Tilton Yard Shark YSH2051Z, Yard Shark YSH2460Z, Yard Shark YSK2560Z, Yard Shark YSK2151Z Operator's Manual

Page 1

Operator’s Manual

Covers Models:

YSH2051Z, YSH2460Z

YSK2151Z, YSK2560Z

Your Authorized Yard Shark Dealer:

Congratulations on the purchase of

your new Yard Shark commercial mower!

Before operating the mower read and understand

this operator’s manual!

Part # YZ2007

Rev 2007-03-26

Page 2

Page 2

Page 3

Page 3

Proudly Distributed by:

Tilton Equipment Company

P.O. Box 68

Rye, New Hampshire 03870-0068

1 About This Manual..........................................................................................................................................6

2 Delivery Checklist............................................................................................................................................7

3 Safety Instructions...........................................................................................................................................8

3.1 Training .....................................................................................................................................................8

3.2 Preparation................................................................................................................................................8

3.3 Maintenance and Storage..........................................................................................................................9

3.4 Serial Number and Model Identification..................................................................................................10

4 Machine Operation........................................................................................................................................11

4.1 Filling The Fuel Tank ..............................................................................................................................11

4.2 Motion Control Levers.............................................................................................................................12

4.3 Parking Brake..........................................................................................................................................12

4.4 PTO Engagement Switch .........................................................................................................................13

4.5 Choke Control..........................................................................................................................................13

4.6 Throttle Control.......................................................................................................................................13

4.7 Ignition Switch.........................................................................................................................................13

4.8 Fuel Gauge / Hour Meter.........................................................................................................................13

4.9 Seat and Armrests....................................................................................................................................14

4.10 Setting Mower Deck Cutting Height........................................................................................................15

4.11 Cold Engine Starting Procedure.............................................................................................................. 16

4.12 Warm Engine Starting Procedure............................................................................................................16

4.13 PTO / Blades............................................................................................................................................16

4.14 Deck Deflector.........................................................................................................................................16

4.15 Stopping PTO...........................................................................................................................................16

4.16 Shutting Down Engine .............................................................................................................................16

5 Service and Maintenance Procedures..........................................................................................................17

5.1 Clean Dust and Dirt From Engine Clean Air Intake Screen & Cooling Fins – Check Daily..................18

5.2 Check Seat Safety Switch Operation – Check Daily ................................................................................18

Page 4

Page 4

5.3

Check Engine Oil Level – Check Daily....................................................................................................18

5.4 Check Mower Blades – Check Daily........................................................................................................18

5.5 Clean Underside of Deck – Check Daily .................................................................................................18

5.6 Air Filter Inspect / Clean.........................................................................................................................19

5.7 Engine Oil / Filter Change.......................................................................................................................19

5.8 Check Hydraulic Oil Level.......................................................................................................................19

5.9 Check Tire Pressure.................................................................................................................................19

5.10 Check / Adjust Deck Drive Belt Tension..................................................................................................20

5.11 Lubricate Control Levers........................................................................................................................21

5.12 Grease Deck Lift Pivots ...........................................................................................................................21

5.13 Grease Front Wheel Axle Bearings..........................................................................................................22

5.14 Check Pump Drive Belt............................................................................................................................22

5.15 Spark Plugs Check/Adjust/Replace..........................................................................................................23

5.16 Air Filter Replace ....................................................................................................................................23

5.17 Check / Adjust Valve Clearances.............................................................................................................23

5.18 Fuel Filter Change...................................................................................................................................23

5.19 Change Hydraulic Filter..........................................................................................................................23

5.20 Change Hydraulic Oil and Filter.............................................................................................................23

6 Service & Adjustments Perform as Needed.................................................................................................24

6.1 Adjusting Throttle Cable..........................................................................................................................24

6.2 Adjusting Choke Cable.............................................................................................................................25

6.3 Deck Adjustments.....................................................................................................................................25

6.4 Transmission Neutral Setting...................................................................................................................26

6.5 Deck Belt Replacement............................................................................................................................28

7 Fuel & Lubricant Recommendations...........................................................................................................28

7.1 Oxygenated Fuels.....................................................................................................................................28

7.2 Fuel Stabilizer / Conditioner....................................................................................................................29

7.3 Engine Oil Recommendation....................................................................................................................29

7.4 Hydraulic Oil Recommendation...............................................................................................................29

7.5 Engine Specifications...............................................................................................................................29

7.6 Hydrostatic System Specs.........................................................................................................................30

7.7 Fuel Tank Capacity............................................................................................................. .....................30

8 Service Record................................................................................................................................................31

Page 5

Page 5

9

Parts lists and drawings.................................................................................................................................33

9.1 Aftermarket Replacement Parts NOT SHOWN in Drawings...................................................................33

9.2 Decals ......................................................................................................................................................34

9.3 Wiring Assemblies....................................................................................................................................36

9.4 Rear Wheel and Wheel Motor Group.......................................................................................................37

9.5 51′′ Deck Group.......................................................................................................................................38

9.6 60′′ Deck Group.......................................................................................................................................40

9.7 Deck Spindle Hub Detail..........................................................................................................................41

9.8 Deck Deflector Detail ..............................................................................................................................42

9.9 Deck Lift Group .......................................................................................................................................43

9.10 Front Caster Group .................................................................................................................................44

9.11 Honda 20hp Engine & Pump Drive Group..............................................................................................45

9.12 Kaw 21,25 & Honda 24 Engine & Pump Drive Group ...........................................................................46

9.13 Seat Group...............................................................................................................................................47

9.14 Fuel Tank Group......................................................................................................................................48

9.15 Hydraulic Pump & Lines Group..............................................................................................................49

9.16 Control Lever Group................................................................................................................................50

9.17 Control Panel Group ...............................................................................................................................51

9.18 Frame Parts Group..................................................................................................................................52

Page 6

Page 6

Congratulations On The Purchase Of Your New Yard Shark Mower.

When you purchase a Yard Shark you are part of a family of satisfied customers – people who

appreciate a mower that will provide you with years of excellent performance, durability, and

trouble free service when operated and maintained as directed in this manual.

Read and understand this operator’s and parts manual and follow all instructions and warnings

before operating this machine.

If you did not sign and receive your copy of your warranty registration, contact your Yard Shark

dealer to do so immediately! Before any warranty service can be authorized you must register this

product with Tilton Equipment Company.

1 About This Manual

This Yard Shark operator’s manual is considered a permanent part of the mower. It must be

available to all operator’s and/or person(s) servicing the mower. Should the mower be resold , this

manual must remain with the mower.

Should you ever have any questions regarding the operation, maintenance, or safety of your

mower, please contact your authorized Yard Shark mower dealer who h as been trained on

operation and service of this mower.

All information, illustrations, and specifications contained in this manual were in effect at the time

of publication. The manufacturer reserves the right to change, modify, and/or discontinue

specifications and/or design without notice. If you notice that a change has been made to your

mower which is not shown or reflected in this manual, please see your authorized Yard Shark

mower dealer before operating or servicing the mower.

This manual identifies potential hazards and has safety messages identified by the safety alert

example symbols shown below, which signal a hazard that may cause serious injury or death if

you do not follow the recommended precautions.

DANGER

WARNING

CAUTION

Failure to follow instructions WILL

result in SERIOUS INJURY or DEATH!

Failure to follow instructions CAN result

in SERIOUS INJURY or DEATH!

Failure to follow instructions can result

in personal injury.

Page 7

Page 7

2 Delivery Checklist

Before you, the owner or primary operator uses this machine, go through this check list so that you

understand the safe and proper operating procedures for your new Yard Shark machine.

________ Read and understand this operator’s manual before ope rating your Yard Shark mower.

________ Understand the “Safety Instructions” section of manual.

________ Record engine and mower serial numbers in space provided.

________ Checking Engine Oil

________ Checking Hydro Oil

________ Filling Fuel Tank

________ Seat and Armrest Adjustments

________ Motion Control Levers and Parking Brake Operation

________ Engine Controls – Throttle/Choke/Ignition Switch

________ Fuel Gauge / Hour Meter

________ Setting Deck Height

________ Cold Engine Start Procedure

________ Warm Engine Start Procedure

________ Deck Deflector

________ PTO / Starting and Stopping Blades

________ Shutting Down Engine

________ Fill Out the Warranty Registration Form through your Yard Shark Dealer.

Page 8

Page 8

3 Safety Instructions

3.1 Training

WARNING

o Read the operator’s manual and other training material. If the operator(s) or mechanic(s)

cannot read English it is the owner’s responsibility to explain this material to them.

o Become familiar with the safe operation of the equipment, operator controls, and

safety signs.

o All operators and mechanics should be trained. The owner is responsible for training

the users.

o NEVER let children or untrained people operate or service the equipment.

Local regulations may restrict the age of the operator.

o The owner/user can prevent and is responsible for accidents or injuries occurring to

themselves, other people or property.

3.2 Preparation

WARNING

o ALWAYS evaluate the terrain to determine what accessories and attachments are needed

to properly and safely perform the job. Only use accessories and attachments approved by

the manufacturer.

o ALWAYS wear appropriate clothing including safety glasses an d hearing protection.

o ALWAYS inspect the area where the equipment is to be used and remove all objects such

as rocks, toys and wire which can be thrown by the machine

o ALWAYS use extra care when handling gasoline and other fuels. They are flam mable and

vapors are explosive.

o ALWAYS use only an approved safety fuel container.

o ALWAYS check that operator’s presence controls, safety switches and shields are

attached and functioning properly.

o ALWAYS be sure all drives are in neutral and parking brake is engaged before starting

engine. Only start engine from the operator’s position.

o ALWAYS slow down and use extra care on hillsides. Be sure to travel in a safe direction

on hillsides. Turf conditions can affect the machine’s stability. Use caution while operating

near drop-offs.

o ALWAYS turn uphill when changing directions while mowing left to right and right to left

on hill sides.

o ALWAYS use care when approaching blind corners, shrubs, trees, or other objects that

may obscure vision.

o ALWAYS stop on level ground, lower implements, disengage drives, engage parking

brake, shut off engine before leaving the operator’s position for any reason including

emptying the catchers or unclogging the chute.

o ALWAYS stop equipment, shut off the engine, set parking brakes and inspect blades after

striking objects or if an abnormal vibration occurs. Make necessary sharpening repairs o r

replace all blades before resuming operations.

o ALWAYS keep hands and feet away from the cutting units.

