Page 1

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

INSTALLATION AND

OPERATING INSTRUCTIONS

This heater has been tested to ASTM E 1509, ULC/ORD C1482M-90, ULC S627 AND ULC S628.

TPSI35

PELLET

STOVE / INSERT

1

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA METHODS.

SAFETY INFORMATION

!

WARNING

PLEASE READ ENTIRE MANUAL

BEFORE YOU INSTALL OR USE THIS

PELLET BURNING HEATER.

If the heater is not properly installed, a

house fi re may result causing personal

injury or loss of life.

- Authorities having jurisdiction (such as

municipal building department, fi re department,

fi re prevention bureau, etc.) should be consulted

before installation to determine the need to obtain

a permit.

- Contact local building or fi re offi cials about

restrictions and installation inspection

requirements in your area.

- This heater is hot while in operation. Keep

children, clothing and furniture away. Contact may

cause skin burns.

- Do not start a fi re with chemicals or fl uids such

as gasoline, engine oil, etc...

STOVE ILLUSTRATED

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 4Y8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.timberwolffi replaces.com • ask@timberwolffi replaces.com

1.18A

$10.00

W415-0865 / 04.07.10

Page 2

2

TABLE OF CONTENTS

1.0 INSTALLATION OVERVIEW 3

1.1 STOVE 3

1.2 INSERT 4

2.0 INTRODUCTION 5

2.1 DIMENSIONS 6

2.1.1 STOVE 6

2.1.2 INSERT (COMPLETE WITH FLASHING) 6

2.2 SPECIFICATIONS 7

2.3 GENERAL INSTRUCTIONS 7

2.4 GENERAL INFORMATION 8

2.4.1 PELLET QUALITY 8

2.4.2 SAFETY FEATURES 9

2.4.3 EPA COMPLIANCE 9

2.5 RATING PLATE INFORMATION 9

3.0 INSTALLATION PLANNING 10

3.1 INSTALLATION OPTIONS 10

3.2 APPLIANCE PLACEMENT 10

3.3 MINIMUM CLEARANCE TO COMBUSTIBLES 11

3.3.1 STRAIGHT INSTALLATION 11

3.3.2 CORNER INSTALLATION 11

3.4 FLOOR PROTECTION REQUIREMENTS 12

3.5 OUTSIDE AIR 12

3.6 MOBILE HOME INSTALLATION 12

4.0 STOVE ASSEMBLY 13

4.1 CONTROL PANEL ASSEMBLY 13

4.2 STOVE SIDE AND REAR PANEL ASSEMBLY 14

4.3 STOVE HOPPER DOOR INSTALLATION 15

4.4 INSERT HOPPER DOOR INSTALLATION 15

5.0 VENTING 16

5.1 TYPE OF VENT 16

5.2 INSTALLING THE PELLET VENT 16

5.3 VENTING THE PELLET APPLIANCE 16

5.4 PELLET VENT TERMINATION 17

5.5 VENT TERMINAL CLEARANCES 17

5.6 STOVE VENTING INSTALLATION EXAMPLES 18

5.6.1 HORIZONTAL TERMINATION (THROUGH WALL) 18

5.6.2 VERTICAL RISE HORIZONTAL TERMINATION (THROUGH WALL) 18

5.6.3 VERTICAL TERMINATION 19

5.6.4 CLASS A CHIMNEY RETROFIT 19

5.6.5 HEARTH MOUNT INSTALLATION 20

5.7 INSERT VENTING INSTALLATION EXAMPLES 21

5.7.1 TYPICAL EXISTING MASONRY INSTALLATION 21

5.7.2 FACTORY BUILT FIREPLACE 22

6.0 FRAMING (INSERT ONLY) 23

6.1 INSTALLATION INTO A COMBUSTIBLE ENCLOSURE 24

6.2 MINIMUM ENCLOSURE CLEARANCES 25

6.3 MINIMUM CLEARANCE TO COMBUSTIBLES 25

6.4 MINIMUM MANTEL CLEARANCES 26

6.5 ALCOVE INSTALLATION REQUIREMENTS (MINIMUM) 26

7.0 FINISHING 27

7.1 INSTALLING VIEWING DOOR 27

7.2 DOOR HANDLE INSTALLATION 28

7.3 DECORATIVE INSET 28

7.4 FLASHING INSTALLATION 29

8.0 WIRING DIAGRAM 30

9.0 OPERATING INSTRUCTIONS 31

9.1 PROPER PELLET LOADING 31

9.2 PRE-START CHECK 31

9.3 LIGHTING APPLIANCE MANUALLY 31

9.4 LIGHTING INSTRUCTIONS 32

9.5 CONTROLS 32

9.6 CONTROL ADJUSTMENT 33

9.7 INSTALLING A THERMOSTAT 33

9.8 SHUTDOWN INSTRUCTIONS 33

10.0 NORMAL OPERATING SOUNDS 34

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

W415-0865 / 04.07.10

Page 3

3

11.0 MAINTENANCE 35

11.1 DAILY (WHENEVER USING THE APPLIANCE) 35

11.1.1 DISPOSAL OF ASHES 35

11.1.2 INSPECT THE BURN POT 35

11.1.3 CARE OF GLASS 35

11.1.4 CLEANING THE HEAT EXCHANGER TUBES 36

11.1.5 MAKE SURE PELLETS ARE NOT PILING UP 36

11.1.6 CLEANING THE BURN POT 37

11.2 BI-WEEKLY (OR EVERY 10 BAGS OF PELLETS) 37

11.2.1 VACUUM FIREBOX 37

11.3 SEMI-ANNUALLY (OR EVERY TWO TONS OF PELLET) 38

11.3.1 VACUUM HOPPER 38

11.3.2 SOOT AND FLY ASH FORMATION 38

11.3.3 CLEAN THE VERTICAL EXHAUST DUCT 38

11.3.4 CLEAN THE EXHAUST BLOWER 39

11.3.5 CHECK ALL SEALS 39

11.3.6 CLEAN THE VENT 40

11.4 IN THE EVENT OF A JAMMED AUGER 40

12.0 REPLACEMENTS 41

13.0 TROUBLESHOOTING 44

14.0 WARRANTY 47

15.0 SERVICE HISTORY 48

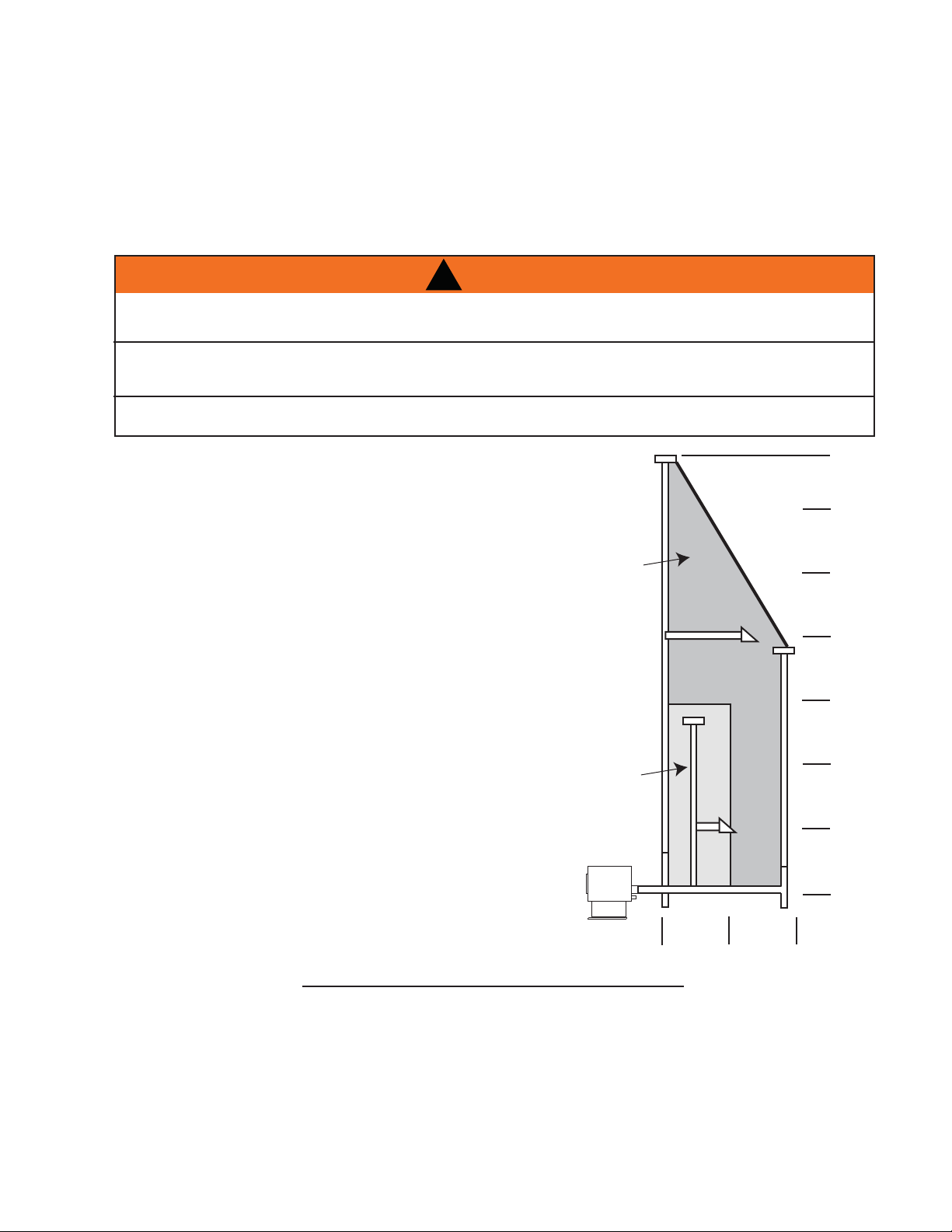

1.0 INSTALLATION OVERVIEW

1.1 STOVE

Door, see “FINISHING - INSTALLING

THE VIEWING DOOR” section.

Venting, see “GENERAL VENTING”

and “INSTALLATION” sections.

Floor, see “INSTALLATION PLANNING FLOOR PROTECTION REQUIREMENTS” section.

Rating plate, see

“RATING PLATE

INFORMATION”

section.

See “OUTSIDE AIR”

section.

Handle, see “DOOR

HANDLE INSTALLATION”

section.

W415-0865 / 04.07.10

Page 4

4

1.2 INSERT

Door, see “FINISHING INSTALLING THE VIEWING DOOR” section.

Flashing, see “FLASHING

INSTALLATION” section.

Venting, see “GENERAL VENTING”

and “INSTALLATION” sections.

Rating plate, see “RATING PLATE

INFORMATION” section.

W415-0865 / 04.07.10

Handle, see “DOOR

HANDLE INSTALLATION”

section.

Page 5

2.0 INTRODUCTION

• THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE BURNS IF

CONTACTED.

• Do not operate appliance before reading and understanding operating instructions. Failure to operate

appliance according to operating instructions could cause fi re or injury.

