PNEUMATIC CHAINSAW

OPERATING MANUAL

Models

TKA 015A, TKA 017A, TKA 021A, TKA 025A,

TKA 015Z, TKA 017Z, TKA 021Z and TKA 025Z

(A = Aluminium, Z = Zinc)

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

2

WARNING!

IT IS VERY IMPORTANT THAT YOU READ THIS

MANUAL BEFORE OPERATING YOUR CHAINSAW

CHAINSAWS CAN BE DANGEROUS

Each year many people are injured in chainsaw

accidents. Most of these accidents can be avoided. The

hands, knees, feet and head are most vulnerable to

being cut by the saw chain.

If you use a chainsaw often, there are also other health

risks. The continual noise of the chainsaw can lead to

permanent hearing loss and vibration can cause

permanent damage to the hands.

These hazards mean that chainsaws are potentially one

of the most dangerous pieces of industrial equipment if

not used correctly.

With the use of the correct protective clothing, and

proper work practices, this equipment can be used

safely.

In the next few pages you’ll read valuable information

concerning safe chainsaw operation. There is a checklist

of the safety instructions. Tips on the protective clothing

you should wear, and suggestions for safe work methods

are provided. Please read on!

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

3

GENERAL SAFETY PRECAUTIONS

This owner’s manual will tell you the safety features of your

chainsaw and the correct way of operating it.

Check your chainsaw thoroughly before use. Make sure your

bar, chain and sprocket are in top condition and that all safety

devices are working properly.

Regularly service your chainsaw.

Always wear protective clothing. Gloves, safety helmet with

visor or goggles, earmuffs, protective leggings and safety

boots should be worn at all times whilst operating your

chainsaw.

Do not start cutting until you have a clear work area, secure

footing and a planned retreat path from the operating area.

Keep other people and animals well away from the working

area.

Make sure there is a second person within calling distance.

Do not operate a chainsaw that is beyond your ability.

Use the chainsaw only to cut the correct material with the

correct chain.

Do not become distracted. Stop the chainsaw if somebody

starts speaking to you.

If you are tired, rest! Chainsaw operation requires maximum

and constant concentration. Tired operators can have

accidents.

PERSONAL SAFETY EQUIPMENT

Gloves, safety helmet with visor or goggles, earmuffs, protective

leggings and safety boots should be worn at all times whilst

operating your chainsaw to protect you from chain saw injury.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