Failure to follow instructions CAN result

in SERIOUS INJURY or DEATH!

Failure to follow instructions CAN result

in SERIOUS INJURY or DEATH!

Page 9

Page 9

o ALWAYS look behind and down before backing up to be sure of a clear path.

o ALWAYS be aware of the mower discharge direction and do not point it at anyone.

o ALWAYS slow down and use caution when making turn s and crossing roads

and sidewalks.

o ALWAYS stop blades if not mowing.

o ALWAYS use care when loading or unloading the machine into a trailer or tru ck.

o ALWAYS operate in good light, keeping away from holes and hidden hazards.

o NEVER operate with long hair, loose clothing or jewelry that may get tangled in

moving parts.

o NEVER remove gas cap or add fuel when engine is running.

o NEVER smoke while fueling the machine or near any fuels or fuel fumes.

o NEVER refuel or drain the machine indoors.

o NEVER raise deck with the blades running.

o NEVER operate with guards not securely in place.

o NEVER operate with the discharge deflector raised, removed or altered, unless using

a grass catcher.

o NEVER run an engine in an enclosed area.

o NEVER change the engine governor setting or over speed the engine.

o NEVER carry passengers and keep pets and bystanders clear of the work area.

o NEVER operate the mower under the influence of alcohol or drugs.

3.3 Maintenance and Storage

o Disengage drives, lower implement, set parking brakes, stop engine, remove key and

disconnect spark plug wires. Wait for all movement to stop before adjusting, cleaning

or repairing.

o Clean grass and debris from cutting units, drives, mufflers, and engine to help

prevent fires. Clean up oil or fuel spillage.

o Let engine cool before storing and do not store near flame.

o Do not store fuel near flames or drain indoors.

o Park machine on level ground. Never allow untrained personnel to service machine.

o Use jack stands to support components when required.

o Carefully release pressure from components with stored energy

(example, hydraulic components).

o Disconnect battery and remove spark plug wires before making any repairs. Disconnect

the negative terminal first and the positive last. Reconnect positive first and negative last.

o Use care when checking blades. Wrap the blade with a heavy rag or towel or wear gloves,

and use caution when servicing them. If blades are bent or damaged, replace all of the

blades. Never straighten or weld them.

o Keep hands and feet away from moving parts. Do not make adjustments with the

engine running.

o Charge batteries in an open well ventilated area, away from spark and flames.

o Charge battery with a 2 amp charger and disconnect the battery ground cable before

storing the machine for 30 days or more. Improper battery care will void battery warranty.

o Unplug charger before connecting or disconnecting from battery. Wear protective clothing

and use insulated tools.

o Keep all parts in good working condition and all hardware tightened. Replace all worn or

damaged decals.

Page 10

Page 10

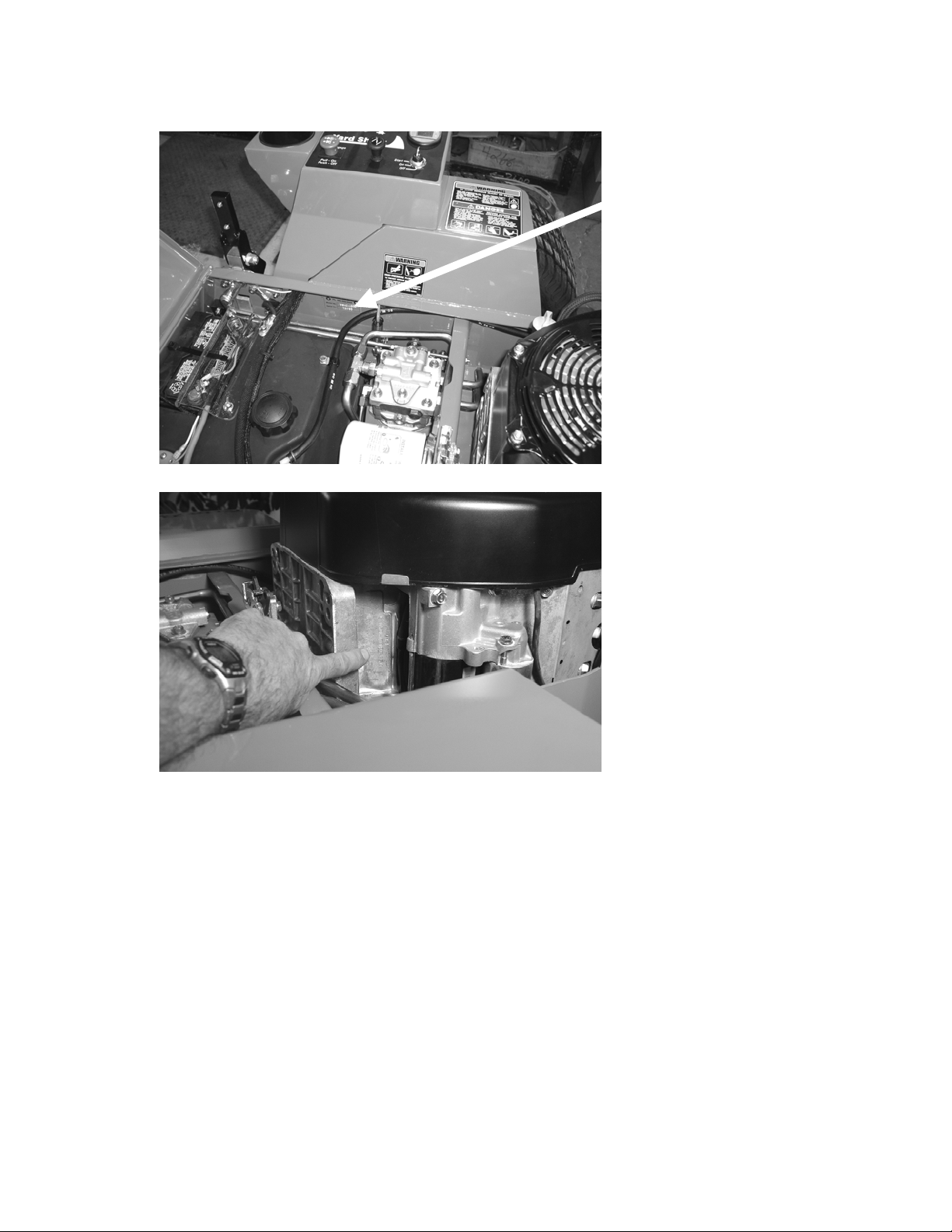

3.4 Serial Number and Model Identification

The serial number/model number tag can be found at the RH side of the mower under the seat in

front of the engine compartment.

The engine serial number can be found on the Front LH side of the engine as shown below.

Record serial numbers here for future reference.

Mower Model Number____________________________

Mower Serial Number____________________________

Engine Serial Number____________________________

Page 11

Page 11

4 Machine Operation

Left Side of machine is determined by sitting in the seat in the operating position.

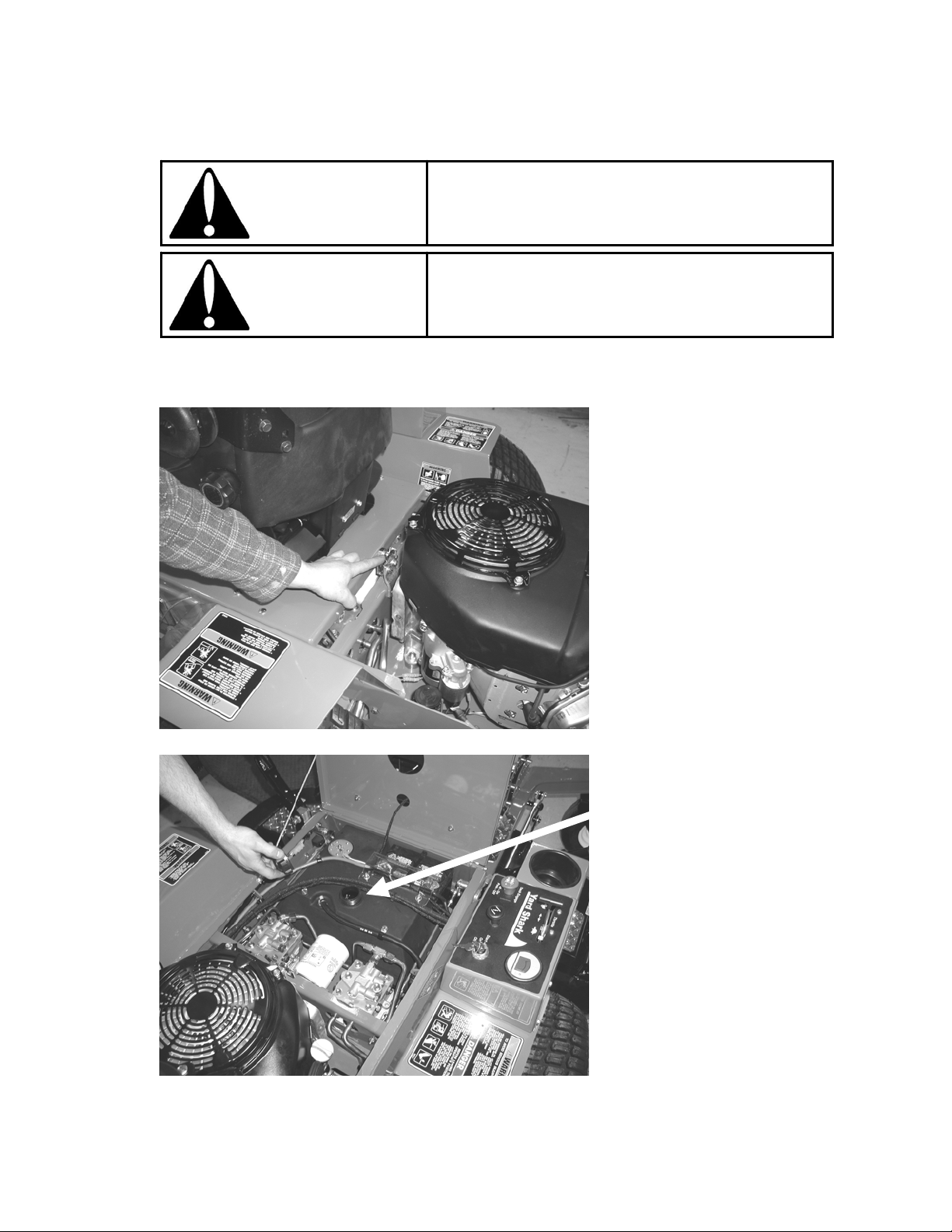

4.1 Filling The Fuel Tank

WARNING

WARNING

o Fill fuel tank outside in a well ventilated area

o Shut the engine off and set parking brakes.

o Allow engine to cool to ambient temperatures.

