Page 1

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

INSTALLATION AND

OPERATING INSTRUCTIONS

CERTIFIED UNDER U.S. ENVIRONMENTAL PROTECTION AGENCY (E.P.A.) JULY 1990 40 C.F. R. PART 60 AND THE OREGON DEPARTMENT OF

ENVIRONMENTAL QUALITY (D.E.Q.) PARTICULATE EMISSION STANDARDS BY E.E.M.C THESE STOVES HAVE BEEN TESTED AND LISTED BY OMNI

TESTING SERVICES TO STANDARDS: CSA B366.2, ULC S627, UL 1482.

2100 & 2200

LEG MODELS &

PEDESTAL MODELS

1

SAFETY INFORMATION

!

WARNING

If the information in these instructions is not followed exactly ,

a fi re or explosion may result causing property damage,

personal injury or death. Improper installation, adjustment,

alteration, service or maintenance can cause injury or property

damage, bodily injury or even death. Please read entire

manual before you install and use your appliance.

- This appliance can be very hot when burning.

- Combustible materials such as fi rewood, wet clothing, etc. placed too

close can catch fi re.

- Children and pets must be kept from touching the appliance when it

is hot.

- The chimney must be sound and free of cracks. Before installing

this unit, contact the local building or fi re authority and follow their

guidelines.

- Operate only with the door tightly closed.

- Burn wood behind the log retainer directly on the fi rebricks.

- Do not use an elevated grate or otherwise raise the fi re.

- At least 14 square inches of outside air must be admitted to the room

or directly to the unit through a 4” diameter pipe.

- This appliance is designed to burn natural wood only. Higher

effi ciencies and lower emissions generally result when burning air

dried seasoned hardwoods, as compared to softwoods or to green or

freshly cut hardwoods.

- Do not start a fi re with chemicals or fl uids such as gasoline, engine

oil, etc.

- Do not burn treated wood, coal, charcoal, coloured paper, cardboard,

solvents or garbage.

- Do not let the appliance become hot enough for any part to glow red.

- KEEP THE STOVE TOP TEMPERATURE BELOW 700°F (371°C).

Attempts to achieve heat output rates that exceed design

specifi cations can result in steel distortion and damage.

2100 LEG MODEL

ILLUSTRATED

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 4Y8 Canada /

Phone (705)721-1212 • Fax (705)722-6031 • www.napoleonfi replaces.com • ask@napoleon.on.ca

$10.00

103 Miller Drive, Crittenden, Kentucky, USA, 41030

1.14

W415-0842 / 07.28.09

Page 2

2

TABLE OF CONTENTS

1.0 INTRODUCTION 3

1.1 WARRANTY 5

1.2 DIMENSIONS 6

1.3 SPECIFICATIONS 6

1.4 INSTALLATION OVERVIEW 7

1.5 GENERAL INFORMATION 8

1.6 GENERAL INSTRUCTIONS 9

2.0 INSTALLATION 9

2.1 CLEARANCE TO COMBUSTIBLES 10

2.2 FLOOR PROTECTION 10

2.3 CHIMNEY 11

2.3.1 CHIMNEY CONNECTION 12

2.3.2 TYPICAL THROUGH THE CEILING 13

2.3.3 ADDING SECTIONS 14

2.3.4 TYPICAL THROUGH THE WALL 15

2.3.5 TYPICAL EXISTING MASONRY 16

2.4 ASH LIP INSTALLATION 16

2.5 LEG INSTALLATION 17

2.6 PEDESTAL INSTALLATION 18

2.7 DOOR HANDLE INSTALLATION 18

2.8 SECONDARY AIR TUBES 19

2.9 BRICK AND BAFFLE INSTALLATION 20

2.10 OPTIONAL BLOWER KIT INSTALLATION 21

2.11 OUTSIDE AIR 22

2.12 OPTIONAL ASH DRAWER KIT (EP20LAD) 22

2.13 OPTIONAL ASH PAN KIT (EP20PAD) 23

2.14 ASH REMOVAL WITH ASH DRAWER 23

3.0 OPERATION 24

3.1 DRAFT 25

3.2 FIRE EXTINGUISHERS / SMOKE DETECTORS 25

3.3 FUEL 25

3.4 LIGHTING A FIRE 26

3.4.1 FLASH FIRE 26

3.4.2 EXTENDED FIRE 26

4.0 MAINTENANCE 26

4.1 ASH REMOVAL PROCEDURES 26

4.2 CREOSOTE FORMATION AND REMOVAL 27

4.3 RUNAWAY OR CHIMNEY FIRE 27

4.4 CHIMNEY CLEANING 27

4.5 CARE OF GLASS 28

4.6 DOOR REMOVAL 28

4.7 GLASS REPLACEMENT 29

4.8 WOOD 29

5.0 REPLACEMENTS 30

6.0 TROUBLE SHOOTING 32

7.0 SERVICE HISTORY 33

8.0 NOTES 34

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

W415-0842 / 07.28.09

Page 3

1.0 INTRODUCTION

3

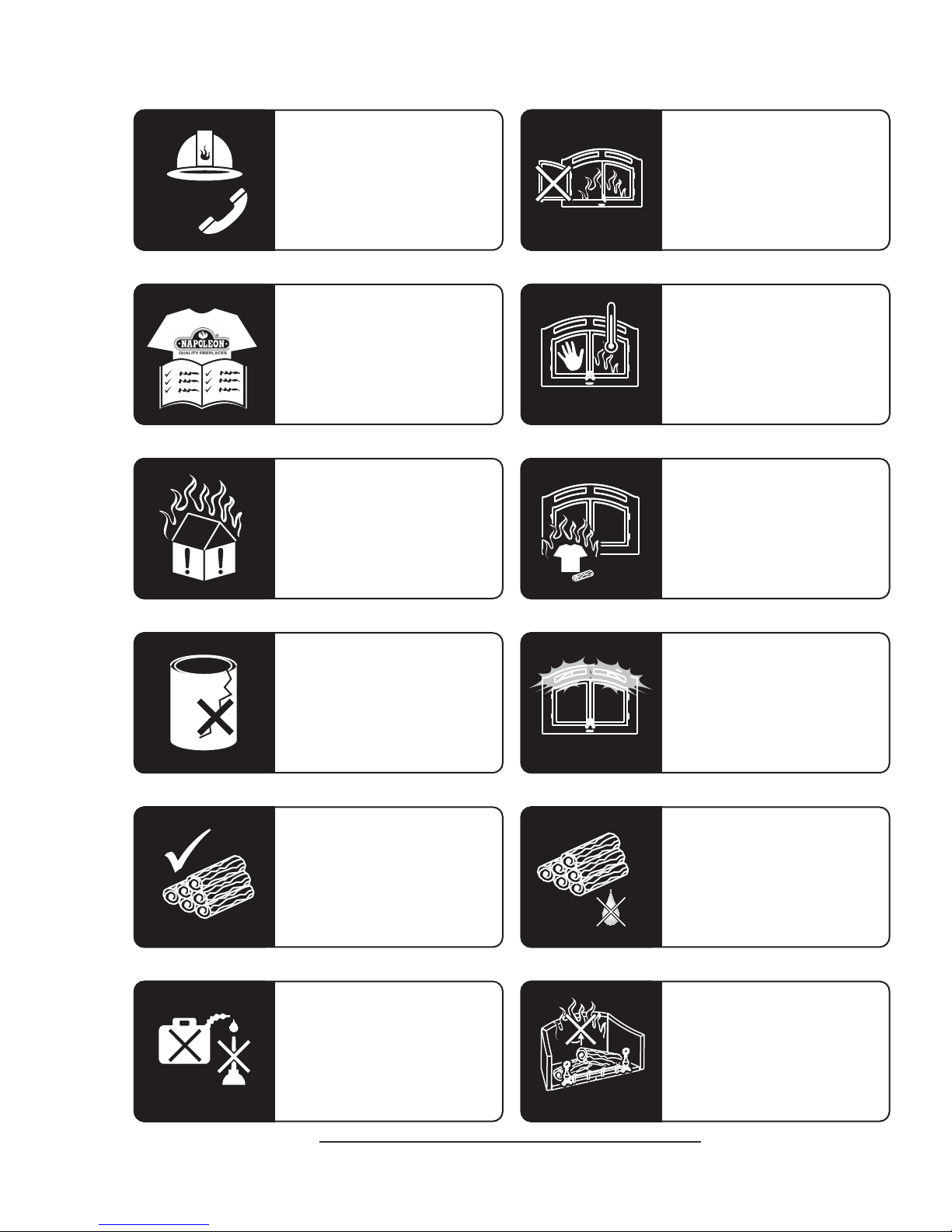

Before installing this unit, contact the

local building or fire authority and

follow their guidelines.

Operate only with the doors tightly

closed.

THIS APPLIANCE IS HOT WHEN

This appliance must be installed by a

qualified installer.

Follow the installation directions.

4.

1.

5.

2.

6.

3.

Do not operate without fully

assembling all components.

OPERATED AND CAN CAUSE

SEVERE BURNS IF CONTACTED.

Children and pets must be kept from

touching the appliance when it is hot.

Contact your local authorized

dealer/distributor for safety screens that

may be available for this product.

If this appliance is not properly

installed, a house fire may result.

Combustible materials such as

firewood, wet clothing, etc. placed too

Do not expose the appliance to the

elements (ex. rain, etc.) and keep the

appliance dry at all times. Wet

insulation will produce an odour when

Objects placed in front of the fireplace

close can catch fire.

must be kept a minimum of 48" from

the front face of the unit.

the appliance is used.

The chimney must be sound

and free of cracks.

Clean your chimney a minimum of

twice a year and as required.

This appliance is designed to burn

natural wood only.

Do not burn treated wood, coal,

charcoal, coloured paper, cardboard,

solvents or garbage.

Do not start a fire with chemicals or

fluids such as gasoline, engine oil, etc.

Do not let the fireplace

become hot enough for any part to

glow red.

Higher efficiencies and lower emissions

generally result when burning air dried

seasoned hardwoods, as compared to

softwoods or too green or freshly cut

hardwoods.

Burning wet unseasoned wood can cause

excessive creosote accumulation. When

ignited it can cause a chimney fire that may

result in a serious house fire.

Burn wood behind the log retainer

directly on the firebricks.

Do not use elevated grate or otherwise

raise the fire.

Do not store wood within appliance

installation clearances or within the

space required for re-fueling and ash

removal.

3.15

W415-0842 / 07.28.09

Page 4

4

!

WARNING

• THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE BURNS IF CONTACTED.