4

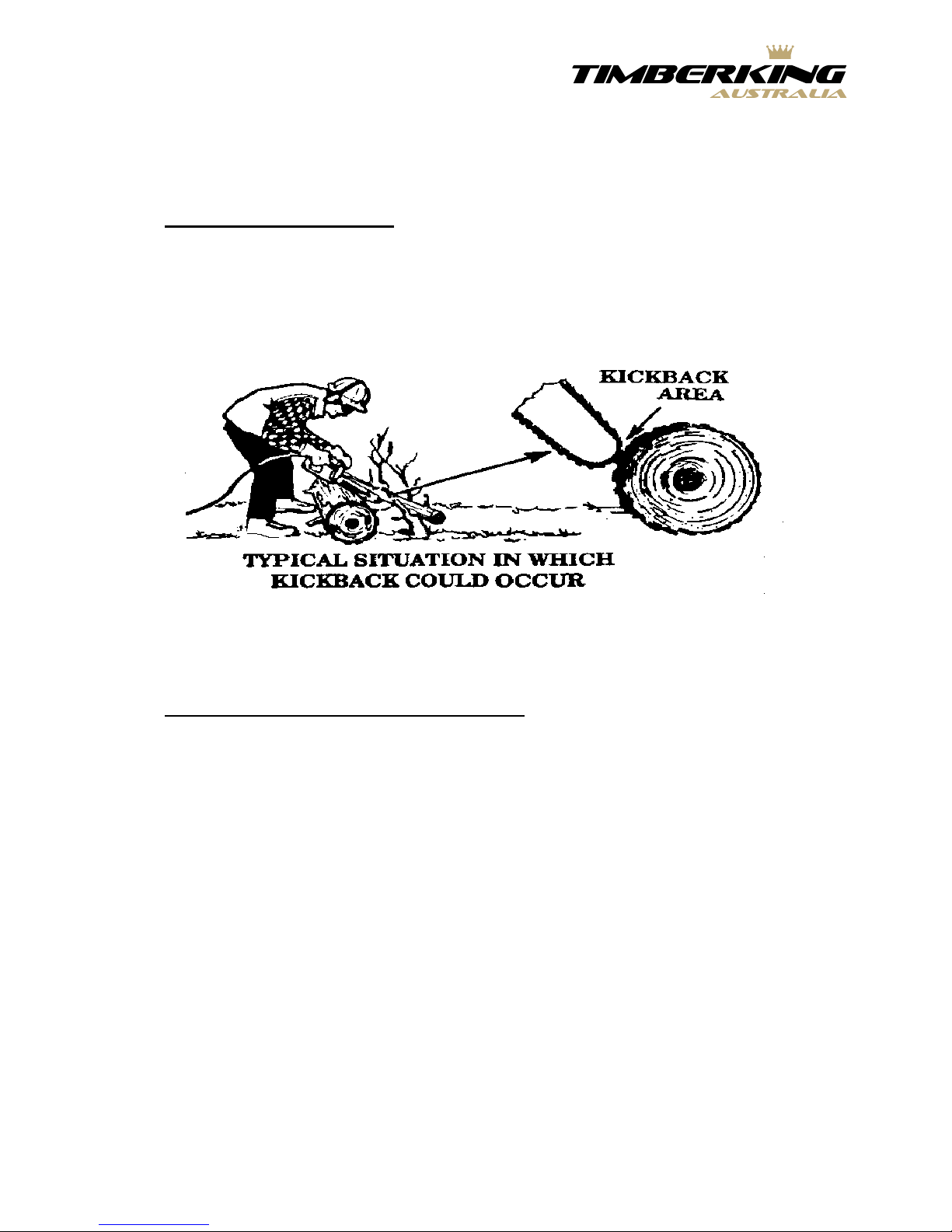

PREVENTING KICKBACK

Kickback is a sudden upward and backward movement of the

saw. It occurs when the tip of the bar nose contacts a log,

branch or nail. It can cause serious injury.

FIGURE 1

TO PREVENT INJURY FROM KICKBACK

Ensure your chain saw is fitted with a chain protector safety bar

and a bumper spike.

Use low kickback chain types and avoid lowering the depth

gauges too much when sharpening.

Hold the chainsaw firmly making sure that the left hand

encircles the top handle with the thumb underneath.

Avoid bringing the upper quadrant of the guide bar into

contact with any foreign object.

Wear correct head protection and safety pants at all times.

Avoid cutting above your shoulder height.

Never hold the chainsaw in one hand.

Always begin at peak (rev’s) power.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

5

PREVENTING RAYNAUD’S DISEASE AND OCCUPATIONAL OVERUSE

SYNDROME

The vibration from chainsaws can cause damage to the hands if

used for long periods of time.

Use the chainsaw with ergonomically angled handles. These

greatly reduce uneven and undue pressure on the hands.

Take regular rest breaks from continuous operations.

Wear gloves.

Sharpen your chain regularly. This will ensure smoother cutting

and less vibration.

MAINTAINING YOUR CHAINSAW

A chainsaw is designed to meet various safety requirements. Use

the diagrams to check and understand the safety features, even

if they may be optional extras when you buy it.

Never operate a chainsaw that is damaged, not properly

adjusted or wrongly assembled. Your chainsaw requires regular

maintenance.

IMPORTANT!

If your chainsaw is used underwater, the motor must be flushed

immediately after use with preservatives such as Valvoline Tectyl

930.

BEFORE YOU START WORK, CHECK THAT…

1. The machine is in good condition (no leaks, wear or damage).

2. The throttle trigger and safety throttle lock operate correctly.

3. The chain is lubricated, sharp and tension is correct.

4. The air pressure is correct. Maximum 7 bar – do not exceed!

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

6

AFTER FINISHING YOUR WORK, OR DAILY…

1. Clean the chainsaw, particularly the sprocket guard.

2. Check the chainsaw thoroughly from top to bottom, see that it

is lubricating properly.

REGULARLY…

1. Sharpen your saw chain.

2. Check the guide bar for burring.

3. Check the sprocket for wear. It can clog up with oil and dirt

and may malfunction.

4. Have your chainsaw serviced regularly.

PREVENTING NOISE INDUCED HEARING LOSS

Most chainsaws emit noise levels that can cause permanent

damage to your hearing if used for long periods at a time.

Always use safety standards approved earmuffs or plugs.

Ensure your chainsaw is tuned to manufacturers specifications.