Gasoline is extremely flammable and gasoline vapor can

explode. Failure to follow proper procedures can result in

personal injury or death.

Do not add fuel while the engine is running or hot. Keep

open flames, sparks and heat away from fuels and store

fuel in

containers specifically designed for that purpose.

o Unlatch seat and tip forward to access the fuel tank.

o Use a funnel and be careful to not spill fuel.

o Wipe up possible fuel spills and allow to completely dry before re-starting engine

Page 12

Page 12

4.2 Motion Control Levers

Motion Control Levers in Operating Position

Motion control levers are in the operating position when they are as shown above. Left hand lever

controls the speed and direction of the LH drive wheel. Right hand lever controls the speed and

direction of the RH drive wheel.

Moving both levers forward together causes mower to travel forward in a straight line.

Moving both levers rearward together causes the mower to travel in reverse in a straight line.

To turn left while moving forward, pull back slightly on the LH lever. To turn right while moving

forward, pull back slightly on the RH lever.

To make a zero radius turn, move one lever slightly ahead of neutral and the other lever slightly

behind neutral center position.

4.3 Parking Brake

The parking brake system on the Yard Shark mower is not really a brake, but is actually a pin and

cog system that is activated every time the control levers are moved out into the neutral locked

position as shown below. It is an automatic system that sets itself when you move the levers out to

get off the mower and releases itself when you move the levers back in to start moving. If the

mower will not move or sounds like it is straining, simply move the control levers slightly forward or

backwards to release the pin.

Motion Control Levers in Non-Operating Position – Parking Brakes On

Page 13

Page 13

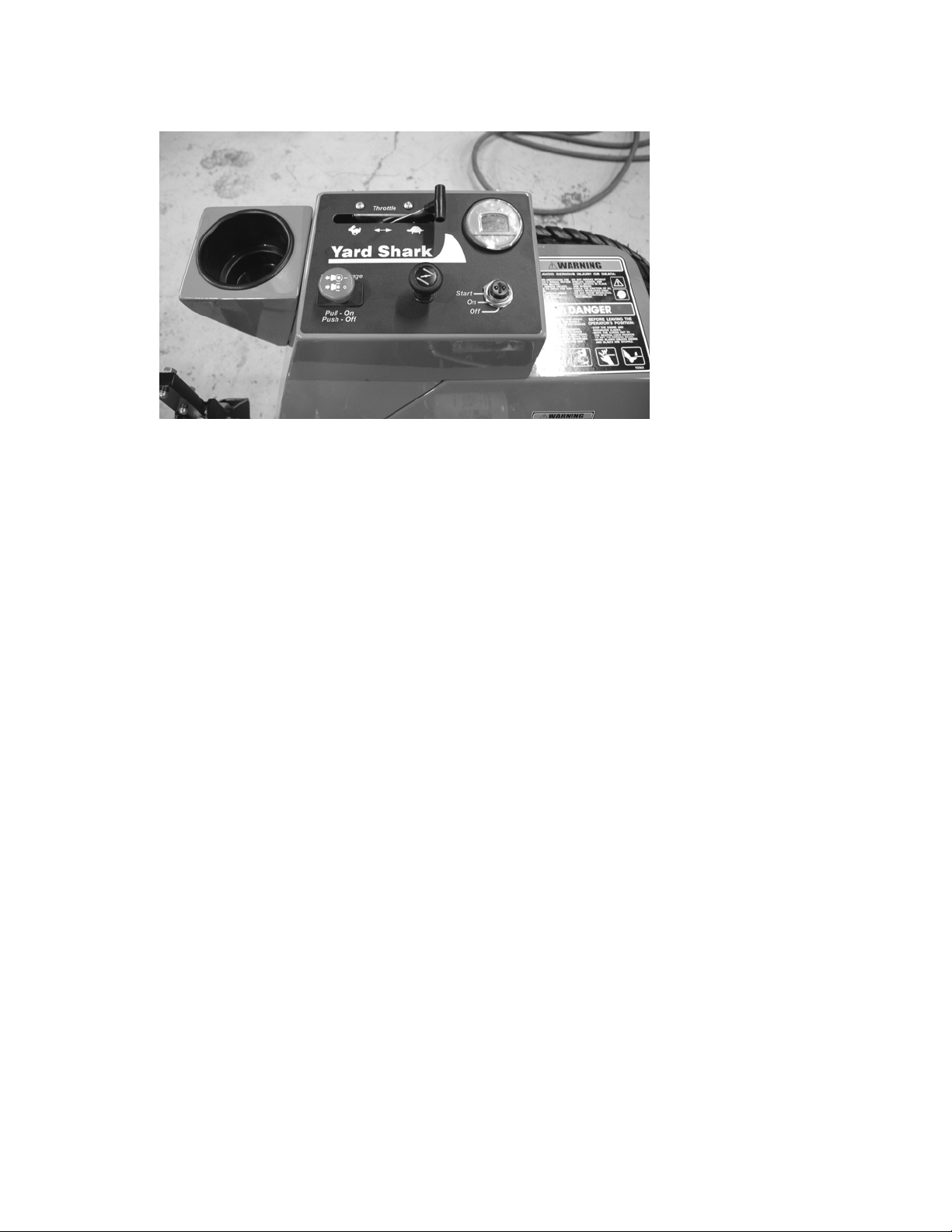

4.4 PTO Engagement Switch

Located on RH control panel. Switch is pulled UP (“ON” position) to engage the blades.

Switch must be in the DOWN or OFF position in order to start the engine.

4.5 Choke Control

Pull choke knob UP or OUT to the choke “ON” position.

Push choke knob DOWN or IN the choke “OFF” position.

4.6 Throttle Control

Move lever forward to increase engine speed.

Move lever to the rear to idle position.

When mowing the throttle should be in the full forward (fastest) position.

4.7 Ignition Switch

Three (3) position switch. The first position is OFF, second position is ON or RUN. The third

position is the start position.

4.8 Fuel Gauge / Hour Meter

Digital display indicates amount of fuel remaining. When red light flashes, unit is very low on fuel

and should be refueled.

Refer to all items in filling the tank (Section 4.1).

The hour meter records time the key is on. Use hour meter to reco rd service intervals.

Page 14

Page 14

4.9 Seat and Armrests

There are two adjustments at the front of the seat.

The knob controls the stiffness of the suspension seat. This should be adjusted to fit the

operator weight.

The lever, shown above left with an arrow, allows for fore and aft adjustment. While seated, pull

lever to the left to release seat and move seat into desired position. Make sure the latch is fully

locked so that seat is secure.

The armrest height can be adjusted with the small knobs, above right, screw out to raise armrests.

Setting the armrests at the proper height will assist you in maintaining better control of

the machine.

The other settings are located on either side of the seat backrest. The knob on the RH side adj usts

the angle of the backrest. The knob on the LH side adjusts the lumbar support. Adjust these for

your personal preference.

Page 15

Page 15

4.10 Setting Mower Deck Cutting Height

While seated on the seat, push on foot lever to raise deck. The deck can now be locked in the

upper position by using the deck latch lever located on the LH side of the mower (shown below).

Move the lever to the rear to engage the deck lock. Remove pin and move to the desired position.

The decal next to the foot lever indicates the cutting height. Moving the pin one hole adjusts the

cutting height by 1/4′′.

To release deck lock, push forward on the deck latch lever while pushing forward with the

foot pedal.

Page 16

Page 16

4.11 Cold Engine Starting Procedure

o Be sure engine has oil to the proper level and gas in the fuel tank.

o Pull up on Choke to “ON”.

o Move throttle control about 1/3 of the way forward.

o Turn key to “START” position and hold until engine starts.

o If engine fails to start within 5 seconds, release the key, wait at least 10 seconds.

o Note: Using the starter for more than 5 seconds at a time can overheat and damage

the starter.

o Gradually push choke knob in as engine warms up.

4.12 Warm Engine Starting Procedure

Same as above but leave choke in the “OFF” position.

4.13 PTO / Blades

DANGER

The PTO switch engages the cutting blades. Be certain everyone including pets are clear of the

mower deck and the RH discharge area before engaging the PTO.

Operator must be seated before the PTO can be engaged. The motor will kill if the seat switch is

not depressed.

Move throttle to halfway position. Pull up on PTO switch to the “ON” position. Then move throttle to

full forward “FAST” position.

4.14 Deck Deflector

DANGER

Deck is equipped with a rubber deck discharge deflector.

Deflector can be pivoted upwards for clearance, for storing or transporting.

NEVER mow with the deflector in the UP position unless using an approved grass

catcher/collector.

Operating PTO creates a thrown object hazard. NEVER

operate with deflector or guards missing. Make sure

discharge chute is not pointed toward pets or bystanders.

Operating PTO creates a thrown object hazard. NEVER

operate with deflector or guards missing. Make sure

discharge chute is not pointed toward pets or bystanders.

4.15 Stopping PTO

In an emergency, deck blades can be stopped anytime by pushing down on the PTO switch, also

by turning the ignition key switch to “OFF”.

Normal operation - move throttle to halfway position. Push down on PTO switch to “OFF” position.

4.16 Shutting Down Engine

In an emergency simply turn the ignition key switch to “OFF”.

For normal shutdown, stop machine, turn off PTO, move throttle all the way to SLOW. Turn ignition

key switch to OFF.