• Risk of fi re or asphyxiation do not operate appliance with fi xed glass removed.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not install damaged, incomplete or substitute components.

• Young children should be carefully supervised when they are in the same room as the appliance. Tod-

dlers, young children and others may be susceptible to accidental contact burns. A physical barrier is

recommended if there are at risk individuals in the house. To restrict access to an appliance or stove,

install an adjustable safety gate to keep toddlers, young children and other at risk individuals out of the

room and away from hot surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Due to high temperatures, the appliance should be located out of traffi c and away from furniture and

draperies.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot

surfaces.

• Even after the appliance is out, the glass and/or screen will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children

from hot surfaces. These screens and guards must be fastened to the fl oor.

• Any safety screen or guard removed for servicing must be replaced prior to operating the appliance.

• The appliance is a vented gas-fi red appliance. Do not burn wood or other materials in the appliance.

• It is imperative that the control compartments, burners and circulating blower and its passageway in

the appliance and venting system are kept clean. The appliance and its venting system should be

inspected before use and at least annually by a qualifi ed service person. More frequent cleaning may

be required due to excessive lint from carpeting, bedding material, etc. The appliance area must be

kept clear and free from combustible materials, gasoline and other fl ammable vapors and liquids.

• Under no circumstances should this appliance be modifi ed.

• This appliance must not be connected to a chimney fl ue pipe serving a separate solid fuel burning

appliance.

• Do not use this appliance if any part has been under water. Immediately call a qualifi ed service

technician to inspect the appliance and to replace any part of the control system and any gas control

which has been under water.

• Do not operate the appliance with the glass door removed, cracked or broken. Replacement of the

glass should be done by a licensed or qualifi ed service person.

• Do not strike or slam shut the appliance glass door.

• Only doors / optional fronts certifi ed with the unit are to be installed on the appliance.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As

with all plastic bags, these are not toys and should be kept away from children and infants.

!

WARNING

5

3.13

W415-0865 / 04.07.10

Page 6

6

2.1 DIMENSIONS

2.1.1 STOVE

1

21

/4"

5

30

/16"

11

19

/16"

2.1.2 INSERT (COMPLETE WITH FLASHING)

3

38

/8"

7

25

/8"

1

24

/4"

5

16

/8"

7

11

/8"

1

23

/2"

CENTRE LINE

OF AIR INTAKE

B

A

*

*

CENTRE

LINE OF

EXHAUST

3

29

/8"

5

10

1

8

/2" CENTRE LINE

/8"

OF AIR INTAKE

5

" CENTRE LINE

OF EXHAUST

21

38

13

20

/16"

1

7

/8"

7

1

/8"

CENTRE LINE

CENTRE

LINE OF

EXHAUST

OF AIR INTAKE

CENTER LINE

OF INSERT

1

1

/4"

1

/4"

3

/8"

* A and B are adjustable, see "SPECIFICATIONS" section.

W415-0865 / 04.07.10

Page 7

7

2.2 SPECIFICATIONS

Min Depth 11" 12 1/2"

Max Depth 13" 10 1/2"

Electrical Rating 115 Volts, 3.6 Amps, 60Hz

Watts During Ignition Sequence 400 (approximately)

Watts During Operation 180 (approximately)

Weight Stove 158 lbs / Insert 140 lbs

Exhaust Collar 3"

Intake Collar 2"

Hopper Capacity 45 Pounds

EPA Exempt

Burn Rate 1.5 to 4.5 (Pounds Per Hour)

BTU/H 12750 to 38250

Approximate Maximum Heating Capacity (in square feet)* 800 to 2000 Sq. Feet

Maximum Burn Time on Low Burn** 30 Hours

* Heating capacity will vary depending on the home's fl oor plan, degree of insulation, and the outside temperature. It is

also affected by the fuel size, quality, and moisture level.

** Small pellets will increase or decrease the stated burn rates and burn times. Differences of plus or minus 20% depend-

ing on fuel quality may occur.

AB

2.3 GENERAL INSTRUCTIONS

ALL WIRING SHOULD BE DONE BY A QUALIFIED ELECTRICIAN AND SHALL BE IN COMPLIANCE

WITH LOCAL CODES. IN THE ABSENCE OF LOCAL CODES, USE THE CURRENT CSA C22.1

CANADIAN ELECTRIC CODE (IN CANADA) OR THE ANSI/NFPA NO. 70 NATIONAL ELECTRIC CODE

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE. DO

NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM.

PROVIDE ADEQUATE CLEARANCE FOR SERVICING AND OPERATING THE APPLIANCE.

PROVIDE ADEQUATE VENTILATION.

NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE.

OBJECTS PLACED IN FRONT OF THE APPLIANCE MUST BE KEPT A MINIMUM OF 48” FROM THE

FRONT FACE OF THE APPLIANCE.

!

WARNING

IN THE UNITED STATES.

W415-0865 / 04.07.10

Page 8

8

Thank you for purchasing a Wolf Steel Ltd. Pellet Appliance. This appliance is designed for use with Pelletized

Wood Only.

Please read this entire manual before installation and use of this pellet fuel-burning room appliance. Failure to

follow these instructions could result in property damage, bodily injury or even death.

Keep this manual handy for future reference.

This Pellet Appliance, when installed, must be electrically grounded in accordance with the local codes, or in

the absence of local codes, use the current CSA C22.1 Canadian Electrical Code in Canada or the ANSI/NFPA

70 National Electrical Code in the United States.

This appliance will not operate using natural draft or without a power source for the blower systems and fuel

feed system.

The protective wrap on plated parts is best removed when the assembly is at room temperature but this can be

improved if the assembly is warmed, using a hair dryer or similar heat source.

If the appliance is installed directly on carpeting, vinyl tile or other combustible material other than wood

fl ooring, the appliance shall be installed on a metal or wood panel extending the full width and depth.

2.4 GENERAL INFORMATION

4.5

2.4.1 PELLET QUALITY

IT IS IMPORTANT TO SELECT AND USE ONLY PELLETS THAT ARE DRY AND FREE OF DIRT OR ANY

IMPURITIES SUCH AS HIGH SALT CONTENT. DIRTY FUEL WILL ADVERSELY AFFECT THE OPERA-

TION AND PERFORMANCE OF THE APPLIANCE AND WILL VOID THE WARRANTY. THE PELLET

FUEL INSTITUTE (P.F.I.) HAS ESTABLISHED STANDARDS FOR WOOD PELLET MANUFACTURERS.

WE RECOMMEND THE USE OF PELLETS THAT MEET OR EXCEED THESE STANDARDS. ASK YOUR

Pellet quality is important, please read the following:

Your Wolf Steel Ltd. Pellet Appliance has been designed to burn premium hard or soft wood pellets only. Do

not use any other type of fuel such as fi re logs or fi re starting pellets, as this will void the warranties stated in

this manual.

The performance and heat output of the pellet appliance is directly related to the quality and moisture of the

pellets. Store pellets in a cool dry area to prevent moisture absorption.

P.F.I. PELLET STANDARDS:

Fines (fi ne particles) 1% maximum through a 1/8" screen

Bulk Density 40 pound per cubic foot minimum

Size 1/4" to 5/16" diameter, 1/2" - 1 1/2" long maximum

Ash Content 1% maximum (Premium grade)

3% maximum (Standard grade)

Moisture Content 8% maximum

Heat Content Approximately 8200 BTU per pound minimum

!

WARNING

DEALER FOR A RECOMMENDED PELLET TYPE.

If the fuel does not comply to

this standard the appliance may

not operate as designed.

We recommend the use of

premium grade (1% ash

content) for longer stove life and

less frequent cleaning.

64.1

W415-0865 / 04.07.10

Page 9

2.4.2 SAFETY FEATURES

HIGH LIMIT SWITCH: Your appliance is equipped with a high limit switch. In the event that the temperature of

the appliance approaches an unsafe operating temperature, this switch will shut down the pellet feed, which

will eventually shut down the unit. If this happens, it is important to fi nd out why the unit overheated. Contact

your local dealer.

LOW LIMIT SWITCH: This switch will automatically shut down the appliance if the fi re goes out or fails to light

within 15 minutes.

HOPPER DOOR INTERLOCK: Your appliance is equipped with a micro switch in the hopper assembly that

shuts-off the auger when the hopper door is opened. Closing the door switches the auger back on, allowing

pellets to feed again.

VACUUM SWITCH: This switch will sense lack of air fl ow through the appliance and shut down the pellet feed.

This lack of fl ow could be caused by a blocked vent.

POWER FAILURE: In the event of a power failure, the appliance will shut down. Once power is restored, the

appliance will re-start, unless the convection air temperature has gone above the high limit switch setting. If

this happens, contact your local dealer.

2.4.3 EPA COMPLIANCE

9

This appliance is EPA exempt from Phase II

prerequisites, but complies with Oregon /

Washington emissions requirements.

2.5 RATING PLATE INFORMATION

- INSTALL AND USE ONLY IN ACCORDANCE WITH THE

MANUFACTURER’S INSTRUCTIONS AND LOCAL

BUILDING CODES.

- MINIMUM CEILING HEIGHT: 7FT (2.13M) HEARTH

REFERENCE # W/N

16544

POWER BEFORE SERVICING UNIT.

- KEEP VIEWING AND ASH REMOVAL DOORS TIGHTLY CLOSED DURING OPERATION.

- CONTACT LOCAL BUILDING AND FIRE OFFICIALS ABOUT RESTRICTIONS AND

INSTALLATION INSPECTION IN YOUR LOCAL AREA.

- SUITABLE FOR USE IN MOBILE HOMES WHEN USED WITH OUTSIDE AIR INSTALLATION KIT.

- REFER TO INSTALLATION INSTRUCTIONS OR LOCAL BUILDING CODES WHEN

PASSING EXHAUST SYSTEM THROUGH COMBUSTIBLE WALL OR CEILING.

- FUEL: FOR USE WITH PELLET FUEL ONLY.

CAUTION: HOT WHILE IN OPERATION. DO NOT TOUCH. KEEP

CHILDREN, CLOTHING AND FURNITURE AWAY. CONTACT MAY CAUSE

SKIN BURNS.

- INSTALLER ET UTILISER CONFORMÉMENT AUX INSTRUCTIONS DU FABRICANT ET

AUX CODES DU BÂTIMENT LOCAUX.

- HAUTEUR DE PLAFOND MINIMALE 7 PI. (2,13 m)

BASE DE PROTECTION/PROTECTION DE PLANCHER COMBUSTIBLE : SI INSTALLÉ

SUR UN PLANCHER COMBUSTIBLE, L’APPAREIL DOIT ÊTRE PLACÉ SUR UNE

PLAQUE PROTECTRICE INCOMBUSTIBLE S’ÉTENDANT SUR 6” À L’AVANT.

- NE PAS RACCORDER CET APPAREIL À LA CHEMINÉE D’UN AUTRE APPAREIL.

- REMPLACER LA VITRE PAR UNE VITRE EN CÉRAMIQUE SEULEMENT.