• Do not operate appliance before reading and understanding operating instructions. Failure to operate

appliance according to operating instructions could cause fi re or injury.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves and safety glasses during installation. Sheet metal

edges may be sharp.

• Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children and others may be susceptible to accidental contact burns. A physical barrier is

recommended if there are at risk individuals in the house. To restrict access to an appliance or stove,

install an adjustable safety gate to keep toddlers, young children and other at risk individuals out of the

room and away from hot surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Due to high temperatures, the appliance should be located out of traffi c and away from furniture and

draperies.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot

surfaces.

• Even after the appliance is out, the glass and/or screen will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children

from hot surfaces. These screens and guards must be fastened to the fl oor.

• Any safety screen or guard removed for servicing must be replaced prior to operating the appliance.

• Under no circumstances should this appliance be modifi ed.

• Do not operate the appliance with the glass door removed, cracked or broken. Replacement of the glass

should be done by a licensed or qualifi ed service person.

• Do not strike or slam shut the appliance glass door.

• Only doors / optional fronts certifi ed with the unit are to be installed on the appliance.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As

with all plastic bags, these are not toys and should be kept away from children and infants.

3.17

W415-0842 / 07.28.09

Page 5

1.1 WARRANTY

TIMBERWOLF products are manufactured under the strict Standard of the World Recognized

TIMBERWOLF products are designed with superior components and materials, assembled by trained craftsmen

who take great pride in their work. The complete appliance is thoroughly inspected by a qualifi ed technician before

packaging to ensure that you, the customer, receives the quality product that you expect from TIMBERWOLF.

TIMBERWOLF WOOD APPLIANCE PRESIDENT’S LIMITED WARRANTY

The following materials and workmanship in your new TIMBERWOLF appliance are warranted against defects as

defi ned below:

The combustion chamber is warranted against defects for a period of 25 years.

The secondary air tubes are warranted against defects for a period of fi ve years.

All other wearable parts and electrical components such as blowers, thermal switches, switches, wiring,

rheostats, fi rebrick, ceramic glass (thermal breakage only), fi bre baffl es and gasketing are covered and Wolf

Steel will provide replacement parts free of charge during the fi rst year of the limited warranty.

Labour related to warranty repair is covered free of charge during the fi rst year. Any labour related to secondary

air tubes is not covered. Repair work, however, requires the prior approval of an authorized company offi cial.

Labour costs to the account of Wolf Steel are based on a predetermined rate schedule and any repair work must

be done through an authorized TIMBERWOLF dealer.

5

ISO 9001 : 2000 Quality Assurance Certifi cate.

CONDITIONS AND LIMITATIONS

Wolf Steel warrants its TIMBERWOLF products against manufacturing defects to the original purchaser only. Registering your warranty is not

necessary. Simply provide your proof of purchase along with the model and serial number to make a warranty claim. Provided that the purchase

was made through an authorized TIMBERWOLF dealer your appliance is subject to the following conditions and limitations:

This factory warranty is non-transferable and may not be extended whatsoever by any of our representatives.

The appliance must be installed by an authorized service technician or contractor. Installation must be done in accordance with the installation

instructions included with the product and all local and national building and fi re codes.

This limited warranty does not cover damages caused by misuse, lack of maintenance, accident, alterations, abuse or neglect. Operating the

appliance on high for extended periods of time, is neglect. Parts installed from other manufacturers will nullify this warranty.

This limited warranty further does not cover any scratches, dents, corrosion or discoloring caused by excessive heat, abrasive and chemical

cleaners nor chipping on porcelain enamel parts, nor any venting components used in the installation of the appliance.

In the fi rst year only, this warranty extends to the repair or replacement of warranted parts which are defective in material or workmanship

provided that the product has been operated in accordance with the operation instructions and under normal conditions.

After the fi rst year, with respect to the TIMBERWOLF’S President’s Limited Warranty, Wolf Steel may, at its discretion, fully discharge all

obligations with respect to this warranty by refunding to the original warranted purchaser the wholesale price of any warranted but defective

parts.

After the fi rst year, Wolf Steel Ltd. will not be responsible for installation, labour or any other costs or expenses related to the reinstallation of a

warranted part, and such expenses are not covered by this warranty.

Notwithstanding any provisions contained in the TIMBERWOLF’S President’s Limited Warranty, Wolf Steel’s responsibility under this warranty is

defi ned as above and it shall not in any event extend to any incidental, consequential or indirect damages.

This warranty defi nes the obligations and liability of Wolf Steel with respect to the TIMBERWOLF appliance and any other warranties expressed

or implied with respect to this product, its components or accessories are excluded.

Wolf Steel neither assumes, nor authorizes any third party to assume, on its behalf, any other liabilities with respect to the sale of this product.

Wolf Steel will not be responsible for: over-fi ring, downdrafts, spillage caused by environmental conditions such as rooftops, buildings, nearby

trees, hills, mountains, inadequate vents or ventilation, excessive venting confi gurations, insuffi cient makeup air, or negative air pressures

which may or may not be caused by mechanical systems such as exhaust blowers, furnaces, clothes dryers, etc.

Any damages to appliance, combustion chamber, heat exchanger or other components due to water, weather damage, long periods of

dampness, condensation, damaging chemicals or cleaners will not be the responsibility of Wolf Steel.

Regular cleaning of the fi ne ash generated during the operation of this appliance is a necessary part of maintaining your appliance. Failure of

any components, which is attributed to poor maintenance, is not warrantable and will not be covered by this policy.

Wolf Steel reserves the right to have its representative inspect any TIMBERWOLF product or part thereof prior to honouring any warranty claim.

ALL SPECIFICA TIONS AND DESIGNS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE DUE TO ON-GOING PRODUCT IMPROVEMENTS.