Page 17

Page 17

5 Service and Maintenance Procedures

Service and Maintenance

Procedures

Clean Dust and Dirt From Engine

Clean Air Intake Screen and

Cooling Fins

Check Seat Switch Interlock X

Check Engine Oil Level X

Check Mower Blades X

Clean Underside of Deck X

Air Filter Inspect/Clean X

Engine Oil / Filter Change X X

Check Hydraulic Oil Level X X

Check Tire Pressure X X

Check/Adjust Deck Belt Tension X X

Lubricate Control Levers X

Grease Deck Lift Pivots X

Grease Front Wheel Bearings X

Check Pump Drive Belt X

Spark Plugs Check / Adjust X

Clean Oil Cooler Fins X

Air Filter Replace (Both) X

Spark Plugs / Replace X

Valve Clearance X

Fuel Filter / Change X

Change Hydraulic Filter X X

Change Hydraulic Oil & Filter X

X

Daily

After First

10 Hours

Every 25

Hours

Every 50

Hours

Every100

Hours

Every 300

Hours

Page 18

Page 18

5.1 Clean Dust and Dirt From Engine Clean Air Intake Screen & Cooling Fins – Check Daily

Check for accumulations of dust, grass clippings, dirt, etc. Check around the fresh air intake

screen on top of the engine. Also check cooling fins on engine and oil coolers and clean with

compressed air. Be careful on the Honda 24 so the cooling fins on the separate oil cooler are not

damaged. Remove excess accumulations around the base of the engine, under the se at, around

hydro pumps and the top of the deck. Keeping the machine clean will guarantee a cooler and safer

operating environment.

5.2 Check Seat Safety Switch Operation – Check Daily

WARNING

o When raised off the seat, turn key switch to start.

o Engine should not crank.

o If engine cranks, contact your dealer to resolve this problem before using mower.

o While seated on mower, start engine, then engage PTO.

o With the control levers moved outward to the locked/parking brake position, raise yourself

off the seat.

o Engine should shut off immediately.

o If engine does not shut off, contact your dealer to resolve this problem before

using mower.

5.3 Check Engine Oil Level – Check Daily

At rear right of mower, unscrew dipstick. Wipe clean. Then, reinsert without screwing it in. Add

oil, if needed to bring up to the full mark.

Safety interlock is designed to prevent PTO/blades

operating unless operator is seated. Failure to maintain

proper operation of system can result in injury or death.

5.4 Check Mower Blades – Check Daily

Raise front of mower and check condition of mower blades.

If blades are not sharp they must be sharpened or replaced.

If blades are bent or damaged replace all of the deck blades. Don’t attempt to straighten bent

blades. It is dangerous to straighten because it could cause the blades to crack/break in operation.

5.5 Clean Underside of Deck – Check Daily

While checking conditions of blades, scrape out any accumulated grass clipping from under the

mower deck. Mower performance will deteriorate if blades are not in good condition and grass

builds up under deck.

Page 19

Page 19

5.6 Air Filter Inspect / Clean

Follow instructions in the respective Honda or Kawasaki owner’s manual for details.

5.7 Engine Oil / Filter Change

o Drain used oil while the engine is warm. Warm oil drains quickly and more completely.

Replace oil filter at each oil change.

o Place a suitable container under the engine to catch used oil.

o Remove the oil filler cap / dipstick, drain plug and oil filter. Allow used oil to

drain completely.

o Reinstall drain bolt and tighten securely.

o Clean the filter mounting base and coat the rubber seal on the new filter with new

engine oil.

o Screw on the new filter by hand until seal contacts filter base, then tighten another

3/4 - 7/8 turn, alternatively tighten to 16 lbf-ft (22Nm).

o Refill crankcase with new oil (See engine operator’s manual for proper oil selection).

o Start engine and check for leaks. Stop engine then check oil level. Add oil if needed to

bring oil to top of safe mark.

o Dispose of used oil and filter at local recycling center and obey all local and federal laws

for these products.

5.8 Check Hydraulic Oil Level

o Be extremely careful with dirt and contamination when you are servicing the

hydrostatic system.

o Contamination is the worst enemy of the hydrostatic system.

o Clean around dipstick and filters BEFORE removing.

o Only add oil from a sealed container.

o Thoroughly clean funnels and anything that will come into contact with the oil.

o Contamination in the system will void the warranty on the hydrostatic system.

o Check level when oil is cold.

o Unscrew dipstick and wipe clean. Insert into oil tank without screwing it in. If oil shows

on the dipstick (approximately 1/4″-1/2″ up from the bottom), then the oil level is adequate.

If no oil shows on dipstick, then add oil to bring up to the dipstick. The upper mark is a high

level mark for when the oil is hot. If oil tank is overfilled, oil will expand and come out of the

dipstick / vent when the oil gets hot.

o See Section 7.4 for proper oil recommendation.

5.9 Check Tire Pressure

Inflate all 4 tires to 12 psi. A special low pressure air gauge (available at most auto parts stores)

should be used to accurately check the pressure.

Page 20

Page 20

5.10 Check / Adjust Deck Drive Belt Tension

o Spring for deck belt tension can be found by looking under the RH side of the mower.

To check belt tension, measure the length of the spring. The body of the spring should

measure 3-1/2′′ to 3-3/4′′.

o An alternative method is to use a U.S quarter, to use as a feeler gauge between the coils.

Spring tension is correct when quarter will just fit between coils with minimal resistance.

If belt tension needs adjusting remove hair pin and unhook the deck belt tension arm from its stud

at the front of the deck (photo above).There are 2 holes for the arm to hook into. Use the front hole

for normal operation. If belt becomes stretched enough that you can’t get the proper tension then

use the second hole.

Page 21

Page 21

Go to left side of mower. Loosen the flat idler pulley (use a 9/16′′ wrench) and move slightly to the

rear. Retighten pulley, rehook spring tension arm and recheck spring length. Adjust until body of

spring measures 3-1/2′′ to 3-3/4′′ or a quarter fits snugly between the coils.

5.11 Lubricate Control Levers

o Raise seat. Use a grease gun with multipurpose grease.

o Grease zerks at the control arm pivots (2).

o Use a light “dry lube” type spray lubricant (use a dry lube containing Teflon or “moly” )to

lube the brake linkage and the control arms.

o Lubricate the pivot for the park lock position, where the side plates of the handle mount to

the control arm block.

o Applying a small amount of multipurpose grease to the tab that actuates the parking lock

will make the entire park lock system work more smoothly.

o Use (2) 3/4′′ wrenches to adjust the amount of tension on control lever arm mounts so the

levers have the proper amount of resistance. (This is a personal preference on how stiff to

make the arms to move back and forth from the locked position to the travel position).

5.12 Grease Deck Lift Pivots

Use a grease gun with multipurpose grease. Grease zerks at the rear deck lift pivots (2).

Page 22

Page 22

5.13 Grease Front Wheel Axle Bearings

Use a grease gun with multipurpose grease. Grease the zerks on e ach the front wheels. One zerk

per wheel.

5.14 Check Pump Drive Belt

Raise rear of mower to access pump drive belt. Use blocks as necessary to support mower safely.

Pump belt idler arm should be free to move with firm hand force. If arm is sticky or stiff, remove

arm and coat the mounting surfaces with anti-seize lubricate. Reassemble and adjust tension at

pivot bolt. Proper tension can be achieved by tightening ½′′ nut on pivot bolt until spring washers

are compressed, then back off ¼ turn. Arm should be free to move with firm hand force. Install the

lock nut and tighten making sure that the adjustment is not changed.

Measure length of the spring – Proper length is 4-1/4′′ inside spring hooks, OR length of coils

should measure 3-1/4′′.

Another method to check tension – A quarter ($.25 US coin) should just fit in between the coils in

the spring.

Adjust position of idler to achieve proper belt tension. Use (2) 9/16′′ wrenches to move the idler in

its adjustment slot.

Page 23

Page 23

5.15 Spark Plugs Check/Adjust/Replace

Disconnect spark plug caps.

Remove dirt from around spark plug areas.

Remove the spark plugs with a 13/16 spark plug wrench.

Replace plugs if the electrodes are worn or if insulator is cracked or chi pped.

Regap spark plugs to .030′′ (.75 mm).

Reinstall plugs by hand, be careful to avoid cross threading.

To reinstall used plugs, tighten 1/8-1/4 turn after the spark plug seats lightly.

To install new spark plugs, remove old plugs and gap new plugs.

Thread new spark plugs into engine by hand, then use a 13/16′′ spark plug wrench and tighten

1/2 turn after the spark plug seats. (or tighten to 16 ft lb.)

5.16 Air Filter Replace

Each year or 300 hours replace primary (paper) air filter elements. Follow instructions in resp ective

engine owner’s manual. Secondary filter should be replaced according to engin e owner’s manual.

5.17 Check / Adjust Valve Clearances

Both Kawasaki and Honda recommend valve clearance be checked every year or 300 hours.

This should be performed by your servicing dealer unless you have the proper t ools and are

mechanically adept. Refer to Honda or Kawasaki shop manual for procedure s.

5.18 Fuel Filter Change

Replace every year or 300 hrs, replace sooner if it becomes clogged.

Consult engine owner’s manual for instructions.

5.19 Change Hydraulic Filter

o Place a pan under the hydrostatic oil filter, unscrew oil filter enough so the oil can drain

into the oil pan. It is possible to get a little oil on the drive belt at this point. It is

recommended to place a small shield over the belt to prevent it from coming into contact

with the oil.

o Allow oil to drain completely

o Apply a thin film of clean oil to oil filter seal.

o Screw filter on by hand until seal contacts base, then tighten an additional 3/4 turn.

o Add proper oil to bring up to proper level – See section 5.8 in this manual.

o See Section 7.4 for proper oil recommendation.

o Dispose of used oil and filter at local recycling center and obey all local and federal laws

for these products.

5.20 Change Hydraulic Oil and Filter

o Be extremely careful with dirt and contamination when you are servicing the

hydrostatic system.

o Contamination is the worst enemy of the hydrostatic system.

o Clean around dipstick and filter BEFORE removing.

o Only add oil from a sealed container.

o Thoroughly clean funnels and anything that will come into contact with the oil.

o Contamination in the system will void the warranty on the hydrostatic system.

o Place a pan under the oil tank, remove magnetic oil plug and drain the oil.