DANGER : RISQUE DE SECOUSSE ÉLECTRIQUE. DÉBRANCHER L’ALIMENTATION

ÉLECTRIQUE AVANT DE PROCÉDER À L’ENTRETIEN.

- GARDER LA PORTE VITRÉE ET LA PORTE DU TIROIR À CENDRES BIEN FERMÉES

DURANT LE FONCTIONNEMENT.

- CONTACTER LES AUTORITÉS LOCALES DU BÂTIMENT ET DU SERVICE DES

INCENDIES AU SUJET DES RESTRICTIONS ET DES INSPECTIONS D’INSTALLATION

DANS VOTRE RÉGION.

- PEUT ÊTRE INSTALLÉ DANS UNE MAISON MOBILE SI INSTALLÉ CONJOINTEMENT

AVEC UNE PRISE D’AIR EXTÉRIEUR.

- SE RÉFÉRER AUX INSTRUCTIONS D’INSTALLATION OU AUX CODES DU BÂTIMENT

LOCAUX LORSQUE LE SYSTÈME D’ÉVACUATION TRAVERSE UN MUR OU UN

PLAFOND COMBUSTIBLES.

- COMBUSTIBLE : POUR USAGE AVEC DES GRANULES SEULEMENT.

ATTENTION : L'APPAREIL EST CHAUD LORSQU’IL FONCTIONNE. NE PAS

TOUCHER. TENIR LES ENFANTS, LES VÊTEMENTS ET LES MEUBLES À

L’ÉCART. LE CONTACT PEUT CAUSER DES BRÛLURES DE PEAU.

MADE IN / FABRIQUÉ AU:

WOLF STEEL LTD. BARRIE, ONTARIO CANADA

24 NAPOLEON ROAD, BARRIE, ON, L4M 4Y8 CANADA

NAC GUANGZHOU P.R.C.

NO.69 HEFENG ROAD, GUANGZHOU,CHINA

EXTENSION / COMBUSTIBLE FLOOR PROTECTION: IF

INSTALLED ON A COMBUSTIBLE FLOOR, UNIT MUST BE

PLACED ON A NON-COMBUSTIBLE FLOOR PROTECTOR

EXTENDING 6” IN FRONT.

- DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE

SERVING ANOTHER APPLIANCE.

- REPLACE GLASS WITH ONLY CERAMIC GLASS.

DANGER: RISK OF ELECTRICAL SHOCK. DISCONNECT

TPSI35

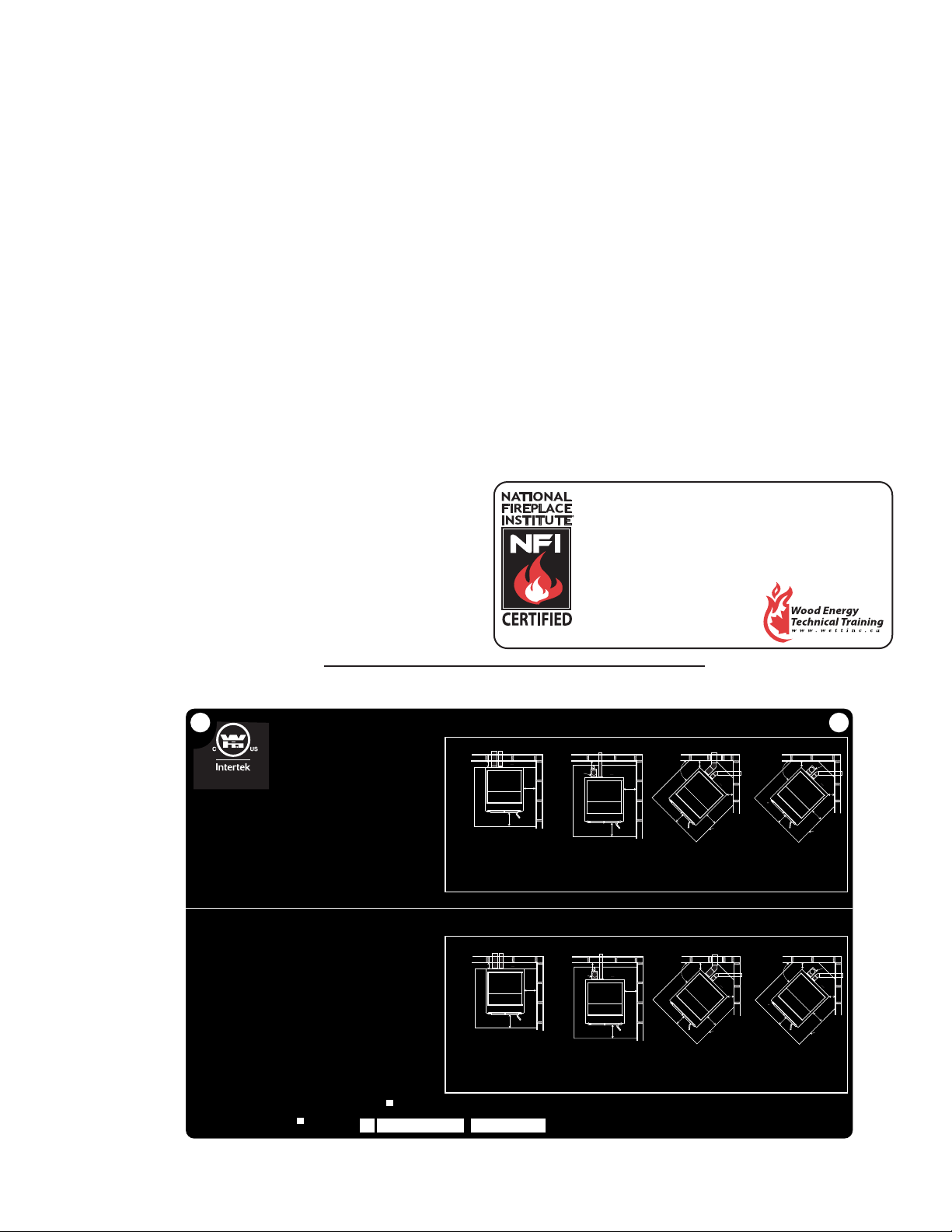

We suggest that our pellet hearth

products be installed and serviced by

professionals who are certified in the U.S.

by the National Fireplace Institute

as NFI Pellet Specialists or who are

certified in Canada by

Wood Energy Technical

www.nficertified.org

MODEL TPS35 LISTED PELLET FUEL BURNING ROOM HEATER TESTED TO:

Straight Installation Corner Installation

3”

Through

Wall

Installation

Floor

Protection

MINIMUM CLEARANCES TO COMBUSTIBLE

SIDE 6”

REAR 3”

CORNER 2”

CEILING 48”

U.S. ENVIROMENTAL PROTECTION AGENCY Certified to comply with July 1992 Particulate Emission Standards

MODÈLE TPS35 APPAREIL DE CHAUFFAGE AUX GRANULES HOMOLOGUÉ TESTÉ SELON LES

Installations

à travers le

mur

Protection de

plancher

DÉGAGEMENTS MINIMAUX AUX MATÉRIAUX COMBUSTIBLES

CÔTÉ 6”

ARRIÈRE 3”

COIN 2”

PLAFOND 48”

Certifié conforme à la norme d'émanation de particules de juillet 1992 du U.S. ENVIROMENTAL PROTECTION AGENCY

DATE CODE / DE DATE

6”

6”

Installation droite

3”

6”

6”

Training (WETT).

66.1A

ASTM E 1509, ULC/ORD C1482-M90, ULC S627

3”

2”

Interior

Vertical

Vent

Tee

Floor

Protection

6”

6”

NORMES : ASTM E 1509, ULC/ORD1482-M90, ULC S627

3”

2”

Té

Évents

verticaux

intérieurst

Protection de

plancher

6”

6”

2”

Through

Wall Vents

45°

Elbow

45°

2”

6”

6”

Floor Protection

INPUT RATING

MIN 1.5 LB/HR

MAX 4.5 LB/HR

ELECTRICAL RATING

120V 3.6A 60HZ

Installation de coin

Évents à

travers le

mur

Coude

2”

45°

45°

2”

6”

6”

Protection de

plancher

IDÉBIT D’ALIMENTATION

MIN. 1.5 LB/H

MAX. 4.5 LB/H

CARACTÉRISTIQUES ÉLECTRIQUES

120 V 60 Hz

Interior

Vertical

Vent

Évents

verticaux

intérieurs

6”

6”

2”

2”

Tee

6”

Floor Protection

Té

6”

Protection de

plancher

W385-0498

®

(NFI)

2”

2”

Stove rating plate illustrated

For rating plate location, see “INSTALLATION OVERVIEW” section.

W415-0865 / 04.07.10

Page 10

10

3.0 INSTALLATION PLANNING

!

WARNING

READ ENTIRE MANUAL BEFORE YOU INSTALL OR USE THIS HEATER. FAILURE TO FOLLOW THE

INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH.

USE ONLY WOLF STEEL APPROVED OPTIONAL ACCESSORIES AND REPLACEMENT PARTS WITH

THIS APPLIANCE. USING NON-LISTED ACCESSORIES AND REPLACEMENT PARTS (BLOWERS,

DOORS, LOUVRES, TRIMS, GAS COMPONENTS, VENT COMPONENTS, ETC.) COULD RESULT IN A

SAFETY HAZARD AND WILL VOID THE LIMITED LIFETIME WARRANTY.

Check with local building offi cials for any permits required for installation of this pellet appliance and notify your

insurance company before proceeding with installation.

Before installing we recommend placing the appliance outside and load 5 pounds of pellets inside the hopper.

Plug the appliance in and let it run on HIGH until the pellets run out. This will cure the paint and burn off most

of the oils on the steel, thereby minimizing any smell inside the home.

3.1 INSTALLATION OPTIONS

Stove model:

To install in a Residential or Mobile Home see "MOBILE HOME INSTALLATION" section. For alcove

installations see "ALCOVE INSTALLATION REQUIREMENTS" section. For horizontal vent or vertical vent see

"VENTING" section. Outside air, see "OUTSIDE AIR" section.

68.1

Insert model:

To install as an insert into an existing masonry appliance or factory built appliance see "VENTING" section. To

install into a combustible enclosure, see "INSTALLATION INTO A COMBUSTIBLE ENCLOSURE" section.

3.2 APPLIANCE PLACEMENT

Have an authorized dealer install the appliance. If you install the appliance yourself, have your dealer review

your installation plans and/or installation.

Draw out a detailed plan of the installation including dimensions and verify the dimensions with the requirements listed in this manual.

You may wish to adjust the appliance position slightly to ensure the vent does not intersect with a framing

member. Appliance must be positioned so that no combustibles are within, or can swing within (e.g. drapes,

doors), 48” of the front of the appliance.

67.1A

W415-0865 / 04.07.10

Page 11

3.3 MINIMUM CLEARANCE TO COMBUSTIBLES

!

WARNING

DO NOT INSTALL INTO ANY AREA HAVING LESS THAN 48" (CEILING TO APPLIANCE BOTTOM,

EXCLUDING HEARTH HEIGHT).

