Page 1

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE.

INSTALLATION AND

EN

OPERATING INSTRUCTIONS

MODEL TPS35/TPI35 MEET THE 2015 U.S ENVIRONMENTAL PROTECTION AGENCY (E.P.A.) PELLET FUEL EMISSION LIMITS FOR PELLET APPLIANCES SOLD

AFTER MAY 15, 2015, 40 C.F. R. PART 60. THESE STOVES HAVE BEEN TESTED AND LISTED BY INTERTEK TESTING SERVICES TO STANDARDS: ASTM E 1509,

ULC/ORD C1482M-90, ULC S627 AND ULC S628.

TPS35

PELLET STOVE

TPI35

PELLET INSERT

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA METHODS.

SAFETY INFORMATION

!

WARNING

PLEASE READ ENTIRE MANUAL

BEFORE YOU INSTALL OR USE THIS

PELLET BURNING APPLIANCE.

If the appliance is not properly installed,

a house fi re may result causing personal

injury or loss of life.

- Authorities having jurisdiction (such as

municipal building department, fi re department, fi re

prevention bureau, etc.) should be consulted before

installation to determine the need to obtain a permit.

- Contact local building or fi re offi cials about

restrictions and installation inspection

requirements in your area.

- This appliance is hot while in operation. Keep

children, clothing and furniture away. Contact may

cause skin burns.

- Do not start a fi re with chemicals or fl uids such as

gasoline, engine oil, etc...

- Do not burn trash or garbage, lawn clippings /

waste, rubber, waste petroleum products, paints

or paint thinners / solvents, plastic, materials

containing asbestos, construction debris, railroad

ties, manure or animal remains, salt water driftwood

or salted materials, unseasoned wood, coloured

paper, cardboard, plywood or particleboard.

FOR INDOOR USE ONLY

!

WARNING

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

FR

PG

49

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)720-9081 • www.timberwolffi replaces.com • ask@timberwolffi replaces.com

$10.00

1.18F

W415-1477 / A / 10.19.16

Page 2

EN

2

TABLE OF CONTENTS

1.0 INSTALLATION OVERVIEW 3

1.1 STOVE 3

1.2 INSERT 4

2.0 INTRODUCTION 5

2.1 DIMENSIONS 6

2.1.1 STOVE 6

2.1.2 INSERT (COMPLETE WITH FLASHING) 6

2.2 SPECIFICATIONS 7

2.3 GENERAL INSTRUCTIONS 7

2.4 GENERAL INFORMATION 8

2.4.1 FUEL 8

2.4.2 PELLET SPECIFICATIONS 9

2.4.3 CORN SPECIFICATIONS 9

2.4.4 SAFETY FEATURES 10

2.4.5 EPA COMPLIANCE 10

2.5 RATING PLATE INFORMATION 10

3.0 INSTALLATION PLANNING 11

3.1 INSTALLATION OPTIONS 11

3.2 APPLIANCE PLACEMENT 11

3.3 LEVELLING THE APPLIANCE 11

3.4 MINIMUM CLEARANCE TO COMBUSTIBLES 12

3.4.1 STRAIGHT INSTALLATION 12

3.4.2 CORNER INSTALLATION 12

3.5 FLOOR PROTECTION REQUIREMENTS INSTALLATION 13

3.6 OUTSIDE AIR 13

3.7 MOBILE HOME 13

4.0 VENTING 14

4.1 TYPE OF VENT 14

4.2 PELLET VENT INSTALLATION 14

4.3 VENTING THE PELLET APPLIANCE 14

4.4 PELLET VENT TERMINATION 15

4.5 VENT TERMINAL CLEARANCES 15

4.6 STOVE VENTING INSTALLATION EXAMPLES 16

4.6.1 HORIZONTAL TERMINATION (THROUGH WALL) 16

4.6.2 VERTICAL RISE HORIZONTAL TERMINATION (THROUGH WALL) 16

4.6.3 VERTICAL TERMINATION 17

4.6.4 CLASS A CHIMNEY RETROFIT 17

4.6.5 HEARTH MOUNT INSTALLATION 18

4.7 INSERT VENTING INSTALLATION EXAMPLES 19

4.7.1 TYPICAL EXISTING MASONRY INSTALLATION 19

4.7.2 FACTORY BUILT FIREPLACE 20

5.0 FRAMING (INSERT ONLY) 21

5.1 INSTALLATION INTO A COMBUSTIBLE ENCLOSURE 22

5.2 MINIMUM ENCLOSURE CLEARANCES 23

5.3 MINIMUM CLEARANCE TO COMBUSTIBLES 23

5.4 INSERT MINIMUM MANTEL CLEARANCES 24

5.5 MINIMUM STOVE ALCOVE INSTALLATION REQUIREMENTS 24

6.0 FINISHING 25

6.1 VIEWING DOOR INSTALLATION 25

6.2 DOOR HANDLE INSTALLATION 26

6.3 DECORATIVE INSET 26

6.4 FLASHING INSTALLATION 27

7.0 WIRING DIAGRAM 28

8.0 OPERATING INSTRUCTIONS 29

8.1 PROPER PELLET LOADING 29

8.2 PRE-START CHECK 29

8.3 MANUAL APPLIANCE LIGHTING 29

8.4 LIGHTING INSTRUCTIONS 30

8.5 REMOTE CONTROL 30

8.6 CONTROL ADJUSTMENT 31

8.7 THERMOSTAT INSTALLATION 32

8.8 SHUTDOWN INSTRUCTIONS 32

9.0 NORMAL OPERATING SOUNDS 32

10.0 MAINTENANCE 33

10.1 DAILY MAINTENANCE 33

10.1.1 ASH DISPOSAL 33

10.1.2 BURN POT INSPECTION 33

10.1.3 CARE OF GLASS 33

10.1.4 HEAT EXCHANGER TUBES CLEANING 34

10.1.5 PELLET PILE UP MAINTENANCE 34

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

W415-1477 / A / 10.19.16

Page 3

10.1.6 BURN POT CLEANING 35

10.2 BI-WEEKLY (OR EVERY 10 BAGS OF PELLETS) 35

10.2.1 VACUUM FIREBOX 35

10.3 SEMI-ANNUALLY (OR EVERY TON OF PELLET) 36

10.3.1 HOPPER CLEANING 36

10.3.2 SOOT AND FLY ASH FORMATION 36

10.3.3 VERTICAL EXHAUST DUCT CLEANING 36

10.3.4 EXHAUST BLOWER CLEANING 37

10.3.5 SEAL CHECK 37

10.3.6 VENT CLEANING 38

10.4 JAMMED AUGER 38

11.0 REPLACEMENT PARTS 39

12.0 TROUBLESHOOTING 41

13.0 WARRANTY 44

14.0 SERVICE HISTORY 45

15.0 NOTES 46

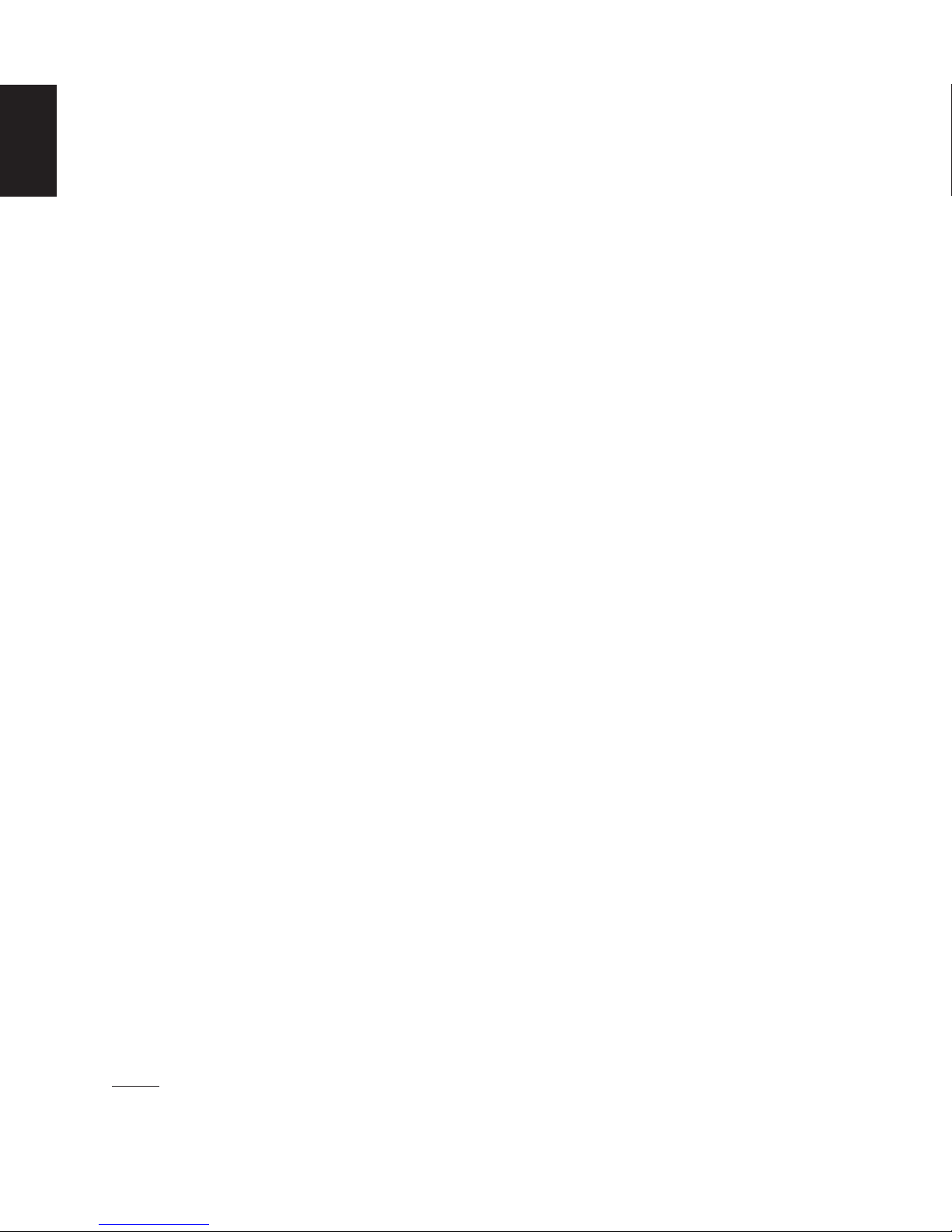

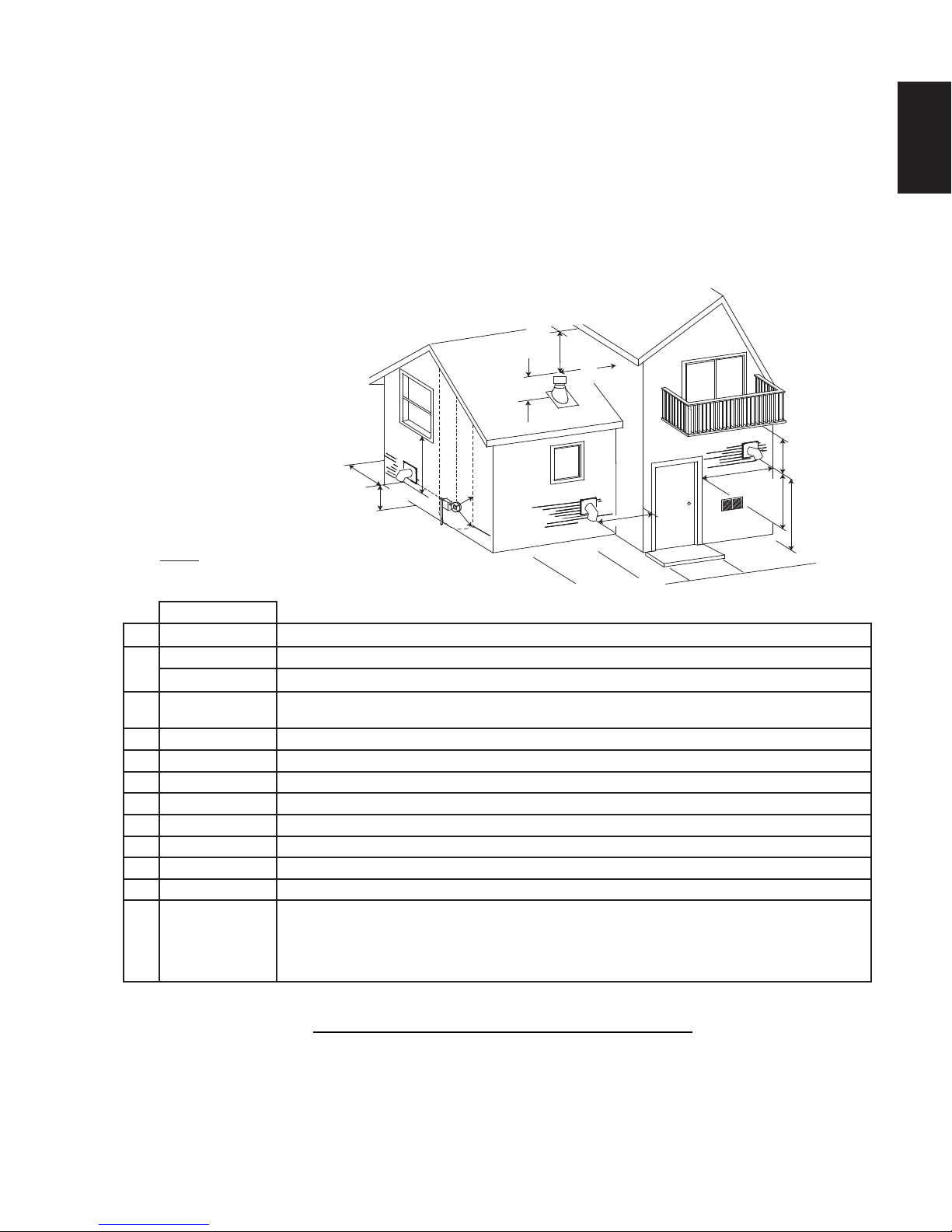

1.0 INSTALLATION OVERVIEW

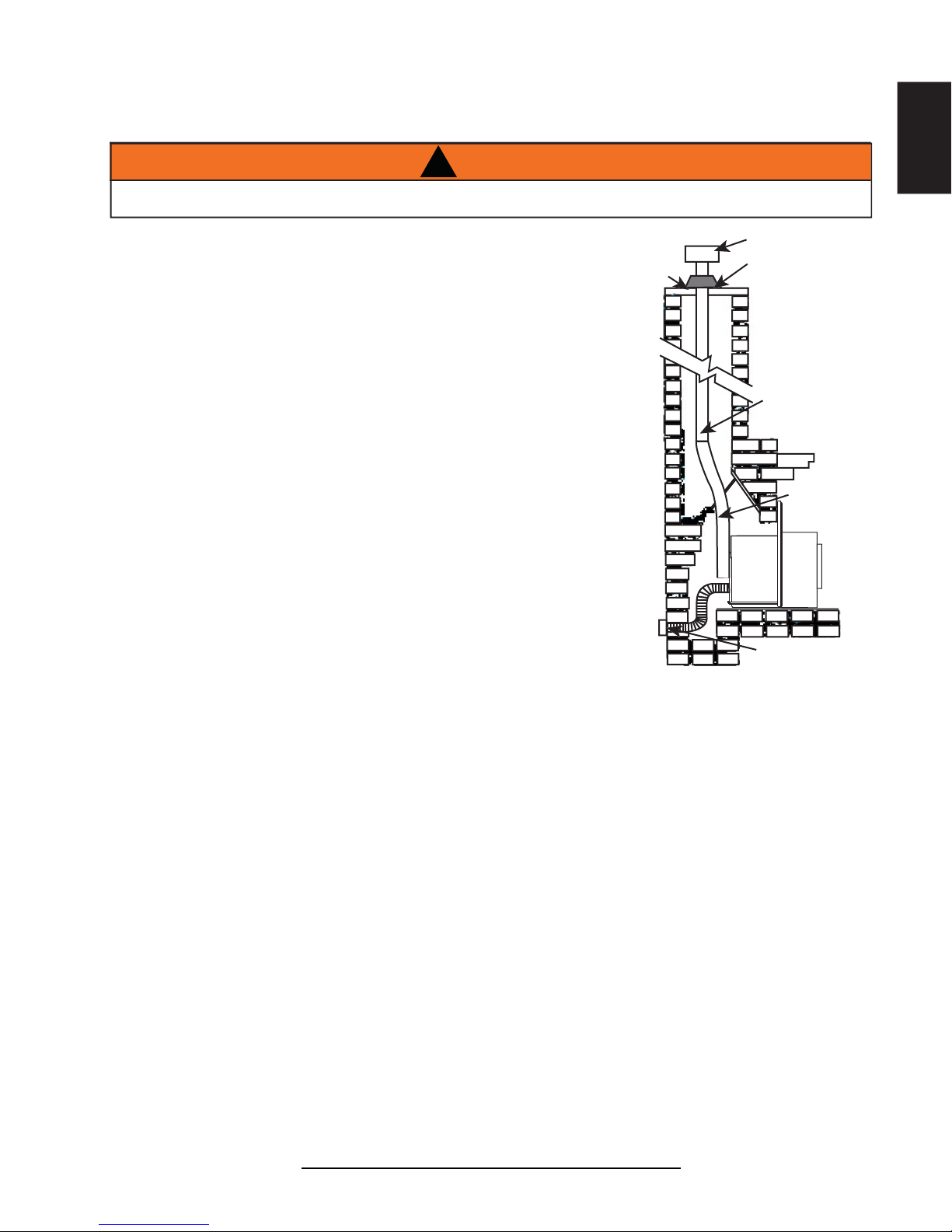

1.1 STOVE

Rating plate, see

“RATING PLATE

INFORMATION”

section.

Venting, see “GENERAL VENTING”

Door, see “FINISHING - INSTALLING

THE VIEWING DOOR” section.

and “INSTALLATION” sections.

3

EN

Floor, see “INSTALLATION PLANNING FLOOR PROTECTION REQUIREMENTS” section.

See “OUTSIDE AIR”

section.

Handle, see “DOOR

HANDLE INSTALLATION”

section.