Page 24

Page 24

o Place a pan under the hydrostatic oil filter, unscrew oil filter enough so the oil can drain

into the oil pan. It is possible to get a little oil on the drive belt at this point. It is

recommended to place a small shield over the belt to prevent it from coming into contact

with the oil.

o Allow oil to drain completely

o Thoroughly clean the drain plug and replace.

o Apply a thin film of clean oil to oil filter seal.

o Screw filter on by hand until seal contacts base, then tighten an additional 3/4 turn.

o Add oil to hydraulic reservoir until oil shows on the dipstick, approximately 7 quarts.

o See Section 7.4 for proper oil recommendation.

o To prime system – raise the rear of mower so that the rear wheels can spin freely.

o Secure machine with jack stands.

o Start engine and run at idle.

o Immediately push both levers full forward and hold for 10 seconds. Then pull both levers

fully rearward and hold for ten seconds. Repeat this procedures several times until all air is

purged from the system.

o Lower mower to the ground and check oil level. The oil level should be approximately 1/2′′

on the dipstick without the cap screwed in. Add oil to bring to proper level.

o Screw dipstick / cap onto hydraulic reservoir.

o Dispose of used oil and filter at local recycling center and obey all local and federal laws

for these products.

6 Service & Adjustments Perform as Needed

6.1 Adjusting Throttle Cable

o If the throttle cable is not properly adjusted, the engine may not be operating at full speed

or the throttle may not stay in the fast position.

o Procedure should be done on a cold engine to prevent any chance of burns from the

hot engine.

o Shut down mower, set parking brakes and remove the key.

o Move throttle lever full forward until it reaches its limiting stop and then back off about

1/8′′ - 1/4′′.

o Go to rear of mower. Throttle linkage should be fully opened (fast position).

o Loosen the clamp on the throttle cable and pull cable tight so the throttle is fully open.

o Retighten clamp.

o If throttle doesn’t hold its position while mowing, then the friction discs on the throttle lever

need to be tightened.

o Remove the cover on the control panel. Use a 7/16′′ combination wrench and a 7/16′′

socket to adjust the tension on the throttle pivot.

o Adjust pinch bolt so that it is tight enough to hold throttle in position.

Page 25

Page 25

6.2 Adjusting Choke Cable

If choke cable is not properly adjusted, it is possible that either the choke won’t fully close or fully

open. This will cause either hard starting, rough running or poo r fuel economy.

When the choke control is pushed all the way in (off), the knob should not contact the base of the

choke mounting. There should be about a 1/8′′ - 1/4′′ gap as shown below.

If adjustment is needed, go to back of mower. Loosen the clamp holding the choke cable.

Now position choke knob 1/4′′ up. Go to rear of mower and gently push choke cable to the right

(opens choke) and tighten screw on cable when the choke is fully opened.

6.3 Deck Adjustments

To level the cutting deck, proceed as follows. Set mower deck at 3″ cutting height.

Measure from top of frame rail to top of deck as shown below.

Page 26

Page 26

The front left and front right measurements should be within 1/16′′ of each other. If adjustment is

needed at the front, adjust the front rockshaft hangers (as shown below).

The hangers at the front rockshaft (shown above) provide vertical adjustment. Normally these

hangers are adjusted all the way UP. If one side of the deck is higher that the other, loosen the

bolts at the higher side of the deck and move hanger slightly lower so that equal measurement is

achieved at both sides. When equal measurements are achieved, proceed with the rear

adjustment.

Measure from the top rear of the frame rail to the deck top on both sides of the machine (as

shown above). These measurements should be within 1/16” of each other and should also be

1-3/4″ – 1-7/8″ less than the measurement at the front of the deck to the top of the rail. This will

make the rear of the blades cut slightly higher than the front of the blades.

If adjustment is needed, remove cotter pin and clevis pin at the front of the lift linkage rods.

Shorten or lengthen linkage rod to achieve the proper height.

When adjustment is complete, all 4 carrier links should have equal pressure on them.

6.4 Transmission Neutral Setting

If mower creeps when levers are in the neutral position (not the locked position) then the neutral

position needs to be adjusted. Do the adjustments in this order only.

o Raise rear of mower slightly off the ground so the rear wheels can turn freely.

o Secure machine with jack stands.

o Control levers should be in the operating position (handles together).

o With engine at a fast idle, wheels should not be turning.

Page 27

Page 27

o Proceed with adjustment as follows.

o Adjust centering on pumps first. To adjust pump neutral – use a 17mm open end wrench

and an 8mm open end wrench.

o Use the 17mm wrench to loosen the locknut (loosen just enough to turn eccentric with the

8mm wrench). Turn eccentric back and forth to see which way it needs to be adjusted.

Adjust so wheel stops turning. When wheel stops turning move the lever forward and

backward and let return to neutral. If necessary, readjust until neutral is achieved then

retighten locknut with the 17mm wrench.

Picture above shows location of adjustments.

o Shut down engine and lower mower to the ground.

o When the pumps’ neutral positions have been readjusted, the linkage rods will have to be

adjusted, also.

o With engine off, and control handles in the operating position, check linkage adjustment.

As you move the levers into the parking lock position the tab at the lower end of the control

levers should enter the square hole perfectly centered. Neither side of the tab should

touch the sides as the lever is moved into its locked position. The locations are shown in

the figures below.

Page 28

Page 28

Loosen 5/16′′ locknuts on the linkage rod. Keep in mind that the nuts at the rear of the rods are left

hand thread and the nuts at the front are right hand thread. Turn linkage rod to lengthen or shorten

as needed so correct alignment is achieved.

Retighten locknuts, then recheck alignment. Readjust or fine tune as nece ssary.

6.5 Deck Belt Replacement

Lower deck to its lowest position.

At front of mower deck, remove hairpin clip and lift spring tensioning arm off of its stud.

Flip up the deck pulley covers with the step plates on them on the LH and RH sides of the deck.

Covers can be locked in an open position by opening up 90 degrees and inserting a pin, bolt or

screwdriver in the hole.

Belt can now be removed.

Replace worn belt with the new belt.

Reattach the spring tensioning arm onto its stud, replace hairpin clip.

Follow directions in previous section to adjust to proper tension.

Recheck tension after first few hours as it is normal to have to adjust the belt tension until the belt

becomes “broken in”; see belt tensioning in Section 5.10.

7 Fuel & Lubricant Recommendations

WARNING

Use unleaded gasoline with a pump octane rating of 89 or higher.

These engines are designed to run on unleaded gasoline. Unleade d gas produces fewer engine

and spark plug deposits and extends exhaust system life.

Never use old or stale gasoline or an oil/gas mixture. Avoid getting dirt or water in the tank.

Gasoline is extremely flammable and gasoline vapor

can explode. Failure to follow proper procedures can

result in personal injury or death.

7.1 Oxygenated Fuels

To meet clean air standards, some area of the United States and Canada use oxygenated fuels to

reduce emissions. If you use an oxygenated fuel, be sure it is unleaded and meets the minimum

octane rating of 89.

Ethanol – (ethyl or grain alcohol) 10% by volume. You may use gasoline containing up to 10%

ethanol by volume. Ethanol blends may be marketed under the name “Gasohol”.

Page 29

Page 29

If you notice any undesirable operating symptoms, try another source of gasoline.

Fuel system damage or performance problems resulting from the use of an oxygenated fuel

containing more than the percentages of oxygenates listed above are not covered under warranty.

7.2 Fuel Stabilizer / Conditioner

Use a fuel stabilizer / conditioner to keep gasoline fresh if mower is to be stored longer than 30

days. Fuel stabilizers are most effective when mixed with fresh fuel. Fuel stabilizers will NOT make

old gasoline fresh.

7.3 Engine Oil Recommendation

See engine owner’s manual for proper oil recommendations for the engine on your mo wer.

7.4 Hydraulic Oil Recommendation

We recommend the use of a Universal Tractor Hydraulic Oil.

Viscosity – 60 SUS (10cSt) at no more than 212deg F (100 deg C)

Some acceptable choices are as follows:

o John Deere: J20A, JD20C, Hy-Gard

o Case-IH: Hy-Tran, Hy-Tran Plus, Hy-Tran Ultra

o AGCO: Power Fluid 821, 821XL

o Cenex: Qwiklift HTB, Maxtron THF+

7.5 Engine Specifications

7.5.1 Model YSH2051Z – Honda 20 hp w/ 51′′ Deck

o Make / Model Honda GXV-620

o Engine Type 4-stroke, Overhead Valve, 2 cylinder, 90° V-Twin

o Displacement 37.5 in³ (614 cm³)

o Bore x Stroke 3.03′′ x 2.60′′ (77mm x 66mm)

o Maximum Output 20 bhp (14.9kW) at 3600 rpm

o Maximum Torque 32.5 lbf-ft (44.13 N-m) at 2500 rpm

o Cooling System Forced Air

o Ignition System Transistorized Magneto

o Spark Plug Gap 0.028′′ – 0.031′′ (0.70 mm – 0.80 mm)

o Spark Plug Denso - J16CR-U

o Engine Oil Cap. 2.3 US quarts w/ oil filter change, 1.8 qts. w/o filter change

o Engine Speeds Idle 1,400 ±150 rpm; Fast 3,600 rpm.

7.5.2 Model YSH2460Z – Honda 24 hp w/ 60′′ Deck

o Make / Model Honda GXV-670

o Engine Type 4-stroke, Overhead Valve, 2 cylinder, 90° V-Twin

o Displacement 40.9 in³ (670 cm³)

o Bore x Stroke 3.03′′ x 2.83′′ (77mm x 72mm)

o Maximum Output 24 bhp (17.9kW) at 3600 rpm

o Maximum Torque 37.5 lbf-ft (50.8 N-m) at 2500 rpm

o Cooling System Forced Air

o Ignition System Transistorized Magneto

o Spark Plug Gap 0.028′′ – 0.031′′ (0.70 mm – 0.80 mm)

o Spark Plug Denso - J16CR-U

o Engine Oil Cap. 2.6 US quarts with oil filter change, 2.1 qts w/o filter change

o Engine Speeds Idle 1,400 ±150 rpm; Fast 3,600 rpm.

