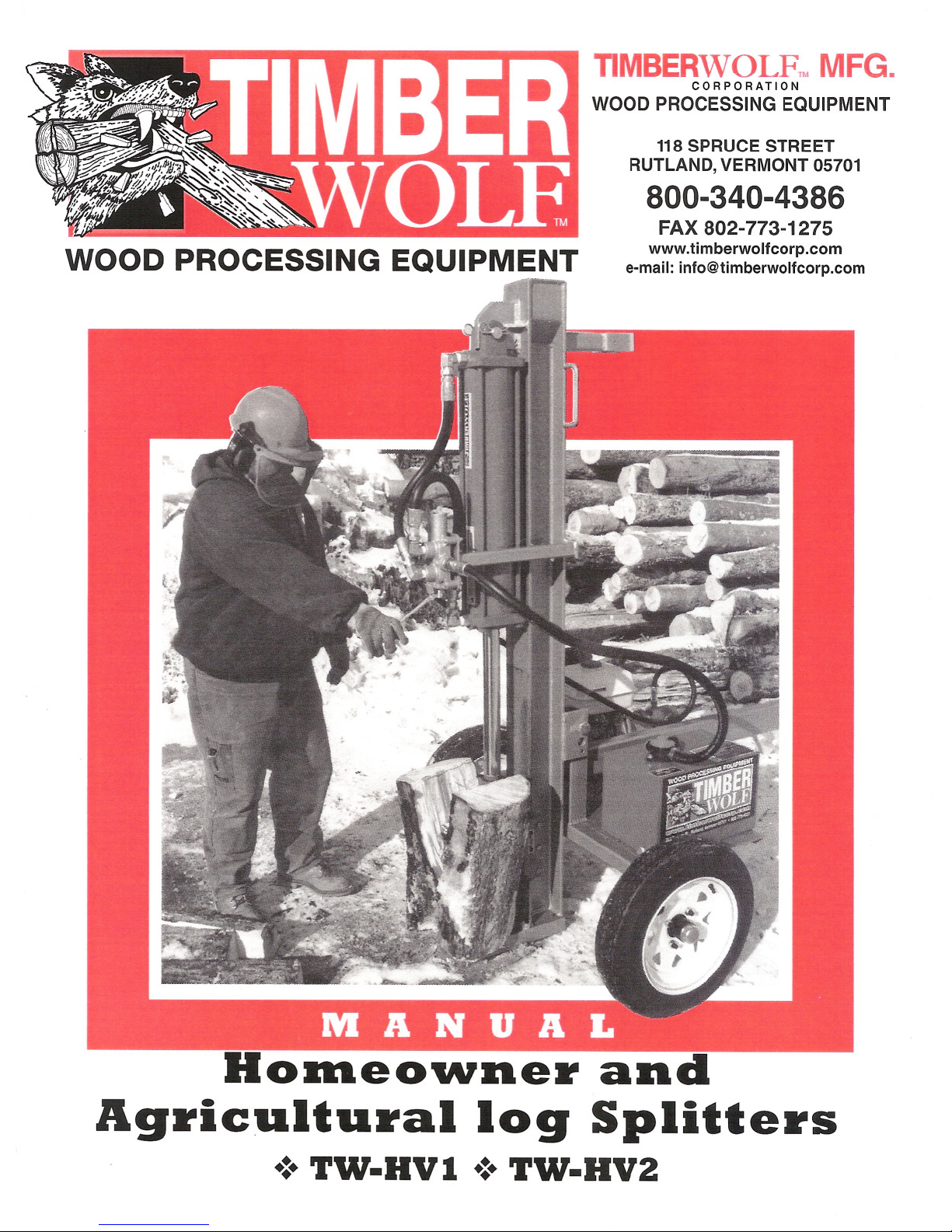

Page 1

WOOD PROCESSING EQUIPMENT

TlMBERWOLFTM MFG.

CORPORATION

WOOD PROCESSING EQUIPMENT

118 SPRUCE STREET

RUTLAND, VERMONT 05701

800-340-4386

FAX 802-773-1275

www.timberwolfcorp.com

e-mail: info@timberwolfcorp.com

[u]ffi~(!10[b

Honaeo1Nner and

Agricultural log Splitters

.:.TW·HVI .:.TW·HV2

Page 2

Page 3

TIMBERWOLF

Manufacturing Corporation

Log Splitter

Operation Manual.

Model TW-HV1

Model TW-HV2

Fill out and submit Registration Form to ensure

warranty coverage and receive product updates.

Page 4

This manual and all its contents Copyright © 2003

TIMBERWOLF Manufacturing Corporation,

Rutland, VT 05701

Every effort has been made to ensure the accuracy of this document.

TIMBERWOLF Manufacturing Corporation

118 Spruce Street

Rutland, Vermont 05701

Phone:

FAX:

E-mail:

Web page:

802-775-4227

802-773-1275

info@timberwolfcorp.com

www.timberwolfcorp.com

TIMBERWOLF is a trademark of TIMBERWOLF Manufacturing Corporation.

All other brands or product names are trademarks or registered trademarks of

their respective holders.

Printed in the USA

No part of this work covered by copyright may be reproduced in any form. Reproduction,

adaptation, or translation without prior written permission is prohibited, except as allowed

under the copyright laws.

TIMBERWOLF Manufacturing Corporation provides this document "as-is" without warranty of

any kind, either express or implied. This includes, but is not limited to, implied warranties or

conditions of merchantability or fitness for a particular purpose. TIMBERWOLF Manufacturing

Corporation shall not be liable for any errors or omissions that may occur in this document, nor

for incidental or consequential damages of any kind resulting from the furnishing, performance,

or use of this document.

The information in this document reflects current or planned product features, functions, and

characteristics as of the publication date. Because of on-going product improvements and

feature additions, information in this document is subject to change without notice.

