TimberTech AZEK Installation Manual

Decking Installation & Maintenance Guide

TimberTech AZEK® Decking

Installation Guidelines .................................................................................................. 2

Tools Required ............................................................................................................... 2

Installation Preparation ................................................................................................ 4

Working with TimberTech AZEK Deck Boards ............................................................... 4

®

Cortex

CONCEALoc

Hidden Fasteners ............................................................................................. 7

®

Hidden Fasteners .................................................................................... 9

Stair Code Compliance ................................................................................................ 13

Trimming an TimberTech AZEK Deck ......................................................................... 14

Care and Cleaning ....................................................................................................... 15

decking | railing | lighting | fastening TimberTech.com

Installing TimberTech AZEK® Decking

TimberTech AZEK® Decking & Rim Joist Covers should be installed using the same good building principals used to install

wood or composite decking and in accordance with the local building codes and the installation guidelines included below.

AZEK® Building Products Inc. accepts no liability or responsibility for the improper installation of this product. TimberTech AZEK

Decking & Rim Joist Covers may not be suitable for every application and it is the sole responsibility of the installer to be sure

that TimberTech AZEK Decking & Rim Joist Covers is fit for the intended use. Since all installations are unique, it is also the

installer’s responsibility to determine specific requirements for each Deck application. AZEK Building Products recommends

that all applications be reviewed by a licensed architect, engineer or local building official before installation. To get more

information visit TimberTech.com.

Tools Required

TimberTech AZEK Decking & Rim Joist Covers can be installed with a minimum number of readily available tools. Many other

tools are available that can be used for installation. All tools should be used per applicable manufacturers’ instructions.

Some of the basic tool requirements:

• Cordless Driver • Carpenter Square

• Chalk Line • Spacing Tools

• Tape Measure • Miter Saw

• Jig Saw • Safety Glasses

Use the jigsaw to cut around obstructions such as posts. For best results a miter saw with a fine-toothed, carbide-tipped

finish trim blade (12”-60 tooth minimum) works well for cutting. For a power miter or compound power miter saw a fine

finish alternate top bevel blade is also recommended. When working with AZEK products be sure to wear proper clothing and

safety equipment. Safety glasses should be used during the entire installation process. Do not use any cordless saws.

STOP! Read this section before you start!

Always make sure to visit TimberTech.com to ensure you are viewing the most current

installation instructions, care and cleaning, technical information and more.

TimberTech AZEK Decking

AZEK does not recommend the use of rubber or vinyl

products (welcome mats, planters, etc.) on deck boards. A

reaction can occur that causes discoloration of the decking

under the rubber/vinyl product. This is a common caution

for polymer decking products.

Do NOT nail AZEK Deck boards.

Cutting or drilling metal should not be done on AZEK Deck

boards as metal shavings may be come hot and embed

themselves into the deck boards.

Always be sure to check and cut the factory cut ends of

boards to ensure they are square.

Walking Surface

AZEK deck boards need to be installed embossed side up.

Static Electricity

The buildup or generation of static electricity is a naturally

occurring phenomenon in many plastic based products such

as carpeting, upholstery, and clothing, and can occur on

alternative decking under certain environmental conditions.

Static electricity is not a defect and can occur naturally.

Cantilevering

For best results, don’t cantilever over 1/2”.

Routing

AZEK Deck/Rim Joist Covers should not be routed with the

exception of the start/stop boards (see page 6 step 8).

Color and Grain Patterns

AZEK Deck is designed to mimic the look of real wood, and

like real wood, there will be a slight difference in color and

grain pattern from board to board. This is intentional and

part of the manufacturing process, giving AZEK Deck the

most realistic and wood-like appearance possible. This

variation is purely aesthetic and does not or will not affect the

performance of the product.

Color and Temperature

Although AZEK Deck products are cooler to the touch than

many other deck board products in similar colors, all decking

products will get hot in the sun. Additionally, the darker the

decking color, the hotter it will feel.

Roof Tops

In areas with obstructed airflow such as roofs and on-grade

applications, a minimum of 1-1/2” sleeper system supported

by and connected to the substructure over which the deck is

built is required.