W415-1477 / A / 10.19.16

Page 4

4

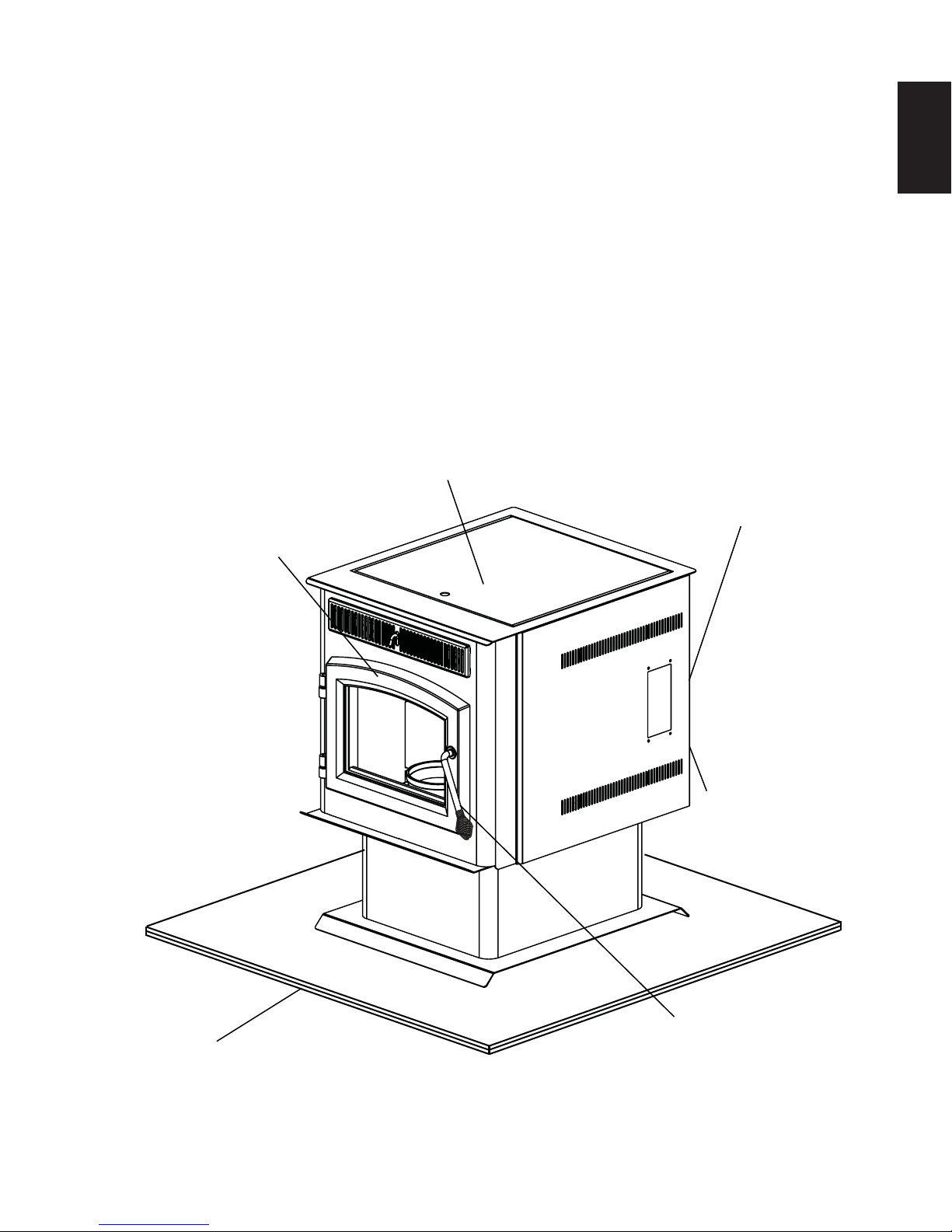

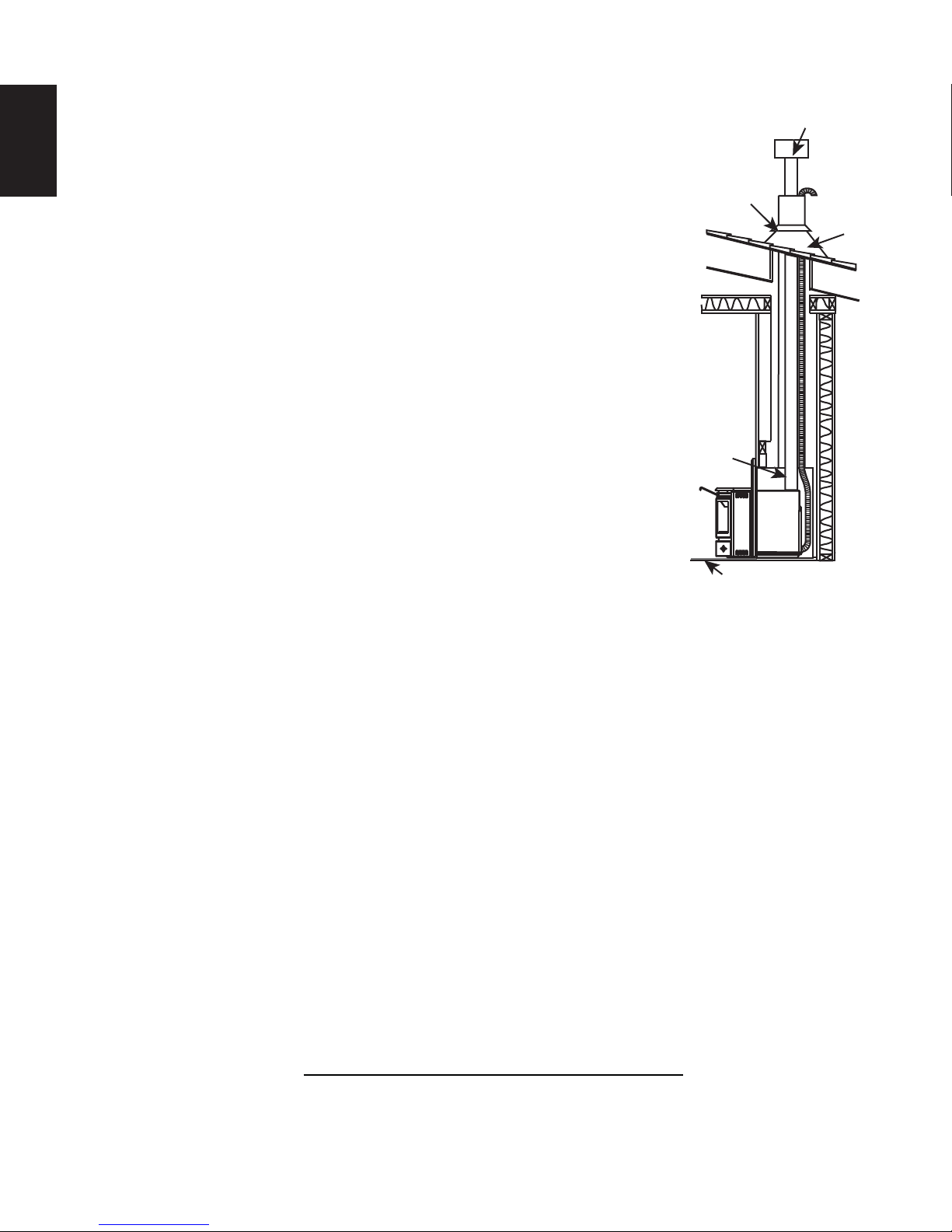

1.2 INSERT

EN

Flashing, see “FLASHING

INSTALLATION” section.

Venting, see “VENTING” and

“INSTALLATION” sections.

Door, see “FINISHING INST ALLING THE VIEWING DOOR” section.

Rating plate, see

“RATING PLATE

INFORMATION”

section.

W415-1477 / A / 10.19.16

Handle, see “DOOR

HANDLE INSTALLATION”

section.

Page 5

2.0 INTRODUCTION

5

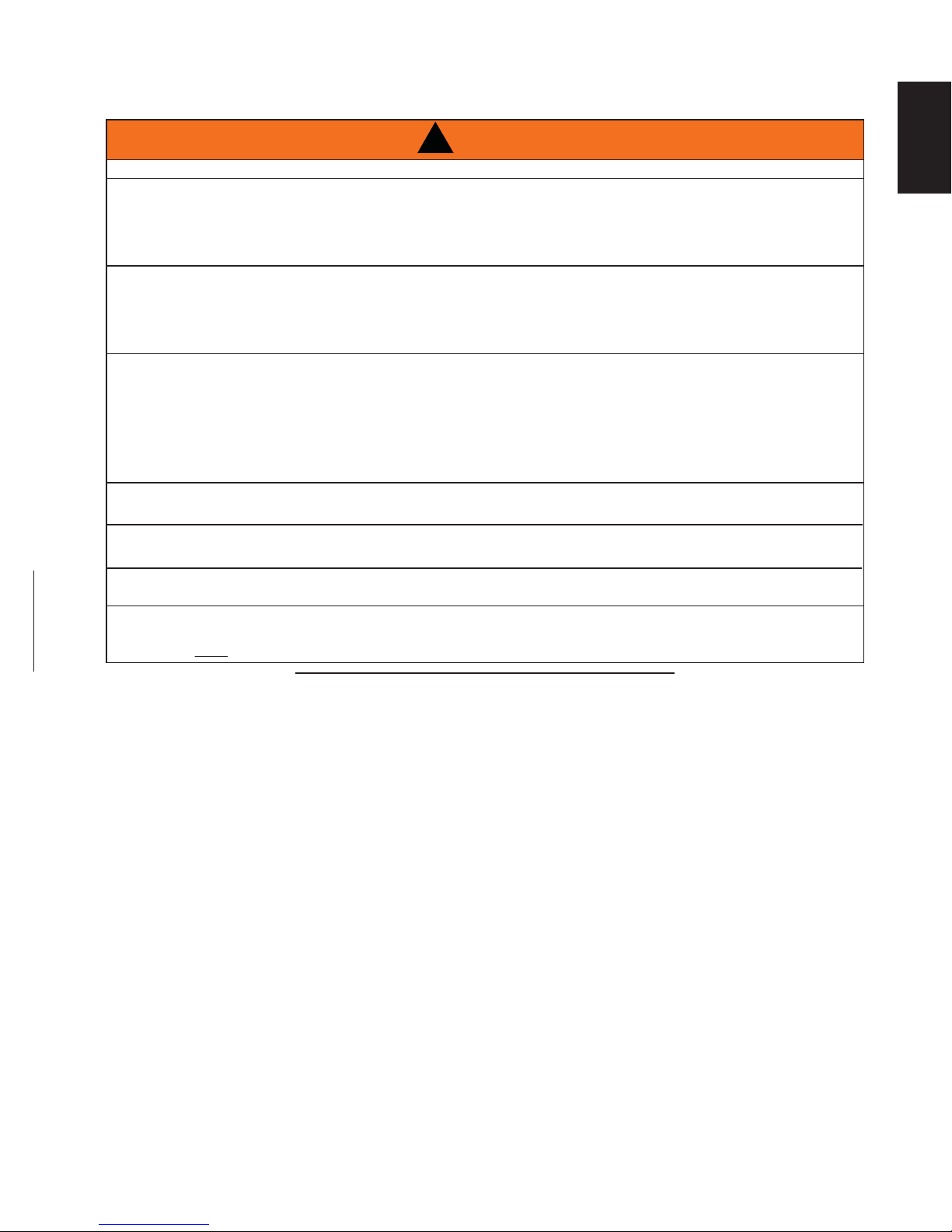

!

WARNING

• THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE BURNS IF CONTACTED.

• Do not operate appliance before reading and understanding operating instructions. Failure to operate appliance according to

operating instructions could cause fi re or injury. Contact the local building or fi re authority and follow their guidelines. Notify

your insurance company of this appliance as well.

• Never try to repair or replace any part of the appliance unless instructions are given in this manual. All other work should be

done by a trained technician.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not operate without fully assembling all components.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves and safety glasses during installation. Sheet metal edges may be sharp.

• Children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or

clothing ignition. Toddlers, young children and others may be susceptible to accidental contact burns. A physical barrier is

recommended if there are at risk individuals in the house. To restrict access to an appliance or stove, install an adjustable

safety gate to keep toddlers, young children and other at risk individuals out of the room and away from hot surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Due to high temperatures, the appliance should be located out of traffi c and away from furniture and draperies.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot surfaces.

• Even after the appliance is out, the glass and/or screen will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children from hot surfaces.

These screens and guards must be fastened to the fl oor.

• Any safety screen or guard removed for servicing must be replaced prior to operating the appliance.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the appliance and venting

system are kept clean. The appliance and its venting system should be inspected before use and at least annually by a

qualifi ed service person. More frequent cleaning may be required due to excessive lint from carpeting, bedding material, etc.

The appliance area must be kept clear and free from combustible materials, gasoline and other fl ammable vapors and liquids.

• Under no circumstances should this appliance be modifi ed.

• Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician to inspect the

appliance and to replace any part of the control system which has been under water.

• Do not operate the appliance with the glass door removed, cracked or broken. Replacement of the glass should be done by a

licensed or qualifi ed service person. The viewing door and ashpan must be closed and latched during operation.

• Do not strike or slam shut the appliance glass door.

• Only doors / optional fronts certifi ed with the unit are to be installed on the appliance.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As with all plastic bags,

these are not toys and should be kept away from children and infants.

• If the appliance is not properly installed, a house fi re may result. Do not expose the appliance to the elements (ex. rain, etc.)

and keep the appliance dry at all times. Wet insulation will produce an odour when the appliance is used.

• The chimney must be sound and free of cracks. Clean your chimney a minimum of twice a year and as required.

• The heater is designed and approved for pelletized wood fuel only. Any other type of fuel burned in this heater will void the

warranty and safety listing. D

or paint thinners / solvents, plastic, materials containing asbestos, construction debris, railroad ties or treated wood, manure

or animal remains, salt water driftwood or salted materials, unseasoned wood, coloured paper, cardboard, plywood or

particleboard.

• Do not start a fi re with chemicals or fl uids such as gasoline, engine oil, etc.

• Ashes must be disposed in a metal container with a tight lid and placed on a non-combustible surface well away from the

home or structure.

• Your appliance requires periodic maintenance and cleaning. Failure to maintain your appliance may lead to smoke spillage in

your home.

• The exhaust system must be completely straight and properly installed. It is recommended that the pellet vent joints be sealed

with a minimum 500°F (260°C) silicone sealant. Install according to the vent manufacturer’s instructions.

• Ensure clearances to combustibles are maintained when building a mantel or shelves above the appliance. Elevated

temperatures on the wall or in the air above the appliance can cause melting, discolouration or damage to decorations, a T.V.

or other electronic components.

• During a power outage this appliance will not operate. If a power outage does occur, check the appliance for smoke spillage

and open a window if any smoke spills into the room.

• Keep foreign objects out of the hopper.

• Disconnect the power cord before performing any maintenance. NOTE: Turning the pellet feed to “OFF” does not

disconnect all power to the heater.

• Do not throw this manual away. This manual has important operating and maintenance instructions that you will need at a

later time. Always follow the instructions in this manual.

• At no point should you use fi rewood or fi relogs in this appliance. The use of which could cause a house fi re.

• This appliance must be connected to a standard 115 V, 50Hz grounded electrical outlet. Do not use an adapter plug or sever

the grounding prong. Do not route the electrical cord underneath, in front of, or over the appliance.

• When installed in a mobile home, the appliance must be bolted to the fl oor, have outside air, and NOT BE INSTALLED IN THE

BEDROOM (per H.U.D. requirements). Check with local building offi cials.

o not burn trash or garbage, lawn clippings / waste, rubber, waste petroleum products, paints

3.8C

EN

W415-1477 / A / 10.19.16

Page 6

EN

6

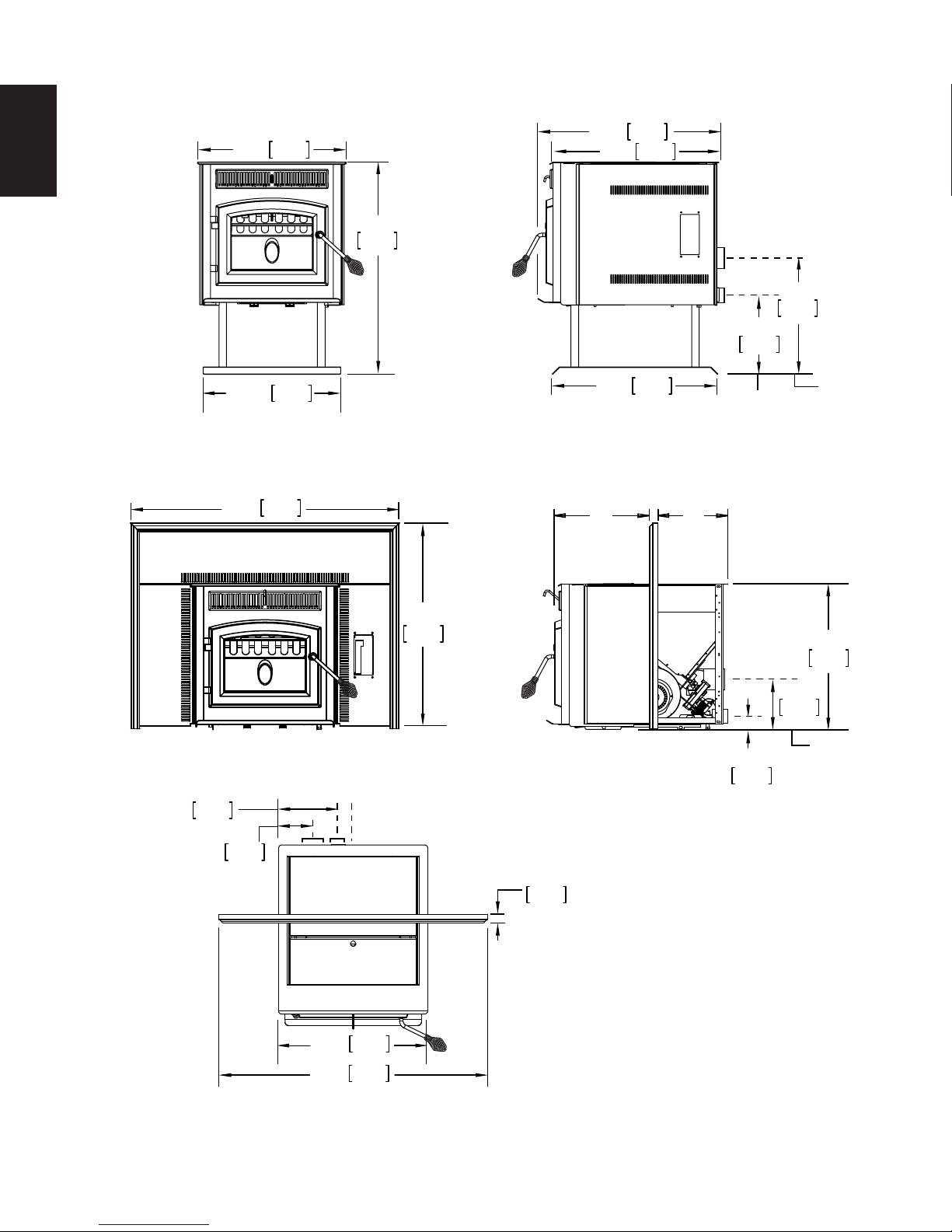

2.1 DIMENSIONS

2.1.1 STOVE

21 1/4"