Page 30

Page 30

7.5.3 Model YSK2151Z – Kawasaki 21 hp w/ 51′′ Deck

o Make / Model Kawasaki FH641V

o Engine Type 4-stroke, Overhead Valve, 2 cylinder, 90° V-Twin

o Displacement 41.19 in³ (675 cm³)

o Bore x Stroke 2.96′′ x 2.99′′ (75.2mm x 76mm)

o Maximum Output 21 bhp (15.7 kW) at 3600 rpm

o Maximum Torque 38.4 lbf-ft (52.1 N-m) at 2400 rpm

o Cooling System Forced Air

o Ignition System Solid State Ignition

o Spark Plug Gap 0.030′′ (0.75 mm)

o Spark Plug Denso W16EPR-U

o Engine Oil Cap. 1.8 US quarts with oil filter change, 1.6 qts w/o filter change

o Engine Speeds Idle 1,550 rpm; Fast 3,600 rpm.

7.5.4 Model YSK2560Z – Kawasaki 25 hp w/ 60′′ Deck

o Make / Model Kawasaki FH721V

o Engine Type 4-stroke, Overhead Valve, 2 cylinder, 90° V-Twin

o Displacement 41.19 in³ (675 cm³)

o Bore x Stroke 2.96′′ x 2.99′′ (75.2mm x 76mm)

o Maximum Output 25 bhp (18.6 kW) at 3600 rpm

o Maximum Torque 41.3 lbf-ft (56.0 N-m) at 2400 rpm

o Cooling System Forced Air

o Ignition System Solid State Ignition

o Spark Plug Gap 0.030′′ (0.75 mm)

o Spark Plug Denso W14EPR-U

o Engine Oil Cap. 1.9 US quarts with oil filter change, 1.6 qts w/o filter change

o Engine Speeds Idle 1,550 rpm; Fast 3,600 rpm.

7.6 Hydrostatic System Specs

Hydrostatic Pumps (2) White KP Series;

Displacement – 10cc / revolution; Variable displacement, axial piston pump.

Wheel Motors (2) White RG Series; 12.2 in³ (200cc)

Component Manufacturer White Hydraulics, Inc.,

PO Box 1127

Hopkinsville, KY. USA 42241

System Capacity 2.1 US gallons (8.0 litres)

7.7 Fuel Tank Capacity

7.0 US gallons (26.5 litres)

Page 31

Page 31

8 Service Record

Record all service and repairs here for future reference.

Performed

By

Date

Hours

Description of Service Performed

Page 32

Page 32

Page 33

Page 33

9 Parts lists and drawings.

9.1 Aftermarket Replacement Parts NOT SHOWN in Drawings

Spare Ignition Key Y3887

Pin Spanner Tool for Spindle Repair Y4259

Orange Touchup Paint

(1 can Rim Orange)

Air Filter – Primary

(Outer)

Air Filter – Secondary

(Inner)

Fuel Filter

Oil Filter

Spark Plug

YET-4381

Honda 20 hp Honda 24 hp Kawasaki 21 Kawasaki 25

Tilton Part No. Y4849 Y3974 Y3375 Y3375

OEM Part No. 17210-Z J 1-842 17210-7 59-013 11013-7020 11013-7020

Tilton Part No. N/A N/A Y3376 Y3376

OEM Part No. N/A N/A 11013-7019 11013-7019

Tilton Part No. Y4195 Y4195 Y3378 Y3378

OEM Part No. 16910-ZE8-015 16910-ZE8-015 49019-7001 49019-7001

Tilton Part No. Y4168 Y4168 Y3374 Y3374

OEM Part No. 15400-PLM-A01PE 15400-PLM-A01PE 49065-2078 49065-2078

Tilton Part

No.(Denso)

Denso

J16CR-U

Denso

J16CR-U

Denso

W16EPR-U

Denso

W14EPR-U

Page 34

Page 34

Decal Y3351 – Qty (1) – Placement as shown above.

Decal Y3356 – Qty(1) - Place underneath

seat plate next to battery compartment.

Decal Y3361 – Qty (2) – Place

under deck pulley covers on LH

and RH sides of deck.

Decal Y3365 – Qty(2) – Place one

on each side of rear “YardShark”

guard, close to the rear in vicinity of

muffler.

Decal Y3366 – Qty(1) – Place on inside

of LH fender, next to seat.

Page 35

Page 35

Decal Y3362 – Qty(1) – Place on top of LH

fender.

Decal Y3359 – Qty(1) - Place on

RH side of deck near discharge

chute.

Decal Y3363 – Qty(1) – Place on top of RH

fender.

Decal Y3352 – Qty(1) – Place by

adjustment holes by deck lift pedal.

Decal Y3360 – Qty(1) - Place

on LH side of deck.

Page 36

Page 36

Y3746 – Qty(1) - Seat switch wire

harness

Y3748 – Qty(1) – Main engine/clutch

wire harness

Y3747 – Qty(1) – Wire assy, main power

Y3750 – Qty(1) – Fuel gauge plug assy.

Y3751 – Qty(1) – Deck switch wiring assy.

Y4481 – 8” Battery Cable

Qty(1) for Hondas

Qty(2) for Kawasakis

Y4482 – Qty(1) - 40” Battery Cable

Y3749 – Qty(1) – Wire assy, key switch

Y3752 – Qty(1) – Relay wiring assy

Y7611 – Qty(1)

– 30 amp bladetype fuse

Y3784 –

Qty(2) Relay

Electrical & Wiring Group

Y3753 – Qty(1) –

Ground wire

Page 37

Itm Qty Part No. Description

Page 37

1

2 Y1006 1/4−20 Top Lock Nut

2 8 Y1007 NUT, 1/2" UNC TOP LOCK

3 4

4

5

6 2 Y196314 1/8 x 2 Cotter Pin

7

8 2 Y30111 5 Bolt Wheel Hub

9 4 Y3458

10

2

Y1594

2 Y191246 1/4 x 1−1/4 UNC Bolt

10 Y193093 1/2−20 UNF Lug Nut

2 Y2692 White CE−14 Wheel Motor

8 Y3972 Hex Cap 1−2x2_3−4 UNC GR5 ZN

9

9

3/16 x 1 Roll Pin

1/2" SAE Flat Washer

7

14

7

4

Itm Qty Part No. Description

11

2 Y4250 3/32 x 1/2 Cotter Pin

12 1 Y4251 Brake Pin Rocker − RH

13 1 Y4258 Brake Pin Rocker − LH

14

2 Y4308 Compression Spring, Brake Pin

15 2 Y4426

16 2 Y4626 Brake Disc

17

2 Y4627 Brake Rod Support at Wheel Motor

10

18

19 2 Y4637 Brake Pin

20

2

Y4630

10

Y4680 Hex Cap 1−2x2_3−4 UNF

10

1/4" SAE FLAT WASHER

Brake Disc Spacer

6

20

16

8

3

12

15

11

4

1

3

11

13

19

17

18

5

Rear Wheel for 60" Mowers − (2) Y3991 − 23x9.50−12−Zero Offset

Rear Wheel for 51" Mowers − (2) Y3989 − 23x9.50−12−1.25" Inset

Rear Axle and Wheel Motor Group

Page 38

Itm Qty Part No. Description

Page 38

1 3

9 3 Y190063

11 1

13 4

15 4 Y2928 Rubber Bumper

16 2

17 4

19 3 Y30207 DECK ROLLER, 3" x 5"

20 6 Y3458

Y1002 1/2−13 Hex Nut

HAIR PIN, #3 FOR 3/8" PINS

Y191332 Hex Cap 3−8x1_1−4 UNC

Y196304 1/8 X 3/4 COTTER PIN

Y2988

Y30064 Torsion Spring − Mower

5/32 x 3/4 Cotter Pin

1/2" SAE Flat Washer

22

17

Itm Qty Part No. Description

41

3

21

22 1 Y3765

24 2 Y4002 Hex Cap 1−2x3_1−2 UNC

28

29 1 Y4313 RH Pulley Cover

30 2 Y4314 Pulley Cover Hinge

31 1 Y4333 Belt Tensioner

32 1 Y4334 Pulley Cover Tread Plate LH

33 1 Y4335 Pulley Cover Tread Plate RH

Y3637

1 Y4311

33

Deck Roller Pin

V−Belt 51" YardShark

LH Pulley Cover

29

42

15

28

Itm Qty Part No. Description

34

16 Y4349 3/8 SAE FLAT WASHER

35 2 Y4350

1 Y4372

38

41

8 Y4376 3/16 X .250 Std Pop Rivet

42 4 Y4377

44 1 Y4660 51 Deck Weldment − Tilton

1 Y4745

46

47 2 Y6916 DECK WHEEL

48 1

32

Y7790 1/4 X 3/4 Tapping Screw

3/8 X .056 BELLEVILLE WASHER

3/8 Std NC Nylock Nut

NUT, 8−32 UNC KEPS

Rubber Discharge Deflector Assy

35

34

35

13

30

38

46

16

31

9

16

1

11

24

20

47

20

48

21

FRONT VIEW

19

20

44

YardShark 51" Deck Group

Page 39

Itm Qty Part No. Description

Page 39

1 3

2 2 Y1006 1/4−20 Top Lock Nut

3 12 Y1018 Hex Cap 3−8x1 UNC

4 1 Y1045

5

6 1 Y1658 Hex Cap 3−8x2 UNC

7

8 14 Y1827 3/8" Lock Washer

9 3 Y190063

10

11 3

Y1002 1/2−13 Hex Nut

1/2−13 UNC Jam Nut

3 Y1053 1/2" Lock Washer

2 Y1826 3/8−16 UNC Hex Nut

HAIR PIN, #3 FOR 3/8" PINS

2 Y191242 Hex Cap 1−4x_3−4 UNC

Y191422

12

1/2 x 1−1/2 UNF Hex Cap Screw

22

19

4

1

8

20

Itm Qty Part No. Description

12 2 Y198119 1/2 X .070 BELLEVILLE WASHER

13 1 Y30065

14 3 Y30207 DECK ROLLER, 3" x 5"

15

6 Y3458 1/2" SAE Flat Washer

16 3 Y3637 Deck Roller Pin

17 3 Y3862

3 Y4145

18

19 3 Y4203 Deck Idler Pulley Assy − Flat

20 2 Y4225 3/8 x 2.25 Carr Bolt

1 Y4333 Belt Tensioner

21

22 16 Y4349

9

21

7

Deck Belt Tightening Spring

Spindle Assy Mowers 2006−

18" Blade − Std.