Page 2

Installing TimberTech AZEK® Decking

STOP! Read this section before you start! (continued)

Always make sure to visit TimberTech.com to ensure you are viewing the most current

installation instructions, care and cleaning, technical information and more.

DO NOT attach deck boards to a floating sub-structure which

is not mechanically fastened frequently and sufficiently to the

building and roof deck.

Note

AZEK Deck is NOT intended for use as columns, support

posts, beams, joist stringers, guard railing or other primary

load-bearing members. AZEK must be supported by a codecompliant substructure. While AZEK products are great for

deck re-planking (removing old deck surface boards and

installing AZEK on code-compliant substructure), AZEK

Deck Boards CANNOT be installed on top of an existing

deck.

Roof Top Decks

®

When considering AZEK

is imperative that the framing/sub-structure to which the

decking will be attached is securely attached to the building

or roof deck using suitable mechanical fasteners. Do not use

adhesives to attach framing to the building or roof surface, and

NEVER ATTACH DECK BOARDS TO A FLOATING FRAME/SUBSTRUCTURE. Frequently check tops of sub-structure framing

members to ensure that they are in plane, as AZEK® Decking

will conform to the contour of the framing members to which

it is attached. It may be necessary to shim or plane framing

members due to thickness variations in lumber, or variations

in the surface to which the framing/sub-structure is attached.

Securely attaching rigid blocking between framing members

Deck in a roof top application, it

Failure to install TimberTech AZEK Decking products

in accordance with applicable building codes and

this Installation Guide may lead to personal injury,

affect deck system performance and void the product

warranty.

at frequent intervals should also be incorporated to help limit

sub-structure movement. Proper drainage and air flow should

also be considered, with a minimum of 1 ½” sleeper height

necessary and deck boards must be attached to the properly

secured sub-structure with a minimum of a 1/8” gap between

deck boards. It is the installer’s responsibility to determine if

AZEK® Deck is suitable for a specific roof top application. The

AZEK Company recommends that all applications be reviewed

by a licensed architect, engineer, or local building official

before installation. If you have any questions or need further

assistance, please call AZEK Customer Service at 1-877-2752935 or visit our website at www.azek.com.

Extreme Heat Warning Metamerism

Be aware of excessive heat on the surface of AZEK products

from external sources, such as but not limited to, fire or

reflection of sunlight from energy-efficient window products.

Low-emissivity (Low-E) glass can potentially harm AZEK

products. Low-E glass is designed to prevent passive heat

gain within a structure and can cause unusual heat buildup on exterior surfaces. This extreme elevation of surface

temperatures, which exceeds that of normal exposure, can

possibly cause AZEK products to melt, sag, warp, discolor,

increase expansion/contraction, and accelerate weathering.

Current or potential AZEK customers that have concerns

about possible damage by Low-E glass should contact the

manufacturer of the product which contains Low-E glass for a

solution to reduce or eliminate the effects of reflected sunlight.

Metamerism is the phenomenon wherein two colored

samples will appear to be of the same shade under one

light source but will appear to be different shades under

a second source. When installing AZEK deck boards

at different angles, metamerism may make the boards

installed at one angle appear to be of a different shade than

the deck boards installed at the other angle, depending on

the lighting and the angle which the deck is viewed. This

is a natural phenomenon, not a defect, and can occur even

when the deck boards are cut from the same boards or

come from the same unit. Metamerism is an aesthetic

issue and not a performance or product warranty issue.

Page 3

Working with TimberTech AZEK® Deck Boards

Excessive Construction Debris

It is important during construction, the deck’s surface stay

clear from excessive build-up of dirt, sand, and dust from tile,

concrete, landscape blocks, or any other masonry products. If

these materials are not removed immediately, the deck surface

will become difficult to clean and can potentially damage the

deck’s surface finish.

If a build-up does occur please refer to the Care and Cleaning

section in AZEK’s installation guide or website, AZEK.com.

IMPORTANT: Do not allow airborne dust from concrete,

landscape blocks, or any masonry product to accumulate on

the AZEK Deck, Porch, Rim Joist Covers, & Riser surface as it

may damage the surface of the deck. Do not cut any product

Do not use AZEK Deck as a work surface.