540mm

30 5/16"

770mm

25 7/8"

24 1/4"

657mm

616mm

17"

432mm

11 5/8"

295mm

19 11/16"

500mm

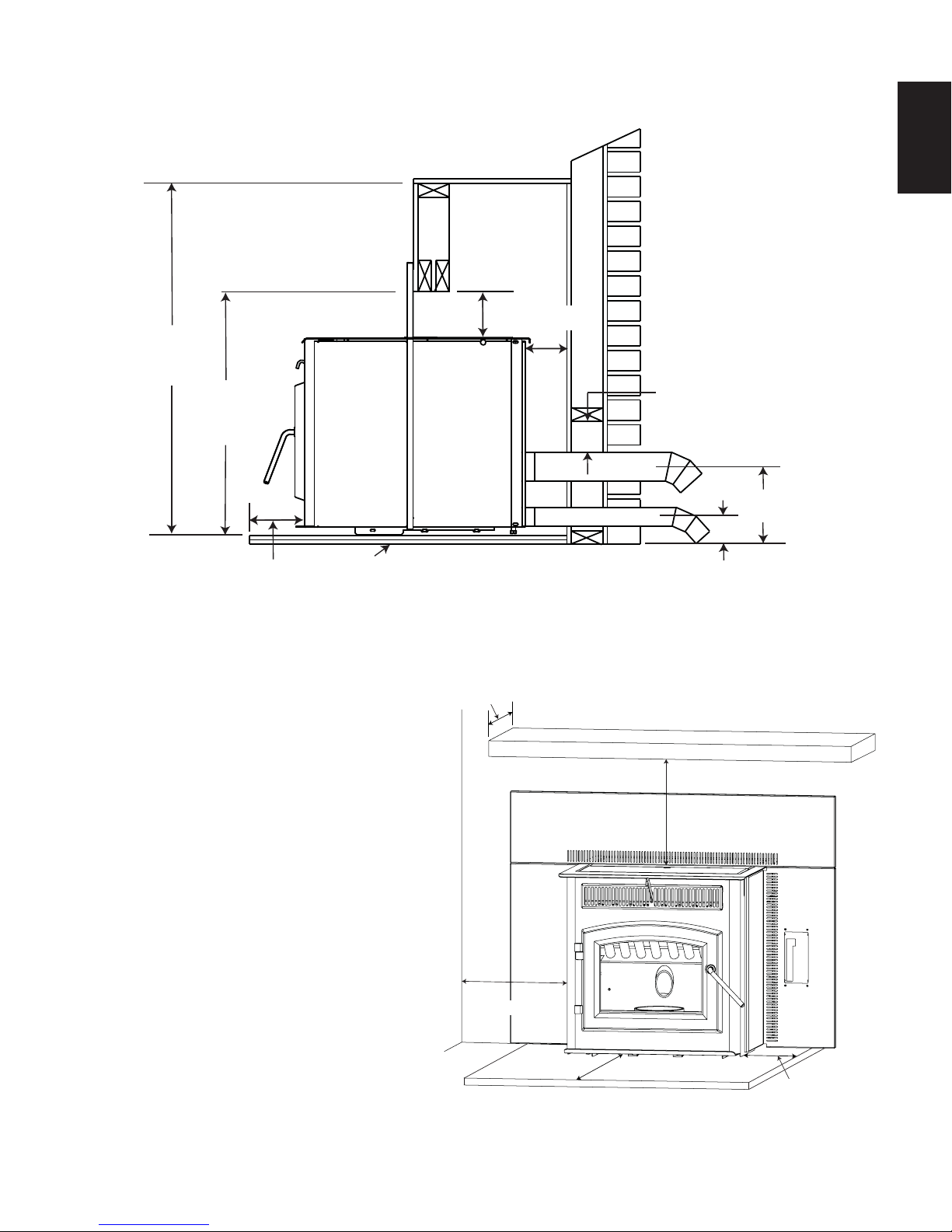

2.1.2 INSERT (COMPLETE WITH FLASHING)

38 3/8"

975mm

29 3/8"

746mm

8 1/2"

220mm

CENTRE OF AIR INTAKE

5 5/8"

143mm

CENTRE OF EXHAUST

1 1/4"

32mm

23 1/2"

A

*

597mm

B

*

CENTRE OF

AIR INTAKE

7 1/8"

181mm

1 7/8"

47mm

CENTRE OF

AIR INTAKE

CENTRE OF

EXHAUST

20 13/16"

529mm

CENTRE OF

EXHAUST

21 1/4

38 3/8"

* A and B are adjustable, see "SPECIFICATIONS" section.

W415-1477 / A / 10.19.16

540mm

975mm

Page 7

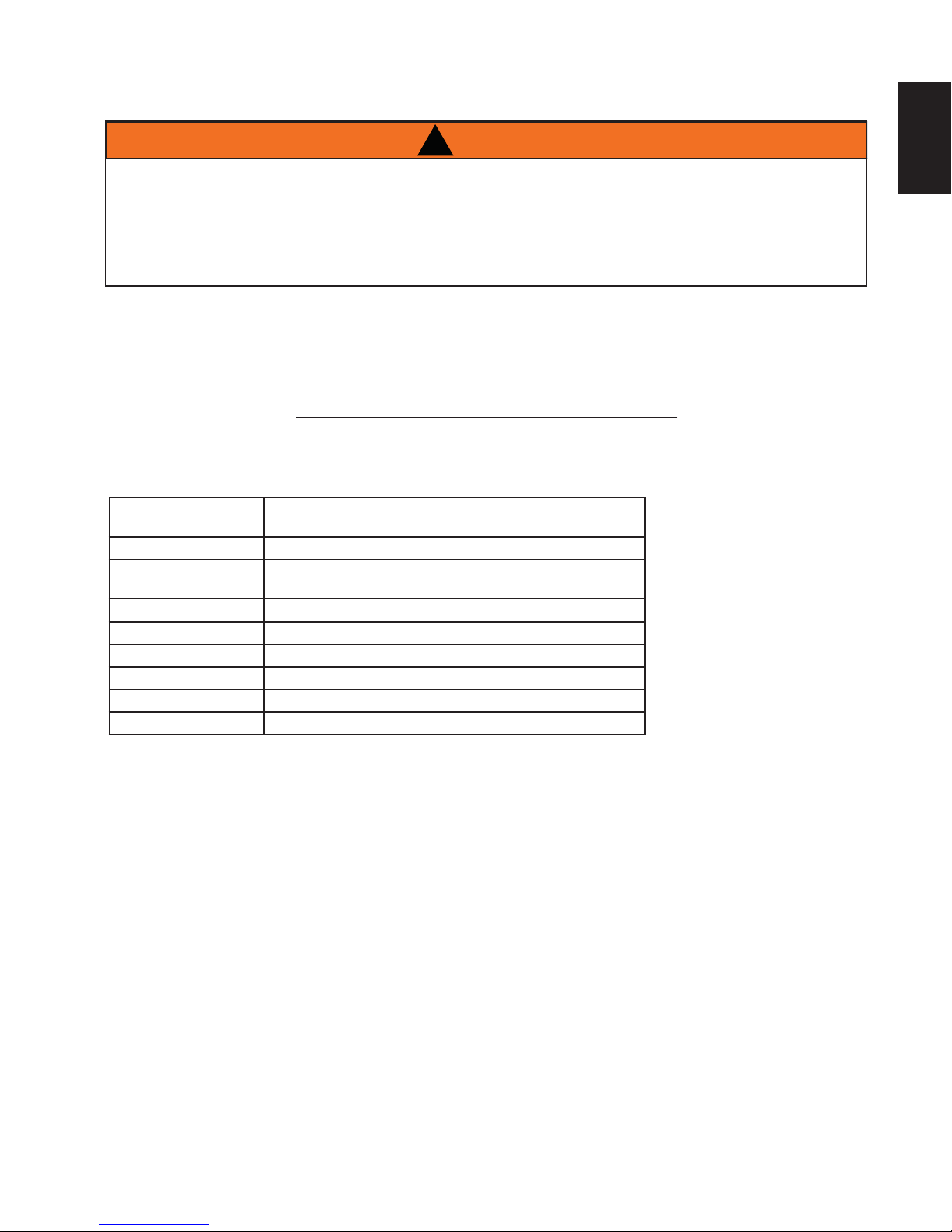

2.2 SPECIFICATIONS

AB

Adjustable Flashing 11" (279mm) to

13" (330mm)

Electrical Rating 115 Volts, 3.6 Amps, 60Hz

Watts During Ignition Sequence 400 (approximately)

Watts During Operation 180 (approximately)

Weight Stove 158 lbs (1003kg) / Insert 140 lbs (889kg)

Exhaust Collar 3" (76mm)

Intake Collar 2" (51mm)

Hopper Capacity 45 Pounds (20kg)

Burn Rate 1.5 to 4.5 (Pounds Per Hour) / 0.7 to 2 (Kilograms Per Hour)

BTU/Hr 12750 to 38250

Approximate Maximum Heating Capacity (in square feet)* 800 to 2000 Sq. Feet / 74 to 186 Sq. Meters

Maximum Burn Time on Low Burn** 30 Hours

* Heating capacity will vary depending on the home's fl oor plan, degree of insulation, and the outside temperature. It is

also affected by the fuel size, quality, and moisture level.

** Small pellets will increase or decrease the stated burn rates and burn times. Differences of plus or minus 20%

depending on fuel quality may occur.

10 1/2" (267mm) to

12 1/2" (317mm)

7

EN

2.3 GENERAL INSTRUCTIONS

!

WARNING

ALL WIRING SHOULD BE DONE BY A QUALIFIED ELECTRICIAN AND SHALL BE IN COMPLIANCE

WITH LOCAL CODES. IN THE ABSENCE OF LOCAL CODES, USE THE CURRENT CSA C22.1

CANADIAN ELECTRIC CODE (IN CANADA) OR THE ANSI/NFPA NO. 70 NATIONAL ELECTRIC CODE

IN THE UNITED STATES.

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE. DO

NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM.

PROVIDE ADEQUATE CLEARANCE FOR SERVICING AND OPERATING THE APPLIANCE.

PROVIDE ADEQUA TE VENTILA TION.

NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE.

OBJECTS PLACED IN FRONT OF THE APPLIANCE MUST BE KEPT A MINIMUM OF 48” (1219.2mm)

FROM THE FRONT FACE OF THE APPLIANCE.

W415-1477 / A / 10.19.16

Page 8

8

Thank you for purchasing a Wolf Steel Ltd. Pellet Appliance. This appliance is designed for use with Pelletized

Wood Only.

EN

Please read this entire manual before installation and use of this pellet fuel-burning room appliance. Failure to

follow these instructions could result in property damage, bodily injury or even death.

Keep this manual handy for future reference.

This Pellet Appliance, when installed, must be electrically grounded in accordance with the local codes, or in

the absence of local codes, use the current CSA C22.1 Canadian Electrical Code in Canada or the ANSI/NFPA

70 National Electrical Code in the United States.

This appliance will not operate using natural draft or without a power source for the blower systems and fuel

feed system.

These appliances are equipped with levelling screws that penetrate the front corners of the fi rebox. If these

screws are missing it will have a negative infl uence on the performance of this appliance. Ensure that the

levelling screws are tightened into position.

The protective wrap on plated parts is best removed when the assembly is at room temperature but this can be

improved if the assembly is warmed, using a hair dryer or similar heat source.

If the appliance is installed directly on carpeting, vinyl tile or other combustible material other than wood

fl ooring, the appliance shall be installed on a non-combustible hearth pad extending the full width and depth.

2.4 GENERAL INFORMATION

2.4.1 FUEL

4.5B

This appliance is designed to burn wood pellet fuel. In addition, a corn/wood pellet mixture with a maximum

50% corn can be burned. Burning any other fuel, that is not approved for use with this appliance, will void the

warranty.

Important: The corn/wood pellet mixture needs to be mixed evenly before being put into the hopper.

W415-1477 / A / 10.19.16

Page 9

2.4.2 PELLET SPECIFICATIONS

9

!

WARNING

IT IS IMPORTANT TO SELECT AND USE ONLY PELLETS THAT ARE DRY AND FREE OF DIRT

OR ANY IMPURITIES SUCH AS HIGH SALT CONTENT. DIRTY FUEL WILL ADVERSELY AFFECT

THE OPERATION AND PERFORMANCE OF THE APPLIANCE AND WILL VOID THE WARRANTY.

THE PELLET FUEL INSTITUTE (P.F.I.) HAS ESTABLISHED STANDARDS FOR WOOD PELLET

MANUFACTURERS. WE RECOMMEND THE USE OF PELLETS THAT MEET OR EXCEED THESE

STANDARDS. ASK YOUR DEALER FOR A RECOMMENDED PELLET TYPE.

Pellet quality is important, please read the following:

Your Wolf Steel Ltd. Pellet Appliance has been designed to burn premium hard or soft wood pellets only. Do

not use any other type of fuel such as fi re logs or fi re starting pellets, as this will void the warranties stated in

this manual.

The performance and heat output of the pellet appliance is directly related to the quality and moisture of the

pellets. Store pellets in a cool dry area to prevent moisture absorption.

P.F.I. PELLET STANDARDS:

Inorganic Fines (fi ne

particles)

Bulk Density 38 pound per cubic foot minimum

Size 1/4" (6.4mm) to 5/16" (8mm) diameter, 1/2" - 1 1/2" (13mm

Ash Content No more than 2%

Moisture Content 8% maximum

Chlorides 300 parts per million by weight

Trace Metals Less than 100mg/kg

Heat Content Approximately 8200 BTU/Hr per pound minimum

Construction Waste Not to contain any waste materials

1% maximum through a 1/8" (3.2mm) screen

- 38mm) long maximum

64.1

If the fuel does not comply to

this standard the appliance

may not operate as designed.

We recommend the use of

premium grade (1% ash

content) for longer appliance

life and less frequent cleaning.

EN

2.4.3 CORN SPECIFICATIONS

Use only clean-shelled corn with a moisture content less than 15% and approximate fuel value of 7,000 BTU/

lb (16,200 kJ/kg). Do not attempt to burn corn with higher moisture content or burn lesser grade fuels. Do not

burn other types of agricultural pellets or by-products (alfalfa, cherry pits, olive pits, nut shells, etc.) as they

are not permitted to be burned in this appliance.

Corn must be clean and free of debris. Never burn corn right from the fi eld. Damage caused by dirty corn is

not covered by the Lifetime Limited Warranty. Ask for screened corn only. Stalk parts, excessive fi nes and

cob remnants will clog the air fl ow holes in the burn plate. Check the corn for foreign objects.

Use only a maximum 50% corn to pellet mixture.

W415-1477 / A / 10.19.16

Page 10

10

U.S. Environmental Protection Agency:

Certifié conforme à la norme d’ émanation de particles de

2015.Non approuvé pour la vente après le 15 mai, 2020

: 40 CFR Part 60, Subpart AAA.

3.3 Grammes par heure.

to comply with 2015 particulate emissions standards.

0, Subpart AAA.

3.3 Grams Per Hour

CorneCo

CORNER 2”CORNE

M

RMIN 1.5 LB/HR

M

MAX 4.5 LB/HR

on

D.D.

DÉGAGEMENTS MINIMDÉGAGEMENT

CÔTÉ 6” CÔTÉ 6”

ARRIÈRE 3” ARRIÈRE 3”

oor

Protection

Protection de Ptti d

plancherplancher

3”

3”

”

CertifieCertif

40 CFR PartCFR Pa

820120192019

22334

66

8

HOT WHILE IN OPERATION. DO NOT TOUCH. KEE HOT WHILE IN OPERATION. DO NOT TOUCH. KE

RMÉES DURANT LE MÉE

SEULEMENT.

I

tInterior

Through Wall Ventsgh Wall Ven

Installations à Travers leInstallations à Travers

Protection deProtection de

Protection deProtection d

Protection d

plancherplancherpl

rplancher

plancher

CHAUFFAGE D’UNE MANIÈRE ALLANT À AUFFAGE D’UNE MANIÈR

2.4.4 SAFETY FEATURES

HIGH LIMIT SWITCH: Your appliance is equipped with a high limit switch. In the event that the temperature

EN

2.4.5 EPA COMPLIANCE

of the appliance approaches an unsafe operating temperature, this switch will shut down the pellet feed,

which will eventually shut down the unit. If this happens, it is important to fi nd out why the unit overheated.

Contact your local dealer.

LOW LIMIT SWITCH: This switch will automatically shut down the appliance if the fi re goes out or fails to

light within 15 minutes.

HOPPER DOOR INTERLOCK: Your appliance is equipped with a micro switch in the hopper assembly that

shuts-off the auger when the hopper door is opened. Closing the door switches the auger back on, allowing

pellets to feed again.

VACUUM SWITCH: This switch will sense lack of air fl ow through the appliance and shut down the pellet

feed. This lack of fl ow could be caused by a blocked vent.

POWER FAILURE: In the event of a power failure, the appliance will shut down. Once power is restored, the

appliance will re-start, unless the convection air temperature has gone above the high limit switch setting. If

this happens, contact your local dealer.

We suggest that our woodburning hearth products

be installed and serviced by professionals who are

certified in the U.S. by the National Fireplace

Institute® (NFI) as NFI Woodburning Specialists or

who are certified in Canada by

Wood Energy Technical

Training (WETT).