3.3.1 STRAIGHT INSTALLATION

Through the Wall Installations complete

with outside air

3”

Interior Vertical Vents

3”

2”

11

6”

6”

3.3.2 CORNER INSTALLATION

Through the Wall Vents complete with outside air Interior Vertical Vents

45°

6”

2”

6”

Floor Protection

6”

6”

Floor Protection

6”

2”

2”

45°

6”

2”

6”

6”

Floor Protection

6”

Floor Protection

NOTE: If interior vertical pellet vent is used, the clearance to the back wall is determined by the

upward-turning elbow or "Tee". It will vary in depth depending on the brand of pellet vent used (it

is approximately 5"). Before placing the appliance, connect the elbow or "Tee" and allow for the

minimum 3" clearance to the combustible wall.

W415-0865 / 04.07.10

2”

Page 12

12

3.4 FLOOR PROTECTION REQUIREMENTS

The appliance must be installed on a non-combustible fl oor protector extending the full depth of the appliance

and extending a minimum 6" in front and on either side (minimum .018" thick - 26 gauge) of the fuel loading

and ash removal openings.

The fl oor protector must extend under and 2" beyond each side and rear of a "Tee" (if used).

NOTE: Floor protection is required for spark and ash shielding, but not for limiting fl oor temperatures

from the radiant heat of the appliance. The appliance was designed and safety tested so that without

any protection, the fl oor would not overheat.

Refer to local building codes for suitable fl oor protection materials.

3.5 OUTSIDE AIR

Available from your Authorized Dealer (114KT)

Outside air must not be drawn from an enclosed space (garage, unventilated crawl space).

NOTE: Wolf Steel Ltd. strongly suggests using outside air for all residential installations, especially for

those that are energy effi cient, air-tight homes.

Outside air supply must not be over 15' long.

Outside air vents must be made with 1 3/4" diameter or larger metal or aluminum duct with a metal screen

attached to the end to keep out rodents (P.V.C. or other materials may not be used).

The outside air inlet must not be above or within 12" of the chimney termination, must have a rain cap or downturned elbow to prevent the water from entering and be located so that it will not become plugged by snow or

other material.

Outside air is required for all combustible built-in enclosure installations.

3.6 MOBILE HOME INSTALLATION

DO NOT INSTALL IN A SLEEPING ROOM.

THE STRUCTURAL INTEGRITY OF THE MANUFACTURED HOME FLOOR, WALL, AND CEILING ROOF

MUST BE MAINTAINED.

Installation into a manufactured home or mobile home should be installed in

accordance with the Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280, in the United States or the Mobile Home Standard,

CAN/CSA Z240 MH Series, in Canada.

The appliance must be grounded to the steel chassis of the mobile home

(Some states do not require this; check with your local building department).

!

WARNING

W415-0865 / 04.07.10

STOVE

ILLUSTRATED

29.4A

Page 13

4.0 STOVE ASSEMBLY

4.1 CONTROL PANEL ASSEMBLY

13

2

1

3

4.1.1 Remove the two screws securing the shipping bracket control panel to the fi rebox.

4.1.2 Remove the four screws securing the control panel to the shipping bracket and discard the shipping

bracket.

4.1.3 Secure the control panel to the right side panel (stove model) or right side fl ashing (insert model) using

the four screws removed in step 2.

W415-0865 / 04.07.10

Page 14

14

4.2 STOVE SIDE AND REAR PANEL ASSEMBLY

4.2.1 Align the slots on the panels with the holes on the rear of the fi rebox and attach with two screws per

panel.

4.2.2 The front of the panels are held by the three magnets on the side of the fi rebox. Ensure top of panel

and outer top are parallel when complete.

4.2.3 Prior to installing the rear panel, remove the receptacle from the bracket and disconnect from the wire

harness. (NOTE: Label the wires when disconnecting).

4.2.4 Attach the receptacle to the rear panel and reconnect the wires.

4.2.5 Secure the rear panel with the four screws provided.

W415-0865 / 04.07.10

Page 15

4.3 STOVE HOPPER DOOR INSTALLATION

15

4.3.1 Align the holes in the hopper lid with the holes in the top

of the fi rebox and use the two shoulder bolts to secure in

place as illustrated.

4.3.2 Install the two bumpers over the small punched holes in

the hopper lid.

HOPPER DOOR INTERLOCK: Your appliance is equipped

with a micro switch in the hopper assembly that will disable

the auger when the hopper door is opened. Closing the door

enables the auger, allowing pellets to feed again.

4.4 INSERT HOPPER DOOR INSTALLATION

4.4.1 Align the holes in the front and rear hopper lid with the

holes in the top of the fi rebox and use the shoulder bolts

provided to secure in place as illustrated.

HOPPER DOOR INTERLOCK: Your appliance is equipped

with a micro switch in the hopper assembly that will disable

the auger when the hopper door is opened. Closing the door

enables the auger, allowing pellets to feed again.

BUMPERS

W415-0865 / 04.07.10

Page 16

16

5.0 VENTING

5.1 TYPE OF VENT

Must be an approved 3" or 4" diameter Type "L" or "PL" vent, vented to the outside or connect the vent to a

factory built type "A" chimney using an adaptor; and/or stainless steel chimney liner for masonry appliance

installations. Use 4" diameter vent if vent or liner height is over 15' or if installation is over 4,000' above sea

level.

5.2 INSTALLING THE PELLET VENT

PELLET VENT MUST MAINTAIN A MINIMUM 3" CLEARANCE TO ANY COMBUSTIBLE (INSTALL VENT

AT CLEARANCES SPECIFIED BY THE VENT MANUFACTURER).

DO NOT CONNECT THE PELLET VENT TO A VENT OR CHIMNEY SERVING ANY OTHER APPLIANCE

DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF THIS UNIT.

!

WARNING

OR HEATER.

The vent must have a support bracket every 5’ when on

the exterior wall. To achieve optimum performance, keep

vent runs as short as possible, especially on horizontal

installations.

MAXIMUM VENTING: Maximum venting height is 33’.

Maximum horizontal vent run is 10’. Use no more than

180° of elbows (two 90’ elbows, or two 45’ elbows and

one 90’ elbow, etc), excluding the tee and the termination.

VENT INSTALLATION: Termination must exhaust above

the air inlet elevation, and parallel or above the exhaust

output of the pellet appliance. It is recommended that at

least 3’ of vertical pipe be installed to create some natural

draft. This is to help prevent the possibility of smoke or

odour entering the home during the appliance shut down

or in the event of a power outage. Horizontal sections

must have a 1/4” rise every 12” of travel if longer than 3’.

The pellet vent connections must be sealed with HI-Temp

RTV Silicone and screwed together with at least 3 3/8”

long stainless steel screws. Seal each vent section by

injecting a liberal amount of 500°F (260°C) RTV silicone

sealant into the gap. We recommend sealing the outside

of the vent connections to permit easier access when

servicing.

Use 4” diameter

“L” vent if

venting in this

region.

Use 3” or 4”

diameter “L”

vent if venting

in this region.

33’

30’

25’

20’

15’

10’

5’

0’

5.3 VENTING THE PELLET APPLIANCE

Use an approved wall thimble when passing the vent through walls and a ceiling support / fi restop spacer when

passing the vent through ceilings (maintain a 3" clearance to any combustibles).

W415-0865 / 04.07.10

0’

7.5A

5’

10’

Page 17

5.4 PELLET VENT TERMINATION

The vent termination must have an approved cap (to prevent water from entering) or a 45° downturn.

If the termination is located on a windy side of the house, a shield is recommended to prevent soot from

building up on the side of the house.

Horizontal terminations must protrude 12" from the wall, vertical terminations require a minimum 24" above the

highest point that it penetrates through the roof.

Depending on pellet quality, vent confi guration and air settings, black soot may occur on the terminal wall.

5.5 VENT TERMINAL CLEARANCES

17

E

C

K

J

G

I

F

H

D

B

B

A

L

E

NOTE: Illustration dimensions are to the center of

the exhaust exit point of the vent.

CLEARANCES

A 24” Clearance above grade, veranda porch, deck or balcony. (Including vegetation and mulch)

B

C 18”

D 0” Clearance to an outside corner wall.

E 3”

F 9” Clearance to a non-mechanical air supply inlet to the building or a combustion air inlet to any other appliance.

G 3” Clearance to a mechanical air supply inlet.

H 7’ ** Clearance above a paved sidewalk or paved driveway located on public property.

I 12” ** Clearance under a veranda, porch, deck or balcony.

J 24” Clearance above the roof.

K 2’ Clearance from an adjacent wall including neighbouring buildings.

L

* Recommended to prevent condensation on windows and thermal breakage

** This is a recommended distance. For additional requirements check local codes.

48” Clearance beside or below any windows or doors that open.

12” * Clearance above any window or door that opens.

Vertical clearance to ventilated soffi t located above the terminal within a horizontal distance of 2 feet

from the center line of the terminal.

Clearance to an inside combustible corner wall or protruding combustible obstructions (vent chase,

etc.)

3’ within a

height of 15 feet

above the meter

/ regulator as-

sembly

Clearance to each side of center line extended above natural gas or propane meter / regulator assembly

or mechanical vent.

12.7A

W415-0865 / 04.07.10

Page 18

18

5.6 STOVE VENTING INSTALLATION EXAMPLES

5.6.1 HORIZONTAL TERMINATION (THROUGH WALL)

3” Minimum

6”

Minimum

Floor

Protection

11 3/8”

16 5/8”

12” Minimum

Wall

Thimble

5’ Maximum

Outside Air

(Recommended)

5.6.2 VERTICAL RISE HORIZONTAL TERMINATION (THROUGH WALL)

Wall Thimble

Outside Air

(Recommended)

6”

Minimum

Floor

Protection

3”

2”

11 3/8”

16 5/8”

W415-0865 / 04.07.10

Page 19

5.6.3 VERTICAL TERMINATION

Storm Collar

19

Vertical Cap

Roof Flashing

Ceiling Support

Floor Protection

5.6.4 CLASS A CHIMNEY RETROFIT

Vertical Cap

Storm Collar

Vent must maintain 3”

clearance to combus-

tibles.

3”

2”

Outside air (Recommended)

(Installation showing inlet of out-

side air in ventilated crawl space)

Roof Flashing

Class A Chimney

Ceiling Support

Floor Protection

Vent must maintain

3” clearance to

combustibles.

3”

2”

Outside air

(Recommended)

(Installation showing inlet of outside

air in ventilated

crawl space)

W415-0865 / 04.07.10

Page 20

20

ect

6

Co

5.6.5 HEARTH MOUNT INSTALLATION

Chimney Cap

Pellet

Liner

Clean-out

ut

tee

Vertical Cap

Storm Collar

Pellet

Vent

torm

Flue Cover

6”

MIN

Floor Protection

Floor Prot

Bring outside air to the stove

Outside Air (Recommended)

W415-0865 / 04.07.10

Page 21

5.7 INSERT VENTING INSTALLATION EXAMPLES

r

o

Cap

5.7.1 TYPICAL EXISTING MASONRY INSTALLATION

!