3/8 SAE FLAT WASHER

13

19

7

8

22

25.2

6

22

19

26

Itm Qty Part No. Description

1

23

24 1 Y4371 1/2−13 X 1−3/4 Carr Bolt

25 3 Y4374 BK57 X 1" Pulley Assy w/ 2 set

25.1 1 Y7187 BK57−1" Pulley

25.2 1 Y4123

25.3 1 Y192575

26

27

28 1 Y4660 51 Deck Weldment − Tilton

29

25.1

25.3

Y4358 Belt Tensioner Arm

screws

SetScrew 5_16−18 UNCx0.25

Knurled

SetScrew 5_16−18 UNCx0.375 −

Knurled

3 Y4375 1/4 x 1 Key

3

Y4466

2 Y4674 Rear Deck Lift Pin

3

8

BLADE SPINDLE WASHER

22

28

12

20

23

17

27

18

5

11

REAR VIEW

29

9

24

15

10

16

14

2

YardShark 51" Deck Group

Page 40

Itm Qty Part No. Description

Page 40

1 3

2

2.1 1 Y3946 BK62−1" BORE PULLEY

2.2 1 Y4123

2.3

3 1 Y3973

4 1 Y4640 60" Deck Weldment

Y2978 20−1/2" Blade − Std.

3

Y3947 BK62 Pulley Assy w/ 2 Set Screws

SetScrew 5_16−18 UNCx0.25 Knurled

1

Y192575 5/16−18 SET SCREW X 3/8

Belt for 60" YardShark

3

4

2.1

1

Parts unique to 60" deck.

All other parts same as

51" deck.

Yard Shark 60" Deck Group

Page 41

Complete Spindle Assy − # Y3862.

Page 41

Itm

Qty Part No.

1 1 Y1074

2 2 Y2755

3 1

5

1

2

6

3

4 1 Y3863

5 1

6

2

Y2959M Machined Hub for Mower Spindle

Y3864 Spindle Nut for Bottom of #3862 Assy

3

Y3865 Ext Ret Ring MSR−30

4

Internal Retaining Ring/MHO−62/ANSI Metric

6206 SEALED BEARING

Spindle Shaft for #3862 Assy

Description

Blade Side

Pulley Side

6

SECTION A-A

SCALE 3 / 4

AA

6

2

1

5

6

3

4

6

6

2

Spindle Assembly

Page 42

Itm

Page 42

Qty Part No.

1 2 Y198046 1/4" Fender Washer

2 2 Y3624

3

6 Y4060 1/4 x 1 Carr Bolt

4 8 Y4062

5 1 Y4730

1

6

7 1 Y4734 Rubber Deflector−Tilton

6

4

Y4732

1/4 x 1 Hex Cap Screw

1/4 Std NC Nylock Nut

Deflector Bottom Clamp Strap

Deflector Mount Weldment

4

Description

7

1

2

3

5

Rubber Discharge Deflector Assy

Page 43

Itm Qty Part No. Description

Page 43

1 1

2

3 1 Y1053 1/2" Lock Washer

4 2

5

6 4 Y3458

7 4 Y4153 1/2−13 UNC Clevis RH

8

9 2 Y4170

15

Y1019

4 Y1045

Y2952

8 Y2988 5/32 x 3/4 Cotter Pin

10

Y4159 O−Ring

Hex Cap 1−2x1_1−4 UNC

1/2−13 UNC Jam Nut

5/32 X Cotter Pin

1/2" SAE Flat Washer

CLEVIS PIN, 5/8 x 1 1/4

17

16

Itm Qty Part No. Description

10 1 Y4274

11

2 Y4276 DECK PUSH ARM

12 4 Y4348

13 1

14 1

15 4 Y4362 DECK LIFT LINK

16 2 Y4453 DECK LIFT ROD

17 1

15

Y4359

Y4360 FOOT PEG

Y4672 REAR LH DECK LIFT w/ LATCH HOOK

Deck Lift Rock Shaft Weldment

CLEVIS PIN, 1/2" DIA. x 1 27/64" LENGTH

REAR DECK LIFT RH

2

7

14

10

8

3

1

15

13

5

12

5

12

6

15

11

5

4

9

Deck Lift Group

Page 44

2

Page 44

6

4

5

7

Itm Qty Part No. Description

1 1

2 1 Y130083 Dust Cap − Zinc

3 1 Y150001

4 1 Y1500031

5 1 Y1500041

6 1

7 1

8 1 Y3064 5/8 Thin NC Nylock Nut

9

10 1

Y1029 Hex Cap 5−8x7 UNC

Grease Seal

Bearing−Cup&Cone 1" Bore

Bearing−Cup&Cone 1.0625" Bore

Y193185 1" Slotted Nut − Thin

Y196314 1/8 x 2 Cotter Pin

1

Y3990

Y4629 FRONT CASTER FORK WELDMNT

13X5 Wheel Assy

3

1

10

8

9

Front Wheel Group

Page 45

24

Page 45

14

30

Itm Qty Part No. Description

1 2 Y1006 1/4−20 Top Lock Nut

4 Y1047

2

3 1

4 1 Y1658 Hex Cap 3−8x2 UNC

5 7

6

7 2 Y191240 Hex Cap 1−4x_1−2 UNC

8

6

7

1

30

34

19

25

28

8

10

32

4

18

33

11

26

5

12

13

31

9

2

16

21

9 2 Y198042

10 2 Y198064 5/16" Lock Washer

11 2 Y3625 1/4−20 HEX NUT

12

13 2 Y4060 1/4 x 1 Carr Bolt

14 1 Y4136 Engine, Honda GXV20

15 1 Y4140

16 2 Y4172 5mm x 25mm Key

17 1

18

19 1 Y4216

20 2 Y4217

21

22 1 Y4267

23 1 Y4268

24

25 1 Y4275

26 2 Y4349

27

28

29 1 Y4354 3/8 X 1−1/2 Carriage Bolt

30 2 Y4462 Loom Clamp 1/2 Dia − 1/4" Mount

31 1

32 1 Y4852 1/4 key x 3/4 long

33 4

34

Y1052 7/16" Lock Washer

Y1826 3/8−16 UNC Hex Nut

5

Y1827 3/8" Lock Washer

2

Y191282

1

Y3781 Loom Clamp 1/2 Dia − 3/8 Mount

Y4199 Belt 5mm pitch x 51.181 x 15mm wide

1

Y4202 2.75" idler Pulley

3

Y4266 Sprocket, 5mm PITCH, 60 GROOVE, SH Bore

1

Y4273

3 Y4350

1

Y4353

Y4474 Pump Drive Idler Arm

Y7194 Hex Cap 3−8x1_3−4 UNC

2 Y8230 5/16−18NC SERR FLANGE ZP

3/8 USS FLAT WASHER

5−16x1 UNC Hex Cap

1/4" Lock Washer

Warner Clutch # I−5218−52 B

Bushing−Engine, SH 1" bore

Bushing−Pumps, SH 15mm

Clutch Spacer − 1" ID

7/16 x 2−1/2 Hex Cap Screw

Muffler−Honda

Clutch Stop

3/8 SAE FLAT WASHER

3/8 X .056 BELLEVILLE WASHER

Pump Drive Idler Spring

22

15

20

17

3

23

5

27

5

29

Honda 20hp Power Group

Page 46

Important!

Page 46

See Note Below

15

29

31

14

33

6

2

27

Itm

Qty Part No.

1 2 Y1012 NUT WHIZ 1/4−20NC ZP

2 4 Y1047

3 1

4 1 Y1658 Hex Cap 3−8x2 UNC

5 7

6

7 2 Y191242 Hex Cap 1−4x_3−4 UNC

8

9 2 Y198042

10 2 Y198064 5/16" Lock Washer

Used on Kaw’s Only

9

1

11

7

5

4

22

6

2

25

32

18

16

20

11 1 Y3313

12

13 1 Y3944 Clutch − 1−1/8" bore

14 1

15 1

16 2 Y4172 5mm x 25mm Key

17 1 Y4199 Belt 5mm pitch x 51.181 x 15mm wide

18

19 2 Y4217

20 3 Y4266

21 1 Y4275

22 2 Y4349 3/8 SAE FLAT WASHER

23 3 Y4350

24 1 Y4353

25

26 1 Y4474 Pump Drive Idler Arm

27 1 Y4652 Muffler−Kawasaki

28

29 1 Y4668 1−1/8" x .050" Narrow Rim Mach Bushing

30 1

31 1

32 4 Y7194 Hex Cap 3−8x1_3−4 UNC

33 2

Y1052 7/16" Lock Washer

Y1826 3/8−16 UNC Hex Nut

5

Y1827 3/8" Lock Washer

2

Y191282

1

Y3326 7/16 X 2 Hex − UNF

Y3948 Bushing−Engine, SH 1−1/8" bore

Y3966 Kawasaki 21 hp

1

Y4202 2.75" idler Pulley

1

Y4354 3/8 X 1−1/2 Carriage Bolt

1

Y4667 Clutch Mount Bushing − 1−1/8"

Y4669 Clutch Spacer − 1−1/8" ID

Y4852

Y8230 5/16−18NC SERR FLANGE ZP

3/8 USS FLAT WASHER

5−16x1 UNC Hex Cap

1/4" Lock Washer

12V Solenoid

Bushing−Pumps, SH 15mm

Sprocket, 5mm PITCH, 60 GROOVE, SH Bore

Clutch Stop

3/8 X .056 BELLEVILLE WASHER

Pump Drive Idler Spring

1/4 key x 3/4 long

Description

21

24

8

10

Important Note − Part #Y4668 (Item 29) is

used only on Kawasaki Engines. It is used to

compensate for a slightly longer crankshaft

than the Honda 24hp. DO NOT USE ON

HONDA’s !!