Rev 04/03

Manual Produced by Osborne Gibbs (ozgibbs@aol.com)

Cover & Line Art by Anything Graphic (norma0765@aol.com)

Page 5

TIMBERWOLF Log Splitters

About the Manual

Operation Manual

Thank you for buying a Timberwolf Manufacturing Corporation log splitter.

This splitter is made with high quality components and will provide years of

service under normal working conditions.

Please read this entire manual before you operate the machine. If you have

any questions regarding assembly, use, safety, or maintenance, please call

TimberwolfManufacturing Corp. at 802-775-4227.

Safety Note

Please take time to read this manual and learn how operate and

maintain the log splitter safely. The log splitter is a powerful piece of

equipment that can generate more than 50,000 pounds of force.

Incorrect use of the log splitter can cause serious injury or death.

Read Entire Manual Before

Qperating the

Lot! Splitter

Attention Rental Companies

It is extremely important that any person who operates this equipment

has access to and has read the operator's manual. Timberwolf

Manufacturing Corporation strongly urges you to keep the manual with

the splitter at all times, and to instruct all persons who will operate this

machine to read the manual.

iii

Page 6

Operation Manual

TIMBERWOLF Log Splitters

Caution!

Residual Hydraulic Energy

Residual energy must be released from the pressurized hydraulic fluid

before any maintenance or repair work is done on the log splitter.

Hydraulic fluid can remain highly pressurized even while the splitter's

motor is off. Escaping pressurized hydraulic fluid can penetrate skin and

cause serious injury.

To release residual hydraulic energy:

1. Shut off splitter motor (tractor motor if splitter is a three-point

hitch model).

2. Move control valve back and forth, from one limit of travel to the

other, at least four times.

3. Hold valve for three seconds at each limit of travel.

Record your log splitter's ID numbers here:

Model #

Serial

#

Motor #

iv

Page 7

TIMBERWOLF Log Splitters

Table of Contents

Operation Manual

About Your Timberwolf Log Splitter

1

General 1

General Description 3

H-Beam Log Carriage 4

Two-stage Hydraulic Pump 5

Single Handle Valve 5

Wedges 5

Specifications 6

Important Safety Instructions 7

What You SHOULD Do 7

What You SHOULD NOT Do 7

What You SHOULD NEVER Do 8

Hydra ulic Safety 10

What You SHOULD Do 10

What You SHOULD NOT Do 10

Before You Start the Log Splitter 11

Check Fluids 11

Location & Setup 11

Vertical Setup 11

Operating Instructions 13

Start Up 13

Splitting Safety 13

Vertical Operation Safety 14

Operating the Log Splitter 14

Transporting the Log Splitter 16

Preparation 16

Towing Safety 17

v

Page 8

Operation Manual

TIMBERWOLF Log Splitters

Maintenance 18

Engine Oil 18

Hydraulic Oil 18

Hydraulic Oil Filter 18

Wedge Assembly 19

Daily Maintenance 19

General 19

Grease 19

Motor 19

Hydraulic Hoses 19

Annual Maintenance

20

Grease 20

Hydraulics 20

Limited Warranty 21

Registration Card 23

vi

Page 9

TIMBERWOLF Log Splitters

Operation Manual

Protect the investment you've made in a Timberwolf

Manufacturing log splitter.

Fill out the Registration Form and send it to us by mail

or Fax to ensure your warranty coverage and enable

you to receive product updates.

All warning stickers and hazard triangles should be secured and

clearly visible at all times. Please check decals daily.

Replacement safety and warning stickers are available free of charge

from Timberwolf Manufacturing. Warning stickers include:

One Man

Operation and Caution.