PREVENTING FIRES

1. Don’t smoke while operating the chainsaw.

2. Keep a fire extinguisher, spray pump and shovel nearby.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

7

TRAINING AND SUPERVISION

Chainsaw operators should be properly trained. Training may be

on-the-job or through a recognised training course. Training

should include instructions on:

Safe working techniques.

Operating conditions, including unusual or dangerous

conditions.

Basic information about the chainsaw and its controls,

attachments and components, design capacity, stability and

limitations.

Correct stopping and starting techniques.

Cleaning and servicing.

Being alert for the possibility of kickback.

Chain sharpening techniques.

Less experienced operators should be carefully supervised.

Certain operations are extremely dangerous and should only be

undertaken by professionals. These include the removal of

branches from standing trees, the removal of trees hung up in

wires, cutting trees thicker than the guide bar length, and working

in windblown and foul weather areas.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

8

A REVIEW OF SAFETY PROCEDURES

Operator should wear dress of close fitting style, safety boots

and leather gloves.

When carrying the chainsaw about, the chain should be fitted

with a chain guard.

Chainsaws should never be run without oil.

Always hold the saw with both hands and keep a firm stance

when working with the chainsaw.

No other person should stand within the working radius of the

saw.

Before you start cutting, press the spike bar against the

material being cut.

When cutting splintered wood, take precaution. Large splinters

can fly towards the operator.

Only use the underside of the bar when cutting at shoulder

height. T

he pressure hose should be closed when the chainsaw is set

aside even for a short while or when the chain tension is tested

or adjusted.

The operator should always work calmly and cautiously and

should also avoid any danger to themselves or other persons.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

