Page 1

INSTALLATION INSTRUCTIONS

600 Series Overhung-mount Pedal Assemblies

Description

The Tilton Overhung pedal assembly has been designed to provide the driver with

the greatest control and comfort from a swing-style pedal assembly. This system al-

lows the mounting of the master cylinders and reservoirs in the driver’s compartment

away from the heat of the engine.

Finite Element optimized pedals provide strength, stiness, and durability to handle

the most severe braking conditions. Adjustable foot pad positioning allows custom-

ization for dierent drivers.

The pedal assembly is set up for dual brake master cylinders and includes the balance

bar assembly. This allows adjustment of the brake pedal force distribution between

the two master cylinders. This system can be used to compensate for fuel load

changes, tire wear, and changing track conditions.

The Remote Brake Bias Adjuster is available as an option. This connects to the balance

bar allowing the driver to make balance bar adjustments quickly while on track.

Fluid reservoirs can be directly mounted to the master cylinders or can be remotely

mounted based on your application. It is important to follow these setup instructions

closely to realize the benets of this design.

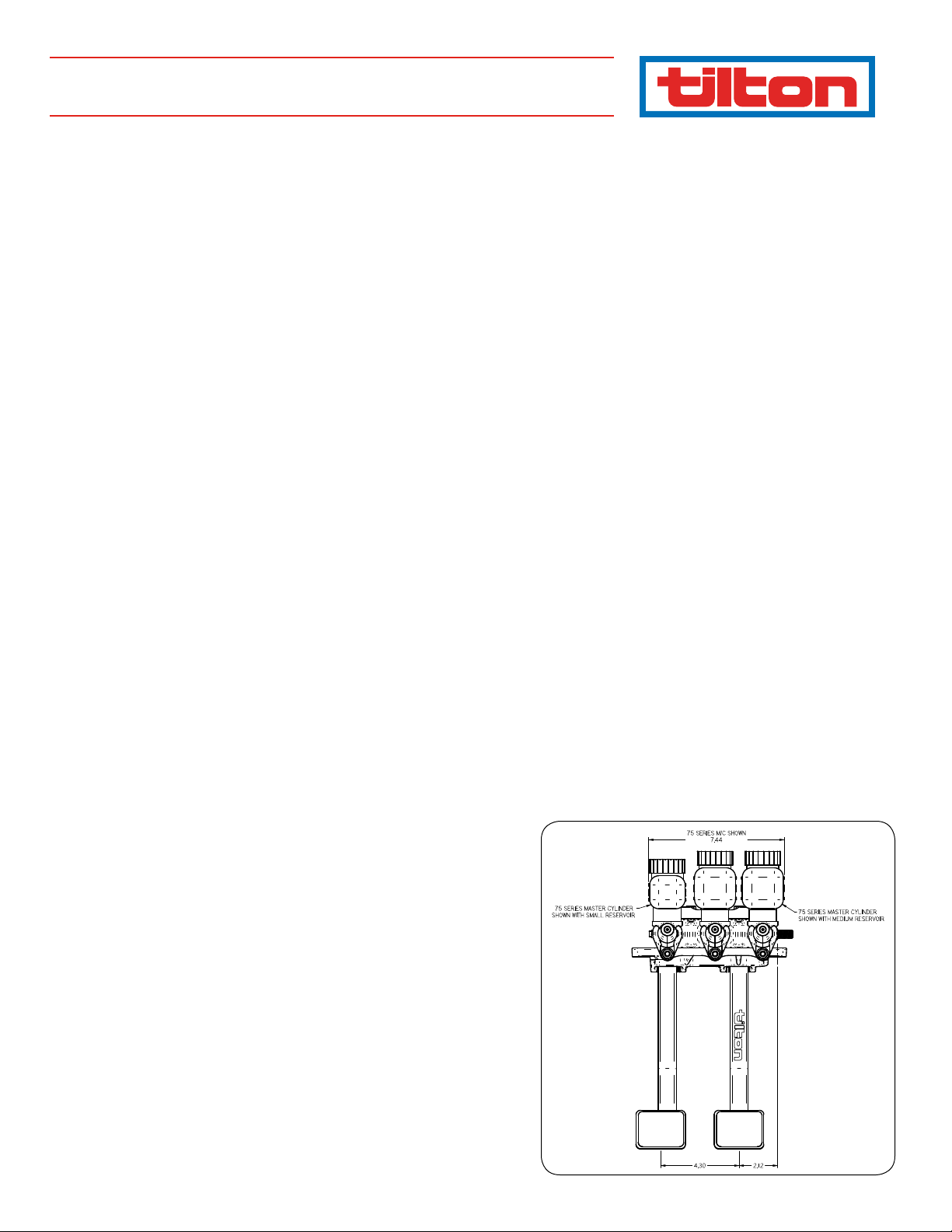

98 -12 01

Steel

Master cylinders sold separately

Aluminum

installation notes

• The pedal assembly must be attached to a very rigid frame structure.

• The mounting location should suit the driver and also provide a stable

platform.

• Be sure that there is no binding during the full stroke of the master cylin-

ders when the pedal is depressed.

• The balance bar mechanism must clear all obstructions when the balance

bar is adjusted to the extreme right or left-of-center and at full stroke of

the master cylinders.

• If you have decided to remotely mount the reservoirs, select the location

for the reservoirs before starting installation.

• This is a gravity fed system, so the reservoirs must be located above the

master cylinders.

• Attention must be paid to the routing and location of the hydraulic lines.

Avoid heat sources such as exhaust pipes.

• Accurate clutch pedal setup is critically important. Improper clutch pedal

installation and/or adjustment can result in expensive clutch damage

and DNFs at the track!

Master cylinders sold separately

Diagram 1

Page 2

installation

1. Set the clevis center-to center distance at 2.620 +/- .040". You need

to do this before attaching the master cylinders.

2. Thread the adjusting shaft left or right until the spherical bearing

is near the center of the pivot sleeve. Note that the right end of the