vii

Page 10

Operation Manual

viii

TIMBERWOLF Log Splitters

Page 11

TIMBERWOLF Log Splitters

Operation Manual

About Your Timberwolf Loq Splitter

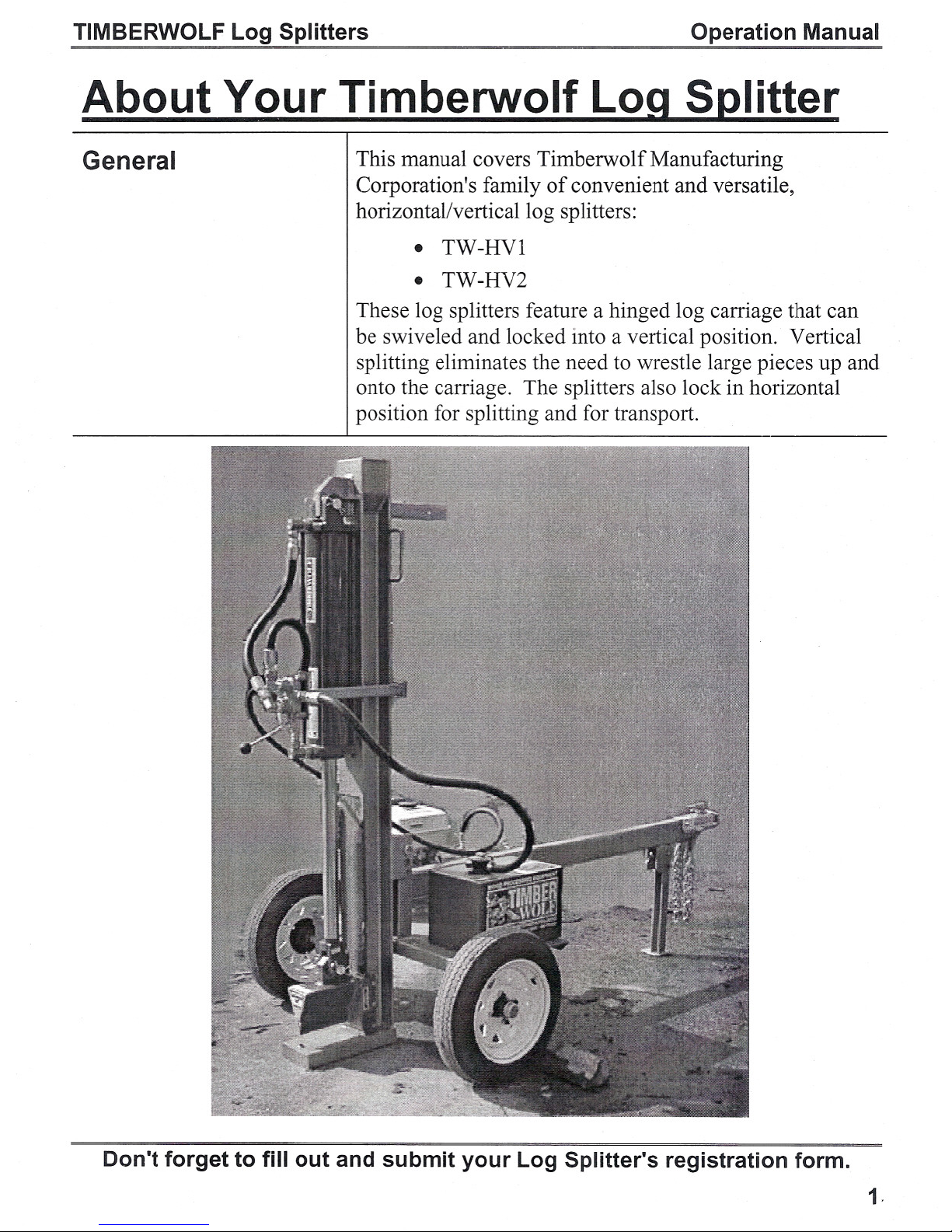

General

This manual covers Timberwolf Manufacturing

Corporation's family of convenient and versatile,

horizontal/vertical log splitters:

• TW-HVI

• TW-HV2

These log splitters feature a hinged log carriage that can

be swiveled and locked into a vertical position. Vertical

splitting eliminates the need to wrestle large pieces up and

onto the carriage. The splitters also lock in horizontal

position for splitting and for transport.

Don't forget to fill out and submit your Log Splitter's registration form.

1.