9

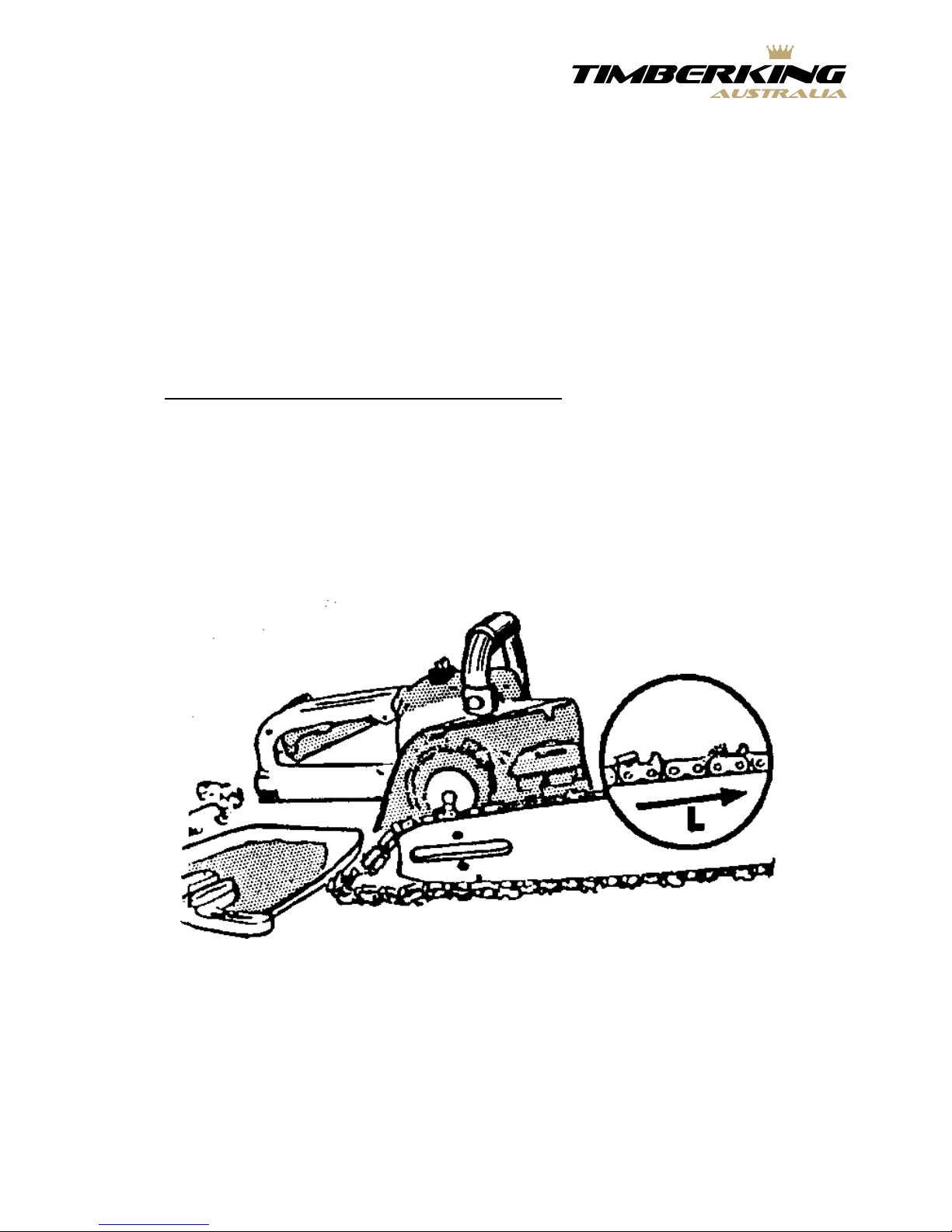

ASSEMBLING THE GUIDE BAR AND CHAIN

Direction of the chain travel (L), the cutting edges of the chipper

chain on the top edge of the guide bar must face in the direction

of the guide bar nose. Put the pivot of the square nut for chain

tensioning into the tap-hole in the guide bar. Assemble the

sprocket guard and screw the nut finger tight.