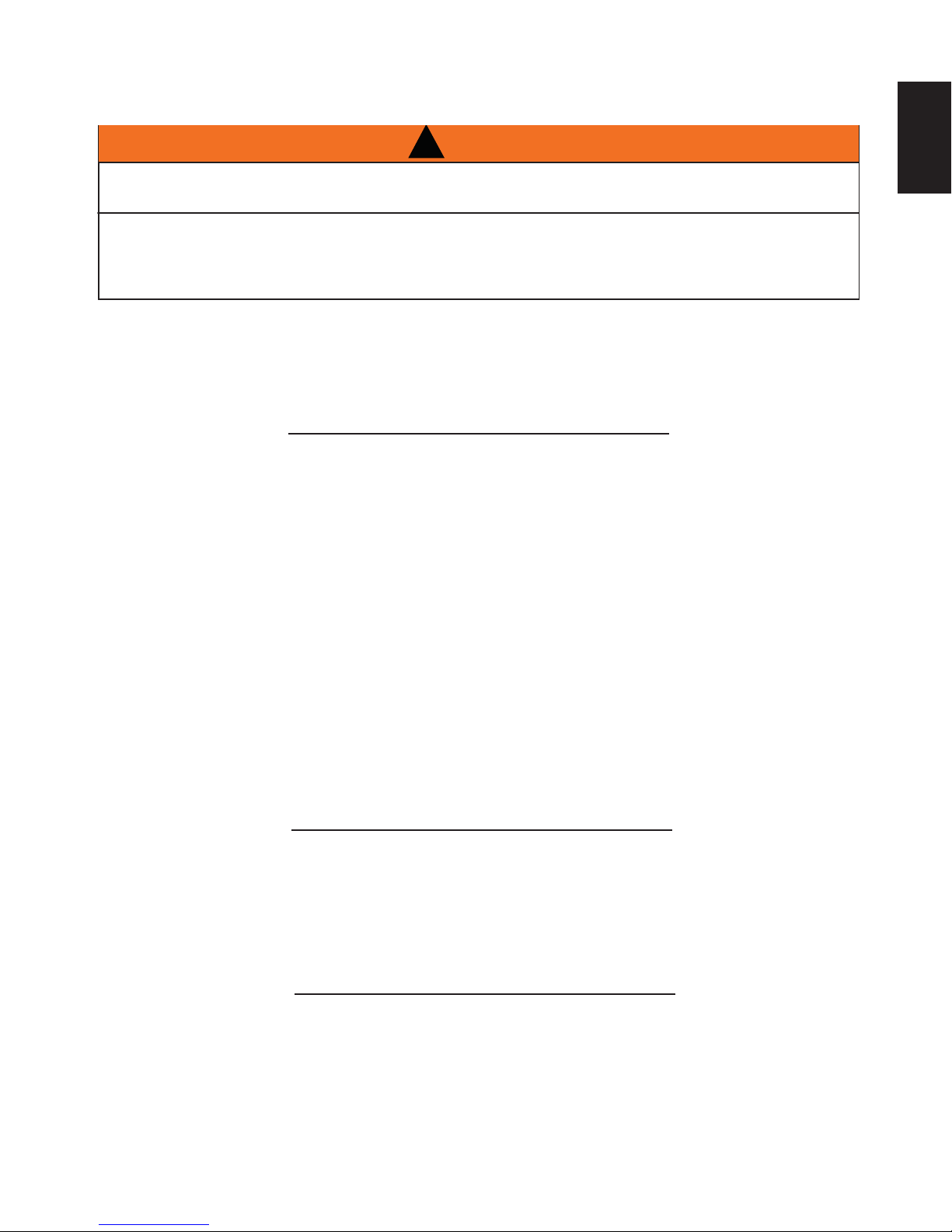

2.5 RATING PLATE INFORMATION

For rating plate location, see

“INSTALLATION OVERVIEW”

section.

This illustration is for reference

only. Refer to the rating plate

on the appliance for accurate

information.

NOTE: The rating plate must

remain with the appliance

at all times. It must not be

removed.

- INSTALL AND USE ONLY IN ACCORDANCE WITH THE

MANUFACTURER’S INSTRUCTIONS AND LOCAL

BUILDING CODES.

- MINIMUM CEILING HEIGHT: 7FT (2.13M) HEARTH

9700539 (WSL)

4001657 (NGZ)

4001658 (NAC)

4001659 (WUSA)

- KEEP VIEWING AND ASH REMOVAL DOORS TIGHTLY CLOSED DURING OPERATION.

- CONTACT LOCAL BUILDING AND FIRE OFFICIALS ABOUT RESTRICTIONS AND

INSTALLATION INSPECTION IN YOUR LOCAL AREA.

- SUITABLE FOR USE IN MOBILE HOMES WHEN USED WITH OUTSIDE AIR

INSTALLATION KIT.

- REFER TO INSTALLATION INSTRUCTIONS OR LOCAL BUILDING CODES WHEN

PASSING EXHAUST SYSTEM THROUGH COMBUSTIBLE WALL OR CEILING.

- FUEL: FOR USE WITH PELLET FUEL ONLY.

THIS WOOD APPLIANCE NEEDS PERIODIC INSPECTION AND REPAIR FOR PROPER OPERATION.

CONSULT THE OWNER’S MANUAL FOR FURTHER INFORMATION. IT IS AGAINST UNITED STATE

FEDERAL REGULATIONS TO OPERATE THIS WOOD APPLIANCE IN A MANNER INCONSISTENT

WITH THE OPERATING INSTRUCTIONS IN THE OWNER’S MANUAL.

- INSTALLER ET UTILISER CONFORMÉMENT AUX INSTRUCTIONS DU FABRICANT ET AUX CODES

DU BÂTIMENT LOCAUX.

- HAUTEUR DE PLAFOND MINIMALE 7 PI. (2,13 m)

BASE DE PROTECTION/PROTECTION DE PLANCHER COMBUSTIBLE : SI INSTALLÉ SUR UN

PLANCHER COMBUSTIBLE, L’APPAREIL DOIT ÊTRE PLACÉ SUR UNE PLAQUE PROTECTRICE

INCOMBUSTIBLE S’ÉTENDANT SUR 6” À L’AVANT.

- NE PAS RACCORDER CET APPAREIL À LA CHEMINÉE D’UN AUTRE APPAREIL.

- REMPLACER LA VITRE PAR UNE VITRE EN CÉRAMIQUE SEULEMENT.

DANGER : RISQUE DE SECOUSSE ÉLECTRIQUE. DÉBRANCHER L’ALIMENTATION ÉLECTRIQUE

AVANT DE PROCÉDER À L’ENTRETIEN.

- GARDER LA PORTE VITRÉE ET LA PORTE DU TIROIR À CENDRES BIEN FERMÉES DURANT LE

FONCTIONNEMENT.

- CONTACTER LES AUTORITÉS LOCALES DU BÂTIMENT ET DU SERVICE DES INCENDIES AU

SUJET DES RESTRICTIONS ET DES INSPECTIONS D’INSTALLATION DANS VOTRE RÉGION.

- PEUT ÊTRE INSTALLÉ DANS UNE MAISON MOBILE SI INSTALLÉ CONJOINTEMENT AVEC UNE

PRISE D’AIR EXTÉRIEUR.

- SE RÉFÉRER AUX INSTRUCTIONS D’INSTALLATION OU AUX CODES DU BÂTIMENT LOCAUX

LORSQUE LE SYSTÈME D’ÉVACUATION TRAVERSE UN MUR OU UN PLAFOND COMBUSTIBLES.

- COMBUSTIBLE : POUR USAGE AVEC DES GRANULES SEULEMENT.

CET APPAREIL AU BOIS DOIT FAIRE L’OBJECT D’UNE INSPECTION ET D’UN ENTRETIEN

PÉRIODIQUES POUR UN FONCTIONNEMENT ADÉQUAT. CONSULTEZ LE MANUEL

D’INSTRUCTIONS POUR PLUS D’INFORMATION. LES RÈGLEMENTS FÉDÉRAUX DE L’ÉTATS-UNIS

INTERDISENT D’UTILISER CET APPAREIL DE CHAUFFAGE D’UNE MANIÈRE ALLANT À

L’ENCONTRE DES INSTRUCTIONS DE FONCTIONNEMENT CONTENUES DANS CE MANUEL.

YEAR:

MONTH:

WOLF STEEL LTD.

24 NAPOLEON ROAD, BARRIE, ON, L4M 0G8 CANADA

MODEL TPS35 LISTED PELLET FUEL BURNING ROOM HEATER TESTED TO: ASTM E 1509, ULC/ORD C1482-M90, ULC S627

EXTENSION / COMBUSTIBLE FLOOR PROTECTION:

IF INSTALLED ON A COMBUSTIBLE FLOOR, UNIT MUST

BE PLACED ON A NON-COMBUSTIBLE FLOOR PROTECTOR

EXTENDING 6” IN FRONT.

- DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE

SERVING ANOTHER APPLIANCE.

- REPLACE GLASS WITH ONLY CERAMIC GLASS.

DANGER: RISK OF ELECTRICAL SHOCK. DISCONNECT

POWER BEFORE SERVICING UNIT.

MANUFACTURE DATE: / DATE DE FABRICATION:

2016

243658710912111

2017 2018

2017201

2019 2020

Straight Installation Corner Installation

3”

Floor

6”

Protection

Through Wall Installation

MINIMUM CLEARANCES TO COMBUSTIBLE

SIDE 6” CORNER 2”

U.S. ENVIROMENTAL PROTECTION AGENCY Certified to comply with July 1992 Particulate Emission Standards

HOT WHILE IN OPERATION. DO NOT TOUCH. KEEP CHILDREN,CLOTHING AND FURNITURE AWAY.

3”

Protection de

Protection de

anche

plancher

plancher

Installations à Travers le Mur

DÉGAGEMENTS MINIMAUX AUX MATÉRIAUX COMBUSTIBLES

CÔTÉ 6” COIN 2”

ARRIÈRE 3” PLAFOND 48”

ATTENTION :

LES ENFANTS, LES VÊTEMENTS ET LES MEUBLES À L’ÉCART. LE CONTACT PEUT CAUSER

DES BRÛLEURS DE PEAU.

U.S. Environmental Protection Agency:

2015.Non approuvé pour la vente après le 15 mai, 2020

3.3 Grammes par heure.

3”

2”

Tee

6”

Floor

Fl

Protection

Interior Vertical Vent

nterior Vertical Ven

3”

2”

2

Protection de

plancher

Évents Verticaux Intérieurst

L'APPAREIL EST CHAUD LORSQU’IL FONCTIONNE. NE PAS TOUCHER. TENIR

Through Wall Vents Interior Vertical Vent

ELECTRICAL RATING

MIN 1.5 LB/HR

IN 1.5 LB/H

MAX 4.5 LB/HR

AX 4.5 LB/HR

40 CFR Part 60, Subpart AAA.

6”

6”

TPS35

120V 3.6A 60HZ

Certified to comply with 2015 particulate emissions standards.

3.3 Grams Per Hour

Installation en Coin

Installation de coin

2”

45°

Coude

45°

2”

6”

6”

Protection de

plancher

Évents à Travers le Mur

IDÉBIT D’ALIMENTATION

MIN. 1.5 LB/H

MAX. 4.5 LB/H

Certifié conforme à la norme d’ émanation de particles de

CARACTÉRISTIQUES ÉLECTRIQUES

120 V 60 Hz

: 40 CFR Part 60, Subpart AAA.

2”

6”

Té

2”

6”

Protection de

plancher

Évents Verticaux Intérieurs

W385-2035 / A

6”

Floor Protection

6”

Tee

2”

2”

W415-1477 / A / 10.19.16

Page 11

3.0 INSTALLATION PLANNING

11

!

WARNING

READ ENTIRE MANUAL BEFORE YOU INSTALL OR USE THIS APPLIANCE. FAILURE TO FOLLOW THE

INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH.

USE ONLY WOLF STEEL APPROVED OPTIONAL ACCESSORIES AND REPLACEMENT PARTS WITH

THIS APPLIANCE. USING NON-LISTED ACCESSORIES AND REPLACEMENT PARTS (BLOWERS,

DOORS, LOUVRES, TRIMS, GAS COMPONENTS, VENT COMPONENTS, ETC.) COULD RESULT IN A

SAFETY HAZARD AND WILL VOID THE LIMITED LIFETIME WARRANTY.

Check with local building offi cials for any permits required for installation of this pellet appliance and notify your

insurance company before proceeding with installation.

Before installing we recommend placing the appliance outside and load 5 lbs (2.3k) of pellets inside the hopper. Plug the appliance in and let it run on HIGH until the pellets run out. This will cure the paint and burn off

most of the oils on the steel, thereby minimizing any smell inside the home.

68.1A

3.1 INSTALLATION OPTIONS

Stove model:

To install in a Residential or Mobile Home see "MOBILE HOME INSTALLATION" section. For alcove

installations see "ALCOVE INSTALLATION REQUIREMENTS" section. For horizontal vent or vertical vent see

"VENTING" section. Outside air, see "OUTSIDE AIR" section.

Insert model:

To install as an insert into an existing masonry appliance or factory built appliance see "VENTING" section. To

install into a combustible enclosure, see "INSTALLATION INTO A COMBUSTIBLE ENCLOSURE" section.

EN

3.2 APPLIANCE PLACEMENT

Have an authorized dealer install the appliance. If you install the appliance yourself, have your dealer review

your installation plans and/or installation.

Draw out a detailed plan of the installation including dimensions and verify the dimensions with the

requirements listed in this manual.

You may wish to adjust the appliance position slightly to ensure the vent does not intersect with a framing

member. Appliance must be positioned so that no combustibles are within, or can swing within (e.g. drapes,

doors), 4 feet (1.2m) of the front of the appliance.

67.1B

3.3 LEVELLING THE APPLIANCE

Move the appliance close to its fi nal position. This appliance is equipped with levelling screws located on the

base. Level using the levelling screws. Levelling the appliance will eliminate rocking or excessive noise when

the fan is in operation. Once the appliance is level, move it partially into place to allow for all connections to be

made. It is not practical to level the appliance once it has been installed. Determine the required depth prior to

installing the appliance and adjust the levelling screws accordingly.

67.2

W415-1477 / A / 10.19.16

Page 12

12

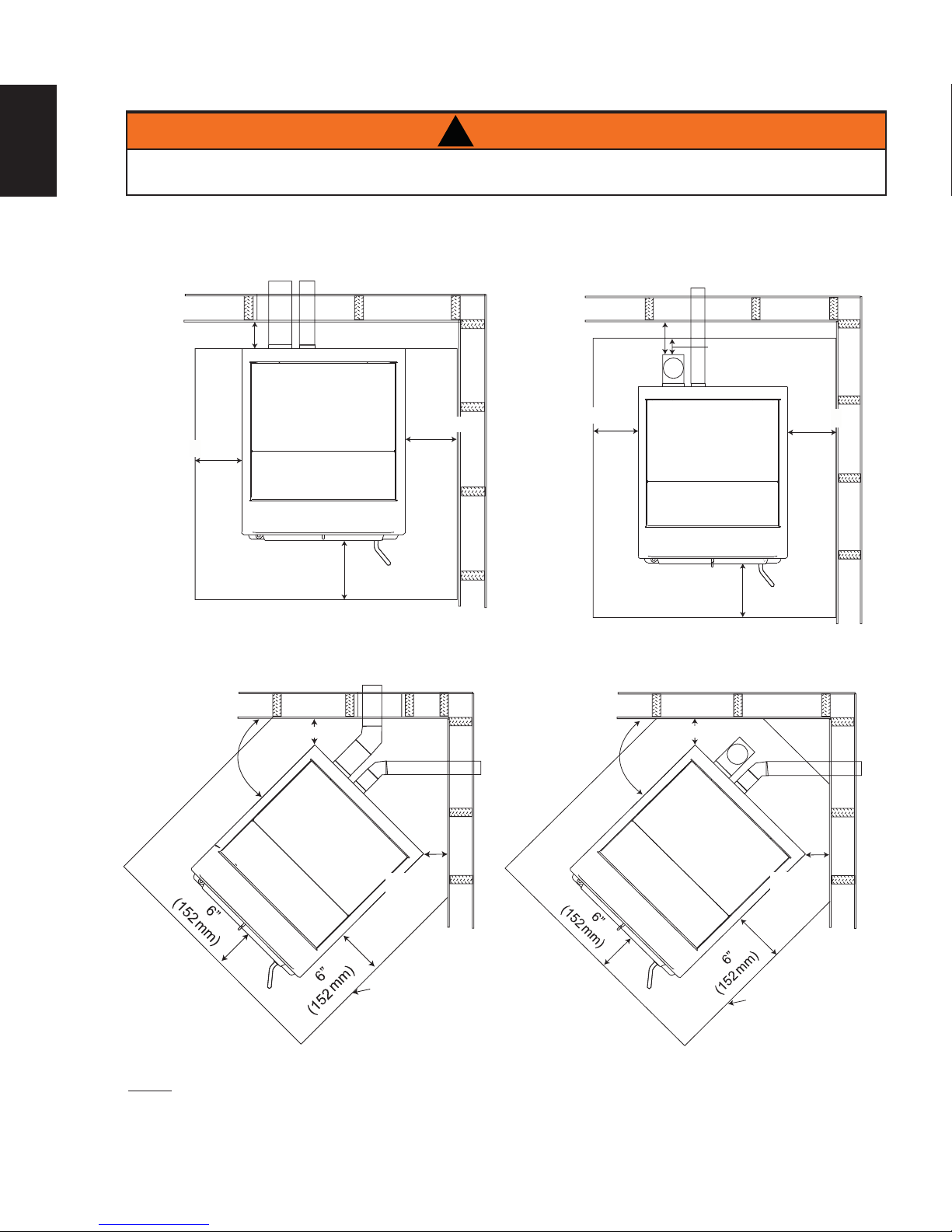

3.4 MINIMUM CLEARANCE TO COMBUSTIBLES

EN

DO NOT INSTALL INTO ANY AREA HAVING LESS THAN 48" (1219mm) (CEILING TO APPLIANCE

BOTTOM, EXCLUDING HEARTH HEIGHT).