2.11

W415-0842 / 07.28.09

Page 6

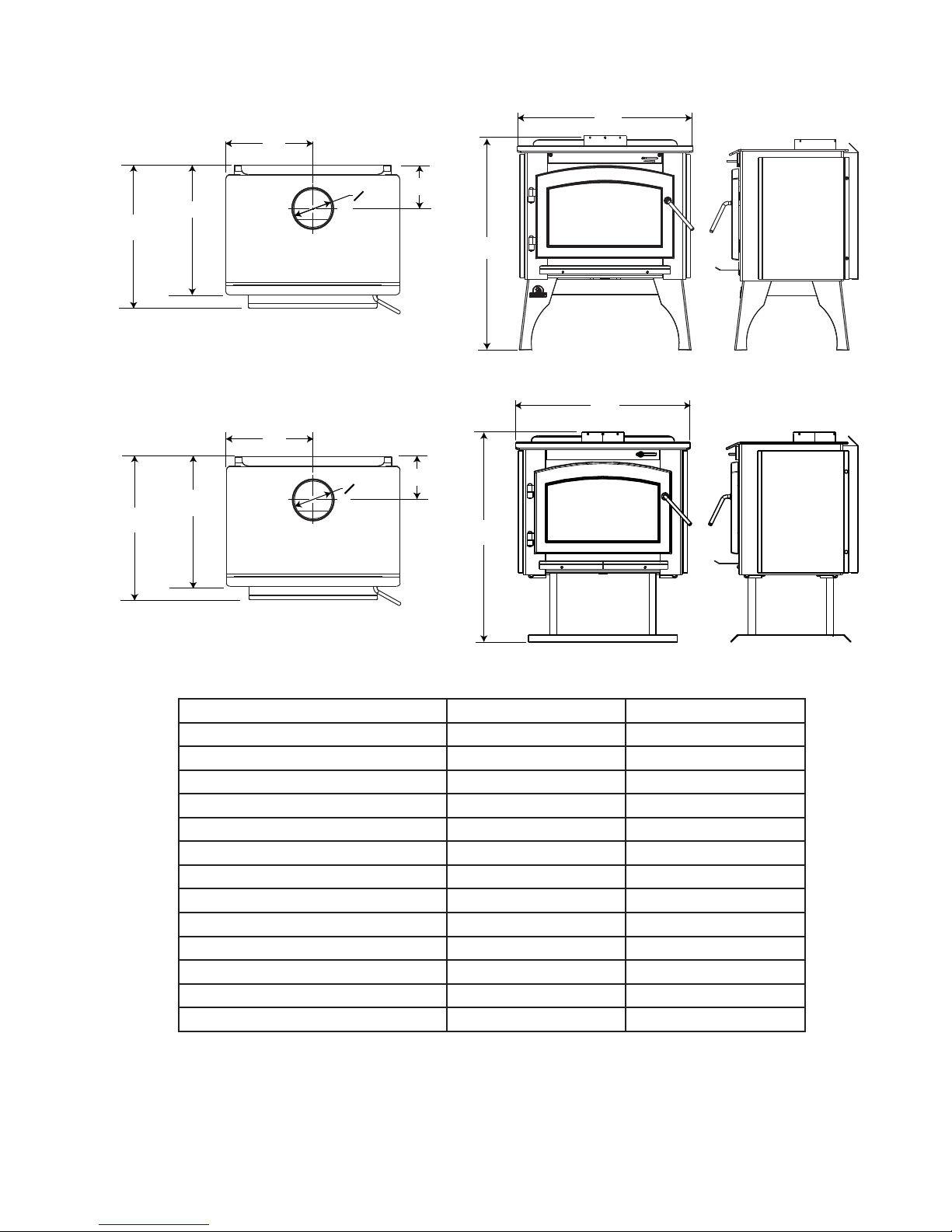

6

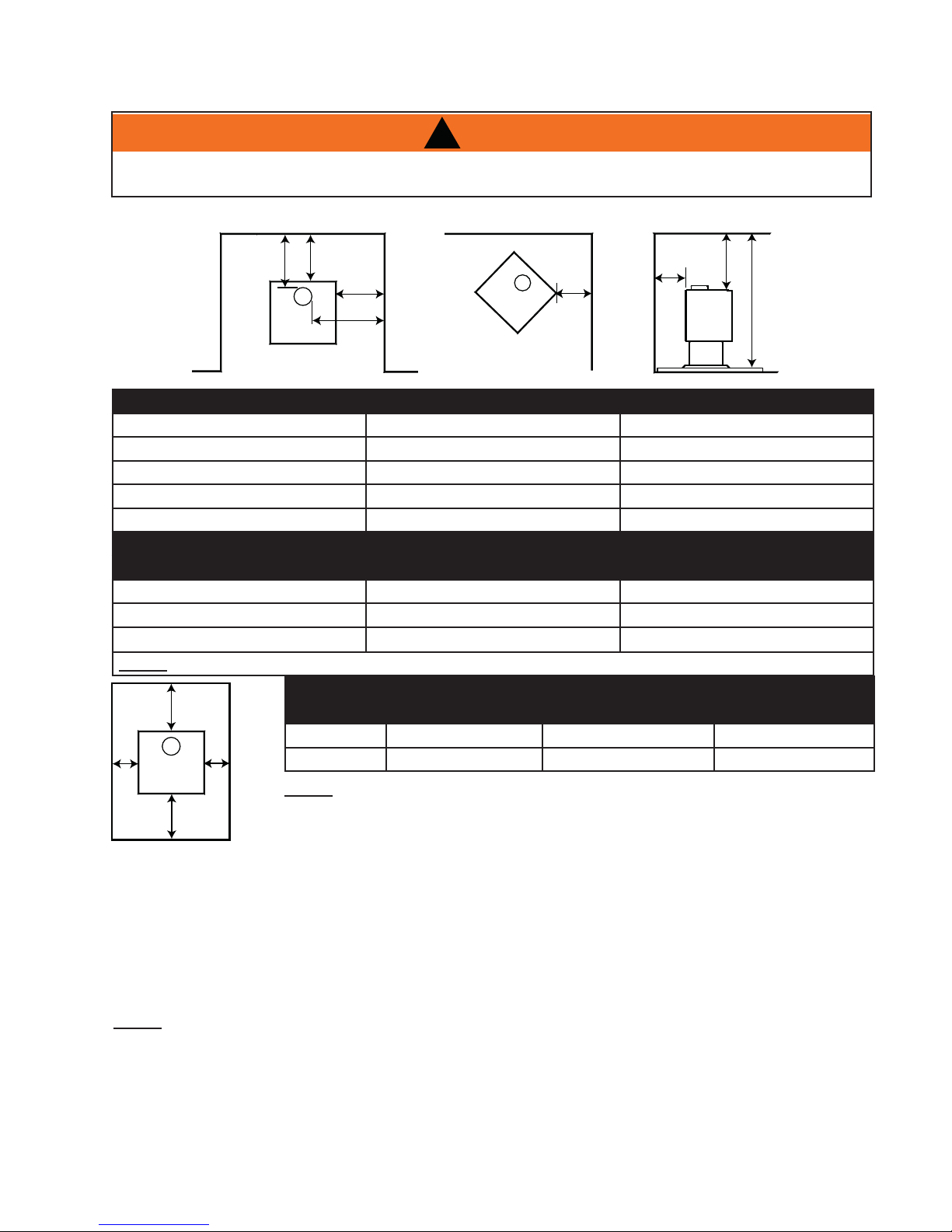

1.2 DIMENSIONS

2100

26”

13”

21 5/8”

2200

24 5/8”

19 3/4”

22 3/4”

13”

O 6”

O 6”

6 1/2”

31 5/8”

26”

6 1/2”

31 5/8”

1.3 SPECIFICATIONS

Specifi cations 2100 2200

FLUE CENTER LINE TO REAR 6 1/2” 6 1/2”

FLUE CENTER LINE TO SIDE 13” 13”

HEIGHT PEDESTAL MODEL 29 7/8” 29 7/8”

APPROX. AREA HEATED* 600-1800 square feet 800-1800 square feet

HEAT OUTPUT (HIGH BURN) ** 45,000 BTU 60, 000 BTU

* Figures will vary considerably with individual conditions.

** Wolf Steel Ltd. estimated realistic BTU/h with hardwood logs and regular refueling.

WIDTH 26” 26”

DEPTH 21 5/8” 24 5/8”

HEIGHT LEG MODEL 31 5/8” 31 5/8”

CHAMBER (D.W.H) 11 5/8 x 20 7/8 x 11 5/8 14 5/8 x 20 7/8 x 11 5/8

CAPACITY 1.5 cubic feet 1.9 cubic feet

DURATION LOW FIRE* 6 hours 8 hours

WEIGHT w/o BRICKS 180 lbs 210 lbs

WEIGHT OF BRICKS 47 lbs 60 lbs

W415-0842 / 07.28.09

Page 7

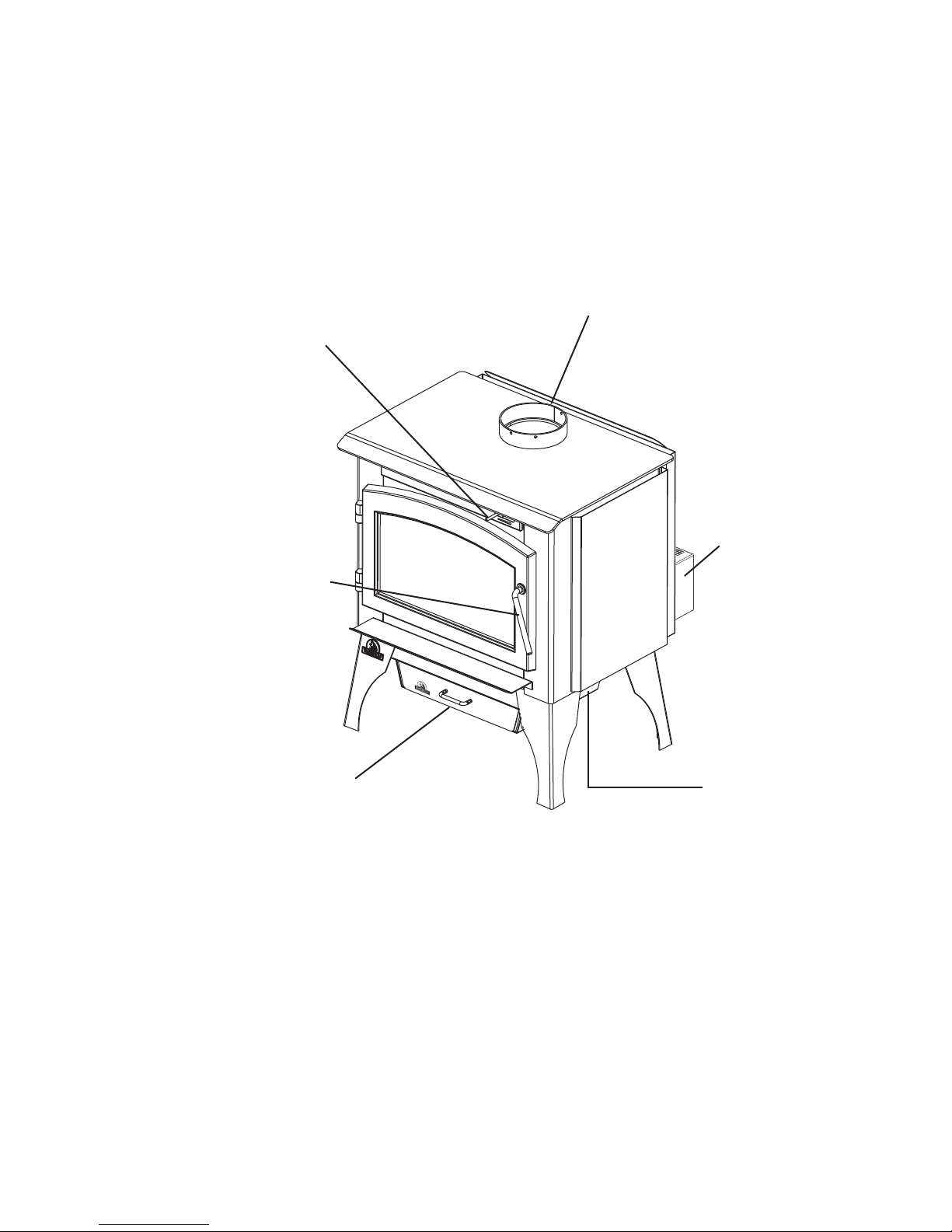

1.4 INSTALLATION OVERVIEW

See “DRAFT”

section

7

Venting, see “INSTALLATION CHIMNEY” section

Handle, see “DOOR

HANDLE INSTALLATION”

section

Ash Drawer, see “OPTIONAL ASH

DRAWER KIT (EP20LAD)” section

for the leg model and “OPTIONAL

ASH PAN KIT (EP20PAD)” section

for the pedestal model.

Blower, see

“OPTIONAL BLOWER

INSTALLATION”

section

Heat sheild, see “LEG

INSTALLATION” section

W415-0842 / 07.28.09

Page 8

8

1.5 GENERAL INFORMATION

ALL WIRING SHOULD BE DONE BY A QUALIFIED ELECTRICIAN AND SHALL BE IN COMPLIANCE

WITH LOCAL CODES. IN THE ABSENCE OF LOCAL CODES, USE THE CURRENT CSA C22.1

CANADIAN ELECTRIC CODE (IN CANADA) OR THE ANSI/NFPA NO. 70 NATIONAL ELECTRIC CODE

BURNING YOUR APPLIANCE WITH THE ASH WELL OPEN OR THE ASH DOOR AJAR CREATES A

FIRE HAZARD AND MAY CAUSE INTERNAL DAMAGE TO THE APPLIANCE OR A HOUSE AND/OR

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE. DO

NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM.

PROVIDE ADEQUATE CLEARANCE FOR SERVICING AND OPERA TING THE APPLIANCE.

NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE.

!

WARNING

IN THE UNITED STATES.

CHIMNEY FIRE.

PROVIDE ADEQUA TE VENTILA TION.

OBJECTS PLACED IN FRONT OF THE APPLIANCE MUST BE KEPT A MINIMUM OF 48” FROM THE

FRONT FACE OF THE APPLIANCE.

DO NOT INSTALL IN A MOBILE HOME.

