Page 1

INSTALLATION INSTRUCTIONS

Premium Remote Bias Adjuster

Tilton’s Billet Remote Cable Adjusters are designed to attach to the balance bar used in the

Tilton Pedal Assemblies and allows the driver or crew to adjust the brake bias quickly and

accurately during competition.

The Remote Cable Adjuster comes with a 6-foot cable that may be cut to length for your

application. Everything on the adjuster has been optimized for function, durability, and of

course weight. Using a cross action spring-loaded dual detent system, we created a smooth-

er, more precise, and longer lasting part. The unit can be easily taken apart for inspection or

cleaning and re-assembled as shown in the Technical section. A single mounting hole allows

for simple installation.

InstallatIon notes

• Select a location that allows the driver or crew to make adjustments easily.

• Route the cable so it does not interfere with the driver’s feet, other pedals or other

equipment in all pedal positions.

• The cable routing and length should allow all of the curves in the cable to have a 6 inch

minimum bend radius. In general, fewer and larger radius bends allow more precise

movement.

• The cable should be shortened to the appropriate length for your application.

• Never try to adjust the brake balance while applying the brakes, since a loaded balance

bar will not turn. Always adjust the brake balance when the pedal is in a relaxed state.

• You can swap the balance bar shaft around in the pedal assembly if you need to attach

the cable from the opposite side of the pedal.

98 -12 71

Exploded Assembly

InstallatIon

1. Select a mounting location that allows the driver and crew to make adjustments easily

and trial t the Remote Cable Adjuster Assembly to note any obstructions for the routing

of the cable.