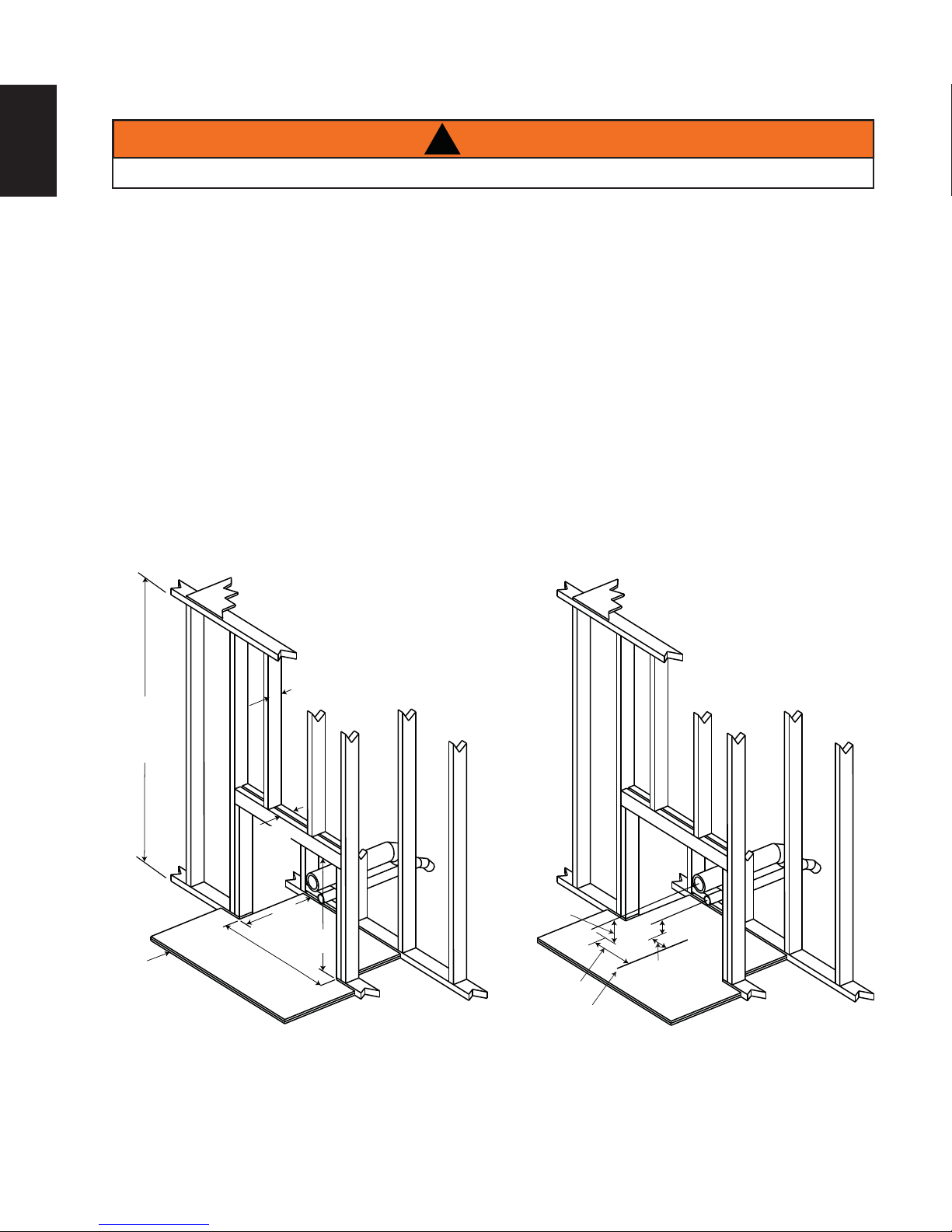

3.4.1 STRAIGHT INSTALLATION

Through the Wall Installations complete

with outside air

3”(76mm)

6”

(152mm)

Floor

Protection

6”

(152mm)

!

6”

(152mm)

WARNING

3”(76mm)

(152mm)

Interior Vertical Vents

2” (51mm)

6”

Floor

Protection

6”

(152mm)

6”

(152mm)

3.4.2 CORNER INSTALLATION

Through the Wall Vents complete with outside air Interior Vertical Vents

2” (51mm)

45°

NOTE: If interior vertical pellet vent is used, the clearance to the back wall is determined by the

upward-turning elbow or "Tee". It will vary in depth depending on the brand of pellet vent used [it is

approximately 5" (127mm)]. Before placing the appliance, connect the elbow or "Tee" and allow for the

minimum 3" (76mm) clearance to the combustible wall.

45°

Elbow

2”

(51mm)

Floor Protection

45°

2” (51mm)

2”

(51mm)

Floor Protection

W415-1477 / A / 10.19.16

Page 13

3.5 FLOOR PROTECTION REQUIREMENTS INSTALLATION

13

The appliance must be installed on a non-combustible fl oor protector extending the full depth of the

appliance and extending a minimum 6" (152mm) in front and on either side (minimum .018" thick - 26 gauge)

of the fuel loading and ash removal openings.

The fl oor protector must extend under and 2" (51mm) beyond each side and back of a "Tee" (if used).

NOTE: Floor protection is required for spark and ash shielding, but not for limiting fl oor temperatures

from the radiant heat of the appliance. The appliance was designed and safety tested so that without

any protection, the fl oor would not overheat.

Refer to local building codes for suitable fl oor protection materials.

3.6 OUTSIDE AIR

Available from your Authorized Dealer (114KT)

Outside air must not be drawn from an enclosed space (garage, unventilated crawl space).

NOTE: Wolf Steel Ltd. strongly suggests using outside air for all residential installations, especially for

those that are energy effi cient, air-tight homes.

Outside air supply must not be over 15' (4.6m) long.

Outside air vents must be made with 1 3/4" (45mm) diameter or larger metal or aluminum duct with a metal

screen attached to the end to keep out rodents (P.V.C. or other materials may not be used).

The outside air inlet must not be above or within 12" (305mm) of the chimney termination, must have a rain

cap or down-turned elbow to prevent the water from entering and be located so that it will not become

plugged by snow or other material.

EN

Outside air is required for all combustible built-in enclosure installations.

3.7 MOBILE HOME

THE STRUCTURAL INTEGRITY OF THE MANUFACTURED HOME FLOOR, WALL, AND CEILING ROOF

Installation into a manufactured home or mobile home should be installed in

accordance with the Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280, in the United States or the Mobile Home Standard,

CAN/CSA Z240 MH Series, in Canada.

The appliance must be grounded to the steel chassis of the mobile home

(Some states do not require this; check with your local building department).

!

WARNING

DO NOT INSTALL IN A SLEEPING ROOM.

MUST BE MAINTAINED.

STOVE

ILLUSTRATED

29.4A

W415-1477 / A / 10.19.16

Page 14

14

4.0 VENTING

EN

4.1 TYPE OF VENT

Must be an approved 3" (76.2mm) or 4" (102mm) diameter Type "L" or "PL" vent, vented to the outside or

connect the vent to a factory built type "A" chimney using an adaptor; and/or stainless steel chimney liner for

masonry appliance installations. Use 4" (102mm) diameter vent if vent or liner height is over 15' (4.6m) or if

installation is over 4,000' (1219m) above sea level.

4.2 PELLET VENT INSTALLATION

PELLET VENT MUST MAINT AIN A MINIMUM 3" (76.2mm) CLEARANCE TO ANY COMBUSTIBLE (INSTALL

VENT AT CLEARANCES SPECIFIED BY THE VENT MANUFACTURER, CHIMNEY LINER EXCLUDED).

DO NOT CONNECT THE PELLET VENT TO A VENT OR CHIMNEY SERVING ANY OTHER APPLIANCE OR

DO NOT INST ALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF THIS UNIT.

The vent must have a support bracket every 5’ (1.5m)when on

the exterior wall. To achieve optimum performance, keep vent

runs as short as possible, especially on horizontal installations.

MAXIMUM VENTING: Maximum venting height is 33’ (10.1m)

Maximum horizontal without vertical rise is 5’ (1.5m) straight

off the back of the appliance. Use no more than 180° of

elbows (two 90° elbows, or two 45° elbows and one 90°

elbow, etc), excluding the tee and the termination.

VENT INST ALLATION: Termination must exhaust above

the air inlet elevation, and parallel or above the exhaust

output of the pellet appliance. It is recommended that at

least 3’ (0.9m) of vertical pipe be installed to create some

natural draft. This is to help prevent the possibility of smoke

or odour entering the home during the appliance shut down

or in the event of a power outage. Horizontal sections must

have a 1/4” (6.4mm) rise every 12” (304.8mm) of travel if

longer than 3’ (0.9m).

The pellet vent connections must be sealed with HI-Temp

RTV Silicone and screwed together with at least 3 3/8”

(85.7mm) long stainless steel screws. Seal each vent

section by injecting a liberal amount of 500°F (260°C) RTV

silicone sealant into the gap. We recommend sealing the

outside of the vent connections to permit easier access

when servicing.

!

WARNING

HEATER.

diameter “L”

vent if venting

in this shaded

Use 3” (76.2mm)

or 4” (101.6mm)

diameter “L”

vent if venting

in this shaded

Use 4”

(101.6mm)

region.

region.

33’ (10.1m)

30’ (9.1m)

25’ (7.6m)

20’ (6.1m)

15’ (4.6m)

10’ (3.1m)

5’ (1.5m)

0

0

5’

(1.5m)

10’

(3.1m)

4.3 VENTING THE PELLET APPLIANCE

Use an approved wall thimble when passing the vent through walls and a ceiling support / fi restop spacer

when passing the vent through ceilings (maintain a 3" (76mm) clearance to any combustibles).

W415-1477 / A / 10.19.16

7.5D

Page 15

4.4 PELLET VENT TERMINATION

15

The vent termination must have an approved cap (to prevent water from entering) or a 45° downturn.

If the termination is located on a windy side of the house, a shield is recommended to prevent soot from

building up on the side of the house.

Horizontal terminations must protrude 12" (305mm) from the wall, vertical terminations require a minimum 24"

(610mm) above the highest point that it penetrates through the roof.

Depending on pellet quality, vent confi guration and air settings, black soot may occur on the terminal wall.

4.5 VENT TERMINAL CLEARANCES

D

A

NOTE: Illustration dimensions are to the center of

the exhaust exit point of the vent.

EN

E

C

K

J

G

I

F

H

B

B

L

E

CLEARANCES

A 12” (30.5cm) Clearance above grade, veranda porch, deck or balcony. (Including vegetation and mulch)

B

C

D 0” (0mm) Clearance to an outside corner wall.

E 3” (75mm) Clearance to an inside combustible corner wall or protruding combustible obstructions (vent chase, etc.)

F 9” (22.9cm) Clearance to a non-mechanical air supply inlet to the building or a combustion air inlet to any other appliance.

G 3’ (0.9m) Clearance to a mechanical air supply inlet.

H 7’ (2.1m) ** Clearance above a paved sidewalk or paved driveway located on public property.

J 24” (61cm) Clearance above the roof.

K 2’ (0.6m) Clearance from an adjacent wall including neighbouring buildings.

L

** This is a recommended distance. For additional requirements check local codes.

9” (22.9cm)* Clearance beside or below any windows or doors that open.

12” (30.5cm)* Clearance above any window or door that opens.

18”

(45.7cm)

I 12” (30.5cm)** Clearance under a veranda, porch, deck or balcony.

3’ (0.9m) within a

height of 15 feet

(13.7m) above the

meter / regulator

assembly

* Recommended to prevent condensation on windows and thermal breakage

Vertical clearance to ventilated soffi t located above the terminal within a horizontal distance of 2 feet

(0.6m) from the center line of the terminal.

Clearance to each side of center line extended above natural gas or propane meter / regulator assembly or

mechanical vent.

12.7C

W415-1477 / A / 10.19.16

Page 16

16

4.6 STOVE VENTING INSTALLATION EXAMPLES

EN

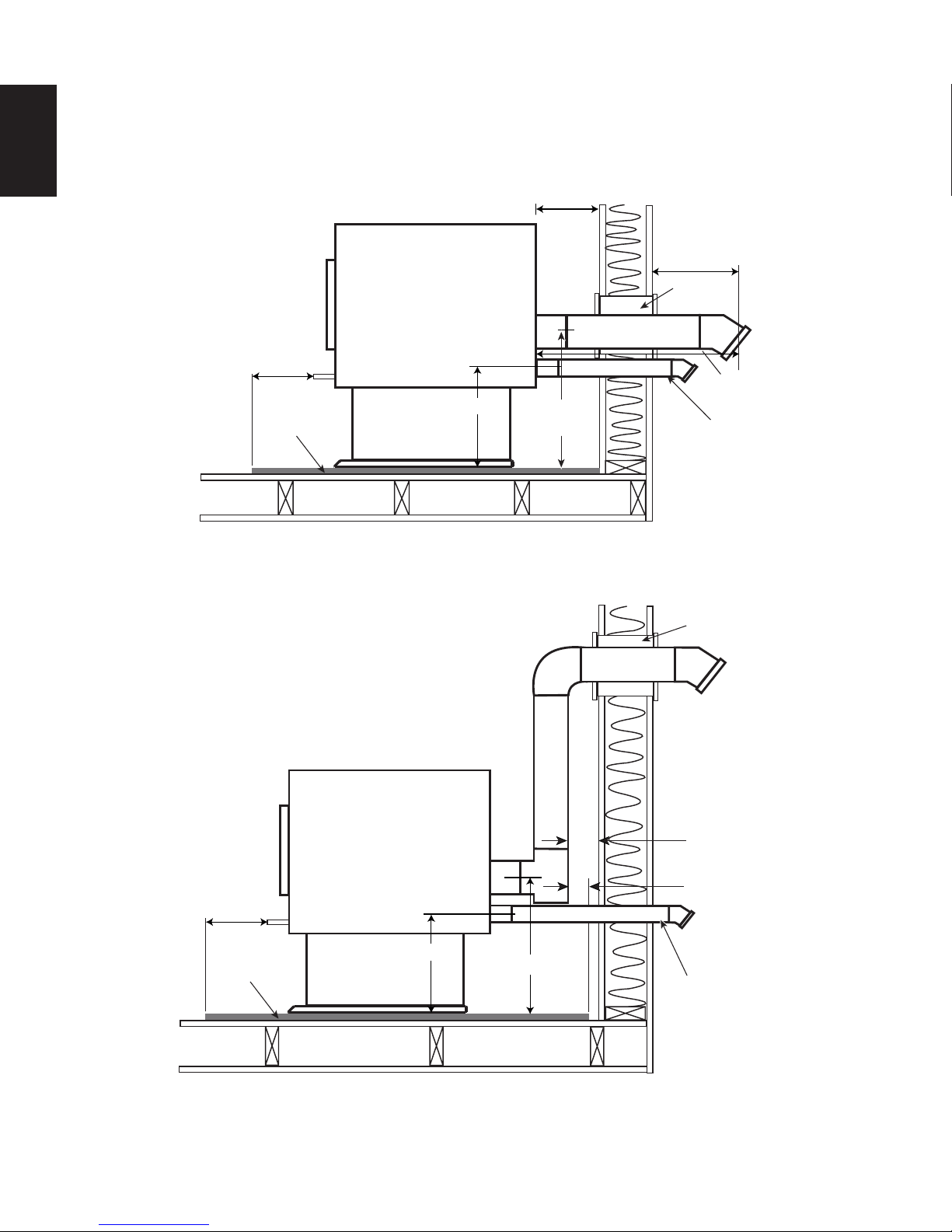

4.6.1 HORIZONTAL TERMINATION (THROUGH WALL)

6”(152mm)

Minimum

Floor

Protection

11 5/8”(295mm)

3”(76mm)

Minimum

17”

(432mm)

12”(305mm)

Minimum

Wall

Thimble

5’(1.5m)

Maximum

Outside Air

(Recommended)

4.6.2 VERTICAL RISE HORIZONTAL TERMINATION (THROUGH WALL)

6”(152mm)

Minimum

Floor

Protection

11 5/8”(295mm)

17”(432mm)

(Recommended)

Wall Thimble

3”(76mm)

2”(51mm)