Page 12

Operation Manual

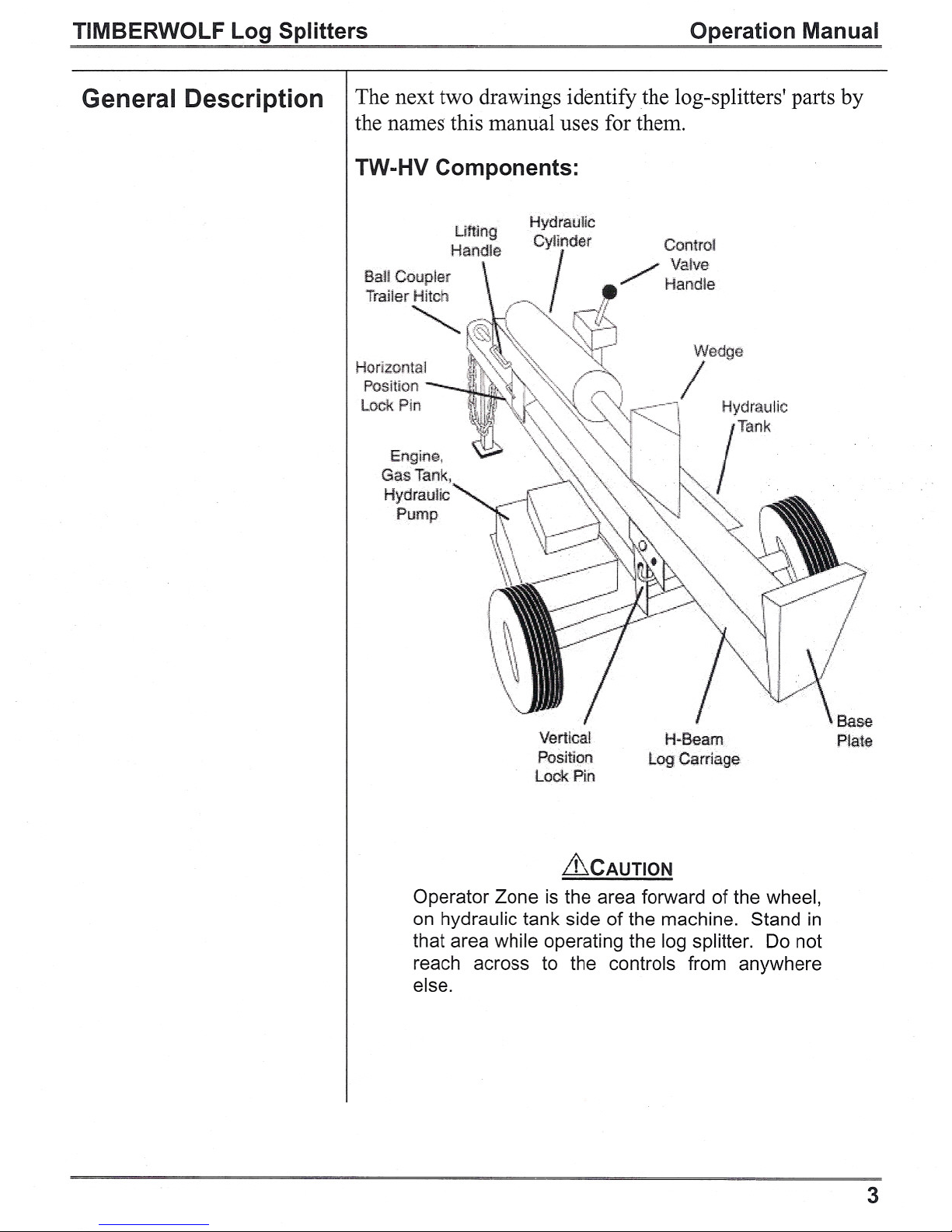

TW-HV2 -

• 9 HP motor,

• 16 GPM pump,

• 5 inch cylinder,

• 25 tons of

force,

• 12 inch tires

2

TIMBERWOLF Log Splitters

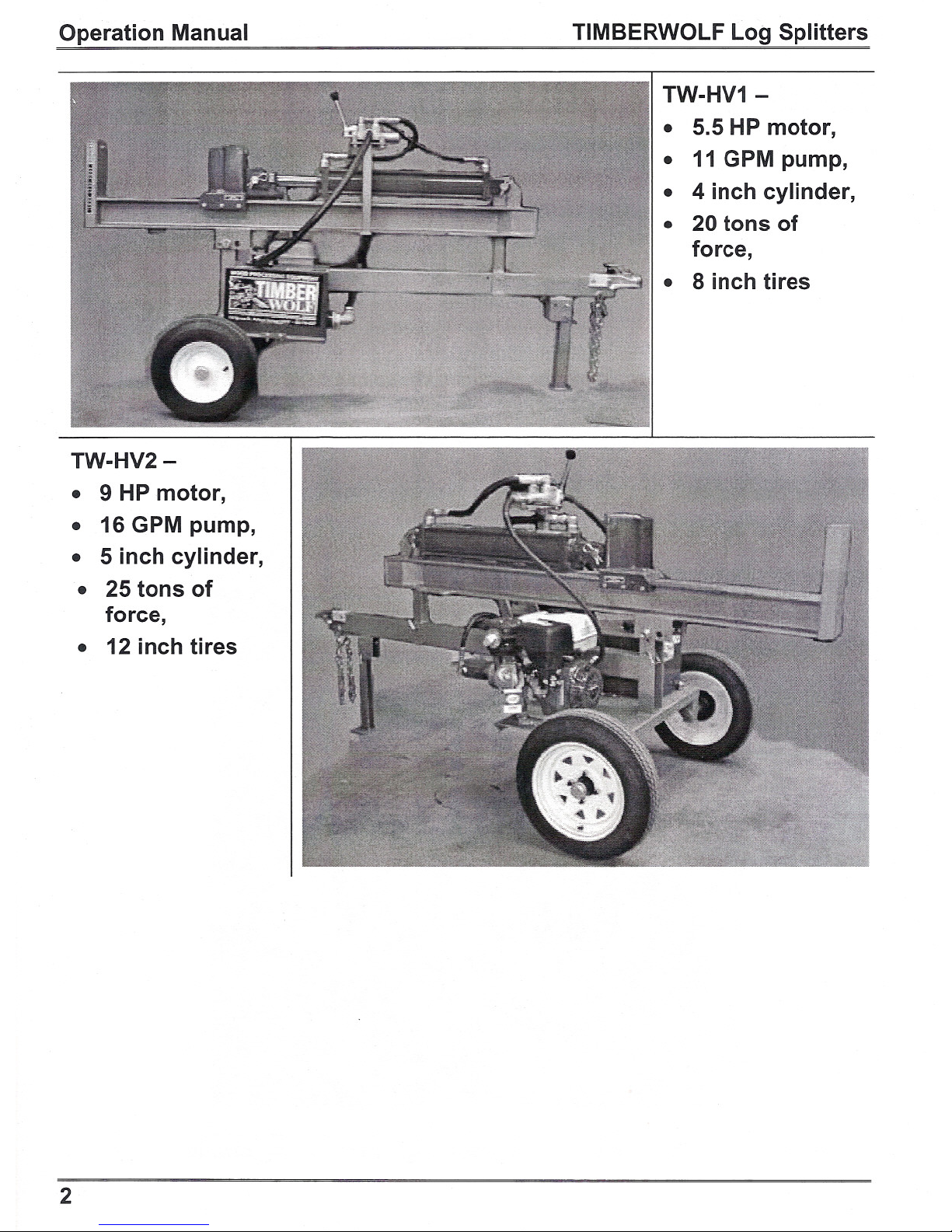

TW-HV1 -

• 5.5 HP motor,

• 11 GPM pump,

• 4 inch cylinder,

• 20 tons of

force,

• 8 inch tires

Page 13

TIMBERWOLF Log Splitters

Operation Manual

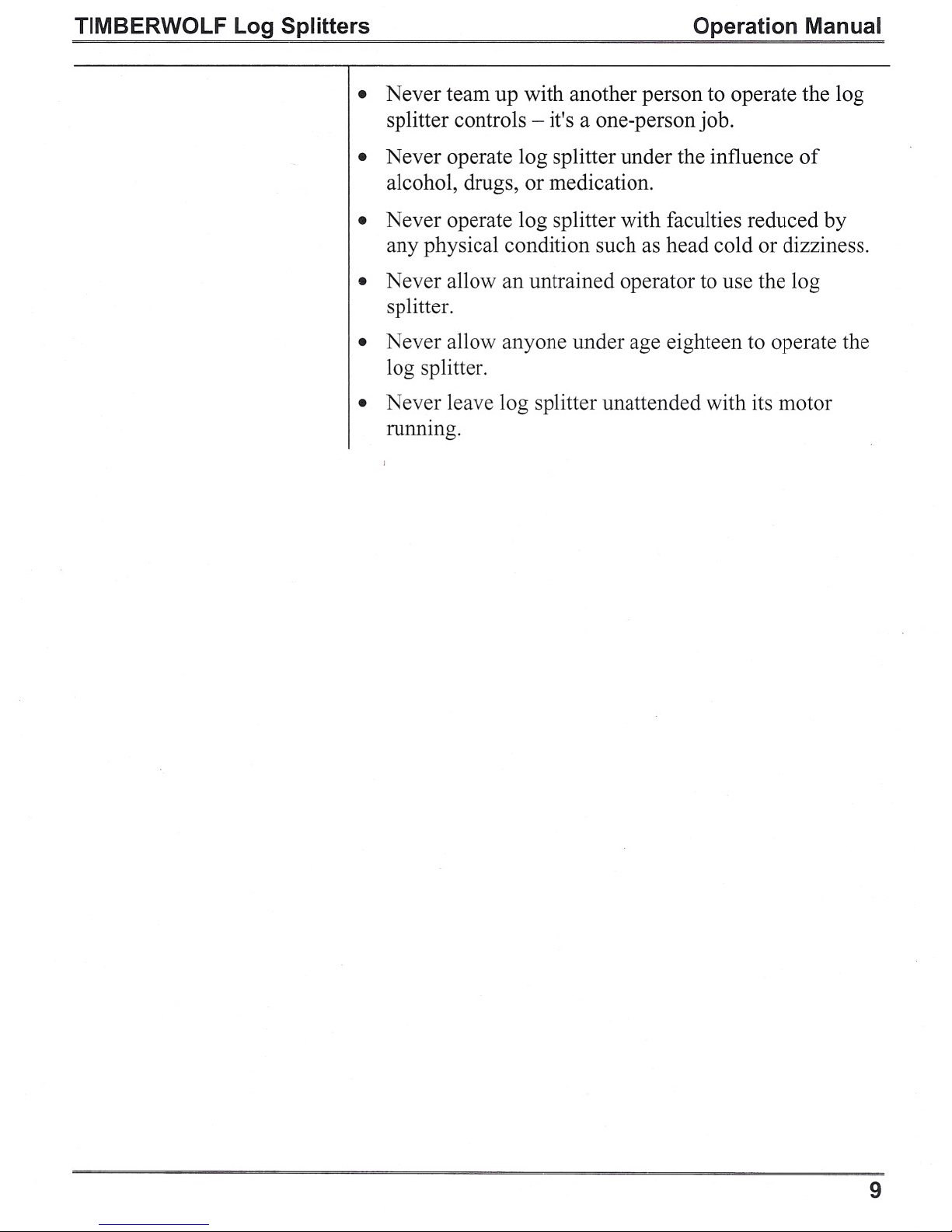

General Description I The next two drawings identify the log-splitters' parts by

the names this manual uses for them.

TWMHVComponents:

&CAUTION

Operator Zone is the area forward of the wheel,

on hydraulic tank side of the machine. Stand in

that area while operating the log splitter. Do not

reach across to the controls from anywhere

else.

3

Page 14

Operation Manual

TIMBERWOLF Log Splitters

Vertical

Position

Lock Holes:

Base

Operator

Zone -

Stand In This

Area When

Operating

Log Splitter

Cpntrol

l:~:e'

Hydraulic

Cylinder

Horizontal

H-beam Log

Carriage

4

• The hydraulic cylinder/wedge assembly is mounted.on

a 5" x 5" H-beam log carriage.

• Carriage hinged for operation in either horizontal or

vertical position.

• H-beam configuration is stronger and more rigid than

equivalent-size I-beam.

&CAUTIONS

A. Always insert locking pin to secure carriage

in the selected position.

B. Never move the log splitter with carriage in

the vertical position.

Page 15

TIMBERWOLF Log Splitters

Operation Manual

Two-stage Hydraulic

Pump

Timberwolf log splitters use a two-stage hydraulic pump

that -

e Normally moves the wedge at high speed with low

force.

• Shifts automatically to low speed and high force when

the log splitter encounters more resistance.

• 1vIayshift two or three times splitting some logs.

If the two-stage hydraulic pump stays in one stage all the

time, contact your local dealer or another authorized

Timberwolf service facility.

Single Handle Valve I Standard-equipment hydraulic control is a single handle

valve.

• Wedge travels forward only while valve handle is held

in position.

• Cylinder automatically completes return stroke when

valve handle is pushed back to detente position and

released.

Wedges

• Timberwolf BV log splitters employ a hydraulically

powered, single-blade wedge.

• Wedge splits logs into two pieces on each stroke.

5

Page 16

Operation Manual

TIMBERWOLF Log Splitters.

6

Specifications