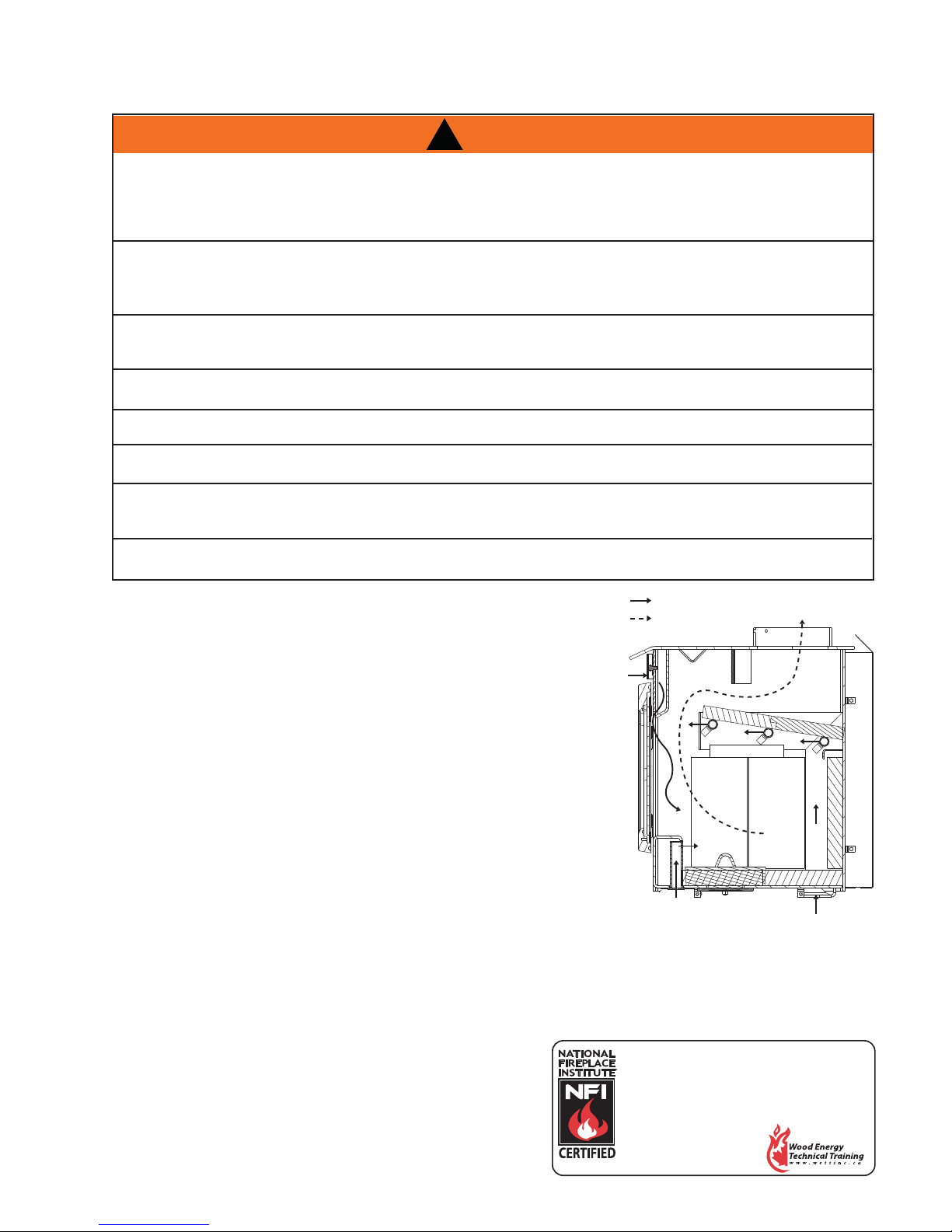

Both models 2100 and 2200 are similar in design and use the same burning

principles.

AIR INLET PATH

EXHAUST PATH

They were specifi cally designed over many months of research to meet the

1990 U.S.A. EP A particulate emission standards and have been extensively

tested in Canadian and American laboratories. This system is the most effi cient, simple and trouble free we know and works as follows:

Secondary air from the rear hole travels up the back in the secondary air

housing to the manifold located at the top and shoots out laterally to oxidize

the gases below the smoke exit.

The lower combustion chamber is lined with high temperature fi rebricks on 2

sides, the back and across the bottom, with a layer of fi bre baffl es at the top to

maintain a high temperature in the combustion chamber so that gases mixing

with the preheated air from the secondary air manifold tube are easily ignited

and burned. The appliance sides and back are shielded to direct the heat

upwards and forwards into the room.

2100 ILLUSTRATED

Be sure to provide suffi cient combustion air. There are many other appliances in your home competing for air such

as: a kitchen range hood, forced air heating devices, clothes dryer or a bathroom exhaust fan.

After extended periods of non-operation such as following a vacation or a warm weather season, the appliance may

emit a slight odour for a few hours. This is caused by dust particles on the fi rebox burning off. Open a window to suf-

fi ciently ventilate the room.

If outside air is utilized, you should never experience a shortage of

combustion air. If you choose not to utilize outside air and experience draft or smoking problems, you may need to open a door, a

window or otherwise provide some method of supplying combustion air to the appliance.

W415-0842 / 07.28.09

We suggest that our woodburning hearth

products be installed and serviced by

professionals who are certified in the U.S.

by the National Fireplace Institute

NFI Woodburning Specialists or who are

certified in Canada by

Wood Energy Technical

www.nficertified.org

Training (WETT).

®

(NFI) as

Page 9

1.6 GENERAL INSTRUCTIONS

DO NOT OPERATE THIS APPLIANCE WITHOUT THE LEGS OR PEDESTAL INSTALLED.

• Before beginning your installation, consult with your local building code agency or fi re offi cials and

insurance representative to ensure compliance.

• Non-toxic smoke will be emitted during the paint curing process, to help dissipate the smoke open a

window near the appliance.

• Remove any dust or debris off the top of the appliance before fi ring the appliance as the paint will be-

come soft as the appliance heats up and will harden as the appliance cures. To cure the paint on your

appliance burn your appliance moderately hot during the fi rst few fi res.

• To keep the gasket from sticking to the appliance as the paint is curing, periodically open the door

every 5-10 minutes.

• For the fi rst two weeks use generous amounts of fuel and burn the appliance with the damper wide

open for an hour as the appliance goes through a process of eliminating moisture in the steel and fi re-

bricks. The initial heat output will be reduced while the moisture is being drawn from the appliance and

it will be necessary to build several hot fi res to remove this moisture. DURING THIS PROCESS DO

NOT OVERFIRE THE APPLIANCE. REDUCE THE AMOUNT OF AIR COMING INTO THE APPLIANCE IF THE APPLIANCE OR CHIMNEY BECOMES RED.

!

WARNING

9

2.0 INSTALLATION

WEAR GLOVES AND SAFETY GLASSES FOR PROTECTION.

CAREFULLY FOLLOW THE INSTRUCTIONS FOR ASSEMBLY OF THE PIPE AND OTHER PARTS NEEDED TO

INSTALL THE APPLIANCE. FAILURE TO DO SO MAY RESULT IN A FIRE, ESPECIALLY IF COMBUSTIBLES ARE

TOO CLOSE TO THE APPLIANCE OR CHIMNEY AND AIR SPACES ARE BLOCKED, PREVENTING THE FREE

DO NOT DRAW OUTSIDE AIR FROM GARAGE SPACES. EXHAUST PRODUCTS OF GASOLINE ENGINES ARE

DO NOT INSTALL OUTSIDE AIR DUCTS SUCH THAT THE AIR MAY BE DRAWN FROM ATTIC SPACES, BASEMENTS

OR ABOVE THE ROOFING WHERE OTHER HEATING APPLIANCES OR FANS AND CHIMNEYS EXHAUST OR UTILIZE

AIR. THESE PRECAUTIONS WILL REDUCE THE POSSIBILITY OF APPLIANCE SMOKING OR AIR FLOW REVERSAL.

THE OUTSIDE AIR INLET MUST REMAIN CLEAR OF LEAVES, DEBRIS ICE AND/OR SNOW. IT MUST BE

UNRESTRICTED WHILE APPLIANCE IS IN USE TO PREVENT ROOM AIR STARVATION WHICH CAN CAUSE SMOKE

SPILLAGE AND AN INABILITY TO MAINTAIN A FIRE. SMOKE SPILLAGE CAN ALSO SET OFF SMOKE ALARMS.

TO PREVENT CONTACT WITH SAGGING OR LOOSE INSULATION, THE APPLIANCE MUST NOT BE INSTALLED

AGAINST VAPOUR BARRIERS OR EXPOSED INSULATION. LOCALIZED OVERHEATING COULD OCCUR AND A

DO NOT USE MAKESHIFT COMPROMISES DURING INSTALLATION.

!

WARNING

MOVEMENT OF COOLING AIR.

HAZARDOUS.

FIRE COULD RESULT.

W415-0842 / 07.28.09

Page 10

10

2.1 CLEARANCE TO COMBUSTIBLES

DO NOT INSTALL INTO ANY AREA HAVING LESS THAN 7 FEET (CEILING TO APPLIANCE BOTTOM,

EXCLUDING HEARTH HEIGHT).

!

WARNING

BACK WALL

C

D

A

BACK WALL

F

G

E

H

B

SIDE WALL

PARALLEL & CORNER SINGLE WALL CONNECTOR DOUBLE WALL CONNECTOR

SIDEWALL (A) 19” 19”

SIDEWALL TO FLUE (B) 28 7/8” 28 7/8”

BACKWALL (C) 17 1/2” 12 1/2”

BACKWALL TO FLUE (D) 21” 16”

CORNER (E) 11” 7”

ALCOVE

PARALLEL & CORNER SINGLE WALL CONNECTOR DOUBLE WALL CONNECTOR

BACKWALL (F) 12 1/2” 12 1/2”

CEILING (G) 42” 42”

CEILING (H) 72” 72”

NOTE: Minimum width 62”, Minimum depth 32”

MINIMUM FLOOR PROTECTION

K

CANADA 18” 8” 8”

J

J

USA 16” 8” 8”

FRONT (I) SIDES (J) BACK (K)

SIDE WALL

NOTE: If a section of horizontal chimney connector is used, fl oor protection is

I

You may decrease the minimum clearances to combustible materials by installing heat radiation shields between the walls or the ceiling and the appliance. Those heat radiation shields must be installed permanently.

These reduced clearances must be approved by a regulatory authority.

required under the chimney connector and 2” beyond each side.

2.2 FLOOR PROTECTION

If the appliance is to be installed on top of a combustible fl oor, it must be guarded by a non-combustible mate-

rial extending a minimum 18” (16” in the United States) from the front and 8” from the sides and back of the

appliance, see “CLEARANCE TO COMBUSTIBLES” section.

NOTE: Floor protection is required for spark and ash shielding, but not for limiting fl oor temperatures

from the radiant heat of the appliance. The appliance was designed and safety tested so that without

any protection, the fl oor would not overheat.

Refer to local building codes for suitable fl oor protection materials.

W415-0842 / 07.28.09

Page 11

2.3 CHIMNEY

NEVER INSTALL A SINGLE WALL SLIP SECTION OR SMOKE PIPE IN A CHASE STRUCTURE. THE HIGHER

TEMPERATURE OF THIS SINGLE WALL PIPE MAY RADIATE SUFFICIENT HEAT TO COMBUSTIBLE

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY SYSTEM SERVING ANOTHER APPLIANCE.

TO AVOID DANGER OF FIRE, ALL INSTRUCTIONS MUST BE STRICTLY FOLLOWED, INCLUDING THE

PROVISION OF AIR SPACE CLEARANCE BETWEEN CHIMNEY SYSTEM AND ENCLOSURE. TO

PROTECT AGAINST THE EFFECTS OF CORROSION ON THOSE PARTS EXPOSED TO THE WEATHER, WE

RECOMMEND THAT THE CHASE TOP BE PAINTED WITH A RUST-RESISTANT PAINT.