Outside Air

W415-1477 / A / 10.19.16

Page 17

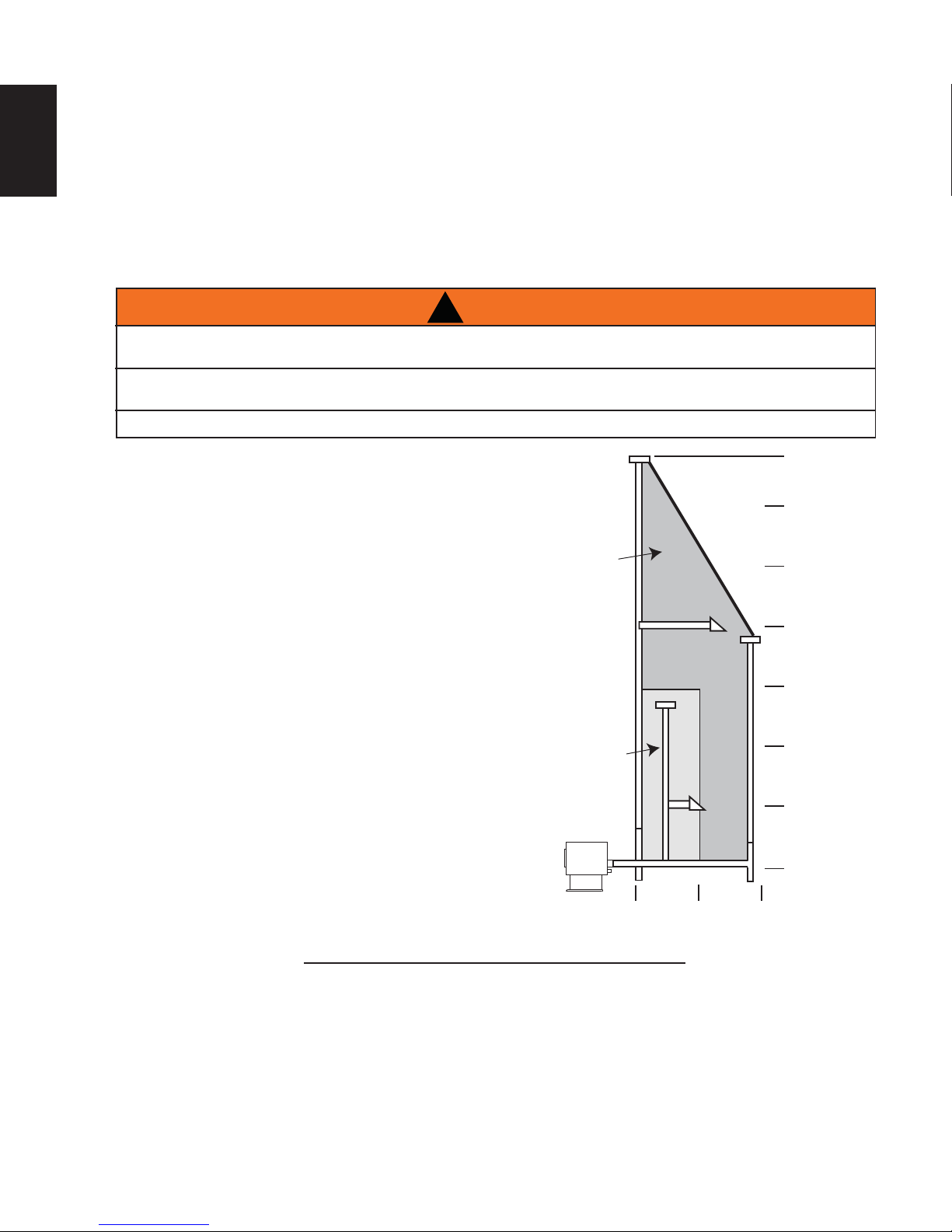

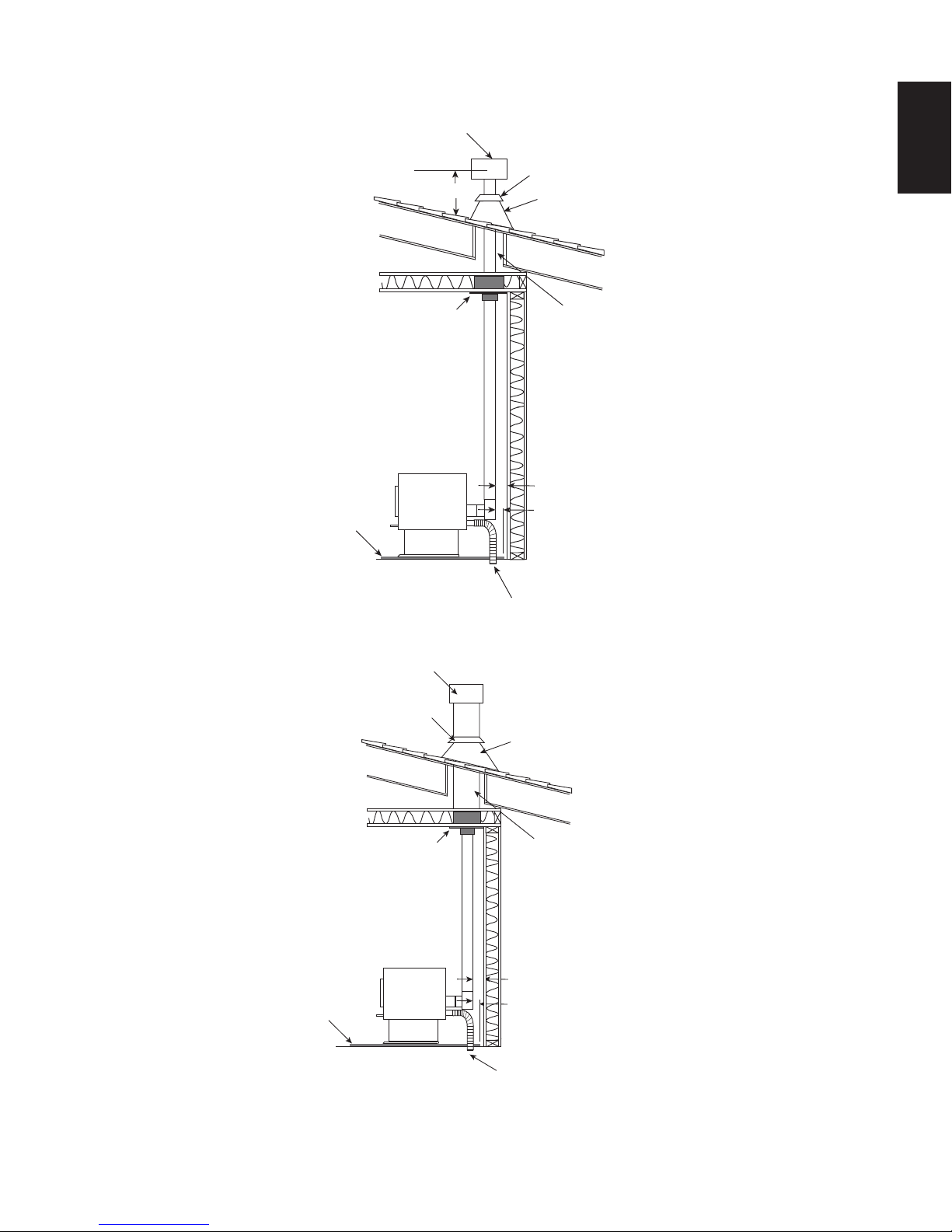

4.6.3 VERTICAL TERMINATION

17

Floor Protection

Vertical Cap

24”(610mm)

Ceiling Support

EN

Storm Collar

Roof Flashing

Vent must maintain

3”(76mm) clearance to

combustibles.

3”(76mm)

2”(51mm)

Outside air (Recommended)

(Installation showing inlet of out-

side air in ventilated crawl space)

4.6.4 CLASS A CHIMNEY RETROFIT

Vertical Cap

Storm Collar

Class A Chimney

Ceiling Support

Floor Protection

Roof Flashing

Vent must maintain

3”(76mm) clearance to

combustibles.

3”(76mm)

2”(51mm)

Outside air

(Recommended)

(Installation showing inlet of outside

air in ventilated

crawl space)

W415-1477 / A / 10.19.16

Page 18

EN

on

S

18

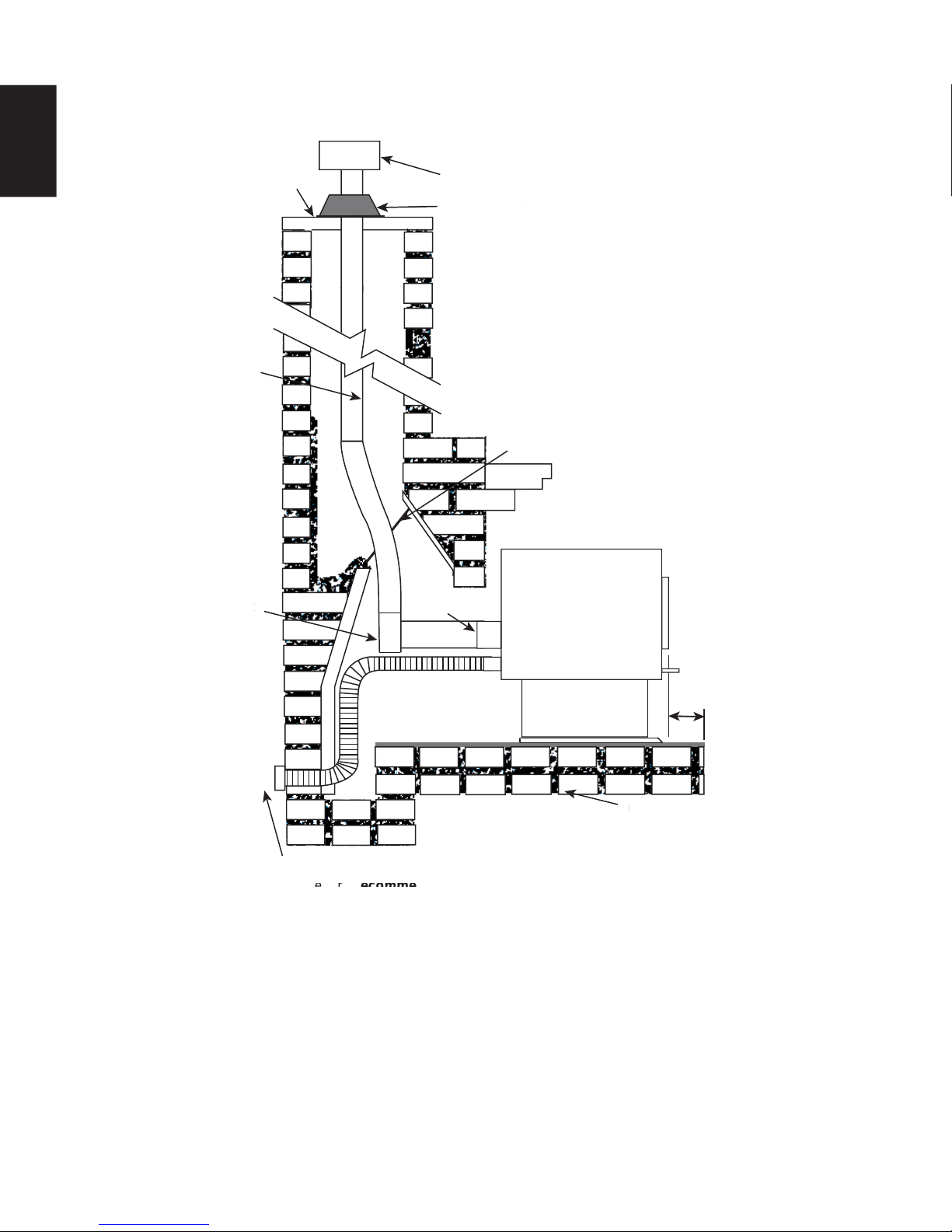

4.6.5 HEARTH MOUNT INSTALLATION

Chimney Cap

Pellet

Liner

Clean-out

ut

tee

Vertical Cap

Pellet

Vent

Storm Collar

torm Collar

Flue Cover

Bring outside air to the stove

Outside Air (Recommended)

For installation instructions See "TYPICAL EXISTING MASONRY" section.

6”(152mm)

MIN

Floor Protection

Floor Protecti

W415-1477 / A / 10.19.16

Page 19

4.7 INSERT VENTING INSTALLATION EXAMPLES

l

e

r

o

Cap

Ver

19

4.7.1 TYPICAL EXISTING MASONRY INSTALLATION

!

WARNING

DO NOT REMOVE BRICKS OR MORTAR FROM THE FIREPLACE.

Prior to installation:

When installing the insert into a masonry fi replace, do not

remove any bricks or masonry. Do not weaken the structure,

or reduce the protection for combustible materials to less then

that required by the National Building Code. Bolted or screwed

together pieces (smoke shelf / defl ectors) may be removed,

but must be able to be re-installed if the appliance is removed.

External trim pieces, which do not affect the operation of the

fi replace, may be removed provided they are available to be reinstalled in event the appliance is removed.

A warning label must be attached to the back wall of the fi replace

stating that “This fi replace has been altered to accommodate a

fi replace insert and must be re-inspected by a qualifi ed person

prior to re-use as a fi replace”.

Non-combustible fl oor protection must cover the fl ooring

underneath, as well as extend a minimum of 6” (152.4mm) in

front and to both sides of the appliance.

Cover Plate

Vertical Cap

Storm Collar

rm Colla

t

Pellet

Liner

Cover

Flue

EN

Clean all ashes out of the inside of the fi replace. Make sure

that the chimney and fi replace are free of cracks, loose mortar,

creosote deposits, blockage or other signs of deterioration.

If necessary, have any repair work done by a qualifi ed

professional before installing the appliance.

A. Remove the fi replace damper or fasten it permanently open.

B. Measure the throat of the fi replace and mark this shape on a piece of 24 (0.511mm) gauge sheet meta

(fl ue cover). Cut a hole sized for the pellet liner to lie directly below the fi replace fl ue opening. Allow 2”

(50.8mm) of material for a fl ange on all sides and cut to these measurements. Bend down the fl anges.

If you have never done this before, it might be a good idea to make a cardboard pattern and test it fi rst.

Fasten this fl ue cover in position as high as possible with two masonry screws per side through the

fl anges into the fi replace.

C. If you plan on connecting outside air it is recommended to do so at this time.

D. Install fl oor protection if necessary.

E. Connect the pellet vent with a clean out tee to the back of the insert. Refer to manufacturer’s

installation instructions to see “REAR TO TOP VENT CONVERSION INSTRUCTIONS” section and th

“GENERAL VENTING” section.

F. Run a liner down the chimney and connect to tee.

Outside Air

(Recommended)

G. Position the insert in it’s fi nal location.

H. Pull the excess length of liner out through the top of the chimney. Trim the excess liner, install the cap

and cap the chimney.

62.3B

W415-1477 / A / 10.19.16

Page 20

20

l

e

4.7.2 FACTORY BUILT FIREPLACE

EN

Prior to installation:

Do not weaken the structure or reduce the protection for

combustible materials to less then that required by the National

Building Code. Bolted or screwed together pieces (smoke shelf /

defl ectors) may be removed, but must be able to be re-installed

if the appliance is removed.

External trim pieces, which do not affect the operation of the

fi replace, may be removed provided they are available to be reinstalled in event the appliance is removed.

A warning label must be attached to the back wall of the

fi replace stating that “This heater has been altered to

accommodate a fi replace insert and must be re-inspected by a

qualifi ed person prior to re-use as a factory built fi replace”.

Non-combustible fl oor protection must cover the fl ooring

underneath, as well as extend a minimum of 6” (152.4mm) in

front and to both sides of the appliance.

Clean all ashes out of the inside of the fi replace. Make sure

that the chimney and fi replace are free of cracks, loose mortar,

creosote deposits, blockage or other signs of deterioration.

Storm

Collar

The smoke

shelf, damper

and baffles may

be removed

Vertical

Cap

Roof

Flashing

If necessary, have any repair work done by a qualifi ed

professional before installing the appliance.

A. Remove the fi replace damper or fasten it permanently

open.

B. Measure the throat of the fi replace and mark this shape on a piece of 24 (0.511mm) gauge sheet meta

(fl ue cover). Cut a hole sized for the pellet liner to lie directly below the fi replace fl ue opening. Allow 2”

(50.8mm) of material for a fl ange on all sides and cut to these measurements. Bend down the fl anges.

If you have never done this before, it might be a good idea to make a cardboard pattern and test it fi rst.

Fasten this fl ue cover in position as high as possible with two masonry screws per side through the

fl anges into the appliance.

C. If you plan on connecting outside air it is recommended to do so at this time.

D. Install fl oor protection if necessary.

E. Connect the pellet vent with a clean out tee to the back of the insert. Refer to manufacturer’s

installation instructions to see “REAR TO TOP VENT CONVERSION INSTRUCTIONS” section and th

“GENERAL VENTING” section.

F. Run a liner down the chimney and connect to tee.

G. Position the insert in it’s fi nal location.

Do not remove any part that would

alter the integrity in any way.

Floor Protection

H. Pull the excess length of liner out through the top of the chimney. Trim the excess liner, install the cap

and cap the chimney.

W415-1477 / A / 10.19.16

80.1A

Page 21

5.0 FRAMING (INSERT ONLY)

21

!

WARNING

RISK OF FIRE!

IN ORDER TO AVOID THE POSSIBILITY OF EXPOSED INSULATION OR VAPOUR BARRIER COMING

IN CONTACT WITH THE APPLIANCE BODY, IT IS RECOMMENDED THAT THE WALLS OF THE

APPLIANCE ENCLOSURE BE “FINISHED” (IE: DRYWALL / SHEETROCK), AS YOU WOULD FINISH

ANY OTHER OUTSIDE WALL OF A HOME. THIS WILL ENSURE THAT CLEARANCE TO

DO NOT NOTCH THE FRAMING AROUND THE APPLIANCE STAND-OFFS. FAILURE TO MAINTAIN

AIR SPACE CLEARANCE MAY CAUSE OVER HEATING AND FIRE. PREVENT CONTACT WITH

SAGGING OR LOOSE INSULATION OR FRAMING AND OTHER COMBUSTIBLE MATERIALS. BLOCK

OPENING INTO THE CHASE TO PREVENT ENTRY OF BLOWN-IN INSULATION. MAKE SURE

WHEN CONSTRUCTING THE ENCLOSURE ALLOW FOR FINISHING MATERIAL THICKNESS TO

MAINTAIN CLEARANCES. FRAMING OR FINISHING MATERIAL CLOSER THAN THE MINIMUMS

LISTED MUST BE CONSTRUCTED ENTIRELY OF NON-COMBUSTIBLE MATERIALS. MATERIALS

CONSISTING ENTIRELY OF STEEL, IRON, BRICK, TILE, CONCRETE, SLATE, GLASS OR PLASTERS,

OR ANY COMBINATION THEREOF ARE SUITABLE. MATERIALS THAT ARE REPORTED AS PASSING

ASTM E 136, STANDARD TEST METHOD FOR BEHAVIOUR OF MATERIALS IN A VERTICAL TUBE

FURNACE AT 1382°F (750°C) AND UL763 SHALL BE CONSIDERED NON-COMBUSTIBLE

MINIMUM CLEARANCE TO COMBUSTIBLES MUST BE MAINTAINED OR A SERIOUS FIRE HAZARD

THE APPLIANCE REQUIRES A MINIMUM ENCLOSURE HEIGHT. MEASURE FROM THE APPLIANCE

IF STEEL STUD FRAMING KITS WITH CEMENT BOARD ARE PROVIDED, OR SPECIFIED IN THE

IF SPECIFIED IN THE INSTALLATION INSTRUCTION FINISHING MUST BE DONE USING A NON-

COMBUSTIBLE MATERIAL SUCH AS NON-COMBUSTIBLE BOARD, CERAMIC TILE, MARBLE, ETC.

DO NOT USE WOOD OR DRYWALL. ANY FIRE RATED DRYWALL IS NOT ACCEPTABLE

COMBUSTIBLES IS MAINTAINED WITHIN THE CAVITY.

INSULATION AND OTHER MATERIALS ARE SECURED.

MATERIALS.

COULD RESULT.

BASE.

INSTALLATION INSTRUCTIONS, THEY MUST BE INSTALLED.

71.1C

EN

W415-1477 / A / 10.19.16

Page 22

22

5.1 INSTALLATION INTO A COMBUSTIBLE ENCLOSURE

EN

!

WARNING

OUTSIDE AIR IS MANDATORY FOR A COMBUSTIBLE BUILT-IN ENCLOSURE INSTALL.

When installing the insert as a "built-in" appliance, it is important to maintain the clearances to combustibles,

see "MINIMUM CLEARANCE TO COMBUSTIBLES" section.

A non-combustible hearth must cover the fl ooring underneath, as well as, a minimum of six inches in front

and to both sides of the appliance.

A. Install fl oor protection.

B. Frame structure maintaining minimum clearances. Locate and frame openings for both the exhaust

and outside air. Outside air is mandatory for enclosure installations. See "OUTSIDE AIR" section.

C. Refer to vent manufacturer's installation instructions and to "GENERAL VENTING" section. Connect

the vent. Install fl ashing, see "FLASHING INSTALLATION" section.

D. Consideration must be taken during installation that removal of the insert is necessary for inspection

and annual maintenance. Install the vent cap.

3 1/2” (89mm)

MAX

40” (1016 mm)

MINIMUM

ENCLOSURE

HEIGHT

3 1/2”

(89mm)

MAX

17”

(432mm)

Non

combustible

floor protection.

This protection must

offer an R value of 0.4 (two

layers of 1/2” (13mm) thick cement board, total 1” (25mm) with each

layer rated with an R value of 0.2).

For temperature requirements, the enclosure space around and

33”

(838mm)

27”

(686mm)

7 1/8” (181mm)

4 7/8”

(124mm)

Centerline of

heater opening

1 7/8”

(48mm)

2” (51mm)

W415-1477 / A / 10.19.16

Page 23

5.2 MINIMUM ENCLOSURE CLEARANCES

(162mm)

40”

(1016mm)

MIN.

27”

(686mm)

MIN.

23

EN

6 3/8”

MIN.

2”

(51mm)

MIN.

3” (76mm) all around (Refer to

vent manufacturer’s instructions)

6”

(152mm)

Non-combustible

floor protection

5.3 MINIMUM CLEARANCE TO COMBUSTIBLES

Side wall to appliance 8" (203mm)

Mantel to top of appliance 8" (203mm)

Top facing to appliance 6 3/8" (162mm)

Side facing to appliance 6" (152mm)

Floor protection* 6"* (152mm)

Mantel Depth / Length 10 (254mm)

* Floor Protection: Minimum 6" (152mm) in

front of door and to either side.