TW-HV1

TW-HV2

590 lb.660 lb.

20 tons25 tons

5.5

9

11 GPM

16 GPM

4.5 gallons

7.5 gallons

26 inches

26 inches

24 x 4 x 1.75 in.

24 x 5 x 2 in.

13 seconds11 seconds

5 in. x 5 in. H-beam5 in. x 5 in. H-beam

8 inch12 inch

2 in. ball coupler

Page 17

TIMBERWOLF Log Splitters

Operation Manual

Important Safety Instructions

What You

SHOULD Do

What You

SHOULD NOT Do

• Read this manual before you operate the log splitter.

• Locate log splitter only on firm, level ground. Site

must be free of slippery surfaces and tripping

obstacles.

• Only operate the log splitter outdoors or in a well-

ventilated area. The motor emits colorless, odorless

carbon monoxide gas that can cause fatal poisoning.

• Only operate the log splitter in a well-lit area.

• Always wear personal protective equipment -

• Goggles or face shield for eye protection

• Ear plugs or hearing protectors

• Snug-fitting work gloves (loose gloves increase

risk of snagging)

• Steel toe safety shoes.

• Keep hands and feet clear of splitting area while the

wedge is in motion.

• Clear pieces from underfoot after each log is split

when operating in horizontal position.

• Never split anything other than logs.

• Don't handle logs by their ends when you position

them for horizontal splitting.

7

Page 18

Operation Manual

What You

SHOULD NOT Do

(Continued)

What You

SHOULD NEVER Do

8

TIMBERWOLF Log Splitters

You don't want your hands at pinch points where they can

get caught between a log and the wedge or base plate.

• Don't put any part of yourself, your clothing, or your

personal protective equipment into a crack in a log

that's being split; it might close suddenly and with

great force.

• Do not straddle or climb over the log splitter at any

time.

• Do not move or reposition the log splitter with the

motor running.

• Do not modify or alter the machine in any way at any

time.

• When splitting vertically, never put any part of your

hand on the top end of the log to steady it. If you must

steady a log, place your hand mid-way down the side.

Page 19

TIMBERWOLF Log Splitters Operation Manual

• Never team up with another person to operate the log

splitter controls - it's a one-person job.

• Never operate log splitter under the influence of

alcohol, drugs, or medication.

• Never operate log splitter with faculties reduced by

any physical condition such as head cold or dizziness.