WARNING

DO NOT REMOVE BRICKS OR MORTAR FROM THE FIREPLACE.

21

Prior to installation:

When installing the insert into a masonry fi replace, do not

remove any bricks or masonry. Do not weaken the structure,

or reduce the protection for combustible materials to less then

that required by the National Building Code. Bolted or screwed

together pieces (smoke shelf / defl ectors) may be removed, but

must be able to be re-installed if the heater was removed. External trim pieces, which do not affect the operation of the fi replace,

may be removed provided they are available to be re-installed in

event the heater is removed.

A warning label must be attached to the back wall of the fi replace

stating that “This fi replace has been altered to accommodate a

fi replace insert and must be re-inspected by a qualifi ed person

prior to re-use as a fi replace”.

A non-combustible hearth must cover the fl ooring underneath, as

well as extend a minimum of six inches in front and to both sides

of the heater.

Clean all ashes out of the inside of the fi replace. Make sure that

the chimney and fi replace are free of cracks, loose mortar, creo-

sote deposits, blockage or other signs of deterioration.

If necessary, have any repair work done by a qualifi ed profes-

sional before installing the heater.

Cover Plate

Vertical Cap

Storm Collar

(Recommended)

rm Colla

t

Pellet

Liner

Flue

Cover

Outside Air

A. Remove the fi replace damper or fasten it permanently open.

B. Measure the throat of the fi replace and mark this shape on a piece of 24 gauge sheet metal (fl ue

cover). Cut a hole sized for the pellet liner to lie directly below the fi replace fl ue opening. Allow two

inches of material for a fl ange on all sides and cut to these measurements. Bend down the fl anges. If

you have never done this before, it might be a good idea to make a cardboard pattern and test it fi rst.

Fasten this fl ue cover in position as high as possible with two masonry screws per side through the

fl anges into the fi replace.

C. If you plan on connecting outside air it is recommended to do so at this time.

D. Install fl oor protection if necessary.

E. Connect the pellet vent with a clean out tee to the back of the insert. Refer to manufacturer’s instal-

lation instructions to see “REAR TO TOP VENT CONVERSION INSTRUCTIONS” section and the

“GENERAL VENTING” section.

F. Run a liner down the chimney and connect to tee.

G. Position the insert in it’s fi nal location.

H. Pull the excess length of liner out through the top of the chimney. Trim the excess liner, install the cap

and cap the chimney.

62.3A

W415-0865 / 04.07.10

Page 22

22

5.7.2 FACTORY BUILT FIREPLACE

Prior to installation:

Do not weaken the structure, or reduce the protection for

combustible materials to less then that required by the National

Building Code. Bolted or screwed together pieces (smoke shelf /

defl ectors) may be removed, but must be able to be re-installed

if the heater was removed.

External trim pieces, which do not affect the operation of the

fi replace, may be removed provided they are available to be reinstalled in event the heater is removed.

A warning label must be attached to the back wall of the fi re-

place stating that “This heater has been altered to accommodate a fi replace insert and must be re-inspected by a qualifi ed

person prior to re-use as a factory built fi replace”.

A non-combustible hearth must cover the fl ooring underneath,

as well as extend a minimum of six inches in front and to both

sides of the heater.

Clean all ashes out of the inside of the heater. Make sure that

the chimney and fi replace are free of cracks, loose mortar, creo-

sote deposits, blockage or other signs of deterioration.

Storm

Collar

The smoke

shelf, damper

and baffles may

be removed

Vertical

Cap

Roof

Flashing

If necessary, have any repair work done by a qualifi ed profes-

sional before installing the heater.

A. Remove the fi replace damper or fasten it permanently

open.

B. Measure the throat of the fi replace and mark this shape on a piece of 24 gauge sheet metal (fl ue

cover). Cut a hole sized for the pellet liner to lie directly below the fi replace fl ue opening. Allow two

inches of material for a fl ange on all sides and cut to these measurements. Bend down the fl anges. If

you have never done this before, it might be a good idea to make a cardboard pattern and test it fi rst.

Fasten this fl ue cover in position as high as possible with two masonry screws per side through the

fl anges into the heater.

C. If you plan on connecting outside air it is recommended to do so at this time.

D. Install fl oor protection if necessary.

E. Connect the pellet vent with a clean out tee to the back of the insert. Refer to manufacturer’s instal-

lation instructions to see “REAR TO TOP VENT CONVERSION INSTRUCTIONS” section and the

“GENERAL VENTING” section.

F. Run a liner down the chimney and connect to tee.

G. Position the insert in it’s fi nal location.

Do not remove any part that would

alter the integrity in any way.

Floor Protection

H. Pull the excess length of liner out through the top of the chimney. Trim the excess liner, install the cap

and cap the chimney.

80.1

W415-0865 / 04.07.10

Page 23

6.0 FRAMING (INSERT ONLY)

!

WARNING

RISK OF FIRE!

IN ORDER TO AVOID THE POSSIBILITY OF EXPOSED INSULATION OR VAPOUR BARRIER COMING

IN CONTACT WITH THE APPLIANCE BODY, IT IS RECOMMENDED THAT THE WALLS OF THE APPLI-

ANCE ENCLOSURE BE “FINISHED” (IE: DRYWALL / SHEETROCK), AS YOU WOULD FINISH ANY

OTHER OUTSIDE WALL OF A HOME. THIS WILL ENSURE THAT CLEARANCE TO COMBUSTIBLES IS

MAINTAINED WITHIN THE CAVITY.

DO NOT NOTCH THE FRAMING AROUND THE APPLIANCE STAND-OFFS. FAILURE TO MAINTAIN AIR

SPACE CLEARANCE MAY CAUSE OVER HEATING AND FIRE. PREVENT CONTACT WITH SAGGING

OR LOOSE INSULATION OR FRAMING AND OTHER COMBUSTIBLE MATERIALS. BLOCK OPENING

INTO THE CHASE TO PREVENT ENTRY OF BLOWN-IN INSULATION. MAKE SURE INSULATION AND

OTHER MATERIALS ARE SECURED.

WHEN CONSTRUCTING THE ENCLOSURE ALLOW FOR FINISHING MATERIAL THICKNESS TO MAIN-

TAIN CLEARANCES. FRAMING OR FINISHING MATERIAL CLOSER THAN THE MINIMUMS LISTED

MUST BE CONSTRUCTED ENTIRELY OF NON-COMBUSTIBLE MATERIALS. MATERIALS CONSISTING

ENTIRELY OF STEEL, IRON, BRICK, TILE, CONCRETE, SLATE, GLASS OR PLASTERS, OR ANY COM-

BINATION THEREOF ARE SUITABLE. MATERIALS THAT ARE REPORTED AS PASSING ASTM E 136,

STANDARD TEST METHOD FOR BEHAVIOUR OF MATERIALS IN A VERTICAL TUBE FURNACE AT

750°C AND UL763 SHALL BE CONSIDERED NON-COMBUSTIBLE MATERIALS.

23

MINIMUM CLEARANCE TO COMBUSTIBLES MUST BE MAINTAINED OR A SERIOUS FIRE HAZARD

COULD RESULT.

THE APPLIANCE REQUIRES A MINIMUM ENCLOSURE HEIGHT. MEASURE FROM THE APPLIANCE

BASE.

IF STEEL STUD FRAMING KITS WITH CEMENT BOARD ARE PROVIDED, THEY MUST BE INSTALLED.

71.1

W415-0865 / 04.07.10

Page 24

24

6.1 INSTALLATION INTO A COMBUSTIBLE ENCLOSURE

!

WARNING

OUTSIDE AIR IS MANDATORY FOR A COMBUSTIBLE BUILT-IN ENCLOSURE INSTALL.

When installing the insert as a "Built-in" appliance, it is important to maintain the clearances to combustibles,

see "MINIMUM CLEARANCE TO COMBUSTIBLES" section.

A non-combustible hearth must cover the fl ooring underneath, as well as, a minimum of six inches in front and

to both sides of the appliance.

6.1.1 Install fl oor protection.

6.1.2 Frame structure maintaining minimum clearances. Locate and frame openings for both the exhaust

and outside air. Outside air is mandatory for enclosure installations.

6.1.3 Refer to vent manufacturer's installation instructions and to "GENERAL VENTING" section. Connect

the vent.

6.1.4 Install fl ashing, see "FLASHING INSTALLATION" section.

6.1.5 Consideration must be taken during installation that removal of the insert is necessary for inspection

and annual maintenance. Install the vent cap.

3 1/2” MAX

40”

MINIMUM

ENCLOSURE

HEIGHT

3 1/2”

MAX

17”

Non

combustible

floor protection.

This protection must

offer an R value of 0.4 (two

layers of 1/2” thick cement board, total 1” with each layer rated with an

R value of 0.2).

33”

27”

Centerline of

heater opening

8”

4 1/4”

7 5/8”

2 3/4”

For temperature requirements, the enclosure space around and

above the heater must be left unobstructed.

W415-0865 / 04.07.10

Page 25

6.2 MINIMUM ENCLOSURE CLEARANCES

6 3/8”

MIN.

40” MIN.

27” MIN.

25

2” MIN.

3” all around (Refer to vent

manufacturer’s instructions)

6”

Non-combustible

floor protection

6.3 MINIMUM CLEARANCE TO COMBUSTIBLES

Side wall to appliance 8"

Mantel to top of appliance 8"

Top facing to appliance 6 3/8"

Side facing to appliance 6"

Floor protection* 6"*

* Floor Protection: Minimum 6" in front of door

and to either side.

10”

Side Wall

7 1/8”

1 7/8”

10” Mantel

8” MIN

8”

MIN

6”

6”

W415-0865 / 04.07.10

Page 26

26

6.4 MINIMUM MANTEL CLEARANCES

RISK OF FIRE, MAINTAIN ALL SPECIFIED AIR SPACE CLEARANCES TO COMBUSTIBLES. FAILURE

TO COMPLY WITH THESE INSTRUCTIONS MAY CAUSE A FIRE OR CAUSE THE APPLIANCE TO

OVERHEAT. ENSURE ALL CLEARANCES (I.E. BACK, SIDE, TOP, VENT, MANTEL, FRONT, ETC.) ARE

CLEARLY MAINTAINED.

WHEN USING PAINT OR LACQUER TO FINISH THE MANTEL, THE PAINT OR LACQUER MUST BE

HEAT RESISTANT TO PREVENT DISCOLOURATION.

16” MANTEL

14”

12”

10”

14”

12”

10”

8”

!

WARNING

73.1

6.5 ALCOVE INSTALLATION REQUIREMENTS (MINIMUM)

35”

30”

48”

STOVE

Minimum Alcove Dimensions

W415-0865 / 04.07.10

Page 27

7.0 FINISHING

7.1 INSTALLING VIEWING DOOR

GLASS MAY BE HOT, DO NOT TOUCH GLASS UNTIL COOLED.

THE DOOR LATCHES ARE PART OF A SAFETY SYSTEM AND MUST BE PROPERLY ENGAGED. DO

NOT OPERATE THE APPLIANCE WITH LATCHES DISENGAGED.