10”

(254mm)

Side Wall

10” (254mm)

8”(203mm)

7 1/8” (181mm)

1 7/8”

(48mm)

Mantel

MIN

8” (203mm)

MIN

6” (152mm)

6” (152mm)

W415-1477 / A / 10.19.16

Page 24

24

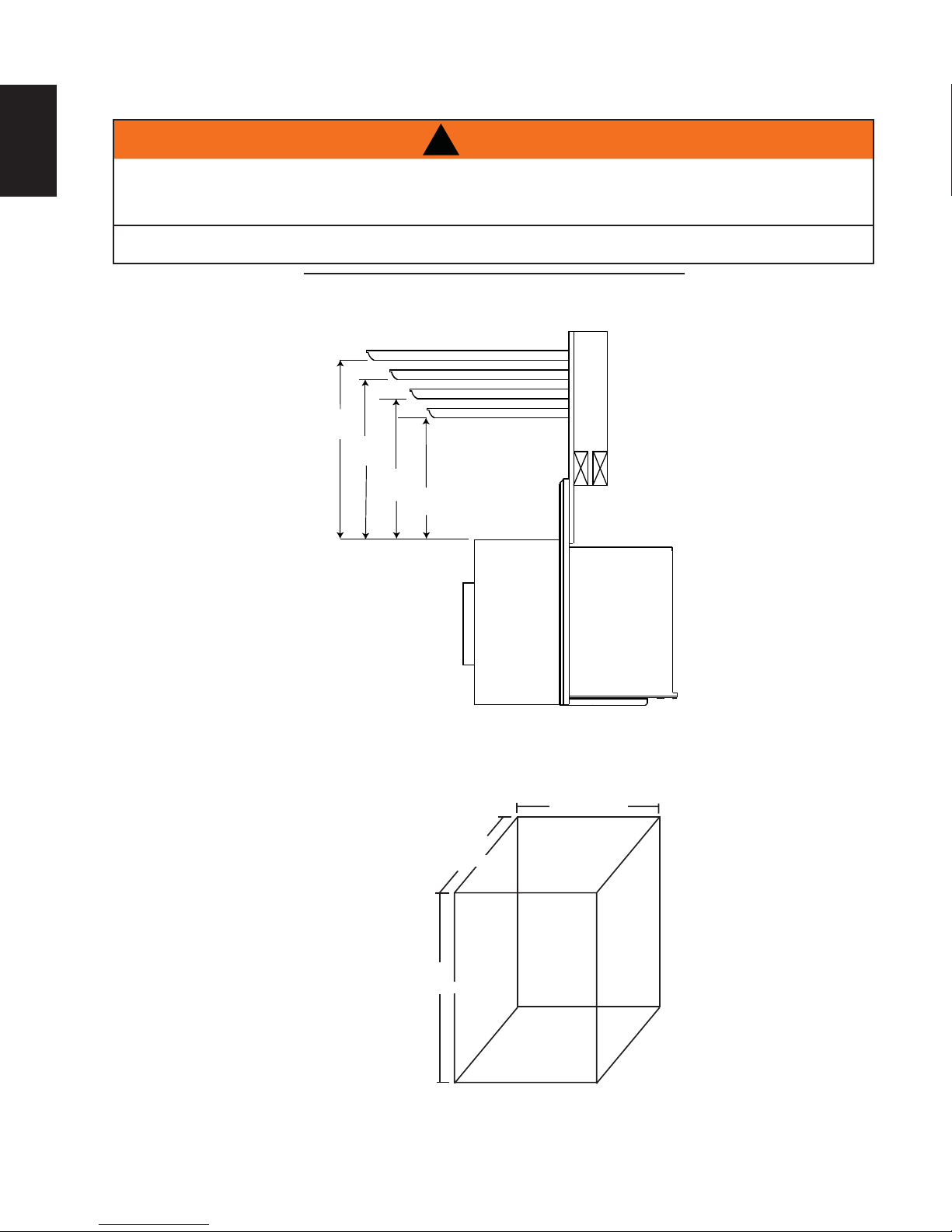

5.4 INSERT MINIMUM MANTEL CLEARANCES

EN

!

WARNING

RISK OF FIRE, MAINTAIN ALL SPECIFIED AIR SPACE CLEARANCES TO COMBUSTIBLES. FAILURE

TO COMPLY WITH THESE INSTRUCTIONS MAY CAUSE A FIRE OR CAUSE THE APPLIANCE TO

OVERHEAT. ENSURE ALL CLEARANCES (I.E. BACK, SIDE, TOP, VENT, MANTEL, FRONT, ETC.) ARE

CLEARLY MAINTAINED.

WHEN USING PAINT OR LACQUER TO FINISH THE MANTEL, THE PAINT OR LACQUER MUST BE

HEAT RESISTANT TO PREVENT DISCOLOURATION.

73.1

16” (406mm)MANTEL

14” (356mm)

12” (305mm)

10”

(254mm)

10” (254mm)

8”

(203mm)

14”

(356mm)

12”

(305mm)

5.5 MINIMUM STOVE ALCOVE INSTALLATION REQUIREMENTS

W415-1477 / A / 10.19.16

35”(889mm)

30”

(762mm)

48”

(1219mm)

STOVE

Minimum Alcove Dimensions

Page 25

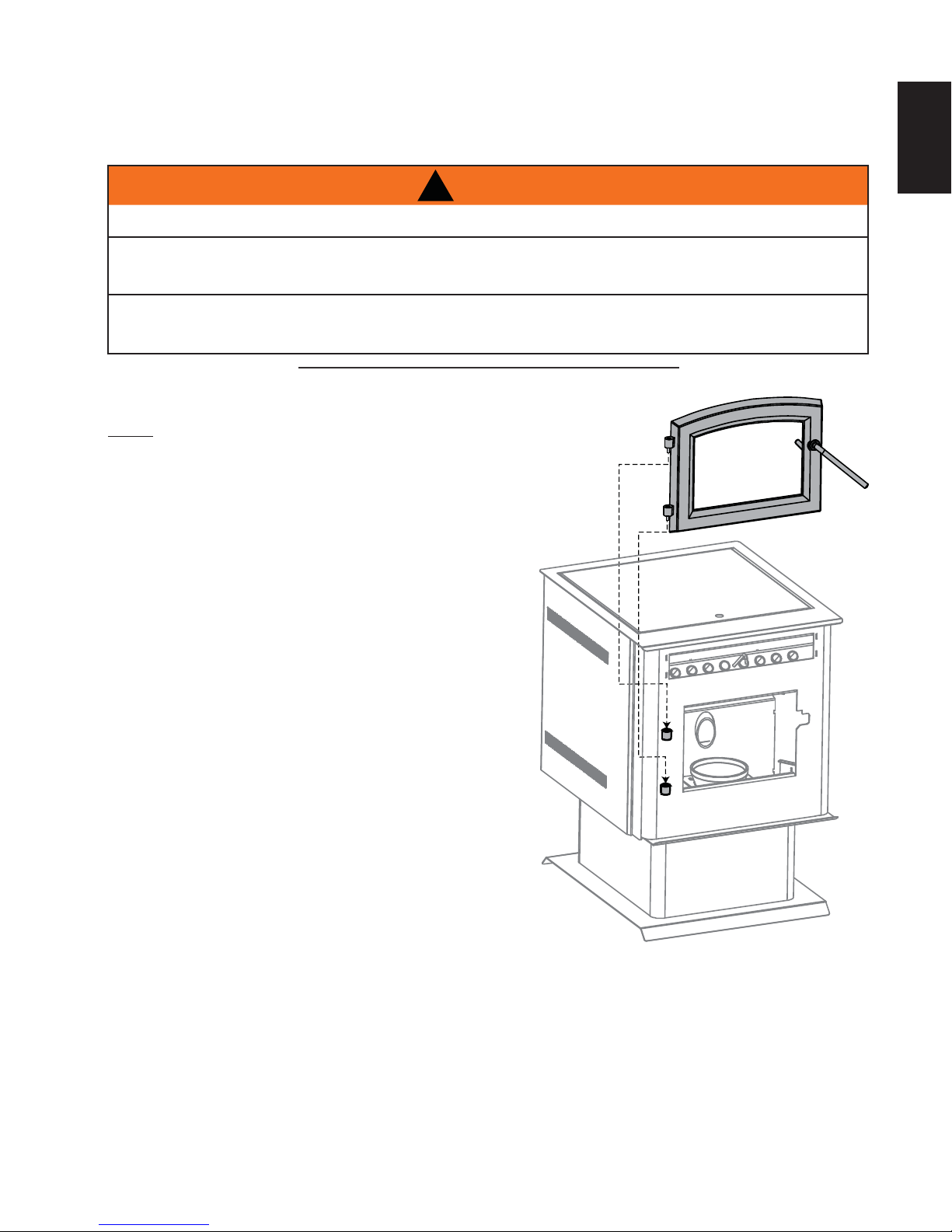

6.0 FINISHING

25

6.1 VIEWING DOOR INSTALLATION

!

WARNING

GLASS MAY BE HOT, DO NOT TOUCH GLASS UNTIL COOLED.

THE DOOR LATCHES ARE PART OF A SAFETY SYSTEM AND MUST BE PROPERLY ENGAGED. DO

NOT OPERATE THE APPLIANCE WITH LATCHES DISENGAGED.

BEFORE DOOR IS REMOVED TURN THE APPLIANCE OFF AND WAIT UNTIL APPLIANCE IS COOL TO

THE TOUCH. DOORS ARE HEAVY AND FRAGILE SO HANDLE WITH CARE.

75.2

The main viewing door has been boxed separate from the appliance, but

MUST be installed before burning the appliance.

A. Align the pins on the door to the bushing on the left side of the

appliance. Lower into place until both bushings touch.

EN

W415-1477 / A / 10.19.16

Page 26

EN

26

6.2 DOOR HANDLE INSTALLATION

NOTE: DOOR MAY NOT BE AS

ILLUSTRATED

FRONT VIEW

DOOR

SPRING

WASHER

DOOR HANDLE

LATCH

LOCK

NUT

DOOR

HANDLE

6.3 DECORATIVE INSET

SPACER

NOTE: Position of

door handle latch.

98.1

W415-1477 / A / 10.19.16

Page 27

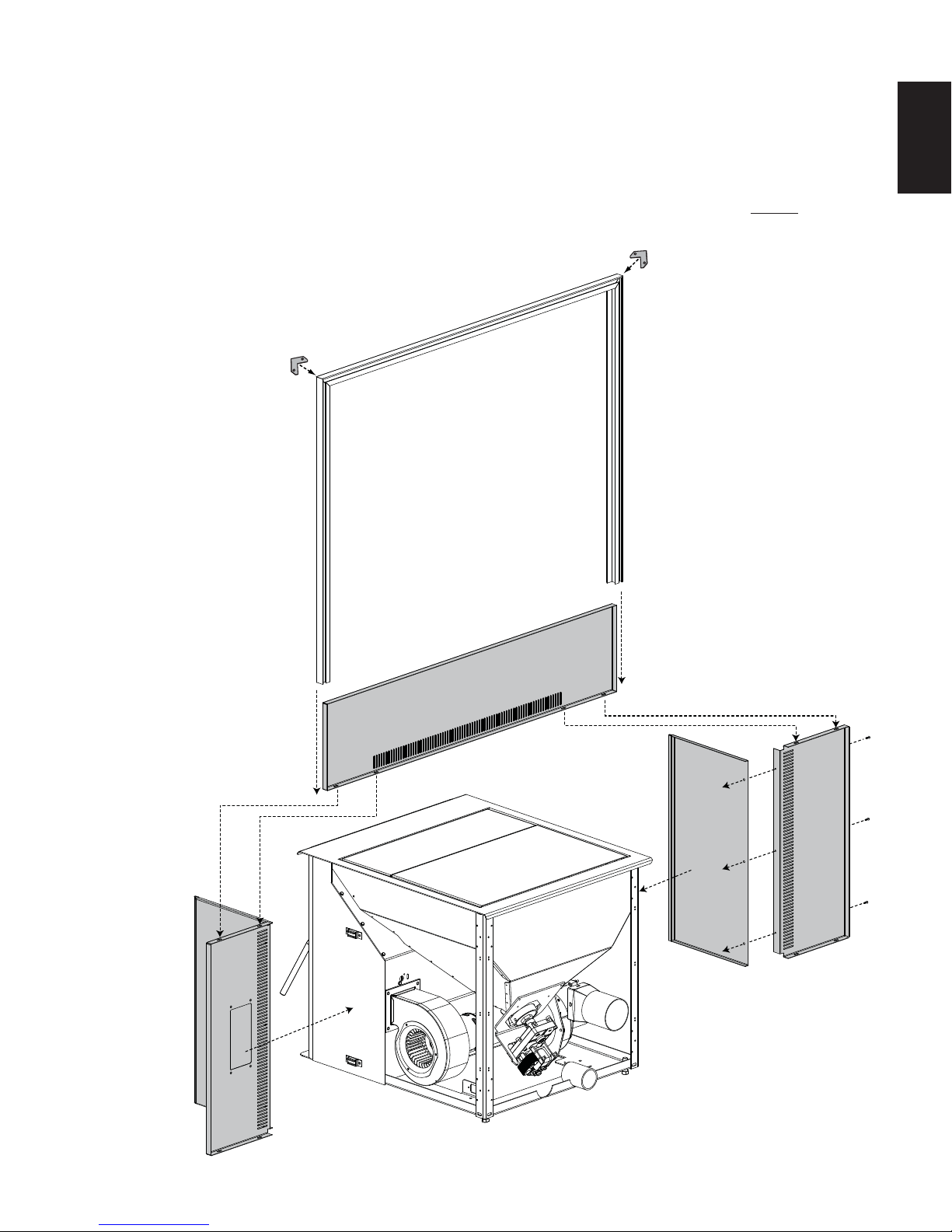

6.4 FLASHING INSTALLATION

A. Secure the left fl ashing to the left side with the three screws provided. Repeat for the right side.

B. Side panels are attached to the fi rebox by the three magnets per side.

C. Lower the top panel, aligning the slots in the top panel with the holes in the side panel.

D. Secure the top panel by to the side panels with the screws and washers provided. NOTE: Make sure

the side panels are tight to the fi rebox before securing the screws.

E. The fl ashing can be adjusted forward and

backward by re-adjusting the

fl ashing along the

27

EN

magnets.

F. Slide trim over

fl ashing.

TRIM

TOP

PANEL

RIGHT

SIDE

RIGHT

FLASHING

LEFT

SIDE

LEFT

FLASHING

W415-1477 / A / 10.19.16

Page 28

EN

28

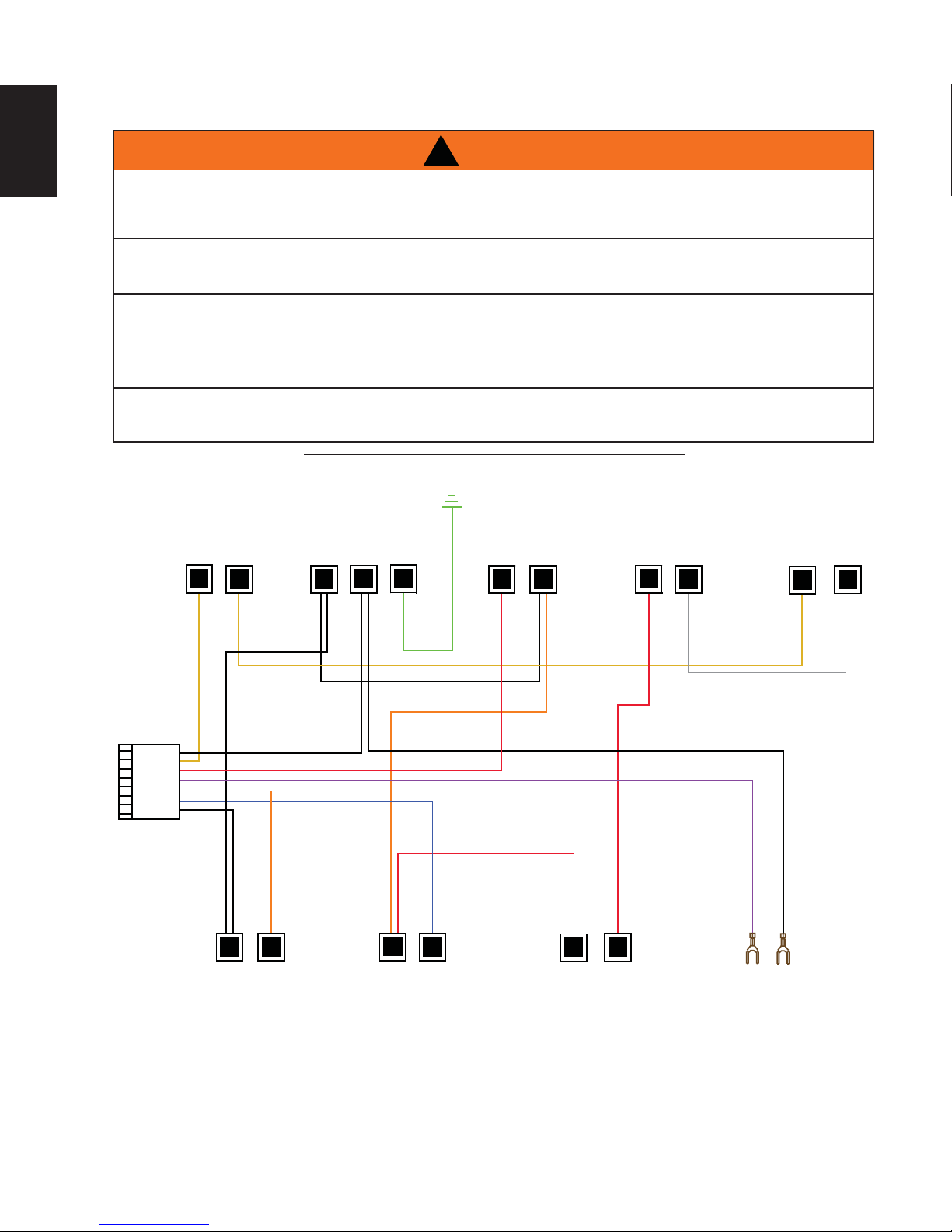

7.0 WIRING DIAGRAM

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER WATER. CALL A QUALIFIED

SERVICE TECHNICIAN IMMEDIATELY TO HAVE THE APPLIANCE INSPECTED FOR DAMAGE TO THE

RISK OF ELECTRICAL SHOCK OR EXPLOSION. DO NOT WIRE 110V TO THE VALVE OR TO THE

APPLIANCE WALL SWITCH. INCORRECT WIRING WILL DAMAGE CONTROLS.