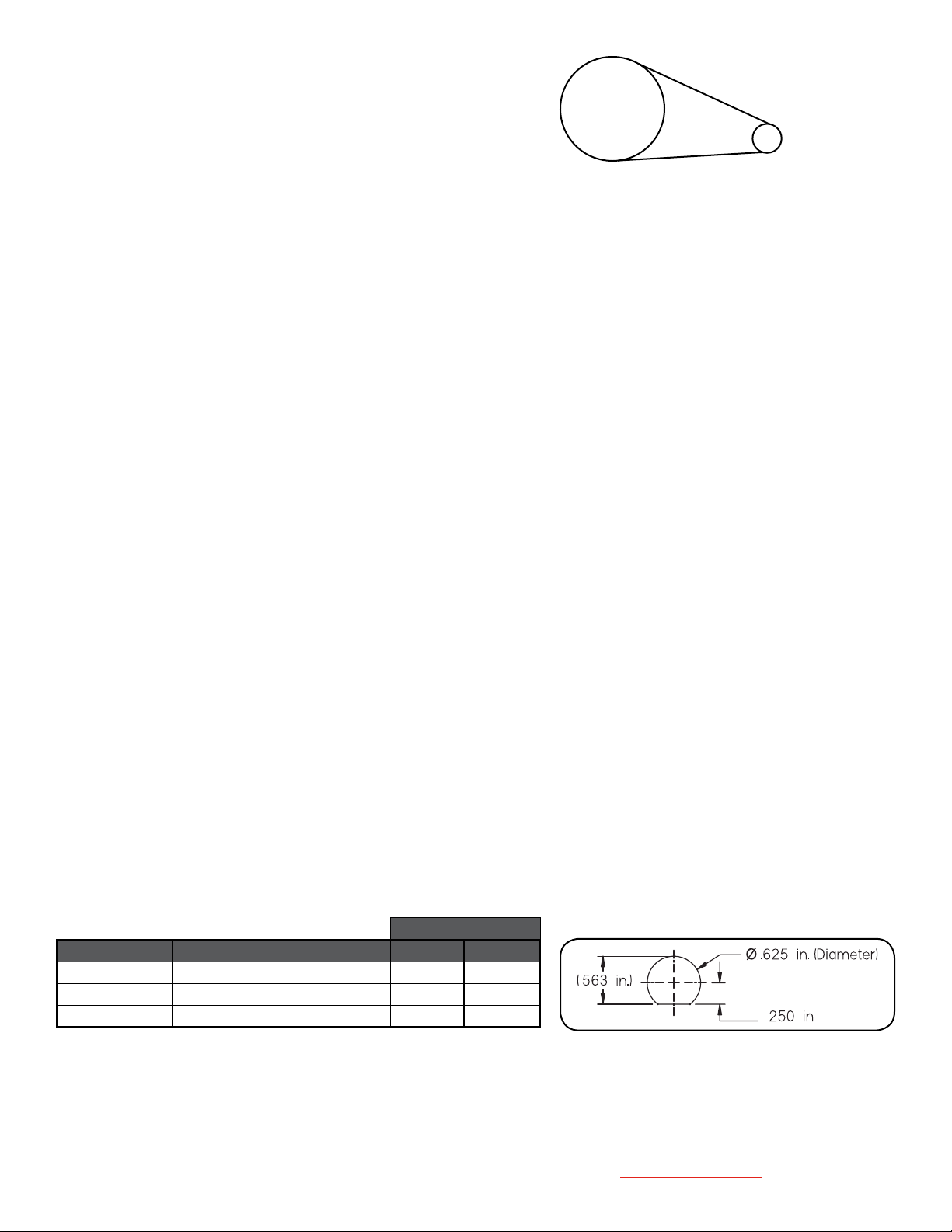

2. When satised with a location, refer to Diagram 6 for the ideal shape of the hole. A “D”

shape hole helps to keep the remote adjuster from rotating if the retaining nut ever

becomes loose.

3. Debur the mounting hole and temporally install the Remote Cable Adjuster

using the supplied 5/8" retaining nut.

4. Route the cable so it does not interfere with the driver’s feet, other pedals or other com-

ponents in all pedal positions.

5. Make sure all curves in the cable have a 6-inch minimum bend radius

(in general, fewer and larger bends allow more precise movement).

6. Mark the end of the cable where it needs to be cut to length and move the Remote Cable

Adjuster Assembly from the vehicle to a clean workbench.

7. Remove the black sleeve from the cable before brazing. This will

prevent melting the sleeve.

8. Braze the cable at the cutting point before cutting. This will prevent fraying of the cable

end.

9. Cut the cable to length at the brazed point in the cable.

10. Slip the (black) plastic sleeve onto the cable and cut it to a length 0.50" shorter than the

cable length.

11. Re-install the Remote Cable Adjuster Assembly in the vehicle and tighten the retaining

nut to 15 lb-ft (using thread locking compound). Do Not Over Tighten.

12. Thread the jam nut included in the kit onto the hex broached or longer end of the bal-

ance bar shaft.

Detent Balls

Large Washer

Small Washer

Black Cable Sleeve

Knob

Detent Spring

Cable

Base

Retainer Clip

Nut

Page 2

13. Thread the coupling onto the hex broached or longer end of the balance bar shaft. Typi-

cally, this is on the right side. Tighten jam-nut against coupler.

(900 series balance bars do not require a coupling)

14. Insert the cable end into the coupling and secure the cable by tightening the set-screw in

the coupling. For the 900 series balance bar, the cable goes directly into the balance bar

end and is secured using the set screw located in the balance bar itself.

15. Secure the cable along its route with the six (6) cable clamps that are included in the kit.

Less cable housing movement provides better balance bar adjustment and more percise

movement. Make sure the balance bar end is free to move throughout the range of the

brake pedal.

16. Rotate the adjustment knob and observe the direction and eect it has on the balance

bar position. Rotating the balance bar so it shif ts towards the master cylinder for the rear

calipers increases the amount of rear braking.

17. Apply the proper directional decal on the adjustment knob according to

previous observation (Diagram 5).

MaIntenance

• Periodically inspect the balance bar assembly and the Remote Cable Adjuster.

• Lubricant should not be used for the cable, but could be used on the detent mechanism

and knob shaf t. Use a light oil.

• Lubrication is not recommended for the balance bar since dirt and other foreign particles

that can hinder operation tend to stick to oil and grease.

technIcal

¼ or full Turn of Knob = % Bias Change (Chart 1)

Diagram 2

Diagram 3

Diagram 4

DIs-asseMbly:

1. Remove retaining clip and washer and place hand over assembly to retain the ball and

spring assembly.

2. Pull the knob from the base until the ball and spring assembly comes out

Warning: Ball and Spring assembly under Preload.

asseMbly:

1. Slide the knob with the large washer into the base and align the cross hole of the knob

with the slot on the base (Diagram 2).

2. Position the knob far enough into the base so to retain the rst ball inserted into the

cross hole of the knob.

3. Follow this with the spring and second ball (Diagram 3). Using a pointed object or nger,

recess the second ball into the cross hole and gently push the knob into the base.

To nish, install the small washer and retaining clip (making sure the clip is in the groove).

(See Diagram 4)

Chart 1

Balance Bar Size Clevis Center to Center Distance 1/4 Turn Full Turn

3/8" x 24 2.5" 0.42% 1.67%

7/16" x 20 2.62" 0.48% 1. 91%

1/2" x 20 2.75" 0.45% 1.82%

% Bias Change

Diagram 5

Diagram 6

Tilton Engineering, Inc. 25 Easy Street • PO Box 1787 • Buellton, CA 93427 • www.tiltonracing.com

Loading...

Loading...