BEFORE DOOR IS REMOVED TURN THE APPLIANCE OFF AND WAIT UNTIL APPLIANCE IS COOL TO

THE TOUCH. DOORS ARE HEAVY AND FRAGILE SO HANDLE WITH CARE.

The main viewing door has been boxed separate from the appliance, but MUST

be installed before burning the appliance.

7.1.1 Align the pins on the door to the bushing on the left side of the

appliance. Lower into place until both bushings touch.

!

WARNING

27

75.2

W415-0865 / 04.07.10

Page 28

28

7.2 DOOR HANDLE INSTALLATION

FRONT VIEW

DOOR

DOOR HANDLE

LATCH

LOCK

WASHER

NUT

DOOR

HANDLE

7.3 DECORATIVE INSET

SPRING

WASHER

SPACER

NOTE: Position of

door handle latch.

W415-0865 / 04.07.10

Page 29

7.4 FLASHING INSTALLATION

7.4.1 Secure the left fl ashing to the left side with the three screws provided. Repeat for the right side.

7.4.2 Side panels are attached to the fi rebox by the three magnets per side.

7.4.3 Lower the top panel, aligning the slots in the top panel with the holes in the side panel.

7.4.4 Secure the top panel by to the side panels with the screws and washers provided. NOTE: Make sure

the side panels are tight to the fi rebox before securing the screws.

7.4.5 The fl ashing can be adjusted forward and

backward by re-adjusting the fl ashing

along the magnets.

7.4.6 Slide trim over

fl ashing.

29

TRIM

RIGHT

SIDE

TOP

PANEL

LEFT

SIDE

LEFT

FLASHING

RIGHT

FLASHING

W415-0865 / 04.07.10

Page 30

30

8.0 WIRING DIAGRAM

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER WATER. CALL A QUALIFIED

SERVICE TECHNICIAN IMMEDIATELY TO HAVE THE APPLIANCE INSPECTED FOR DAMAGE TO THE

RISK OF ELECTRICAL SHOCK OR EXPLOSION. DO NOT WIRE 110V TO THE VALVE OR TO THE

APPLIANCE WALL SWITCH. INCORRECT WIRING WILL DAMAGE CONTROLS.

ALL WIRING SHOULD BE DONE BY A QUALIFIED ELECTRICIAN AND SHALL BE IN COMPLIANCE

WITH LOCAL CODES. IN THE ABSENCE OF LOCAL CODES, USE THE CURRENT CSA22.1 CANADIAN

ELECTRIC CODE IN CANADA OR THE CURRENT NATIONAL ELECTRIC CODE ANSI/NFPA NO. 70 IN

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RAN OUT,

WITH THE GLASS DOOR OPENED OR REMOVED.

!

WARNING

ELECTRICAL CIRCUIT.

THE UNITED STATES.

69.2

HIGH

LIMIT

YELLOW

YELLOW

WHITE

WHITE

CONVECTION

BLOWER

ORANGE

WHITE

POWER

CORD

BLACK

BLACK

WHITE

COMBUSTION

BLOWER

RED

ORANGE

GREEN

BLUE

IGNITOR

RED

WHITE

ORANGE

RED

HOPPER

SWITCH

RED

AUGER

MOTOR

RED

GREY

PURPLE

LOW LIMIT

VACUUM

SWITCH

YELLOW

BLACK

GREY

W415-0865 / 04.07.10

Page 31

9.0 OPERATING INSTRUCTIONS

9.1 PROPER PELLET LOADING

Before loading pellets into the hopper fi rst transfer the pellets from it’s original plastic bag to a metal bucket.

Keep in mind that the auger stops when the lid is opened. If the lid is opened for several minutes, the fi re may

extinguish.

NOTE: If the pellets are kept in the plastic bag, the bag may come in contact with the appliance causing

the bag to melt and the pellets to spill.

DO NOT load pellets into the hopper if they have been exposed to moisture. Moisture can cause pellets

to swell and cause blockage in the feed system. Thoroughly dry pellets before placing into hopper.

9.2 PRE-START CHECK

Before installing this appliance we recommend a “PRE-BURN” inspection to help burn off the odours that are

associated with the fi rst burn. If possible, move the appliance outside and add approximately 5 lbs of pellets

into the hopper. Plug the power cord into a typical wall receptacle.

The appliance is equipped with a control board that has been shipped in manual mode.

When fi rst starting a new pellet appliance, or when you completely empty the hopper of pellets you can press

and hold the prime button to get the pellets into the burn pot quicker.

● Slide the "ON/OFF" button to "ON":

This starts the ignition cycle.

31

47.10

● The auger comes on and runs for approximately 3 minutes.

● The igniter comes on and will stay on until proof of fi re determined by the appliance temperature.

● At anytime during the ignition cycle, once proof of fi re is met, the appliance goes into normal operating

mode.

NOTE: Flame should appear in the burn pot within 3 to 7 minutes from commencing the ignition cycle.

The ignition cycle should end in approximately 12 to 15 minutes. At this point adjustments to feed rate

can be made or the appliance will revert to the previous setting. If proof of fi re is not established in 15

minutes, the appliance will shut down and will need to be turned back on again. If the appliance shuts

down, empty the pellets from the burn pot into an empty non-combustible container and restart. Never

empty pellets from burn pot back into hopper.

9.3 LIGHTING APPLIANCE MANUALLY

!

APPLIANCE MAY BE HOT.

OTHER THAN PLACING A HANDFUL OF PELLETS IN THE BURN POT FOR LIGHTING MANUALLY,

NEVER FEED PELLETS THROUGH THE GLASS VIEWING DOOR. AN "OVERFIRE" CONDITION

COULD OCCUR, IF MORE PELLETS ENTER THE FIREBOX THAN WHAT THE FEED TUBE CAN

DELIVER. PELLETS MUST ONLY BE BURNED WITHIN THE BURN POT.

WARNING

NEVER USE GASOLINE TYPE LANTERN FUEL, KEROSENE, CHARCOAL LIGHTER FLUID, OR

SIMILAR LIQUIDS TO START OR ‘FRESHEN UP’ A FIRE IN THIS APPLIANCE. KEEP ALL SUCH

LIQUIDS WELL AWAY FROM THE APPLIANCE WHILE IT IS IN USE.

Your appliance can be lit manually without using the automatic igniter by following the procedure below.

• Press the ON / OFF button.

• Place a “handful” of pellets into the burn pot.

• Cover with a small amount of approved (non-volatile) fi re starter gel.

• Light fi re starter with a match and close the viewing door.

47.11

W415-0865 / 04.07.10

Page 32

32

9.4 LIGHTING INSTRUCTIONS

After fi lling the hopper with pellets, switch the control to manual so that you have full control of the appliance

until you have familiarized yourself with its functions.

Do not try to operate your appliance with the viewing door or hopper lid open. Safety switches will disable the

pellet feed auger.

9.4.1 Slide the "ON/OFF" button "ON" to initiate the ignition cycle.

9.4.2 Once the ignition cycle has ended (approximately 12 to 15 minutes) adjustments can be made to the

control.

9.5 CONTROLS

INDICATOR LIGHTS

Solid

- Indicates set feed rates.

Flashing

- Indicates an operation failure.

HEAT ADJUSTMENT

Increases or decreases the heat

level.

PRIME

Speed feeding of pellets into the burn

pot.

OPERATING MODE

Sets the appliances operating

mode.

ON / OFF

Used to turn the appliance on or

off.

W385-0500

AUTO / MANUAL

This switch is used to select the operating mode.

MANUAL: Sliding the switch down to manual will allow you to manually select the heat level. In

manual mode the appliance will run at your desired settings indefi nitely, until you manually turn the

appliance off or the appliance runs out of pellets.

AUTO: Slide the switch to the top position (AUTO). The auto mode operates using either a wall or a

remote control thermostat. If the thermostat does not call for heat in a 60 minute period the appliance

will turn off completely. When the thermostat does call for heat, it will initiate an ignition cycle.

ON / OFF

Use this button to turn the appliance on and off.

HEAT LEVEL

Pressing the heat level button will increase the heat level one setting. Pressing the heat level button down will

decrease the heat level one setting. The red lights at the top left of the control will indicate the heat setting 1

through 3.

PRIME

Pressing and holding this button will turn the auger continuously which increases the feed of pellets into the

burn pot. This is convenient when using the appliance for the fi rst time or when you have completely emptied

the hopper and need to restart the appliance.

W415-0865 / 04.07.10

Page 33

9.6 CONTROL ADJUSTMENT

FEED TRIM

Both the combustion fan speed and the feed rate have been factory set but may need to be adjusted (trimmed)

on site. Due to the variables (i.e. vent size, length and pellet quality), the factory settings may not be ideal for

every installation. To help keep the fl ame from extinguishing on the minimum heat level, the feed rate can be

trimmed when in normal operation (after the 15 minute ignition cycle). Depress and hold the prime button while

you push the heat level button. This will slightly increase the amount of fuel being fed into the burn pot. When

trimming the feed rate for the fi rst time, the LED’s will display the (#3 and #1 light) indicating that the appliance

is factory set to (#2) with the ability to increase up one level (#3) or decrease down one level (#1) the length

of time between the prime cycle. NOTE: The light that isn't on indicates the trim setting of the appliance,

trimmed down, neutral or trimmed up.

BLOWER TRIM

Similar to the feed rate, it may be necessary to trim the speed of the

combustion blower. Due to specifi c installations, it may be necessary

to increase or decrease the amount of air moving through the burn pot

to achieve maximum effi ciency. In order to adjust the blower trim you

need access to the back of the control panel. Start by either removing

the side panel (pedestal) or behind the fl ashing (insert), using a small

screw driver turn the screw to adjust the blower (clockwise to increase/

counter-clockwise to decrease) and reinstall the panel / fl ashing that was

removed. NOTE: It is recommended to adjust the blower trim prior to

installing the insert.

9.7 INSTALLING A THERMOSTAT

33

BLOWER

TRIM

An optional millivolt thermostat is available to help keep the room

temperature constant.

NOTE: The thermostat must be installed by a qualifi ed installer.

● Disconnect the power supply.

● Remove the right side panel to gain access to the rear of the

control panel.

● Strip and connect the two thermostat wires to the two screw terminals on the back of the control panel.

NOTE: The control must be in AUTO to control the appliance with a thermostat.

9.8 SHUTDOWN INSTRUCTIONS

Slide the "ON/OFF" button to "OFF". Your appliance will cycle down and the blower will remain operating until

your appliance has cooled.

SCREW

TERMINALS

W415-0865 / 04.07.10

Page 34

34

10.0 NORMAL OPERATING SOUNDS

EXHAUST BLOWER

The flow of exhaust gases may

create a low-pitched hum. As

the pellet feed rate is altered

this sound will change.

CONVECTION BLOWER

A low hum might be heard due to the high

efficiency fan, especially on high. As the

fan dial is turned this noise will change.

AUGER MOTOR

An irregular buzz of the motor

running might be heard when

pellets are being fed.

Expansion / contraction noises during heating up and cooling down cycles are normal and are to be

expected.