30

13

28 12

19

26

3

23

17

Kawasaki 25 hp Engine Part #Y3965

Honda 24 hp Engine Part #Y3960

Kaw21/25 & Honda24 Engine Group

Page 47

Itm

Page 47

1

2 1 Y140016

3 1 Y1623 5/16 x 3/4 Bolt

4

5 1 Y198064 5/16" Lock Washer

6 1

7

8 1 Y4236

9

10 1

11 2 Y4426

12 1 Y4625

13

14 4 Y8230

Part No. Description

Qty

4 Y1006 1/4−20 Top Lock Nut

Seat Cable − 1/8" x 18"

2 Y191240 Hex Cap 1−4x_1−2 UNC

Y3919 Michigan Suspension Seat

2 Y4060 1/4 x 1 Carr Bolt

Seat Latch Pin

1

Y4238 Seat Hinge Pin − Zinc

Y4250 3/32 x 1/2 Cotter Pin

1/4" SAE FLAT WASHER

Seat Plate Weldment

2 Y4691 Seat Support Bumper

5/16−18NC SERR FLANGE ZP

3

7

6

12

13

11

10

1

1

9

4

2

14

8

5

Seat Group

Page 48

Itm Qty Part No. Description

Page 48

1 5

2 3 Y191240 Hex Cap 1−4x_1−2 UNC

3 2

17

13

15

16

2

4

6

12

11

1

4

9

18

14

4

19

3

4

4 7

5 2 Y198046 1/4" Fender Washer

6 2

7 1

8 2 Y3787

9

10 1

11 1 Y4341

12 1 Y4342 Gas Cap

13

14 1 Y4344 Battery Terminal Cover

15 1 Y4345 Gas Tank Fitting

16

17 1 Y4347 Elbow, 1/4 pipe, 1/4 Hose barb

18 2 Y4426

19 2 Y4462 Loom Clamp 1/2 Dia − 1/4" Mount

Y191211 10−32 UNF x 1−2 Phillips Pan Head Zinc

Y191246

Y198042

Y3783 Loom Clamp 3/8 Dia − 1/4" Mount

Y3786 Gas Line 1/4" SAE 30R7 − 43"

2

Y3789 1/4−20 UNC x 1−1/4" Stud

Y4255

Y4343

2

1

Y4346 Gas Tank Draw Tube

1/4 x 1−1/4 UNC Bolt

1/4" Lock Washer

Clamp. Tension Spring 1/2"

Fuel Tank, Molded Plastic

Fuel Sender

Wing Nut 1/4−20

1/4" SAE FLAT WASHER

10

5

8

7

Fuel Tank Group

Page 49

Itm Qty Part No. Description

Page 49

1 4 Y1001 7/16 Hex Nut UNC

2 6

3 4 Y1052 7/16" Lock Washer

4 2

5

6 2 Y198042 1/4" Lock Washer

7 2 Y3624

8

9 1 Y4232

10 1

11 1

12 1 Y4487

13 4 Y4488

14 1

15 1

16 1 Y4491

17 1

18

Y1047

Y1826 3/8−16 UNC Hex Nut

2 Y1827 3/8" Lock Washer

1

Y4231

Y4393

Y4486 Parker Triple−Lok 45° Straight Thread Elbow, 8−6 V5OX−S

Y4489 Parker Triple−Lok Straight Thread Connector, 8−6 F5OX−S

Y4490

Y4492

1

Y4493

33

3/8 USS FLAT WASHER

1/4 x 1 Hex Cap Screw

White LH Pump (Our RH)

White RH Pump (Our LH)

Hydraulic Oil Reservoir

Parker Triple−Lok 45° Straight Thread Elbow, 8 V5OX−S

Parker Triple−Lok Straight Thread Elbow, 8−10 C5OX−S

6801−08−08 Jic(−8) to Male O−ring (−8), 90 degrees

Parker Triple−Lok Swivel Nut Branch Tee, 8 S6X−S

6 C5OX−S (St Thd El.−3/8 JIC x 9/16 ORB)

Parker Triple−Lok Straight Thread Branch Tee, 6 S5OX−S

24

35

35

12

21

35

35

Itm Qty Part No. Description

1

19

20

21 1 Y4496 Oil Filter 10 Micron

22 1

23

24 1 Y4503

25 1 Y4504 Hyd Line−Filter to RH Pump

26

27 1 Y4508 3/8" NPT Magnetic Drain Plug

28 1 Y4631 LH Top Oil Line

29

30 1 Y4633 RH Top Oil Line

31 1 Y4634 RH Bottom Oil Line

32

33 1

34 4 Y7654 7/16 X 1−1/2 Carr Bolt

35 4

Y4494

1

Y4495

Y4497 Oil Filter Head SAE 8 ports

1

Y4498 Oil Reservoir Dipstick

1 Y4505 Hyd Line−Pump to Pump

1

Y4632 LH Bottom Oil Line

1

Y4685 Oil Line−Return−Center

Y4686 Oil Return Line−To Tank

Y7944 Str Thrd Conn, 8 F5OX−S,1/2 JIC x 3/4−16 ORB

8 GTX−S − (Female Adapter,3/8 Pipe x 1/2"JIC)

8 GTX−S − (Female Adapter,1/4 Pipe x 3/8"JIC)

Hyd Oil Suction Line to Filter

8

16

14

9

11

13

29

13

23

28

15

19

20

4

5

2

10

27

REAR VIEW

22

6

7

31

13

30

25

13

34

34

1

32

26

18

FRONT VIEW

3

17

Oil Filter/Reservoir Group

Page 50

25

Page 50

20

15

30

3

Itm Qty Part No. Description

1 2

2 4 Y1018 Hex Cap 3−8x1 UNC

16

2

27

5

31

9

10

19

9

23

11

32

4

11

6

17

14

7

1

18

29

34

11

34

22

13

35

20

28

26

21

8

13

12

33

31

3 4 Y1073 1/4 X 1−1/8 ROLL PIN

4 2

5 4

6 2 Y191282 5−16x1 UNC Hex Cap

7 2

8 2 Y198064 5/16" Lock Washer

9 4 Y198119 1/2 X .070 BELLEVILLE

10

11 6 Y4064 5/16 x 3/4 Carr Bolt

12 2 Y4151

13 4 Y4193 5/16−24 UNF Hex Nut

14 2

15

16 2 Y4226 Foam Grip,.875" x 17"

17 2 Y4250 3/32 x 1/2 Cotter Pin

18 2 Y4260 Control Shaft Weldment

19 2 Y4263 Control Arm Block

20 2 Y4271 5/16−18 x 1.75 Carr Bolt

21 2 Y4286 5/16−24 LH/RH Adjustment

22 2 Y4287

23

24 1 Y4292 LH BRAKE ACTUATOR

25 2 Y4294 Control Lever Mount

26 2 Y4297 CONTROL WELDMENT

27 2 Y4301 CONTROL HANDLE WELDMENT

28 2 Y4304

29 2 Y4305 BEARING BLOCK FOR BRAKE

30

31 6 Y4349

32 2 Y4353

33

34 6 Y7731

35 6

Y1008 1/2 Std NC Nylock Nut

Y1279

Y1827 3/8" Lock Washer

Y196304 1/8 X 3/4 COTTER PIN

Y3050

2

Y4194

2 Y4208 5/16−18 UNC X 1−1/2 CARR BOLT

1

Y4289 RH BRAKE ACTUATOR

Y4331

2

2 Y4426 1/4" SAE FLAT WASHER

Y8230 5/16−18NC SERR FLANGE ZP

1/2 x 2−1/2 Hex Cap

WASHER

ZERK, 1/4−28 90 DEG.

5/16−24 NF Rod End W/ Stud,

LH Thd Inside Rod End

5/16−24 UNF LH Hex Nut

Rod − 12.50" OAL

5/16−24 RH Spherical Rod End

WELDMENT

WELDMENT

Brake Linkage

ROD

3/16 x 1.75 Roll Pin

3/8 SAE FLAT WASHER

Pump Drive Idler Spring

5/16 Std NC Nylock Nut

24

32

Control Group

Page 51

Itm Qty Part No. Description

Page 51

1 7 Y1012 NUT WHIZ 1/4−20NC ZP

1

2

3 2 Y1623 5/16 x 3/4 Bolt

4 2

5 3

6 4 Y191242 Hex Cap 1−4x_3−4 UNC

7 2

8

9 1 Y3350 Cup Holder Insert − Black Plastic

10 1 Y3772 Wire Loom − 3/8 ID − 44"− Not Pictured−Use to route

11 2 Y3778 Jumper, Hole Mount

12 1

Y140012−6FT Throttle Cable Assy

Y191211

Y191240 Hex Cap 1−4x_1−2 UNC

Y193004 10−32 NF Serr. Flange nut

4

Y198042

Y3779 Barrier Strip − 10 Terminal

14

20

10−32 UNF x 1−2 Phillips Pan Head Zinc

1/4" Lock Washer

throttle & choke cables

15

13

2

4

Itm Qty Part No. Description

13 1

14 1 Y4144

15 1 Y4160

16 1 Y4213 BATTERY 12 V

17 1

18 2 Y4245

19

20

21 7 Y4426

22 6 Y4485

23

24 1 Y4623 Control Box Weldment

25 1 Y4670 Control Panel Overlay

26

27 2 Y8230

9

1

Y3970

Y4243 Barrier Strip Mount − SS

2 Y4377

1

Y4383 Fuel Gauge

1

Y4622 Control Box Cover

1

Y4671 Cup Holder

Choke Cable − 61−1/2"

Key Switch

PTO Switch

8−32 x 1/2 Pan Hd Mach Screw

NUT, 8−32 UNC KEPS

1/4" SAE FLAT WASHER

#10−24 x 1/2" Washer Head Screw − ZP

5/16−18NC SERR FLANGE ZP

26

24

25

16

7

17

18

11

12

19

21

5

6

1

3

27

1

21

8

6

22

23

Control Box Group

Page 52

4

Page 52

25

25

1

39

6

40

23

43

D

Itm Qty Part No. Description