ALL WIRING SHOULD BE DONE BY A QUALIFIED ELECTRICIAN AND SHALL BE IN COMPLIANCE

WITH LOCAL CODES. IN THE ABSENCE OF LOCAL CODES, USE THE CURRENT CSA22.1 CANADIAN

ELECTRIC CODE IN CANADA OR THE CURRENT NATIONAL ELECTRIC CODE ANSI/NFPA NO. 70 IN

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT,

WITH THE GLASS DOOR OPENED OR REMOVED.

!

WARNING

ELECTRICAL CIRCUIT.

THE UNITED STATES.

69.2_2

HIGH

LIMIT

YELLOW

YELLOW

WHITE

WHITE

CONVECTION

BLOWER

ORANGE

WHITE

POWER

CORD

BLACK

BLACK

WHITE

COMBUSTION

BLOWER

RED

ORANGE

GREEN

BLUE

IGNITOR

RED

WHITE

ORANGE

RED

HOPPER

SWITCH

RED

AUGER

MOTOR

RED

GREY

PURPLE

LOW LIMIT

VACUUM

SWITCH

YELLOW

BLACK

GREY

W415-1477 / A / 10.19.16

Page 29

8.0 OPERATING INSTRUCTIONS

29

8.1 PROPER PELLET LOADING

Before loading pellets into the hopper fi rst transfer the pellets from it’s original plastic bag to a metal bucket.

Keep in mind that the auger stops when the lid is opened. If the lid is opened for several minutes, the fi re may

extinguish.

NOTE: If the pellets are kept in the plastic bag, the bag may come in contact with the appliance causing

the bag to melt and the pellets to spill.

DO NOT load pellets into the hopper if they have been exposed to moisture. Moisture can cause pellets

to swell and cause blockage in the feed system. Thoroughly dry pellets before placing into hopper.

47.10

8.2 PRE-START CHECK

Before installing this appliance we recommend a “PRE-BURN” inspection to help burn off the odours that are

associated with the fi rst burn. If possible, move the appliance outside and add approximately 5 lbs (2.3kg) of

pellets into the hopper. Plug the power cord into a typical wall receptacle.

The appliance is equipped with a control board that has been shipped in manual mode.

When fi rst starting a new pellet appliance, or when you completely empty the hopper of pellets you can press

and hold the prime button to get the pellets into the burn pot quicker.

Slide the "ON/OFF" button to "ON":

This starts the ignition cycle.

The auger comes on and runs for approximately 3 minutes.

EN

The igniter comes on and will stay on until proof of fi re determined by the appliance temperature.

At anytime during the ignition cycle, once proof of fi re is met, the appliance goes into normal

operating mode.

NOTE: Flame should appear in the burn pot within 3 to 7 minutes from commencing the ignition cycle.

The ignition cycle should end in approximately 12 to 15 minutes. At this point adjustments to feed rate

can be made or the appliance will revert to the previous setting. If proof of fi re is not established in 15

minutes, the appliance will shut down and will need to be turned back on again. If the appliance shuts

down, empty the pellets from the burn pot into an empty non-combustible container and restart. Never

empty pellets from burn pot back into hopper.

8.3 MANUAL APPLIANCE LIGHTING

APPLIANCE MAY BE HOT.

OTHER THAN PLACING A HANDFUL OF PELLETS IN THE BURN POT FOR LIGHTING MANUALLY,

NEVER FEED PELLETS THROUGH THE GLASS VIEWING DOOR. AN "OVERFIRE" CONDITION

COULD OCCUR, IF MORE PELLETS ENTER THE FIREBOX THAN WHAT THE FEED TUBE CAN

DELIVER. PELLETS MUST ONLY BE BURNED WITHIN THE BURN POT.

NEVER USE GASOLINE TYPE LANTERN FUEL, KEROSENE, CHARCOAL LIGHTER FLUID, OR

SIMILAR LIQUIDS TO START OR ‘FRESHEN UP’ A FIRE IN THIS APPLIANCE. KEEP ALL SUCH

LIQUIDS WELL AWAY FROM THE APPLIANCE WHILE IT IS IN USE.

Your appliance can be lit manually without using the automatic igniter by following the procedure below.

!

WARNING

• Press the ON / OFF button.

• Place a “handful” of pellets into the burn pot.

• Cover with a small amount of approved (non-volatile) fi re starter gel.

• Light fi re starter with a match and close the viewing door.

47.11

W415-1477 / A / 10.19.16

Page 30

30

8.4 LIGHTING INSTRUCTIONS

After fi lling the hopper with pellets, switch the control to manual so that you have full control of the appliance

EN

until you have familiarized yourself with its functions.

Do not try to operate your appliance with the viewing door or hopper lid open. Safety switches will disable the

pellet feed auger.

A. Press the "ON/OFF" button "ON" to initiate the ignition cycle.

B. Once the ignition cycle has ended (approximately 12 to 15 minutes) adjustments can be made to the

control.

8.5 REMOTE CONTROL

INDICATOR LIGHTS

Solid

- Indicates set feed rates.

Flashing

- Indicates an operation failure.

HEAT ADJUSTMENT

Increases or decreases the heat

level.

PRIME

Speed feeding of pellets into the burn

pot.

OPERATING MODE

Sets the appliances operating

mode.

ON / OFF

Used to turn the appliance on or

off.

W385-0500

AUTO / MANUAL

This switch is used to select the operating mode.

MANUAL: Sliding the switch down to manual will allow you to manually select the heat level. In

manual mode the appliance will run at your desired settings indefi nitely, until you manually turn the

appliance off or the appliance runs out of pellets.

AUTO: Slide the switch to the top position (AUTO). The auto mode operates using either a wall or a

remote control thermostat. If the thermostat does not call for heat in a 60 minute period the appliance

will turn off completely. When the thermostat does call for heat, it will initiate an ignition cycle.

ON / OFF

Use this button to turn the appliance on and off.

HEAT LEVEL

Pressing the heat level button will increase the heat level one setting. Pressing the heat level button down will

decrease the heat level one setting. The red lights at the top left of the control will indicate the heat setting 1

through 3.

PRIME

Pressing and holding this button will turn the auger continuously which increases the feed of pellets into the

burn pot. This is convenient when using the appliance for the fi rst time or when you have completely emptied

the hopper and need to restart the appliance.

W415-1477 / A / 10.19.16

Page 31

8.6 CONTROL ADJUSTMENT

FEED TRIM

Both the combustion fan speed and the feed rate have been factory set but may need to be adjusted

(trimmed) on site. Due to the variables (i.e. vent size, length and pellet quality), the factory settings may not be

ideal for every installation. To help keep the fl ame from extinguishing on the minimum heat level, the feed rate

can be trimmed when in normal operation (after the 15 minute ignition cycle).

31

EN

HEAT

LEVEL

PRIME

HEAT

LEVEL

PRIME

HEAT

LEVEL

PRIME

FACTORY SET MORE FUEL LESS FUEL

Pushing the "PRIME" button when in the lowest heat setting will indicate the current trim.

To slightly increase the amount of fuel being fed into the burn pot, hold the prime button down while you

toggle the heat level button so that the top light goes out.

To slightly decrease the amount of fuel being fed into the burn pot, hold the prime button down while you

toggle the heat level button so that the bottom light goes out.

BLOWER TRIM

Similar to the feed rate, it may be necessary to trim the speed of the

combustion blower. Due to specifi c installations, it may be necessary

to increase or decrease the amount of air moving through the burn pot

to achieve maximum effi ciency. In order to adjust the blower trim you

need access to the back of the control panel. Start by either removing

the side panel (pedestal) or behind the fl ashing (insert), using a small

screw driver turn the screw to adjust the blower (clockwise to increase/

counter-clockwise to decrease) and reinstall the panel / fl ashing that

was removed.

NOTE: The blower voltage is factory set for 92.5 V, it must not be

turned lower than 90 V. Every 180° degree turn of the trim screw

will increase or decrease the voltage by 0.2 V. Increasing the blower

speed beyond 95 V is not recommended as this will increase the

pellet consumption, reduce the heat output and may also damage

some of the components.

BLOWER

TRIM

SCREW

TERMINALS

W415-1477 / A / 10.19.16

Page 32

32

8.7 THERMOSTAT INSTALLATION

EN

An optional millivolt thermostat is available to help keep the room temperature constant.

NOTE: The thermostat must be installed by a qualifi ed installer.

• Disconnect the power supply.

• Remove the right side panel to gain access to the rear of the control panel.

• Strip and connect the two thermostat wires to the two screw terminals on the back of the control

panel.

NOTE: The control must be in AUTO to control the appliance with a thermostat.

8.8 SHUTDOWN INSTRUCTIONS

Slide the "ON/OFF" button to "OFF". Your appliance will cycle down and the blower will remain operating until

your appliance has cooled.

9.0 NORMAL OPERATING SOUNDS

EXHAUST BLOWER

The flow of exhaust gases may

create a low-pitched hum. As

the pellet feed rate is altered

this sound will change.

CONVECTION BLOWER

A low hum might be heard due to the high

efficiency fan, especially on high.

AUGER MOTOR

An irregular buzz of the motor

running might be heard when

pellets are being fed.

Expansion / contraction noises during heating up and cooling down cycles are normal and are to be expected.

W415-1477 / A / 10.19.16

BURN POT

A light clicking sound

might be heard as the

pellets are fed into

the burn pot.

Page 33

10.0 MAINTENANCE

33

10.1 DAILY MAINTENANCE

THE FRONT OF THE APPLIANCE BECOMES VERY HOT DURING OPERATION. LET THE APPLIANCE

COOL COMPLETELY BEFORE CONDUCTING SERVICE.

10.1.1 ASH DISPOSAL

Ashes should be placed in a metal container with a tight fi tting lid. The container should be placed on a non-

combustible fl oor, well away from combustible materials, pending fi nal disposal. If ashes are disposed of by burial

in soil or otherwise locally dispersed, they should be retained in the closed container until all cinders are thoroughly

cooled.

10.1.2 BURN POT INSPECTION

When burning, the fl ames should be bright orange with embers jumping from the

burn pot. If not see “MAKE SURE PELLETS ARE NOT PILING UP” or “CLEANING

THE BURNPOT” sections.

!

WARNING

EN

40.2

10.1.3 CARE OF GLASS

If the glass is not kept clean permanent discolouration and / or

blemishes may result. Normal operation of your pellet appliance

will produce a build-up on the glass that should be wiped off

daily. However, poor quality pellets or extended burning on the

low setting will cause the glass to “smoke up” faster.

Refer to “REPLACEMENT PARTS” section to fi nd out what this

product is equipped with. Use only replacement glass available

from your Authorized dealer.

DO NOT CLEAN GLASS WHEN HOT!

If necessary, clean the glass with a soft cloth or paper towel. You could use “wood stove” glass cleaner to

remove heavy build-up.

Do not operate the appliance with broken glass, as leakage of fl ue gases may result.

40.3A

!

WARNING

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

5.2

W415-1477 / A / 10.19.16

Page 34

EN

34

10.1.4 HEAT EXCHANGER TUBES CLEANING

!

WARNING

THE FRONT EDGE OF THE HOPPER LID BECOMES VERY HOT, DO NOT TOUCH THE AREA BELOW

THE HANDLE.

THIS ROD BECOMES VERY HOT DURING OPERATION. WAIT UNTIL APPLIANCE HAS COOLED

COMPLETELY OR WEAR HEAT RESISTANT GLOVES WHEN CLEANING OR HANDLING THIS

APPLIANCE.

With the appliance cool (or wearing heat resistant gloves),

slide the heat exchange cleaner rod up and down several

times to prevent the build up of ash on the heat exchange

tubes.

Keep the viewing door closed so the fl y ash does not enter the

room.

NOTE: More frequent cleaning may be required depending

upon pellet quality.

HEAT

EXCHANGE

CLEANER

ROD

10.1.5 PELLET PILE UP MAINTENANCE

If the fl ames seem to be coming only from the sides, are orange/black, turn

the appliance off and check for a build up of pellets. If the pellets build up over

the burn pot, turn the pellet feed switch to “OFF”.

The most likely causes are:

A. Feed rate has been set to maximum for an extended period of time.

Reduce feed rate.

B. The door, glass, or ash pan is open or has an air leak.

C. The burn pot requires cleaning.

D. The exhaust system requires cleaning.

E. The appliance requires adjustment (trim feed rate and blower).

F. Poor pellet quality.

E. Ensure the leveling bolts are installed in the front corners of the

The door or glass is open or has an air leak.

fi rebox base (TP35 series only).

40.4A

40.5D

W415-1477 / A / 10.19.16

Page 35

10.1.6 BURN POT CLEANING

35

!

WARNING

MAKE CERTAIN THE HEATER HAS FULLY COOLED (APPROXIMATELY 25 MINUTES) BEFORE

OPENING THE DOOR AND CONDUCTING SERVICE.

To clean the burn pot, open the door and knock away any debris on the

burn pot. If severely clogged, remove the burn pot to gain better access.

If removing the burn pot set aside on a non-combustible surface. Once

removed, discard all material that has accumulated in the burn pot.

Make certain that all openings are clear of any build up of ash from the

ledge below the burn pot.

Re-install the burn pot ensuring it sits level in the

appliance. Also must ensure the ignitor and the burn

pot locating notch line up when reinstalling the burn

pot.

LOCATING

NOTCH

NOTE: Fuel and ash build up along with a lazy dark

orange fl ame may indicate that openings in the

burn pot are blocked.

IGNITOR

40.6A

EN

10.2 BI-WEEKLY (OR EVERY 10 BAGS OF PELLETS)

10.2.1 VACUUM FIREBOX

!

WARNING

THE FIREBOX BECOMES VERY HOT DURING OPERATION. LET THE APPLIANCE COOL COM-

PLETELY BEFORE CONDUCTING SERVICE.

NEVER VACUUM HOT EMBERS.

The more frequently you clean out the fl y ash, the more effi cient your appliance

will burn.

A. Open the viewing door.

B. Lift the burn pot out and set aside on a non-combustible

surface.

FIREBOX

C. Vacuum out the fi rebox. Do not use a household

vacuum to clean the appliance. We recommend that

you use a shop vacuum that is equipped with a fi ne dust fi lter or

a vacuum specifi cally made for ashes and soot. Using a vacuum

which is not equipped with a fi ne dust fi lter may clog and disperse

fl y ash and soot into the room. NOTE: The appliance must be

completely extinguished before you vacuum the appliance.

Burning pellets, if sucked into the vacuum will light the

vacuum on fi re and may ultimately cause a house fi re.

AIR

HOUSING

Re-install the burn pot ensuring it sits level in the appliance. Also must ensure the ignitor and the burn pot

locating notch line up when reinstalling the burn pot.

40.18

W415-1477 / A / 10.19.16

Page 36

36

10.3 SEMI-ANNUALLY (OR EVERY TON OF PELLET)

EN

THE FIREBOX BECOMES VERY HOT DURING OPERATION. LET THE APPLIANCE COOL COMPLETELY BEFORE

DISCONNECT THE POWER CORD PRIOR TO CONDUCTING SERVICE.

THE FOLLOWING SECTION DETAILS EXTENSIVE MAINTENANCE PROCEDURES. WE STRONGLY SUGGEST

THESE ITEMS BE CARRIED OUT BY A TRAINED SERVICE TECHNICIAN, POSSIBLY BY A SERVICE AGREEMENT

NOTE: More frequent cleaning may be required depending on pellet quality.

10.3.1 HOPPER CLEANING

The more frequently you clean out the fl y ash, the more effi cient your

appliance will burn.

A. Operate the appliance until the pellets run out, then open the hopper

and vacuum out the entire hopper.

The dust and any other debris near the bottom should be removed to

prevent excessive build-up.

!

WARNING

CONDUCTING SERVICE.

SET UP WITH YOUR DEALER.

40.15

10.3.2 SOOT AND FLY ASH FORMATION

The products of combustion will contain small particles of fl y ash. The fl y ash will collect in the exhaust venting

system and restrict the fl ow of the fl ue gases. Incomplete combustion occuring during startup, shutdown, or

incorrect operation of the room appliance will lead to some soot formation which will collect in the exhaust

venting system. The exhaust venting system should be inspected at least once every year to determine if

cleaning is necessary.

10.3.3 VERTICAL EXHAUST DUCT CLEANING

A. Pivot the viewing door wide open.

B. Remove the one screw on each exhaust port located

on either side of the fi re box. Remove the exhaust port

doors and set aside on a non-combustible surface.

Insert a vacuum into the exhaust port holes and remove as

much fl y ash as possible from behind the left and right exhaust

manifolds. Do not use a household vacuum to clean the

appliance. We recommend that you use a shop vacuum that is

equipped with a fi ne dust fi lter or a vacuum specifi cally made

for ashes and soot. Using a vacuum which is not equipped with

a fi ne dust fi lter may clog and disperse fl y ash and soot into

the room. NOTE: The appliance must be completely extinguished before you vacuum the appliance.

Burning pellets, if sucked into the vacuum will light the vacuum on fi re and may ultimately cause a

house fi re.

40.8B

40.9

EXHAUST

PORT

Once clean, replace the exhaust port doors and secure with the screws.

W415-1477 / A / 10.19.16

Page 37

10.3.4 EXHAUST BLOWER CLEANING

37

NOTE: Do not attempt this maintenance without a

replacement exhaust blower motor mounting gasket.

A. Remove the six nuts holding the exhaust blower motor

in place.

B. Pull the motor out being careful not to damage the

wiring, unplug the two wires that are connecting the

motor and gently set aside. (The pieces of gasket may

be discarded.

C. Start by cleaning the exhaust tube by feeding a brush

or rag through the inside of the tube and out the

exhaust blower housing.

EXHAUST

D. Vacuum out the exhaust ports and the blower housing.

E. With a bristle brush vacuum, clean the blades of the

motor.

F. Place the new exhaust blower mounting gasket around

the screw holes being very careful not to tear it.

G. Re-attach the wiring to the motor and place it back on to the housing, taking care that the side of the

motor does not tear the gasket and then re-attach the nuts.

BLOWER

EXHAUST

HOUSING

40.11

NUTS

EN

10.3.5 SEAL CHECK

Check for air leaks around the door, glass, and ash pan and replace gaskets as required.

Air leaks into the fi rebox will decrease the appliance’s performance greatly, leading to excessive soot,

ineffi cient burning, and may even cause a malfunction.

Test the door seal by shutting the door on a piece of paper in various locations. If the paper can be easily slid

out, air may be leaking around the door seal. Carefully inspect the door gasket and door catch.

Inspect the door gasket to make sure it is fully attached. Appliance gasket cement can be used to re-attach if

necessary. If the door gasket is worn or fl attened, replace.

Check the door to make sure it latches correctly. The latch should engage with a slight amount of resistance,

yet not be too diffi cult.

If the glass is cracked, replace.

40.12

W415-1477 / A / 10.19.16

Page 38

38

10.3.6 VENT CLEANING

EN

!

WARNING