• Never allow an untrained operator to use the log

splitter.

• Never allow anyone under age eighteen to operate the

log splitter.

• Never leave log splitter unattended with its motor

runnmg.

9

Page 20

Operation Manual

.t!Ydraulic Safet'l

TIMBERWOLF Log Splitters·

&WARNINGS

Escaping pressurized fluid from hydraulic system leaks can have enough force to

penetrate skin and cause serious injury or death.

Hydraulic fluid can remain highly pressurized while splitter motor is off.

Never use your hand or any part of your body to check for hydraulic system leaks

while the system is pressurized.

Get professional medical help at once if hydraulic oil penetrates anyone's skin.

Always release residual energy from pressurized hydraulic fluid before doing any

maintenance or repair work on the log splitter.

What You

SHOULD Do

What You

SHOULD NOT Do

10

• Inspect hydraulic hoses every day - check for worn,

frayed, kinked, and cracked areas.

I

• Replace any damaged or worn hoses.

• Use sheet of cardboard or log to check for hydraulic

leaks while system is running. -

• Depressurize system to release residual hydraulic

energy before starting any repairs.

1. Shut off splitter motor.

2. Move control valve handle back and forth, from one

limit of travel to the other, at least four times.

3. Hold valve for three seconds at each limit of travel.

• Contact Timberwolf Manufacturing Corp. or a

qualified hydraulic mechanic to replace worn

components.

• Do not make any adjustments to the pressure relief

valve.

• Never remove cap from hydraulic tank while motor is

running or while tank is still warm after motor is shut

off. Hot pressurized oil can cause serious injury, so

wait for hydraulic tank to cool before removing cap.

• Never use any connectors, valves, or fittings that are

different from the ones originally installed on the log

splitter.

Page 21

TIMBERWOLF Log Splitters Operation Manual

Before You Start the Lo~Splitter

Check Fluids

Location & Setup

• Engine oil should be to the level of the fill pipe.

• Hydraulic oil:

• Timberwolf recommends use of Rando 46 (Texaco) .

• Level should be two inches below the top of the

tank.

• Place log splitter on level ground, in a well lit, well

ventilated spot.

• Check around log splitter for hazards. Make sure there

are no slippery surfaces or objects to trip over in the

,area.

• Make sure there won't be people or animals in the area

around the log splitter.

• Take out cotter pin holding the hitch support leg in the

raised position, swing leg down, and insert cotter pin

in the hole for the down position ..

Vertical • Raising and lowering the log carriage to and from

Setup vertical position requires two people, one on each side

of the machine.

• Finnly block wheels so that log splitter cannot roll in

either direction.

• For best weight distribution, wedge should be fully

extended when raising and lowering log carriage.

• Unclip and remove both the horizontal and vertical

position lock pins.

11

Page 22

LhWARNING

When raising or lowering the log carriage, never

reach across to the handle on the far side .

• Continue supporting the log carriage until the lock pin

is inserted in the vertical locking position and clipped .

• Re-insert and clip the horizontal position lock pin to

keep it from getting lost.

Operation Manual

Vertical I •

Setup

(Continued)

12

TIMBERWOLF Log Splitters

Firmly grasping the log carriage handles, raise the log

carriage into the vertical position.

Page 23

TIMBERWOLF Log Splitters

Qperatin~ Instructions

Operation Manual

Start Up

Splitting Safety

• Start motor.

NOTE

See motor manufacturer's manual for motor

starting and maintenance instructions.

• Run motor at idle for 10 - 15 minutes to let hydraulic

oil warm up.

• Always stand inside the Operator Zone to run the log

splitter. Never operate the log splitter from anyplace

else, including the area in front of the valve handle.

)

,

~operatorZone -

Stand in this area

when operating

log splitter

• Handle logs only from the sides; never by the ends.

• For best splitting results, place log with butt end on the

base plate.

• Be very careful to keep anns and fingers away from

the wedge and base plate.

• Keep hands and fingers clear at all times. Many log-

splitting accidents happen on the return portion of the

stroke.

13

Page 24

Vertical' •

Operation

Safety, •

Operation Manual

Splitting Safety

(Continued)

Operating the Log

Splitter

14

TIMBERWOLF Log Splitters'

• Don't put any part of your body within the splitting

area. Use a stick if you need to remove debris from

the splitting area.

Pieces to be split with the machine in vertical position

should be cut as near to a 90° angle as possible.

Stand piece unsupported or leaned back against the log

carriage beam if possible.

• If you must support a piece, place your hand midway

down the outside surface - away from the beam - and

remove your hand as soon as the pieces is firmly held

between the wedge and the base plate.

• For best splitting results, place logs with the butt

(wider) end on the base plate.

• For horizontal splitting-

• Put one hand on top of log in the middle to keep it

steady until it's held firmly between wedge and

base plate - then get your hand out of there.

• For Vertical splitting -

• Stand piece unsupported or leaned back against the

log carriage beam if possible .

• If you must support a piece, place your hand

midway down the outside surface - away from the

beam - and take it away as soon as the piece is

firmly held between the wedge and the base plate.

• Activate control valve - push handle forward and hold.

• Keep holding valve handle down until split pieces fall

away or wedge reaches full extension, one or two

inches from base plate.

• Before starting return stroke, let hydraulic system

recover by moving valve handle to neutral position for

a moment.

• Make sure nothing will interfere with wedge while it

retracts.

• Press valve handle backward into locked position and

let go. Wedge returns by itself.

Page 25

TIMBERWOLF Log Splitters

Operation Manual

• Valve handle stays in locked position until wedge is

fully retracted.

• To stop wedge -

• During forward stroke, release control handle .

• During return stroke, pull control handle

forward to release it from the locked position.

NOTE

Operate hydraulic control valve smoothly. Allow

a short pause when reversing directions, then

press lever firmly in direction you need to go.

Slamming valve lever in either direction makes

the system wear out faster.

• Clear split pieces from the operator zone frequently.

Allowing pieces to accumulate underfoot can be both

inconvenient and unsafe.