FIGURE 2

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

10

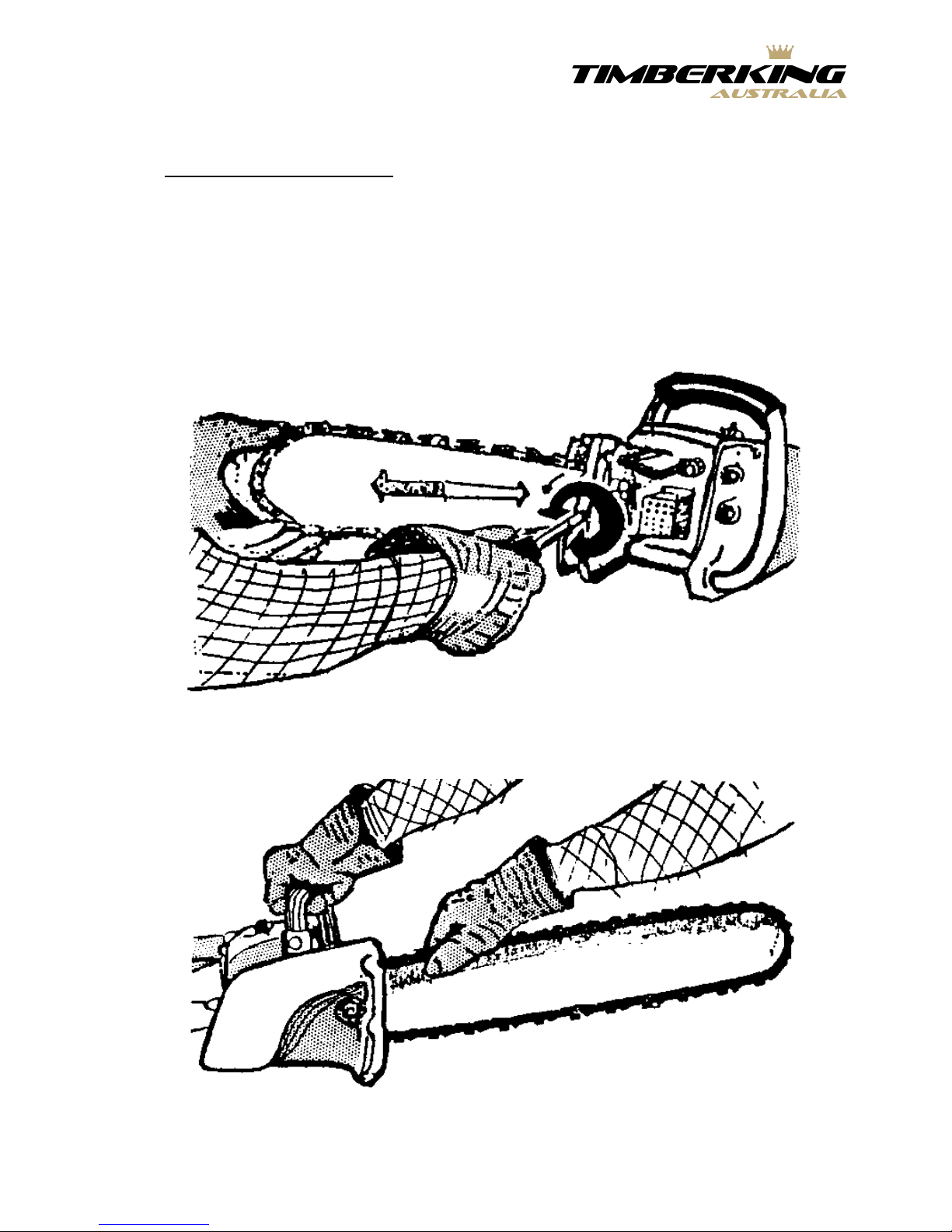

TIGHTENING THE CHAIN

Turn the tensioning screw clockwise. The nose of the guide bar

should be lifted slightly. The chain should not sag but should be

easily moved by hand (wear gloves) alongside the guide bar.

Tighten sprocket guard nut. A newly fitted chain should be

allowed to rotate for 5 minutes with good lubrication and then

re-tighten the chain.

FIGURE 3

FIGURE 4

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

11

FILLING OF SAW CHAIN OIL

Figure 4B – PLEASE: Never use old oil!

Tank cap CHAIN OIL (A): Special non-drip chain oil, otherwise use

regular grade SAE 30 engine oil. Tank capacity is 0.49 Litres.

FIGURE 4B

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

12

CONNECTION OF COMPRESSED AIR

Inside thread in rear handle ¾” B.S.P. For reasons of safety it

should be easy to switch off the compressed air within reach of

the working place. Blow out pressure hose before connecting.

System pressure 85 to 100 p.s.i (6 to 7 bar).

MOUNTING A NEW CHAIN

1. Loosen mounting bolt.

FIGURE 5

2. Tighten chain tension adjustment screw until the coupling links

touch the bar. Lift bar nose slightly whilst adjusting tension.

FIGURE 6

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

13

3. Pull chain around by hand.

FIGURE 7

4. Lift bar and tighten mounting bolt.

FIGURE 8

AFTER MOUNTING A NEW CHAIN

1. Allow chainsaw to run for a short period of time at low speed

while applying a liberal amount of oil to the chain.

2. Turn off motor and re-adjust chain tension. Re-start saw and

make a few light cuts. Re-adjust chain again if necessary. It is

important to monitor chain tension during the first half-hour of

operation.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

14

OPERATING INSTRUCTIONS FOR PNEUMATIC CHAIN SAW

CHAIN CARE (Figure 9)

The illustrations shown in figure 9 clearly show the difference. The

second chain received excellent care. It still cuts, even though

the cutting teeth have been filed almost completely back. The

top chain is no longer serviceable, even though it was hardly

used.

FIGURE 9

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

15

Observe the following rules to obtain the best performance from

your chain:

1. Inspect the bar before mounting a new chain. Never run a

new chain on a worn bar.

2. Make sure the chain tension is correct. Do not run your

chainsaw with a chain that is too loose.

3. Sharpen your chain correctly. Follow the sharpening

instructions shown in figures 10 through to 12.

4. Always use plenty of oil when cutting. Oil is cheaper than a

new chain.

5. Keep the oil hole in the bar and the bar mount clean. Clean

these two points at least once a day.

6. When cutting frozen wood, mix approximately 25% diesel fuel

or kerosene with the chain oil.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

16

CHAIN SHARPENING

(Figure 10)

Use chainsaw file with 5.5mm (7/32”) diameter for 0.404” pitch

chain. It is better to file at frequent intervals. File horizontally and

in the correct top plate angle (35 degrees), filing stroke should go

always from inside to outside. All cutters have to be precisely the

same length and height. Use chain gauge for inspection.

FIGURE 10

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

17

TIMBERKING Pneumatic Chainsaw Exploded View

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

18

TIMBERKING Pneumatic Chainsaw Parts List

Item

Number

Part

Number

Description

Quantity

Required

per Unit

1

TKA 201

Motor Housing Complete (Items 1-16)

1

1Z

TKA 201Z

Motor Housing Complete Zinc (Items 1-16)

1

2

TKA 202

Screw Fillister Head M6 x 65

1

3

TKA 203

Wave Washer 5.5

4

3A

TKA 203A

Spring Washer M6

5

3B

TKA 203B

Flat Washer M6

2

4

TKA 204

Chain Stretcher Complete (Items 2-5)