DO NOT FILL ANY FRAMED SPACE AROUND THE CHIMNEY WITH INSULATION OR ANY OTHER MATERIAL.

INSULATION PLACED IN THIS AREA COULD CAUSE ADJACENT COMBUSTIBLES TO OVERHEAT.

MAINTAIN A MINIMUM 2" AIR CLEARANCE TO ALL PARTS OF THE CHIMNEY SYSTEM AT ALL TIMES.

FAILURE TO MAINTAIN THIS 2" AIR CLEARANCE WILL CAUSE A STRUCTURE FIRE. NEVER FILL THIS

!

WARNING

CHASE MATERIALS TO CAUSE A FIRE.

SPACE WITH ANY TYPE OF MATERIAL.

11

DETAILED INSTRUCTIONS FOR INSTALLATION OF THE CHASE TOP, STORM COLLAR AND

TERMINATION CAP ARE PACKAGED WITH THESE PARTS.

DO NOT CUT RAFTERS OR CEILING JOISTS WITHOUT FIRST CONSULTING A BUILDING OFFICIAL

TO ENSURE STRUCTURAL INTEGRITY IS NOT COMPROMISED.

FIRESTOP SPACERS MUST BE USED WHENEVER THE CHIMNEY PENETRATES A CEILING/FLOOR AREA.

THE TOTAL HORIZONTAL VENT LENGTH SHOULD NOT EXCEED 40% OF THE CHIMNEY HEIGHT

ABOVE THE STOVE. ALL HORIZONTAL SMOKE PIPE MUST SLOPE SLIGHTLY UPWARDS A MINIMUM

OF 1/4” PER FOOT AND ALL CONNECTIONS MUST BE TIGHT AND SECURED BY THREE SHEET

METAL SCREWS EQUALLY SPACED. AN UNINSULATED SMOKE PIPE SHALL NOT PASS THROUGH

AN ATTIC, ROOF SPACE, CLOSET OR SIMILAR CONCEALED SPACE, OR THROUGH A FLOOR,

CEILING, WALL OR PARTITION, OR ANY COMBUSTIBLE CONSTRUCTIONS.

DO NOT USE ANY MAKESHIFT MATERIALS DURING INSTALLATION.

Your appliance may be connected to a factory built or masonry chimney. If you are using a factory built chimney, it must comply with ULCS629 (Canada) or UL103 (USA) standards. It must therefore be a 6” HT Type

(2100°F) chimney. It is extremely important that it be installed according to the manufacturer’s specifi cations.

The manufacturer’s installation instructions and specifi ed clearances should always be followed in accordance

with local and national codes. In Canada the CSA B365 and the CSA C22.1 installation codes are to be followed. In the USA the ANSI NFPA 70 and ANSI NFPA 211 installation codes are to be followed.

Chimney and chimney connector must be in good condition and kept clean.

W415-0842 / 07.28.09

Page 12

12

This room appliance must be connected to:

A. A chimney complying with the requirements for Type

HT chimneys in the Standard for Chimneys, FactoryBuilt, Residential Type and Building Heating Appliance, or

B. A code-approved masonry chimney with a fl ue liner.

Vent the stove into a masonry chimney or an approved, insulated solid-fuel stainless-steel chimney

with as short and straight a length of 6” diameter

smoke pipe as possible. Connection to a masonry

chimney must be by a metal or masonry thimble cemented in place.

2.3.1 CHIMNEY CONNECTION

Your chimney connector and chimney must have the same diameter as the appliance’s exhaust outlet. The

appliance pipe must be made of aluminized or cold roll steel with a minimum 24 gauge thickness. It is strictly

forbidden to use galvanized steel.

For installation of your chimney connector, the following recommendations may be useful.

TOWARD

APPLIANCE

MALE END OF

CONNECTOR

OR CHIMNEY

PIPE

FLUE GAS

DIRECTION

58.1

• The pipe must be short and straight. For optimum performance it is recommended that all horizontal

runs have a minimum 1/4” rise per foot, with the upper end of the section toward the chimney. For safe

and proper operation of the appliance, see “VENTING” instructions.

• To ensure a good draft, the total horizontal length of the connector should never exceed 8’ to 10’. In

the case of vertical installation, the total length of the connector can be longer and connected without

problem to the chimney at the ceiling level.

• There should never be more than two 90° elbows in the entire connector system. Never start with a

90° elbow. Always go up vertically for at least 2 feet from the fl ue before using a 90° elbow.

• The connector must not pass through any combustible material, nor may it pass through a concealed

space (such as an attic, roof space, or closet). If passing through a wall, ceiling, or into a masonry

chimney, use either chimney components listed for that specifi c use, or means acceptable to local

authorities having jurisdiction over the installation.

• A 6” diameter single wall stove pipe, used to connect the appliance to the chimney, must be installed

with the crimped end toward the appliance. This will ensure that the moisture which condenses from

the burning wood will fl ow back into the fi re chamber. Each joint in the stove pipe must be secured with

at least three sheet metal screws.

W415-0842 / 07.28.09

Page 13

2.3.2 TYPICAL THROUGH THE CEILING

A. Move the stove into position with the fl ue centered, midpoint between two

joists to prevent having to cut them. Use a plumb bob to line up the center.

B. Cut and frame an opening in the ceiling to provide a 2” clearance between

the outside of the chimney and any combustible material. DO NOT FILL THIS

SPACE WITH ANY TYPE OF MATERIAL.

Nail headers between the joist for extra support.

Firestop spacers must be placed on the bottom of each framed opening in any fl oor or

ceiling that the chimney passes through.

If your chimney system is enclosed within

the attic area, a rafter radiation shield is

required.

HEADERS

13

A

A

C. Hold a plumb bob from the underside of

the roof to determine where the opening in

the roof should be. Cut and frame the roof

opening to maintain proper 2” clearances.

LISTED

CHIMNEY

CEILING

SUPPORT

CONNECTION

DETAIL

SPECIFIED

CLEARANCE

TO STOVE

FIRESTOP SPACER UNDERSIDE OF JOIST

MAINTAIN 2”

CLEARANCE

LISTED CHIMNEY

CHIMNEY

SUPPORT

CHIMNEY

CONNECTOR

TERMINAL

STORM

COLLAR

FLASHING

ROOF

INSULATION

FLOOR

PROTECTOR

COMBUSTIBLE

WALL

60.1

W415-0842 / 07.28.09

Page 14

14

A

2.3.3 ADDING SECTIONS

dd chimney sections, according to the manufacturers installation instructions, securely, to the required height.

The chimney must extend at least, 3 feet above its point of contact with the roof and at least 2 feet higher than

any wall, roof or building within 10 feet horizontally.

LESS THAN

10 FEET

2 FT

3 FT

MIN

2 FT MIN

10 FT TO

NEAREST

RIDGE

MIN

3 FT

MIN

ROOFLINE

LESS THAN

10 FT OR

10 FT

MORE

2 FT

MIN

3 FT

3 FT

MIN

MIN

FLAT ROOF

WALL

59.1

An insulated stainless steel chimney must be supported at the ceiling or roof and its installation must comply

with its manufacturer’s instructions.

W415-0842 / 07.28.09

Page 15

2.3.4 TYPICAL THROUGH THE WALL

If possible, design the installation so that the connector does not pass through a combustible wall. If during

your installation you must pass through a combustible wall, check with your building inspector before you begin. Also check with the chimney connector manufacturer for any specifi c requirements.

Consult with your dealer regarding special connection components available for use for wall pass-throughs.

Use only parts that have been tested and listed for use in a wall pass-through.

15

CHIMNEY

TO

STOVE

THIMBLE

COMBUSTIBLE

OUTSIDE WALL

SECTION

LISTED

PIPE

WALL SPACER

FOR OUTSIDE

WALL

CONNECTION

DETAIL

LISTED

CHIMNEY

2”

CLEARANCE

INSULATED

“T”

WALL

SUPPORT

ROOF

COMBUSTIBLE

CEILING

CHIMNEY

CONNECTOR

MAINTAIN 2”

CLEARANCE

THROUGH EAVE

TERMINAL

STORM

COLLAR

FLASHING

FLOOR

PROTECTOR

COMBUSTIBLE

WALL

61.1

W415-0842 / 07.28.09

Page 16

16

FLOOR

PROTECTOR

CHIMNEY

CONNECTOR

COMBUSTIBLE

WALL

CLEARANCE

EAVE

RAFTER

CLEARANCE WITH FIRESTOP

CEILING JOIST

THIMBLE

2.3.5 TYPICAL EXISTING MASONRY

You can also install your appliance using your

existing masonry chimney. To do so, follow the

guidelines below. You may want to use a factorybuilt thimble, or construct your own brick thimble.

If you are using a masonry chimney, it is

important that it be built in compliance with

the specifi cations of the Building Code in

your region. It must normally be lined with

fi re clay bricks, metal or clay tiles sealed

together with fi re cement. (Round fl ues are

the most effi cient). The maximum fl ue size

is 8” x 8” square or 6” round.

2.4 ASH LIP INSTALLATION

To avoid damage during transport, the ash lip has been shipped in the fi rebox. Using the two screws that se-

cured the appliance to the shipping bracket, attach the ash lip as illustrated.

62.1

W415-0842 / 07.28.09

Page 17

2.5 LEG INSTALLATION

KNOCKOUT NOT TO BE REMOVED EXCEPT WHEN INSTALLING THE OPTIONAL ASH DRAWER KIT.

To avoid being damaged during shipping, the appliance

has been bolted to the pallet and must be unbolted before

the appliance can be installed.

NOTE: If installing the optional ash drawer, see “OPTIONAL ASH DRAWER KIT (EP20LAD)” section prior

heat shield and leg installation.

NOTE: Legs may need to be adjusted in order to

properly align with the heat shield holes.

2.5.1 With the bolt through the legs, feed the washer and

lock washer onto the bolt. Thread the nut a thread

or two onto the bolt and slide the leg onto the slot

on appliance as illustrated. NOTE: Bolts must

be tight prior to heat shield installation.

!

WARNING

17

2.5.2 Slide the heat shield over the four bolts. Fi-

nally, secure the heat shield in place using

the remaining nuts.

2.5.3 Lift the appliance up and gently set

down on all four legs. Do not pivot appliance up on its legs, as this could

result in damage to the legs.

KNOCKOUT

(SEE WARNING

ABOVE)

For additional logo placement locations, see “OPTIONAL ASH DRAWER”

section.