15

Page 26

Operation Manual

TIMBERWOLF Log Splitters

Transportinq the Log Splitter

Preparation

16

• Never move the log splitter with the log carriage in the

vertical position.

• Never move the log splitter with the motor running.

• Make sure fuel valve on log splitter motor is in the

"OFF" position.

&CAUTION

If fuel valve isn't shut off, fuel will be forced into

the cylinder and crankcase during travel. If that

happens, the engine motor oil and spark plug

have to be replaced.

• Make sure there are no loose parts or debris on the log

splitter to fall off while it's being towed.

• Never tow the log splitter with a log on it.

• Make sure the front leg is retracted and pinned up

before transporting.

• Make sure log splitter's ball coupler is firmly attached

to ball on tow vehicle hitch:

• Raise hitch latch to unlocked position.

• Place hitch onto ball of tow vehicle's trailer

hitch.

• Lower hitch latch into locked position and

secure with locking bolt.

• Make sure that safety chains are securely attached,

with sufficient slack to allow for turning.

Page 27

TIMBERWOLF Log Splitters

Operation Manual

Towing Safety

• Never allow anyone to ride on the log splitter.

• Never transport anything on the log splitter.

• Obey local, state, and federal regulations when you

tow the log splitter on public roads and highways.

NOTE

Some states may require the log splitter to be

registered with the State Department of Motor

Vehicles.

• Fenders and light kits, required in some states, are

available from Timberwolf Manufacturing as optional

equipment.

• Do not exceed 30 MPH while towing the log splitter.

• Towing log splitter can affect handling:

• Log splitter might "off track" tow vehicle .

• Log splitter can turn tighter than tow vehicle does.

• Never back up tow vehicle with log splitter

attached. Log splitter can jack knife, causing damage

to itself and/or tow vehicle.

• Long distance towing is not recommended. The log

splitter does not have springs to absorb road shock.

Extended towing can cause unnecessary wear.

17

Page 28

Operation Manual

Maintenance

TIMBERWOLF Log Splitters·

LhWARNING

Make sure motor is shut off and hydraulic system is depressurized before you

perform any maintenance. Make sure hydraulic oil has cooled. Read "Safety"

section of this manual before performing any repairs.

Engine Oil

Hydraulic Oil

• First change after first 5 hours of operation

• Regular changes after every 20 hours of operation

• Regular changes after every 200 hours of operation

NOTE

If hydraulic oil becomes contaminated it should

be changed immediately.

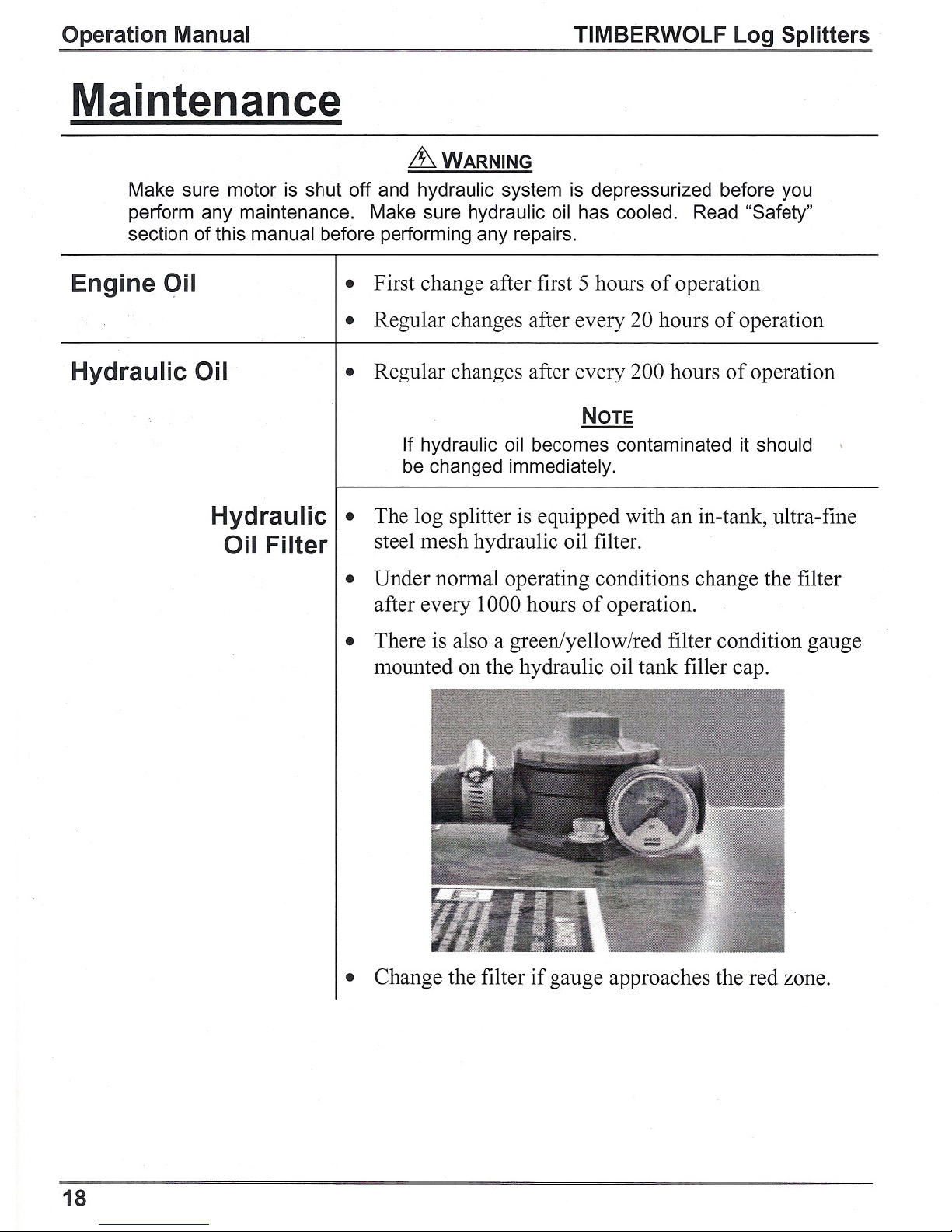

Hydraulic • The log splitter is equipped with an in-tank, ultra-fine

Oil Filter steel mesh hydraulic oil filter.