1

5

TKA 205

Hex Plain Nut M6

2

6

TKA 206

Guide Rail

1

6A

TKA 206A

Guide Rail Pin 3x26

2

7

TKA 207

Stud 1 8

TKA 208

Wave Washer M10

2

9

TKA 209

Hex Nyloc Nut M10

1

10

TKA 210

Hex Plain Nut M10x1

1

11

TKA 211

Seloc Pin 5 x 16

2

12

TKA 212

Capscrew 5.5 M8 x 35

4

13

TKA 213

Wave Washer M8

4

14

TKA 215A

Brass Tube

1

15

TKA 215

Grub Screw

1

16

TKA 216

Gasket 1 17

TKA 217

Handle Complete (Items 17-26)

1

17Z

TKA 217Z

Handle Complete Zinc (Items 17-26)

1

18

TKA 218

Valve Ball

1

19

TKA 219

Pressure Spring

1

20

TKA 220

Spring Retainer (Spacer and Circlip)

1

21

TKA 221

Throttle Valve

1

22

TKA 222

Seloc Pin 5 x 26

2

23

TKA 223

Throttle Lever

1

24

TKA 224

Pressure Spring

1

25

TKA 225

Safety Lever

1

26

TKA 226

Pressure Spring

1

28

TKA 228

Screw, Cap, Socket Head

4

30

TKA 230

Gasket 2 31

TKA 231

Coupling (Customer Specifies Type)

Optional

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

19

Item

Number

Part

Number

Description

Quantity

Required

per Unit

32

TKA 232

Nipple Steel

Optional

33

TKA 233

Oil Tank Cover

1

33Z

TKA 233Z

Oil Tank Cover Zinc

1

35

TKA 235

Pressure Fitting

1

36

TKA 236

Meter Valve Complete (Items 36 + 43)

1

38

TKA 238

Pressure Line

1

39

TKA 239

Fillister Head Screw M6 x 25

3

41

TKA 241

Screw Plug, Oil Filter

1

42

TKA 242

'O' Ring

1

43

TKA 243

Suction Line

1

44

TKA 244

Silencer Complete (Items 44, 44A + 44B)

1

44A

TKA 244A

Silencer Filter

1

44B

TKA 244B

Silencer Gasket

1

45

TKA 245

Screw, Cap, Socket Head M5 x 12

4

47

TKA 247

Tubular Handle Complete (Items 47 + 48)

1

48

TKA 248

Protection Tube Grip

1

49

TKA 249

Stiffening Plate

1

50

TKA 250

Spring Washer M8

2

51

TKA 251

Hex Screw M8x40

1

52

TKA 252

Sprocket Guard

1

52Z

TKA 252Z

Sprocket Guard Zinc

1

53

TKA 253

Spike Bar

1

55

TKA 255

Hex Screw, Spike Bar Only M6 x 16

2

55A

TKA 255A

Hex Screw, Chain Guard, Spike Bar

Optional

56

TKB 356

Motor Complete (Items 57 - 68)

1

57

TKB 357

Cylinder Liner

1

58

TKB 358

Rotor 1 59

TKB 359

Vane

6

60

TKB 360

Back Bearing Disk

1

61

TKB 361

Front Bearing Disk

1

62

TKB 362

Bearing Front

1

63

TKB 363

Cylindrical Pin

1

64

TKB 364

Key

1

65

TKB 365

Spacer

1

66

TKB 366

Bearing Back

1

67

TKB 367

Notched Locking Nut

1

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

20

Item

Number

Part

Number

Description

Quantity

Required

per Unit

68

TKB 368

Hex Retaining Nut

1

69

TKB 369

Pressure Ring

1

70

TKB 370

Distance Ring

1

71

TKB 371

Spacer

1

72

TKB 372

Stop Disk

1

73

TKB 373

Chain Drive Sprocket

1

74

TKB 374

Stop Disk

1

75

TKB 375

(Use TKA 250)

Obsolete

76

TKB 376

Hex Screw M8x30

1

77A

TKC 380

15" Guide Bar

Optional

77B

TKC 430

17" Guide Bar

1

77C

TKC 530

21" Guide Bar

Optional

77D

TKC 630

25" Guide Bar

Optional

78A

TKC 055

15" Semi-Chisel Chain Loop

Optional

78B

TKC 061

17" Semi-Chisel Chain Loop

1

78C

TKC 070

21" Semi-Chisel Chain Loop

Optional

78D

TKC 078

25" Semi-Chisel Chain Loop

Optional

79A

TKC 155

15" Tungsten Carbide Chain (Wood)

Optional

79B

TKC 161

17" Tungsten Carbide Chain (Wood)

Optional

79C

TKC 170

21" Tungsten Carbide Chain (Wood)