LOGO

PLACEMENT

W415-0842 / 07.28.09

Page 18

18

2.6 PEDESTAL INSTALLATION

NOTE: If an optional ash drawer kit is to be installed, ensure open side of pedestal is at the front

of the appliance. If not, opening should be at the

back.

To avoid being damaged during shipping, the appliance

has been bolted to the pallet and must be unbolted

before the appliance can be installed.

2.6.1 Using the machine screws supplied, secure the

pedestal to the four brackets on the bottom of

the fi rebox.

2.6.2 Lift the appliance up and gently set down on

pedestal. Do not pivot appliance up as it could

result in damage to the pedestal.

2.7 DOOR HANDLE INSTALLATION

PEDESTAL

LOGO PLACEMENT

DOOR

HANDLE

W415-0842 / 07.28.09

FRONT VIEW

SPRING

WASHER

DOOR

DOOR HANDLE

LATCH

SPACER

LOCK

WASHER

NUT

NOTE: Position of

door handle latch.

Page 19

2.8 SECONDARY AIR TUBES

HOLE

2.8.1 Start at the back work-

ing forwards by sliding the secondary air

tube in the fi rebox and

inserting the tube into

the hole, as illustrated in

“A”.

2.8.2 Slide the tube into the

opposite hole. With the

holes on the secondary

air tube pointing forward, align the tube with

the tube retainer and

insert the cotter pin.

2.8.3 Spread the cotter pin to

retain.

NOTE: On the 2200 model

there are 4 secondary air

tubes. One of the tubes has

fewer and larger holes. This

tube is to be located to the

front of the appliance.

B

COTTER PIN

C

TUBE

RETAINER

19

A

B

A

2100

ILLUSTRATED

C

2200

ILLUSTRATED

W415-0842 / 07.28.09

Page 20

20

2.9 BRICK AND BAFFLE INSTALLATION

!

OPERATION OF THE APPLIANCE WITHOUT THE BAFFLES CAN RESULT IN EXCESSIVE TEMPERA-

TURES THAT COULD DAMAGE THE APPLIANCE, CHIMNEY AND THE SURROUNDING ENCLOSURE.

With the appliance and chimney installation completed, move the bricks into place as illustrated below.

2.9.1 Install the bottom bricks, working from the back of the appliance forward as illustrated. NOTE: Left

and right rear bricks have been cut (model 2100 only).

2.9.2 Install two (2100) or four (2200) bricks along both sides of the appliance. Install the fi ve bricks along

the back wall by pivoting the bricks up under the brick retainer. NOTE: Place narrow brick in centre.

2.9.3 Carefully pivot fi bre baffl es up onto the secondary air tubes as illustrated. Ensure that the top baffl es

are pushed all the way to the rear of the fi rebox, leaving a minimum of a 1 inch gap along the front.

This will allow the fl ue gases to escape the fi rebox. Ensure overlap joint is tight.

2100 2200

WARNING

W415-0842 / 07.28.09

OVERLAP

JOINT

BAFFLE

SECONDARY

AIR TUBES

Page 21

2.10 OPTIONAL BLOWER KIT INSTALLATION

!

WARNING

RISK OF FIRE AND ELECTRICAL SHOCK.

TURN OFF THE ELECTRICAL POWER BEFORE SERVICING THIS APPLIANCE.

USE ONLY WOLF STEEL APPROVED OPTIONAL ACCESSORIES AND REPLACEMENT PARTS WITH

THIS APPLIANCE. USING NON-LISTED ACCESSORIES (BLOWERS, DOORS, LOUVRES, TRIMS, ETC.)

COULD RESULT IN A SAFETY HAZARD AND WILL VOID THE WARRANTY AND CERTIFICATION.

ENSURE THAT THE BLOWER’S POWER CORD IS NOT IN CONTACT WITH ANY SURFACE OF THE

APPLIANCE TO PREVENT ELECTRICAL SHOCK OR FIRE DAMAGE. DO NOT RUN THE POWER

CORD BENEATH THE APPLIANCE.

Drywall dust will penetrate into the blower

bearings, causing irreparable damage.

Care must be taken to prevent drywall

dust from coming into contact with the

blower or its compartment. Any damage

resulting from this condition is not covered by the warranty policy. Use of the

blower increases the output of heat.

THERMAL SWITCH BRACKET

21

Provisions have been made on this

appliance to install an optional blower

kit (EP65) that comes complete with a

variable speed switch to turn the blower

ON/OFF, as well as adjusting the blower

speed.

2.10.1 Ensure the thermal disc bracket is in the correct

position.

2.10.2 Remove the knock-out from the back of the appliance.

2.10.3 Install the blower and housing as shown using the 4

screws supplied.

2.10.4 Loosen the thermal disc bracket (2 screws) and

slide the bracket until the thermal disc is touching

the rear of the fi rebox and secure.

Check that the thermal

switch bracket is

positioned as illustrated.

SCREWS

KNOCK-OUT

BLOWER

THERMAL DISC

BRACKET

2100 PEDESTAL

MODEL ILLUSTRATED

W415-0842 / 07.28.09

Page 22

22

2.11 OUTSIDE AIR

The following are signs that fresh air for combustion may be required to operate the appliance:

• There are other devices that exhaust house air.

• When the appliance is burning, wood burns poorly, smoke rollouts occur, back-draft takes place and

your appliance does not draw steadily.

• The house has tight fi tting windows and/or is well-sealed.

• In the winter there is excessive condensation on the windows.

• Slightly opening a window on a windless day eases the above conditions.

2.12 OPTIONAL ASH DRAWER KIT (EP20LAD)

!

WARNING

FAILURE TO ACHIEVE A GOOD SEAL BETWEEN THE ASH OPENING AND ASH PLUG WILL RESULT

IN AN OVER FIRE CONDITION THAT COULD CAUSE DAMAGE TO THE APPLIANCE.

Provisions have been made on the appliance to install an optional ash drawer kit. The kit allows for

convenient removal of excess ash.

• If the appliance has been previously operated, the appliance

must be cold and the ashes must be removed in order to access the ash plug. NOTE: Place the ash drawer from the kit

underneath the appliance to catch falling ashes during the

installation.

• From the underside of the appliance, remove the nuts that secures the heat shield and the ash opening cover plate.

• Remove the small light weight brick that is covering the ash

opening, and discard. It is important that the area around the

ash opening be cleaned well to ensure that a proper seal is created between the new ash plug and the ash opening.

• Once the area surrounding the opening has been cleaned,

place the new ash plug (supplied) over the opening.

• Carefully remove the knock out from the heat shield by breaking

the micro tabs.

• Bend out the four bend tabs at a 90 ° angle from the heat shield.

OP

SH

A

R

COVE

IE

H

S

AT

E

H

G

IN

N

E

TE

A

L

P

D

L

• Align the slots in the ash drawer housing with the four bend

tabs. Secure using the four screws supplied.

D TA

EN

• Secure the heat shield and ash drawer housing to the appliance

using the nuts removed in step 2.

B

(X4)

• Slide the ash drawer into the ash housing.

S

B

W415-0842 / 07.28.09

Page 23

2.13 OPTIONAL ASH PAN KIT (EP20PAD)

!

FAILURE TO ACHIEVE A GOOD SEAL BETWEEN THE ASH OPENING AND ASH PLUG WILL RESULT

IN AN OVER FIRE CONDITION THAT COULD CAUSE DAMAGE TO THE APPLIANCE

Provisions have been made on the appliance to install an optional ash drawer kit.

The kit allows for convenient removal of excess ash.

NOTE: It is recommended to install the rails on the pedestal base prior to installing the pedestal assembly to the fi rebox.

• If the appliance has been previously operated, it must be cold and the ashes

must be removed in order to access the ash plug.

• If the pedestal has been installed with the opening to the back, it will be necessary to lay the appliance onto its back, remove the pedestal and re-install it with

the opening to the front. It is recommended all fi re brick, including baffl es, be

removed prior to placing the appliance on its back.

• From the underside of the appliance, remove the nuts that secure the ash

opening cover plate.

• Install the ash pan rails using the screws provided.

• Snap the magnets into place.

• Slide the ash drawer into the ash housing.

• Install the handle using the screws provided and affi x the logo to the ash pan housing cover as illustrated.

• Place the ash pan housing cover in front of the opening, engaging it into the slots.

• Remove the small light weight brick that was covering the ash opening and discard. It is important that the area

around the ash opening be cleaned well to ensure that a proper seal is created between the new ash plug and

the ash opening.

• Once the area surrounding the opening has been cleaned, place the new ash plug (supplied) over the opening,

allowing the protrusion on the brick to recess into the opening on the bottom of the fi rebox.

WARNING

ASH OPENING

COVER PLATE

23

2.14 ASH REMOVAL WITH ASH DRAWER

• To remove the ashes, clear the

ash away from the ash plug.

• Remove the ash plug. It is rec-

ommended to use a poker.

• Rake the excess ash into the

ash drawer.

• Do not overfi ll the ash

drawer. Ash should not accumulate higher than the sides

of the drawer.

• Before removing the drawer,

ensure that the area around the ash opening is clean. Tap the ash from the chute into the drawer, then place

the ash plug back over opening.

LOGO

PLACEMENT

HEAT SHIELD

LOGO

PLACEMENT

MICRO TABS

W415-0842 / 07.28.09

Page 24

24

3.0 OPERATION

ALWAYS OPERATE THIS APPLIANCE WITH THE DOOR CLOSED AND LATCHED EXCEPT DURING

START UP AND RE-FUELING. ALWAYS WEAR GLOVES TO PREVENT INJURY. DO NOT LEAVE THE

FIRE UNATTENDED WHEN THE DOOR IS UNLATCHED AS UNSTABLE WOOD COULD FALL OUT OF

THE FIRE CHAMBER CREATING A FIRE HAZARD TO YOUR HOME.

NEVER LEAVE CHILDREN UNATTENDED WHEN THERE IS A FIRE BURNING IN THE APPLIANCE.

NEVER USE GASOLINE, GASOLINE-TYPE LANTERN FUEL, KEROSENE, CHARCOAL LIGHTER FLUID,

OR SIMILAR LIQUIDS TO START OR ‘FRESHEN UP’ A FIRE IN THIS APPLIANCE. KEEP ALL SUCH

LIQUIDS WELL AWAY FROM THE APPLIANCE WHILE IT IS IN USE.

OBJECTS PLACED IN FRONT OF THE APPLIANCE SHOULD BE KEPT A MINIMUM OF 48” FROM THE

ANY MODIFICATION OF THE APPLIANCE THAT HAS NOT BEEN APPROVED IN WRITING BY THE

TESTING AUTHORITY IS CONSIDERED BREACHING CSA B365 (CANADA) AND ANSI NFPA 211 (USA).