When installing AZEK Deck on a new home, best practice is to

install after all other construction (siding, roofing, painting,

etc.) is completed, otherwise permanent damage may occur.

on or near AZEK Deck, Porch, & Rim Joist Covers.

Installation Preparation

Follow these guidelines for best deck installation:

• AZEK Deck Boards are one-sided products. Deck Boards are to be installed with the grain side up for the walking

surface.

• AZEK Rim Joists Covers are one-sided. Rim Joist Covers are to be installed grain side out.

• As joists are installed, run string line frequently to ensure that the tops of the joists are in plane, as AZEK Decking

will conform to the contour of the joists to which it is attached. It may be necessary to shim or plane joists due to size

variations in lumber. Be sure to sort and exclude any extremely crowned joists/lumber material.

• Prior to installation, check to make sure all joists are level, structurally sound, and there are no nails or screws

protruding.

• Proper joist spacing is required for proper installation. Joist spacing should never exceed 16” on center. For a more

rigid feel, 12” may be preferred.

• Install solid wood blocking between each joist, placed in rows at maximum every 4’ - 6’ within the structure using

exterior grade screws. Solid blocking will help reduce up or down movement and/or twisting of joists. Limiting joist

movement can help reduce excessive gapping and also ensure a more uniform finished surface of the AZEK Deck.