Optional

79D

TKC 178

25" Tungsten Carbide Chain (Wood)

Optional

79E

TKC 255

15" Tungsten Carbide Chain (Soft Stone)

Optional

79F

TKC 261

17" Tungsten Carbide Chain (Soft Stone)

Optional

79G

TKC 270

21" Tungsten Carbide Chain (Soft Stone)

Optional

79H

TKC 278

25" Tungsten Carbide Chain (Soft Stone)

Optional

80

TKC 480

Solid Safety Chain Guard

Obsolete

81

TKC 481

Hinged Safety Chain Guard

Optional

81Z

TKC 481Z

Hinged Safety Chain Guard Zinc

Optional

81A

TKC 481A

Pigtail Spring

Optional

81B

TKC 481B

Post, Spring, Nut Only

Optional

83

TKC 483

Bar Nose Guard, SAF-T-TIP

Optional

84

TKC 484

Combination Screw Driver Wrench

1

84A

TKC 484A

Allan Key M6

1

85

TKC 485

Front Hand Guard

Optional

86

TKC 486

Underwater Kit

Optional

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

21

NOTE:

These parts are available in standard ‘Aluminium’ or ‘Zinc’ for

hazardous area. Please stipulate when ordering.

The Front Hand Guard TKC 485 cannot be fitted unless the Hinged

Safety Chain Guard TKC 481 or TKC 481Z is fitted. These parts are

optional extras but are strongly recommended as necessary items

if the chainsaw is to be operated by other than highly

experienced personnel.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

22

LOWERING THE DEPTH LIMITER

1. When sharpening your chain with a file holder, the clearance

depth limiter must be checked and adjusted if necessary after

sharpening.

2. Check the clearance of the depth limiter at least after every

third sharpening, and after every sharpening when cutting

frozen wood.

3. Place depth limiter gauge on cutting tooth. If depth limiter is

too high, file off protruding part with a flat file (Figure 11A).

4. Round off front edge of depth limiter. Its original shape must be

preserved (Figure 11B).

FIGURE 11

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

23

NOTE: Always completely file away any damaged areas on side

plate and top of tooth.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

24

FIGURE 12

CHAIN BAR – IMPORTANT!

Bars are designed only for the purpose of guiding the chain, and

should never be used as crowbars. Turning, twisting and using the

bar as a lever, will shorten its service life and void the warranty.

The bar of your chainsaw needs as much care as the chain. The

running surfaces must be flat and smooth and the groove must

not be expanded. Inspect the groove as shown (Figure 13).

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

25

FIGURE 13

REGULATING THE CHAIN BAR OIL VALVE

Saw chain oil is supplied to the guide bar from the pressurized

tank by means of an adjustable needle valve.

Loosen lock nut ‘A’ – adjust knurled screw ‘B’ to obtain desired

flow.

Clockwise for minimum flow – anti-clockwise for maximum flow.

Re-tighten ‘A’.

Use Special Chain Oil!

FIGURE 14

Lubricate the motor with an ‘In Line’ oil mist lubricator – Adjust

screw ‘A’ to obtain desired mist – a slight film of oil should be felt

at exhaust port – (Silencer removed), (Clockwise for minimum

flow – anti-clockwise for maximum flow). Setting of 1 – 2 is general

with No. 10 oil. Use light, non-resinous machine oil e.g. Shell, Telsus

C10 or equivalent.

It is desirable to keep lubricator within 6 metres of chain saw.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

26

ASSEMBLY

Assembly is performed essentially the same as disassembly, but in

reverse order. Make sure motor clearance is correct. When the

bearing is tight, the longitudinal clearance between the flat rear

surface of the rotor and the rear gasket should be approximately

0.04mm. Correct by grinding spacer ring if necessary.

FIGURE 15

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

27

HOW TO USE THE SAW STARTING AND STOPPING THE MOTOR

Only after oil tank is filled! Depress safety lever ‘C’, Press the

regulating lever ‘D’ in the rear handle.

Attention! Chain starts immediately. Letting go of the regulating

lever reduces the speed and finally stops the motor and chain. At

working breaks the air pressure should be switched of with a

nearby stopcock.

FIGURE 16

Check lubrication of the chain. At the cutting point the timber

has to be clean from sand, nails and the like. Do not allow the

chain to touch the ground. Underwater cutting has to be done

always with rotating motor so that no water may penetrate to the

motor.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

28

BUCKING: Position the spike bar, press the regulating lever and

make the cut with running chain by lifting up rear handle (1)

Figure 17. Use the front handle for guiding only.