OPEN AIR CONTROL (AND DAMPER WHEN FITTED) BEFORE OPENING FIRING DOOR.

!

WARNING

FRONT FACE.

HOT WHILE IN OPERATION, KEEP CHILDREN, CLOTHING AND FURNITURE AWAY. CONTACT MAY

CAUSE SKIN BURNS. WEAR GLOVES TO OPERATE YOUR APPLIANCE.

BURNING YOUR APPLIANCE WITH THE DOORS OPEN OR AJAR CREATES A FIRE HAZARD THAT MAY

RESULT IN A HOUSE AND OR CHIMNEY FIRE.

Y our T imberwolf EPA listed product is a Hi-tech appliance, designed with the most advanced technology . The appliance is extremely airtight.

The fi rst fi re(s) in your appliance will be diffi cult to get going and keep going with little amount of heat being gener-

ated. This is a result of the moisture being driven out of the fi re brick. Allow 30 to 40 hours of hot fi res (temperatures in

excess of 500°F - 600°F) before your appliance will perform normally . During the break-in period (the fi rst 2 or 3 fi res)

create only small, hot fi res using kindling; this will allow the fi rebrick to cure. Do not be alarmed if small hairline cracks

develop in the fi rebrick. This is a normal occurrence and does not pose a safety hazard. The paint may also smell a

little for the fi rst few fi res as it cures and you may wish to open a door or window to alleviate the smell.

To start, a brisk fi re is required. Place loosely crumpled paper on the fl oor of the appliance and cover with dry kindling.

Open the air control fully by sliding control all the way to the right. Light the paper and leave the door slightly ajar (one

inch) until all kindling is burning. To maintain a brisk fi re, a hot coal bed must be established and sustained.

Slowly add larger wood (2x4 size pieces). Lay the pieces lengthwise from side to side in the hot coal bed with a shallow trench between, so that the primary air can fl ow directly into this trench and ignite the fuel above. When the fi re

seems to be at its peak, medium sized logs may be added. Once these logs have caught fi re, carefully close the door.

(Closing the door too quickly after refueling will reduce the fi rebox temperature and result in an unsatisfactory burn.)

Remember it is more effi cient to burn medium sized wood, briskly, and refuel frequently than to load the appliance with

large logs that result in a smouldering, ineffi cient fi re and dirty glass.

As soon as the door is closed, you will observe a change in the fl ame pattern. The fl ames will get smaller and lazier

because less oxygen is getting into the combustion chamber. The fl ames, however , are more effi cient. The fl ames will

remain lazy but become larger again as soon as the fi rebricks have been heated thoroughly and the chimney becomes

heated and provides a good draft. At this point, the roaring fi re that you see when the door is opened is wastefully

drawing heated room air up the chimney , certainly not desirable. Always operate with the door fully closed once the

medium sized logs have caught fi re.

W415-0842 / 07.28.09

Page 25

You can now add larger pieces of wood and operate the appliance normally. Once the appliance is entirely hot,

it will burn very effi ciently with little smoke from the chimney. There will be a bed of orange coals in the fi rebox

and secondary fl ames fl ickering just below the top baffl es. You can safely fi ll the fi rebox with wood to the top of

the door and will get best burns if you keep the appliance pipe temperatures between 250 degrees Fahrenheit

(120 degrees Celsius) and 450 degrees Fahrenheit (270 degrees Celsius). A surface thermometer will help

regulate this.

Without an appliance thermometer, you are working blindly and have no idea of how the appliance is operating!

An appliance thermometer offers a guide to performance.

Can’t get the fi re going? Use more kindling and paper. Assuming the chimney and vent are sized correctly and

there is suffi cient combustion air, the lack of suffi ciently dry quantities of small kindling is the problem. Thumb

size is a good gauge for small kindling diameter.

Can’t get heat out of the appliance? One of two things may have happened. The appliance door may have

been closed prematurely and the appliance itself has not reached optimum temperature. Reopen the door and/

or draft control to re-establish a brisk fi re. The other problem may have been wet wood. The typical symptom is

sizzling wood and moisture being driven from the wood.

3.1 DRAFT

Draft is the force which moves air from the fi rebox up through the chimney.

The amount of draft in your chimney depends on the length and diameter of

chimney, local geography, nearby obstructions and other factors. Adjusting

the air control all the way to the left reduces the temperature. The draft can be

adjusted from low to high by moving the handle from left to right. Inadequate

draft may cause back-puffi ng into the room through the appliance and chimney

connector points and may cause plugging of the chimney. Too much draft may

cause an excessive temperature in the appliance, glowing red appliance parts

or chimney connectors or an uncontrollable burn which can lead to a chimney

fi re or permanent damage to the appliance. Do not operate your appliance for

longer than 30 minutes with the air control on “HIGH” (fully open).

25

AIR CONTROL

3.2 FIRE EXTINGUISHERS / SMOKE DETECTORS

All homes with a solid fuel burning appliance should have at least one fi re extinguisher in a central location

known to all and at least one smoke detector in the room containing the appliance. If it sounds an alarm, correct the cause but do not deactivate or relocate the smoke detector.

3.3 FUEL

When loading the appliance, ensure that the two upper fi bre baffl es are not lifted up and of f their ledge. For

maximum effi ciency, when the appliance is thoroughly hot, load it fully to the top of the door opening and burn at

a medium low setting. Maximum heat for minimum fuel (optimum burn) occurs when the appliance top temperature is between 500°F (260°C) and 600°F (315°C). The bricks will be nearly all white and the glass mostly clear .

The whiteness of the bricks and the cleanliness of the glass are good indicators of your operating effi ciency. Not

enough heat is produced when only one or two pieces of wood are burned or the wood may not burn completely .

A minimum of three pieces are needed to encase a bed of coals that sustains the fi re.

NOTE: When loading the appliance, ensure to keep fuel back from the glass. If coals are to accumulate

on the front lip, there is a chance they will fall out when the door is opened.

Loosely stacked wood burns quicker than a tightly packed load. Wood burns in cycles rather than giving a steady

output of heat. It is best to plan these cycles around your household routine so that only enough coals are left to

start the next load. In the evening, load your appliance, at least, a half-hour before bed to ensure a good fi re, hot

enough to close the draft control for an overnight burn.

Burn only dry seasoned wood. It produces more heat and less soot or creosote. Do not burn ocean beach wood.

Its salt content can produce a metal eating acid. When refueling open the door slowly to prevent smoke spillage.

Use a pair of long gloves (barbecue gloves) when feeding the fi re. Because these appliances burn at the front,

they are clean and effi cient, but they are also very hot and gloves are useful. Keep a small steel shovel nearby to

use as a poker and to remove ashes. Do not store the wood within 3 feet (1m) of the appliance.

W415-0842 / 07.28.09

Page 26

26

3.4 LIGHTING A FIRE

3.4.1 FLASH FIRE

A fl ash fi re is a small fi re burned quickly when you don’t need much heat. After your kindling has “caught”, load

at least 3 pieces of wood, stacked loosely. Burn with the draft control fully open or closed only slightly.

3.4.2 EXTENDED FIRE

Load your larger pieces of wood compactly, packed close enough to prevent the fl ames from penetrating it

completely.

After approximately 30 minutes, depending on the size of the load, close the draft control completely making

sure that the fi re is not extinguished.

DO NOT OVERFIRE THE APPLIANCE!

Overfi ring can occur by:

A. Burning large amounts of smaller wood pieces such as furniture scraps, skids or treated wood;

B. Vigorously burning large loads of wood with the draft control on “HIGH” (fully open) for long periods of

time (one or two hours).

4.0 MAINTENANCE

TURN OFF THE POWER BEFORE SERVICING THE APPLIANCE.

!

WARNING

APPLIANCE MAY BE HOT, DO NOT SERVICE UNTIL APPLIANCE HAS COOLED.

DO NOT USE ABRASIVE CLEANERS.

Check your chimney and chimney connector for creosote and soot buildup weekly until a safe frequency for

cleaning is established.

If accumulation is excessive, disconnect the appliance and clean both the chimney and the appliance. You

may want to call a professional chimney sweep to clean them. Both have to be cleaned at least once a year or

as often as necessary.

Remove fi bre baffl es and clean above them once a year.

Replace any broken bricks.

4.1 ASH REMOVAL PROCEDURES

IMPROPER DISPOSAL OF ASHES RESULT IN FIRES. DO NOT DISCARD ASHES IN CARDBOARD

BOXES, DUMP IN BACK YARDS, OR STORE IN GARAGES.

IF USING A VACUUM TO CLEAN UP ASHES, BE SURE THE ASHES ARE ENTIRELY COOLED. USING A

VACUUM TO CLEAN UP WARM ASHES COULD CAUSE A FIRE INSIDE THE VACUUM.

NEVER OPERATE YOUR APPLIANCE WITH THE ASH REMOVAL OPENING NOT SEALED.

!

WARNING

Allow the ashes in your fi rebox to accumulate to a depth of two or three inches; they tend to burn themselves

up. When the fi re has burned down and cooled, remove any excess ashes but leave an ash bed approximately

1 inch deep on the fi rebox bottom to help maintain a hot charcoal bed.

DISPOSAL OF ASHES: Ashes should be placed in a metal container with a tight fi tting lid. The closed contain-

er of ashes should be placed on a non-combustible fl oor or ground, well away from all combustible materials,

pending fi nal disposal. If the ashes are disposed of by burial in soil or otherwise locally dispersed, they should

be retained in the closed container until all cinders have thoroughly cooled.

W415-0842 / 07.28.09

Page 27

4.2 CREOSOTE FORMATION AND REMOVAL

When wood is burned slowly, it produces tar and other organic vapours which combine with expelled moisture

to form creosote. These vapours condense in the relatively cooler chimney fl ue of a slow burning fi re and when

ignited, make an extremely hot fi re. So, the smoke pipe and chimney should be inspected monthly during the

heating season to determine if a buildup has occurred. If creosote has accumulated it should be removed to

reduce the risk of a chimney fi re.

IN CASE OF A CHIMNEY FIRE:

4.2.1 Have a well understood plan for evacuation and a place outside for everyone to meet. Prepare to

evacuate to ensure everyone’s safety.

4.2.2 Close air inlet on appliance.

4.2.3 Call local fi re department. Have a fi re extinguisher handy. Contact local authorities for further informa-

tion on how to handle a chimney fi re.