W415-0865 / 04.07.10

BURN POT

A light clicking sound

might be heard as the

pellets are fed into

the burn pot.

Page 35

11.0 MAINTENANCE

11.1 DAILY (WHENEVER USING THE APPLIANCE)

!

WARNING

THE FRONT OF THE HEATER BECOMES VERY HOT DURING OPERATION. LET THE HEATER COOL

COMPLETELY BEFORE CONDUCTING SERVICE.

11.1.1 DISPOSAL OF ASHES

Ashes should be placed in a metal container with a tight fi tting lid. The container should be placed on a non-

combustible fl oor, well away from combustible materials, pending fi nal disposal. If ashes are disposed of by burial

in soil or otherwise locally dispersed, they should be retained in the closed container until all cinders are thoroughly

cooled.

11.1.2 INSPECT THE BURN POT

When burning, the fl ames should be bright orange with embers jumping from the

burn pot. If not see “MAKE SURE PELLETS ARE NOT PILING UP” or “CLEANING

THE BURNPOT” sections.

35

40.2

11.1.3 CARE OF GLASS

If the glass is not kept clean permanent discolouration and / or

blemishes may result. Normal operation of your pellet heater will

produce a build-up on the glass that should be wiped off daily.

However, poor quality pellets or extended burning on the low

setting will cause the glass to “smoke up” faster.

Refer to “REPLACEMENT PARTS” section to fi nd out what this

product is equipped with. Use only replacement glass available

from your Authorized dealer.

DO NOT CLEAN GLASS WHEN HOT!

If necessary, clean the glass with a soft cloth or paper towel. You could use “wood stove” glass cleaner to

remove heavy build-up.

Do not operate the heater with broken glass, as leakage of fl ue gases may result.

40.3A

!

WARNING

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

5.2

W415-0865 / 04.07.10

Page 36

36

11.1.4 CLEANING THE HEAT EXCHANGER TUBES

!

WARNING

THE FRONT EDGE OF THE HOPPER LID BECOMES VERY HOT, DO NOT TOUCH THE AREA BELOW

THE HANDLE.

THIS ROD BECOMES VERY HOT DURING OPERATION. WAIT TILL HEATER HAS COOLED COM-

PLETELY OR YOU MUST WEAR HEAT RESISTANT GLOVES WHEN CLEANING OR HANDLING THIS

HEATER.

With the appliance cool (or wearing heat resistant gloves),

slide the heat exchange cleaner rod up and down several

times to prevent the build up of ash on the heat exchange

tubes.

Keep the viewing door closed so the fl y ash does not enter the

room.

NOTE: More frequent cleaning may be required depending

upon pellet quality.

HEAT

EXCHANGE

CLEANER

ROD

11.1.5 MAKE SURE PELLETS ARE NOT PILING UP

If the pellets build up over the burn pot, turn the pellet feed switch to “OFF”. If

the fl ames seem to be coming only from the sides, or are orange/black, turn

the appliance off and check for build up of pellets.

The most likely causes are:

A. Feed rate has been set to maximum for an extended period of time.

Turn feed rate to optimum.

B. The door, glass, or ash pan is open or has an air leak.

C. The burn pot requires cleaning.

D. The exhaust system requires cleaning.

E. The appliance requires adjustment (trim feed rate and blower).

F. Poor pellet quality

40.4A

40.5B

W415-0865 / 04.07.10

Page 37

11.1.6 CLEANING THE BURN POT

MAKE CERTAIN THE HEATER HAS FULLY COOLED (APPROXIMATELY 25 MINUTES) BEFORE

OPENING THE DOOR AND

To clean the burn pot, open the door and knock away any debris on the

burn pot. If severely clogged, remove the burn pot to gain better access.

If removing the burn pot set aside on a non-combustible surface. Once

removed, discard all material that has accumulated in the burn pot.

Make certain that all openings are clear of any build up of ash from the

ledge below the burn pot.

Re-install the burn pot ensuring it sits level in the

appliance. Also must ensure the ignitor and the burn

pot locating notch line up when reinstalling the burn

pot.

!

WARNING

37

LOCATING

NOTCH

IGNITOR

11.2 BI-WEEKLY (OR EVERY 10 BAGS OF PELLETS)

11.2.1 VACUUM FIREBOX

!

WARNING

THE FIREBOX BECOMES VERY HOT DURING OPERATION. LET THE HEATER COOL COMPLETELY

BEFORE CONDUCTING SERVICE.

NEVER VACUUM HOT EMBERS.

The more frequently you clean out the fl y ash, the more effi cient your appliance

will burn.

A. Open the viewing door.

B. Lift the burn pot out and set aside on a non-combustible surface.

C. Vacuum out the fi rebox. Do not use a household

vacuum to clean the appliance. We recommend that

you use a shop vacuum that is equipped with a fi ne

dust fi lter or a vacuum specifi cally made for ashes and soot.

Using a vacuum which is not equipped with a fi ne dust fi lter may

clog and disperse fl y ash and soot into the room. NOTE: The

appliance must be completely out before you vacuum the

appliance. Live pellets, if sucked into the vacuum will light

the vacuum on fi re and may ultimately cause a house fi re.

FIREBOX

40.6A

AIR

HOUSING

Re-install the burn pot ensuring it sits level in the appliance. Also must ensure the ignitor and the burn pot

locating notch line up when reinstalling the burn pot.

40.18

W415-0865 / 04.07.10

Page 38

38

11.3 SEMI-ANNUALLY (OR EVERY TWO TONS OF PELLET)

!

WARNING

THE FIREBOX BECOMES VERY HOT DURING OPERATION. LET THE HEATER COOL COMPLETELY BEFORE

CONDUCTING SERVICE.

DISCONNECT THE POWER CORD PRIOR TO CONDUCTING SERVICE.

THE FOLLOWING SECTION DETAILS EXTENSIVE MAINTENANCE PROCEDURES. WE STRONGLY SUGGEST

THESE ITEMS BE CARRIED OUT BY A TRAINED SERVICE TECHNICIAN, POSSIBLY BY A SERVICE AGREEMENT

SET UP WITH YOUR DEALER.

NOTE: More frequent cleaning may be required depending on pellet quality.

11.3.1 VACUUM HOPPER

The more frequently you clean out the fl y ash, the more effi cient your

appliance will burn.

A. Operate the appliance until the pellets run out, then open the hopper

and vacuum out the entire hopper.

40.15

The dust and any other debris near the bottom should be removed to

prevent excessive build-up.

11.3.2 SOOT AND FLY ASH FORMATION

The products of combustion will contain small particles of fl y ash. The fl y ash will collect in the exhaust venting

system and restrict the fl ow of the fl ue gases. Incomplete combustion occurs during startup, shutdown, or

incorrect operation of the room appliance will lead to some soot formation which will collect in the exhaust

venting system. The exhaust venting system should be inspected at least once every year to determine if

cleaning is necessary.

11.3.3 CLEAN THE VERTICAL EXHAUST DUCT

A. Pivot the viewing door wide open.

B. Remove the one screw on each exhaust port located

on either side of the fi re box. Remove the exhaust port

doors and set aside on a non-combustible surface.

Insert a vacuum into the exhaust port holes and remove as

much fl y ash as possible from behind the left and right exhaust

manifolds. Do not use a household vacuum to clean the

appliance. We recommend that you use a shop vacuum that is

equipped with a fi ne dust fi lter or a vacuum specifi cally made

for ashes and soot. Using a vacuum which is not equipped with

a fi ne dust fi lter may clog and disperse fl y ash and soot into the

room. NOTE: The appliance must be completely out before you vacuum the appliance. Live pellets, if

sucked into the vacuum will light the vacuum on fi re and may ultimately cause a house fi re.

40.8B

40.9

EXHAUST

PORT

Once clean, replace the exhaust port doors and secure with the screws.

W415-0865 / 04.07.10

40.17A

Page 39

11.3.4 CLEAN THE EXHAUST BLOWER

39

NOTE: Do not attempt this maintenance without a

replacement exhaust blower motor mounting gasket.

A. Remove the six nuts holding the exhaust blower motor

in place.

B. Pull the motor out being careful not to damage the

wiring, unplug the two wires that are connecting the

motor and gently set aside. (The pieces of gasket may

be discarded.

C. Start by cleaning the exhaust tube by feeding a brush

or rag through the inside of the tube and out the

exhaust blower housing.

EXHAUST

D. Vacuum out the exhaust ports and the blower housing.

E. With a bristle brush vacuum, clean the blades of the

motor.

F. Place the new exhaust blower mounting gasket around

the screw holes being very careful not to tear it.

G. Re-attach the wiring to the motor and place it back on to the housing, taking care that the side of the

motor does not tear the gasket and then re-attach the nuts.

BLOWER

EXHAUST

HOUSING

40.11

NUTS

11.3.5 CHECK ALL SEALS

Check for air leaks around the door, glass, and ash pan and replace gaskets as required.

Air leaks into the fi rebox will decrease the appliance’s performance greatly, leading to excessive soot,

ineffi cient burning, and may even cause a malfunction.

Test the door seal by shutting the door on a piece of paper in various locations. If the paper can be easily slid

out, air may be leaking around the door seal. Carefully inspect the door gasket and door catch.

Inspect the door gasket to make sure it is fully attached. Appliance gasket cement can be used to re-attach if

necessary. If the door gasket is worn or fl attened, replace.

Check the door to make sure it latches correctly. The latch should engage with a slight amount of resistance,

yet not be too diffi cult.

If the glass is cracked, replace.

40.12

W415-0865 / 04.07.10

Page 40

40

11.3.6 CLEAN THE VENT

WHENEVER ANY PORTION OF THE PELLET VENT IS DISCONNECTED, THE JOINTS MUST BE

RE-SEALED WITH RTV 500°F SILICONE SEALANT.

!

WARNING

Vent system should be cleaned using

chimney sweep brushes. We recommend this

be done by a qualifi ed chimney sweep.

Flyash will deposit

along sections that

are horizontal

11.4 IN THE EVENT OF A JAMMED AUGER

!

WARNING

DISCONNECT THE POWER CORD PRIOR TO CONDUCTING SERVICE.

Make sure the cap is free of

debris (especially if it has a

screen that could become

blocked).

Check the vent sections for

creosote accumulation

(indicating a poorly burning

heater). Accumulation

greater than 1/4" must be

removed.

On vertically vented

systems, the dirtiest portion

is often the point where the

vent turns upwards (ex. the

"Tee"). Remove the clean

vent cover and inspect and

clean if necessary.

40.13

Occasionally damp fuel or foreign objects could get jammed in the auger screw. When this occurs it will be

necessary to empty the hopper and/or remove the auger screw from the hopper assembly.

Start by emptying the pellets from the hopper. Sometimes the object causing the auger screw not to turn will be

visible once the hopper has been emptied. If it is necessary to remove the auger screw start by removing both

of the side panels and the rear panel. Locate the auger motor, remove the set screw that secures the motor to

the auger screw. Remove the two hex bolts from the auger housing which will allow the auger screw to slide out.