FIGURE 17

RE-POSITIONING (2): Apply vertical pressure to the front handle.

Continue cutting with regulating lever fully pressed in.

PLUNGE-CUTTING (3): Position the chainsaw with the wood, swing

back the nose and make the plunge-cut. Pull out spike bar and

shift to a lower position.

LIMBING: Make a shallow cut on the pressure side (4). Cut through

from the tension side (5).

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

29

INSTRUCTIONS FOR SAFE OPERATION

Please follow these safety rules for your own protection.

1. Plan ahead. Lay your work out before you start and always

work at a deliberate pace. Fatigue leads to carelessness and

accidents.

2. Keep your work area clean and un-cluttered.

3. Wear the proper clothing. Clothing which is too tight or too

loose is not suitable. It can restrict your movements or be

caught up in the saw.

4. Protect your head (eyes and ears), hands and feet.

5. Grab the saw securely with both hands during use! Make sure

the material you are cutting will not roll or slip. Make sure your

feet are firmly planted and your body is well balanced. Always

be alert to possible kickback.

6. Always hold the saw to the side of your body.

7. Never carry the saw with the motor running, and always carry

the saw so that the bar points backwards. A chain guard is

mandatory!

8. Never cut in an awkward position. Never cut above shoulder

level. When cutting logs, always cut from the top tier down. Be

alert for stressed pieces of wood, which could spring upward

when cut.

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

30

GENERAL MAINTENANCE OF PNEUMATIC TOOLS

Only proper maintenance can ensure constant performance,

reduction in wear and thus, a decrease in operating costs and an

increase in service life.

Our pneumatic tools are equipped for an operating pressure of 6

bar. A regulator setting for an operator setting of 4 bar is possible

as well as expedient for grinding machines with a built in

regulator, so as to take full advantage of the speed prescribed

for the corresponding grinding wheels.

Pneumatic tools should not run empty because this results in heat

and higher wear. The compressed air should be clean and dry.

This is guaranteed by a proper pneumatic system. Blow through

the pneumatic hose before connecting it.

For the economical use of pneumatic tools, the prescribed air

quantities are necessary; i.e. the line, armatures and hoses must

have the required cross sections so that the flow pressure remains

constant.

Proper lubrication is a must; for this reason, our pneumatic tools

have built-in oilers, which are located between the inlet valve

and the motor, and which function in any position. In smaller and

lighter hand tools these oilers must often be left out, because the

machines would then be too heavy and not easy to manage. In

such cases, lubrication must be carried out by service units or by

manual hose oilers. We recommend service units for permanently

installed work places. However where longer hose lines are

necessary, line oilers built into hose lines are more effective. The

distance between the tool and the oiler should not be more than

5 metres.

Lubricating oils to be used:

Generally SAE 5W to SAE10

Continued over page…

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

31

For damp compressed air, oils are to be used that take up water

(without losing the lubricating effect) and which contain anticorrosive additives. At lower temperatures (especially for work

outside) it may be necessary to use an anti-freeze lubricant e.g.

Kilfrost, BP Energol AX 10 or Kompronal N 74).

For saw chain lubrication:

Use machine oil with adhesive additive,

Viscosity c ST 49 – 55’ (6.5 – 7.5E)/50C

TIMBERKING Pneumatic Chainsaw Operating Manual V3 | 20.04.15

32

UNDERWATER

ADAPTER

PART # TKC 486

A ¾” I.D Hose is added

to the underwater

adapter to the length

required by your

operation and use.

STANDARD

SILENCER PART

# TKA 244

UNDERWATER OPERATION requires FLUSHING. This should be done

immediately after use – especially when in saltwater. FLUSH with

preservative such as Valvoline Tectyl 930 or equivalent.

The standard above ground silencer, Part # TKA 244 is removed

for underwater operation by removing 4 screws and replacing

the silencer with an underwater adapter kit, Part # TKC 486. (See

reference below).

THANK YOU FOR YOUR TIME IN READING THIS MANUAL

AND PLEASE REMEMBER SAFETY SHOULD BE YOUR HIGHEST

PRIORITY, SO PLEASE WEAR THE CORRECT SAFETY GEAR!

MANUFACTURER:

TIMBERKING AUSTRALIA PTY LTD

Tel. +61 2 9446 2631

www.timberkingaustralia.com.au

sales@timberkingaustralia.com.au

Loading...

Loading...