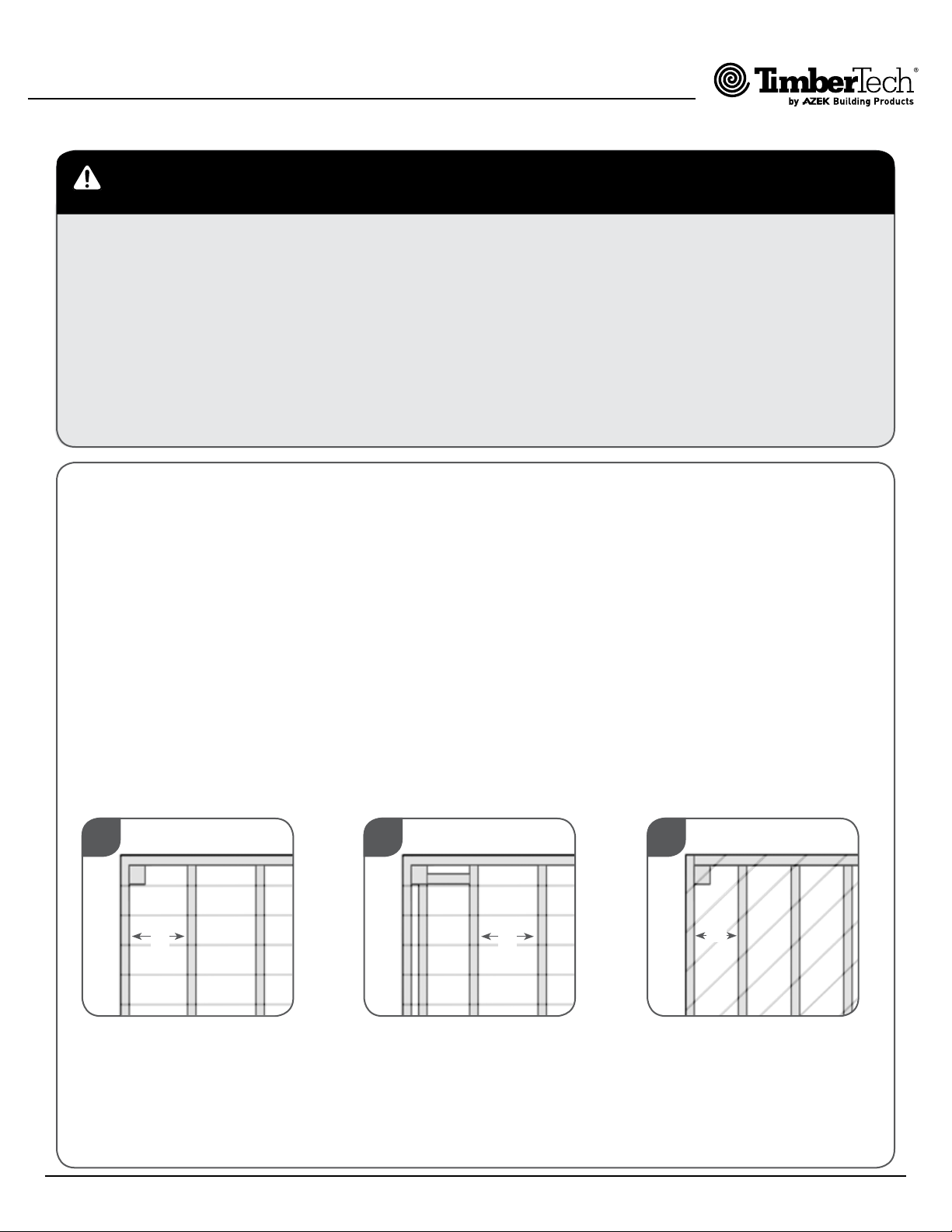

1 2 3

16”

16”BASIC INSTALLATION

SUBSTRUCTURE

16” on center maximum joists.

(12” on center for commercial

applications)

PICTURE FRAME INSTALLATION

SUBSTRUCTURE

16” on center maximum joists plus

additional support for picture frame

structure (12” on center for commercial

applications)

16”

Page 4

12”

DIAGONAL INSTALLATION

SUBSTRUCTURE

12” on center maximum joists.

More severe angles may require closer

joist spacing.

Working with TimberTech AZEK® Deck Boards

Expansion and Contraction

AZEK Deck/Rim Joist Covers will have expansion and contraction with changes in temperature, unlike wood whose size

will fluctuate with moisture changes. The expansion and contraction encountered may result in slight gaps, which might

be noticed at the ends of boards or in splice joints. Fastening the deck boards according to the Installation Guidelines will

help minimize expansion and contraction.

• Expansion/contraction is most significant where extreme temperature change may exist.

• Best practice is to cut and fasten the deck boards as soon after cutting as possible.

• For better results keep decking as cool as possible during attachment. Direct full sun exposure will increase board

temperature and length. If attaching during high heat, larger gapping can be expected. Be sure to keep butt joints

tight. Do not leave a gap at butt joints, splices or miters.

• Be sure to fasten ends of boards, splices, or abutments to building or structure securely into framing using 2

screws. Position the screws at or within 1/2” of each board end or joint and 3/4” from side of deck plank.

• For butt joints, be sure to trim cut factory ends to ensure squareness. Do not scarf cut butt joints.

1/2”

3/4”

• Provide a 1/8” to 1/4” side to side gap between deck boards.

• In areas with obstructed airflow such as roofs and on-grade applications, a minimum of 1-1/2” sleeper system

supported by and connected to the substructure over which the deck is built is required.

• Framing/sub-structure must be securely attached to ground footings or building structure. No floating substructures should be used in any application with AZEK Deck, including on grade, concrete, or in roof top

applications.

• For best results, stagger splices and miters across deck surface so that all splices and miters do not break on the

same joist or beam.

• To further minimize expansion and contraction, proper ventilation and air flow should be considered.

• Some area building codes may require double joisting when joining boards end to end. Double joist and/or secure

double blocking is always required at butt joints when using ConceaLoc or FusionLoc fasteners. Always check with

your local code authority for specific requirements before installation.

• During installation, frequently check that AZEK Deck boards are installed straight and with consistent gapping and

spacing by using a string line.

Fasteners

• Due to the durability of AZEK deck products, a high-quality fastener is recommended that meets the following

specifications:

• Stainless Steel

• Minimum Screw Size: #7

• Face screws to be a minimum length of 2 1/4”

• Be sure that screws are driven to a minimum depth of 1 1/4” into solid wood framing below the bottom of the AZEK

Deck Board. This will enhance holding power and uplift resistance.

• Avoid using flathead screws. Trim head screws typically provide a better result. As always, you should try the

fastener in a sample board before using on your deck.

• Be sure to install 2 screws per joist on each deck board. regardless of temperature during attachment of AZEK

deck boards, be sure to keep butt joints and miters tight and place fasteners within 1/2” of ends.

• For salt water coastal applications, we suggest using the above minimum fastener requirements in 316 stainless

steel.

Page 5

Loading...

Loading...