4.2.4 After the chimney fi re is out, clean and inspect the chimney for stress and cracks prior to lighting an-

other fi re. Also check combustibles around the chimney and the roof.

4.3 RUNAWAY OR CHIMNEY FIRE

27

Runaway fi res can be the result of three major factors:

4.3.1 Using incorrect fuel, or small fuel pieces which wood normally be used as kindling.

4.3.2 Leaving the door ajar too long and creating extreme temperatures as the air rushes in the open door.

4.3.3 Burning your appliance with the ash plug not securely seated.

SOLUTIONS:

4.3.1 Do not burn treated or processed wood, coal,charcoal, coloured paper or cardboard.

4.3.2 Be careful not to over-fi re the appliance by leaving the door open too long after initial start-up. A ther-

mometer on the chimney connector and/or appliance top helps.

4.3.3 Always operate the appliance with the ash plug properly installed.

4.4 CHIMNEY CLEANING

For serious wood burners, chimney cleaning must be done as needed to avoid chimney fi res; the venting sys-

tems for controlled combustion appliances may need cleaning as often as once a month. These rates, however, depend on the burning habits of the individual operating the appliance. For example, it is possible to clog

a solid fuel appliance chimney in a few days if slow, smoldering fi res are burned and the chimney is cold. Wood

burners who consistently operate their appliances with appropriately hot fi res may infrequently have signifi cant

creosote accumulations in the chimney.

Certain items and considerations are important in chimney cleaning:

• Proper tools should be used, including a brush specifi cally designed for chimney cleaning.

• The chimney connector and dampers as well as the chimney should be cleaned.

• The appliance’s fi rebox and baffl e system should be cleaned if needed.

• The chimney should be inspected and repairs made if needed, preferably by a qualifi ed chimney

sweep or mason.

W415-0842 / 07.28.09

Page 28

28

4.5 CARE OF GLASS

If the glass is not kept clean permanent discolouration and / or

blemishes may result. Normally a hot fi re will clean the glass.

The most common reasons for dirty glass include: not using

suffi cient fuel to get the fi replace thoroughly hot, using green or

wet wood, closing the draft so far that there is insuffi cient air for

complete combustion.

If it is necessary to clean the glass, buff lightly with a clean dry

cloth and non-abrasive cleaner.

DO NOT CLEAN GLASS WHEN HOT! Clean the glass after the fi rst 10 hours of operation with a

recommended fi replace glass cleaner. Thereafter clean as required.

The glass is very strong but do not let burning fuel rest or fall against it and always close the door gently.

NEVER FORCE IT SHUT!

If the glass should ever crack or break while the fi re is burning, do not open the door until the fi re is out and do

not operate the fi replace again until the glass has been replaced, available from your Authorized dealer. DO

NOT SUBSTITUTE MATERIALS.

4.6 DOOR REMOVAL

!

WARNING

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

5.3

!

WARNING

BURNING YOUR APPLIANCE WITH THE DOORS OPEN OR AJAR CREATES A FIRE HAZARD THAT

MAY RESULT IN A HOUSE AND OR CHIMNEY FIRE.

DO NOT STRIKE OR SLAM DOOR.

Pivot the door open and lift the door and pins off the bushings. Set the door aside being

careful not to scratch the paint.

PINS

BUSHINGS

W415-0842 / 07.28.09

Page 29

4.7 GLASS REPLACEMENT

GLASS MAY BE HOT, DO NOT TOUCH GLASS UNTIL COOLED.

CARE MUST BE TAKEN WHEN REMOVING AND DISPOSING OF ANY BROKEN GLASS OR DAMAGED COMPO-

NENTS. BE SURE TO VACUUM UP ANY BROKEN GLASS FROM INSIDE THE APPLIANCE BEFORE OPERATION.

DO NOT STRIKE, SLAM OR SCRATCH GLASS. DO NOT OPERATE APPLIANCE WITH GLASS

REMOVED, CRACKED, BROKEN OR SCRATCHED.

4.7.1 When the appliance is cool, open the door and place the

door frame down careful not to scratch the paint.

4.7.2 Remove the screws and brackets holding the glass in

place. Remove all broken glass.

4.7.3 Wrap the edges of the new glass with a U-shaped strip of

fi berglass gasket, covering 1/4” on each side.

!

WARNING

DO NOT USE SUBSTITUTE MATERIALS.

29

4.7.4 Place the glass with the fi berglass gasket in position and

NOTE: For replacement glass, size, thickness and specifi ca-

tions see “REPLACEMENTS” section.

4.8 WOOD

Fuel for the appliance must not be stored closer than the required clearances to combustibles (heat sensitive

material). NEVER STORE WOOD IN THE ASH PAN COMPARTMENT.

Burn only dry, clean unpainted wood that has been seasoned. It produces more heat and less soot or creosote. Freshly cut wood contains about 50% moisture while after proper seasoning only about 20% of the water

remains. As wood is burned, this water boils off consuming energy that should be used in heating. The wetter

the wood, the less heat is given off and the more creosote is produced.

Both hardwood and softwood burn equally well in this appliance but hardwood is denser, will weigh more per

cord and burn a little slower and longer. Firewood should be split, stacked in a manner that air can get to all

parts of it and covered in early spring to be ready for burning that fall. Dry fi rewood has cracks in the end grain.

Cut the wood so that it will fi t horizontally, front to back, making for easier loading and less of a likelihood that

the wood will roll onto the glass. Ideal lengths of wood are approximately 12”.

DO’S

• Build a hot fi re.

• Use only dry wood.

• Several pieces of medium sized wood are

• Clean chimney regularly.

• Refuel frequently using medium sized wood.

• “Fine Tune” the air settings for optimum per-

replace the brackets and screws. When fi nished, you should

be able to move the glass slightly , horizontally and vertically.

DON’TS

• Take ash out immediately. Let it accumulate

better than a few big pieces.

• Burn wet wood.

• Close the door too soon or damper down too

formance.

• Burn one large log rather than two or three

• Burn at continually “low setting”, if glass door

to a depth of at least one inch. A good ash

layer provides for a longer lasting and better

burning fi re.

quickly.

smaller, more reasonably sized logs.

is constantly blackened. This means the fi re-

box temperature is too low.

W415-0842 / 07.28.09

Page 30

30

5.0 REPLACEMENTS

Contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally

all parts can be ordered through your Authorized dealer / distributor.

FOR WARRANTY REPLACEMENT PARTS, A PHOTOCOPY OF THE ORIGINAL INVOICE WILL BE

REQUIRED TO HONOUR THE CLAIM.

When ordering replacement parts always give the following information:

• Model & Serial Number of appliance

• Installation date of appliance

• Part number

• Description of part

• Finish

* IDENTIFIES ITEMS WHICH ARE NOT ILLUSTRATED. FOR

FURTHER INFORMA TION, CONTACT YOUR AUTHORIZED DEALER.

REF NO. 2100 2200 DESCRIPTION

1* W325-0042 W325-0042 SPRING HANDLE - SMALL BLACK

1* W325-0043 W325-0043 SPRING HANDLE - LARGE BLACK

2 W090-0015 W090-0015 BRICK 4.5” X 9”

3 W090-0168 W090-0168 BRICK 4.5” X 6.250”

4 W090-0167 N/A BRICK 4.5” X 7.625” X 1.250”

5 W090-0172 N/A BRICK 2” X 9” X 1.250”

6 N/A W090-0179 BRICK 2.750” X 9” X 1.250”

7 W580-0007 N/A COMPLETE BRICK SET

8 N/A W580-0008 COMPLETE BRICK SET

9 W018-0019 N/A FIBRE BAFFLE

10 N/A W018-0018 FIBRE BAFFLE

11 W135-0238 W135-0238 CAST ASH LIP

12 W225-0214 W225-0214 BLACK DOOR

13 W010-2162 W010-2162 DOOR GLASS W/ GASKET - 5 MIL CERAMIC GLASS

14* W562-0002 W562-0002 DOOR GASKET

15* W562-0004 W562-0004 GLASS GASKET

16* W510-0013 W510-0013 ASH PLUG

17* N/A W720-0134 REAR SECONDARY AIR TUBE

18* N/A W720-0135 FRONT SECONDARY AIR TUBE

19* W720-0131 N/A SECONDARY AIR TUBE

20* W385-0487 W385-0487 TIMBERWOLF LOGO

COMPONENTS

!

WARNING

FAILURE TO POSITION THE PARTS

IN ACCORDANCE WITH THIS

MANUAL OR FAILURE TO USE ONLY

PARTS SPECIFICALLY APPROVED

WITH THIS APPLIANCE MAY

RESULT IN PROPERTY DAMAGE OR

PERSONAL INJURY.

41.1

W415-0842 / 07.28.09

Page 31

13

12

7 8

9

31

11

10

5

4

2

3

2

3

2100 2200

ACCESSORIES

REF NO. 2100 2200 DESCRIPTION

22 EP65 EP65 BLOWER KIT

23 EP20LAD EP20LAD ASH DRAWER KIT - LEG MODEL c/w ASH PLUG

24 EP20PAD EP20PAD ASH PAN KIT - PEDESTAL MODEL c/w ASH PLUG

23

24

6

22

W415-0842 / 07.28.09

Page 32

32

6.0 TROUBLE SHOOTING

SMOKES WHEN DOOR IS OPEN

Always fully open damper before opening door, is the brick baffl e positioned correctly? Has the chimney been

suffi ciently heated to establish a proper draft? Is there a negative air pressure surrounding the appliance?

APPLIANCE EMITS ODOUR

Paint is curing, see “GENERAL INSTRUCTIONS” section.

DIRTY GLASS

Make sure the damper is not closed too far and burn smaller, hotter fi res. Also make sure the wood is well

seasoned and not wet.

POOR DRAFT

If your appliance is not drafting properly the chimney may be the problem. Have the chimney relined to the

proper size or extend the length of the chimney, see “DRAFT” section. Does the chimney and chimney connector need cleaning?

WOOD BURNS TOO FAST

The door gasket may be leaking. Check for leaks and replace if needed. The air control may need to be adjusted (closed down). Check to see if the ash plug is properly seated.

POOR HEAT OUTPUT

Make sure the wood is well seasoned and not wet, see “FUEL” section. The appliance needs to fi nish curing.

W415-0842 / 07.28.09

Page 33

7.0 SERVICE HISTORY

33

Service Performed Special ConcernsDealer Name

Name

Appliance Service History

This heater must be serviced annually depending on usage.

Date Service Technician

43.1

W415-0842 / 07.28.09

Page 34

34

8.0 NOTES

W415-0842 / 07.28.09

44.1

Page 35

35

44.1

W415-0842 / 07.28.09

Loading...

Loading...