After you have removed the shaft, inspect it for bent fl ights, burrs, or broken welds. Remove any foreign material

that might have caused the jam. Also, check the auger tube for signs of damage such as burrs, rough spots, or

grooves cut into the metal that could have caused a jam.

40.14A

W415-0865 / 04.07.10

Page 41

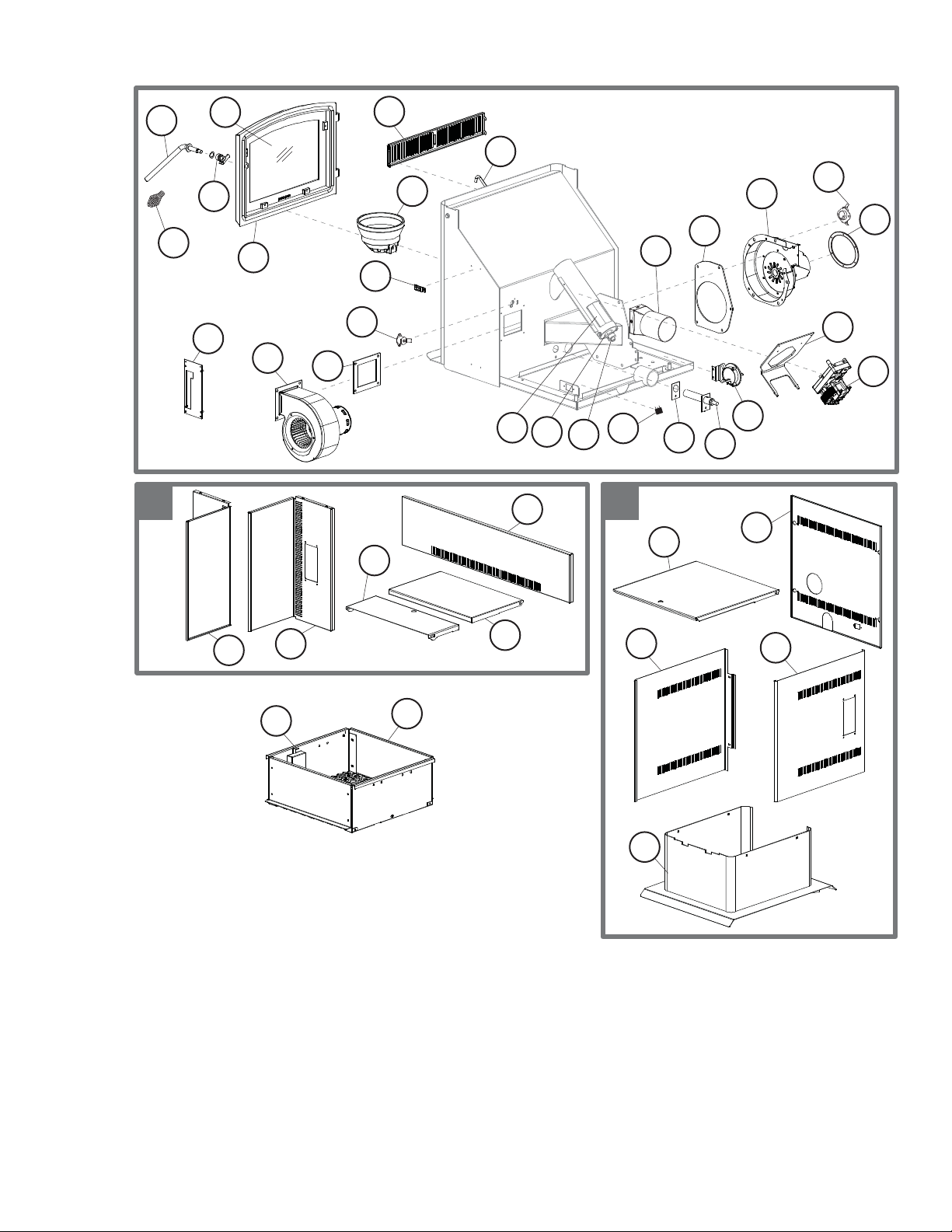

12.0 REPLACEMENTS

Contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally

all parts can be ordered through your Authorized dealer / distributor.

FOR WARRANTY REPLACEMENT PARTS, A PHOTOCOPY OF THE ORIGINAL INVOICE WILL BE

REQUIRED TO HONOUR THE CLAIM.

When ordering replacement parts always give the following information:

• Model & Serial Number of appliance

• Installation date of appliance

• Part number

• Description of part

• Finish

* IDENTIFIES ITEMS WHICH ARE NOT ILLUSTRATED. FOR

FURTHER INFORMATION, CONTACT YOUR AUTHORIZED DEALER.

COMMON COMPONENTS

REF PART NO. DESCRIPTION

1 W660-0052 LOW LIMIT SWITCH 140°F (80°C)

2 W660-0055 HIGH LIMIT SWITCH 200°F (93°C)

3 W660-0056 VACUUM SWITCH

4 W325-0043 HANDLE, SPRING

5* W195-0004 POWER CORD

6 W435-0019 AUGER MOTOR

7 W062-0030 CONVECTION BLOWER

8 W062-0036 COMBUSTION BLOWER

9 W290-0111 COMBUSTION BLOWER MOUNTING GASKET

10 W290-0120 COMBUSTION BLOWER MOTOR MOUNTING GASKET

11 W290-0113 CONVECTION BLOWER GASKET

12 W570-0001 AUGER SCREW

13 W090-0035 CONTROL

14 W105-0012 NYLON BUSHING

15 W570-0110 SET SCREW

16 W555-0061 SCRAPER ROD

17* W750-0227 HARNESS WIRE

18* W385-0487 TIMBERWOLF® LOGO

19* W562-0004 GLASS GASKET (3/4" CHANNEL)

20 W720-0139 EXHAUST TUBE

21 W357-0007 IGNITOR

22

24

25*

26

27*

28

29

30

31* W430-0013 DOOR MAGNET ASSEMBLY

32 W325-0018 DOOR HANDLE

33 W320-0002 DOOR HANDLE LATCH

W135-0320 CAST, BURN POT

W290-0119 IGNITION GASKET

W460-0004 RECEPTACLE

W300-0131 GLASS

W562-0002 DOOR GASKET (1/2" ROPE)

W660-0083 SWITCH, HOPPER

W200-0302 DECORATIVE INSET

W225-0258 DOOR, BLACK

41

!

WARNING

FAILURE TO POSITION THE PARTS

IN ACCORDANCE WITH THIS

MANUAL OR FAILURE TO USE ONLY

PARTS SPECIFICALLY APPROVED

WITH THIS APPLIANCE MAY

RESULT IN PROPERTY DAMAGE OR

PERSONAL INJURY.

41.1

W415-0865 / 04.07.10

Page 42

42

TPP - PEDESTAL COMPONENTS

REF PART NO. DESCRIPTION

34 W010-2274 PEDESTAL BASE ASSEMBLY

35 W475-0655 RIGHT PANEL

36 W475-0654 LEFT PANEL

37 W475-0656 REAR PANEL

38 W225-0268 HOPPER DOOR

TPI - INSERT COMPONENTS

REF PART NO. DESCRIPTION

39 W225-0252 HOPPER FRONT DOOR

40 W225-0253 HOPPER BACK DOOR

41 W263-0103 8" TOP FLASHING

42 W263-0104 8" RIGHT FLASHING

43 W263-0105 8" LEFT FLASHING

ACCESSORIES

REF PART NO. DESCRIPTION

44* 114KT OUTSIDE AIR KIT - 5 FT (2" DIA.)

45 TPHE HOPPER EXTENSION (INCREASES HOPPER CAPACITY FROM 55 LBS TO 100 LBS

PELLETS) STOVE ONLY

46 TPP PEDESTAL KIT (INCLUDES REAR AND SIDE SHIELDS, LARGE HOPPER DOOR)

47 TPI INSERT KIT (INCLUDES FLASHING/SURROUND, SMALL HOPPER DOOR)

48* F50 THERMOSTATIC REMOTE

49* F50-6 BULK THERMOSTATIC REMOTE

50* 270 PAINT, THURMALOX - BLACK

51* F40 ON/OFF REMOTE

52* F50-6 BULK ON/OFF REMOTE

W415-0865 / 04.07.10

Page 43

43

32

47

4

33

13

26

30

7

11

2

31

39

29

22

16

12

41

14

15

25

46

20

38

24

9

1

8

10

23

6

3

21

37

43

28

42

45

40

36

34

35

W415-0865 / 04.07.10

Page 44

44

13.0 TROUBLESHOOTING

!

TURN OFF THE ELECTRICAL POWER BEFORE SERVICING THE APPLIANCE.

APPLIANCE MAY BE HOT, DO NOT SERVICE UNTIL APPLIANCE HAS COOLED.

DO NOT USE ABRASIVE CLEANERS.

WHEN CHECKING CONNECTIONS, INSTALLING JUMPER WIRES (FOR TEST PURPOSES ONLY) OR

REPLACING COMPONENTS, UNPLUG HEATER FROM THE RECEPTACLE TO PREVENT ELECTRICAL

SHOCK OR DAMPAGE TO THE COMPONENT.

NOTE: Many of the following tests will require that the side panels are removed from the appliance

or the insert be removed from its cavity to access the components. Before troubleshooting always

confi rm that all components are clean and free of ash build up.

PROBLEM SOLUTION

The appliance will

not start.

Check the vacuum

switch.

Check the ignitor

switch.

Smoke in the

room.

The exhaust

blower is not

operating.

The ignitor will

not light the

pellets however

everything else

in the appliance

operates.

W415-0865 / 04.07.10

- Make certain there is power to the outlet and that the appliance is plugged in.

- Hopper lid must be closed.

- Start the appliance. If the appliance fails to start, unplug the appliance.

- With the appliance unplugged, examine all connections. Make sure no exposed wires

are touching the appliance (except the chassis ground wire) and that they are all

fi rmly connected.

- Check the manual reset hi limit switch.

- Check the stability and placement of connections against the wiring diagrams in this

manual.

- Check that the burn pot is positioned properly.

- The auger shaft may be jammed. For more information see “IN THE EVENT OF A

JAMMED AUGER” section.

- Blockage in igniter tube or inlet for igniter tube. Find the igniter housing on the back

side of the fi re wall. The air intake hole is a small hole located on the side of the

housing. Make sure it is clear. Also, look from the front of the appliance to make sure

there is not any debris around the igniter element inside of the igniter housing.

- Ensure the burnpot is seated completely into the burner housing.

- Defective igniter. Put power directly to the igniter. Watch the tip of the igniter from the

front of the appliance. After about 2 minutes the tip should glow. If it does not, the

igniter is defective.

- The control board might not be sending power to the igniter. Check the voltage going

to the igniter during setup. It should be a full current (115 volts). If the voltage is lower

than full current, check the wiring. If the wiring checks good, the board is defective.

- Contact your local dealer for service.

- Check all gasket seals.

- Check that the vent connections are sealed.

- Power failure.

- Appliance has failed to reach 140°F within 15 minutes and the blower has shut off.