• Under normal operating conditions change the filter

after every 1000 hours of operation.

• There is also a green/yellow/red filter condition gauge

mounted on the hydraulic oil tank filler cap.

• Change the filter if gauge approaches the red zone.

18

Page 29

TIMBERWOLF Log Splitters Operation Manual

Wedge Assembly

• Grease assembly daily to reduce wear on beam and

sides.

• Use any high-grade tube grease.

• Replace wear plates (also called "gibbs") if wedge can

be raised more than one quarter inch off the beam.

• Sharpen wedge regularly with file or grinder.

Daily Maintenance

General

Grease

Motor

Hydraulic Hoses

• Check all nuts, bolts, and welds to be sure that the

frame and components are secure.

• Make sure that the wear plates attached to the wedge

assembly are firmly bolted in place.

• Make sure wedge assembly and top of beam are well

lubricated with grease.

• Grease push block at grease fittings.

• Smear grease across top of beam.

• Consult motor manufacturer's manual for motor's

daily maintenance requirements.

• Inspect hydraulic hoses for frayed, worn, kinked, or

abraded areas.

• Replace any damaged or worn hydraulic hoses

immediately.

&WARNING

Make sure system is depressurized before you

do any hydraulic system repairs. See Hydraulic

Safety in the Safety section.

19

Page 30

Operation Manual

Annual Maintenance

TIMBERWOLF Log Splitters

Grease

Hydraulics

20

• Grease wheel bearings annually.

• Grease wheel bearings after any trip longer than 50

miles.

• Change hydraulic oil annually.

• Change hydraulic oil filter after 1000 hours of

operation or when filter condition gauge approaches

red zone.

&CAUTION

Make sure system is depressurized before you

do any hydraulic system repairs. See Hydraulic

Safety in the Safety section.

Page 31

TIMBERWOLF Log Splitters

Limited Warranty

Product Covered:

Operation Manual

Date Warranty

Be2ins:

What We Will Do

for You:

What Is Not

Covered:

Limited

Commercial Use

Warranty:

Commercial Use

Definition:

How To Get

Service:

Disclaimer of

ConseQuential

Dama2es:

Limitation of

Implied

Warranties:

Your Ri2hts Under

State Law:

This warranty is for Timberwolf and/or Valley Wood Processing branded log splitters,

conveyors, wood processors, ride-on equipment and their attachments or accessories.

The warranty begins on the date of sale and is warranted by TimberwolfMfg. Corp. to the

original purchaser only.

We or your authorized dealer will, at our option, repair or replace any part found to be

defective in material or workmanship, without charge for parts or labor, to the original

residential purchaser for a period of time of one year. However, charges for pickup,

delivery, and service calls are not covered by this warranty. The engine is warranted

separately by the engine manufacturer.

This warranty does not apply to parts that have been damaged by accident, alteration.

misuse, abuse or improper lubrication. The following items are not covered after the first

six months of home use: hoses, batteries, bushings, seals, filters, tires, wheels, paint, chains,

appearance items, light bulbs, and similar items which are normally replaced through

periodic maintenance.

Ifused for commercial, institutional or rental purposes, the warranty on this product is

limited in duration to 90 days from date of purchase. This wan-anty does not apply to parts

that have been damaged by accident, alteration, misuse, abuse or improper lubrication. The

engine for commercial use is warranted separately by the engine manufacturer.

For the purpose of this wan-anty "consumer use" means personal residential household use

by the original retail consumer. "Commercial use" means all other uses, including use for

commercial, income producing or rental purposes. Once a unit has experienced

"commercial" use it will be considered as a commercial unit for the purposes of this

warranty.

To obtain service, contact our nearest dealer, or TimberwolfMfg. Corp. at 118 Spruce

Street, Rutland, VT 05701, or call us at 802-775-4227. For engines, contact us or our

dealers, or consult your Yellow Pages for the name of the service dealer that is authorized

by the manufacturer.

TimberwolfMfg. Corp. shall not be liable under any circumstances for any incidental or

consequential damages or expenses of any kind, including - but not limited to - the cost of

equipment rental, loss of profits, or cost of hiring services to perform tasks normally

performed by the equipment.

Any implied warranties, including without limitation any implied warranty of

merchantability or fitness for a particular purpose, shall be limited in duration to a period of

one year (90 days if product is purchased for commercial or other non-residential use) from

the date of sale.

Some states do not allow the exclusion or limitation of incidental or consequential damages,

or limitation on how long an implied warranty lasts.

This warranty gives you specific legal rights, and you may also have other rights, which

vary from state to state.

21

Page 32

Operation Manual

22

TIMBERWOLF Log Splitters

Page 33

TIMBERWOLF Log Splitters

Operation Manual

TIMBERWOLF MANUFACTURING CORPORATION

Warranty ReQistration Form

Timberwolf Manufacturing Corporation requires this warranty registration form to

be filled out and returned within 30 days after the machine's purchase. The

record of your purchase helps us to efficiently process any warranty claims that

may arise.

Purchaser Name

(Individual or Company): _

Address:

Purchased From

(Dealer):

Address:

Date of Purchase:

Model Number:

Serial Number:

Motor Serial Number:

Options:

Mail to

OR

Fax to

TIMBERWOLF Manufacturing Corporation

118 Spruce Street

Rutland, Vermont 05701

802-773-1275

23

Page 34

Operation Manual TIMBERWOLF Log Splitters

Detach and Fold this page, Tape Shut, Affix Stamp, and Mail To:

TIMBERWOLF Manufacturing Corporation

118 Spruce Street

Rutland, Vermont 05701

24

Loading...

Loading...