balance bar has a longer threaded section and will stick out farther.

3. If you are using a remote adjuster, remove the jam-nut from the

adjusting shaft. If you are not using a remote adjuster, tighten the

jam-nut against the barrel nut on the longer end (right end) of the

shaft. The round end goes against the barrel nut.

4. Mount the pedal assembly in the car. It is important to mount the

frame rigidly so that it does not move when heavy pedal force is

applied to both pedals. See diagrams 5–8 for mounting hole loca-

tions. The four large through holes are for attaching to the main

support structure while the two tapped holes and the six master

cylinder mounting studs can be used for additional stiening.

5. (Aluminum Pedals Only) Attach the two foot pads. Dierent

osets are available by turning the pad upside down. Choose only

positions that allow connection with all four screws per foot pad.

6. If you are going to bench bleed your master cylinders,

now is the time.

7. Bolt the master cylinders into place with the supplied 5/16"-24

serrated ange nuts. Make sure the master cylinder pushrod has a

jam-nut.

8. Thread the master cylinder pushrods into the clevises equal

amounts (you may need to alter this later) until the pedal foot

pad is in the correct position for the driver (See Diagram 2). A

minimum of .25" thread engagement (6 threads) is recommended.

9. Tighten the master cylinder pushrod jam-nuts against the clevises.

10. Make sure that the chosen pedal position allows a full 1" of stroke

at both master cylinders.

11. Make sure that the adjusted position also allows both master

cylinders to return to their fully relaxed position without binding.

Preload on the master cylinder pushrods can cause the brakes to

lock up when hot when there is no force on the pedal.

12. Attach the hydraulic lines.

13. Attach the reservoirs and bleed as directed in the master cylinder

directions. With a balance bar, always bleed a front and a rear

caliper at the same time to insure total air removal.

14. Apply the brakes and adjust the pushrod length so the adjusting

shaft is parallel to the master cylinder mounting surface (See

Diagram 3). If one pushrod is shortened by one revolution,

lengthening the other by one revolution will maintain the same

pedal position. Do not extend the pushrods to the point where

they preload the master cylinder pistons. After adjusting, tighten

the jam-nuts on both pushrods.

15. You will need to test drive the vehicle to determine if

adjustments need to be made to the brake bias (front/rear brake

force distribution). See Section F for making bias adjustments.

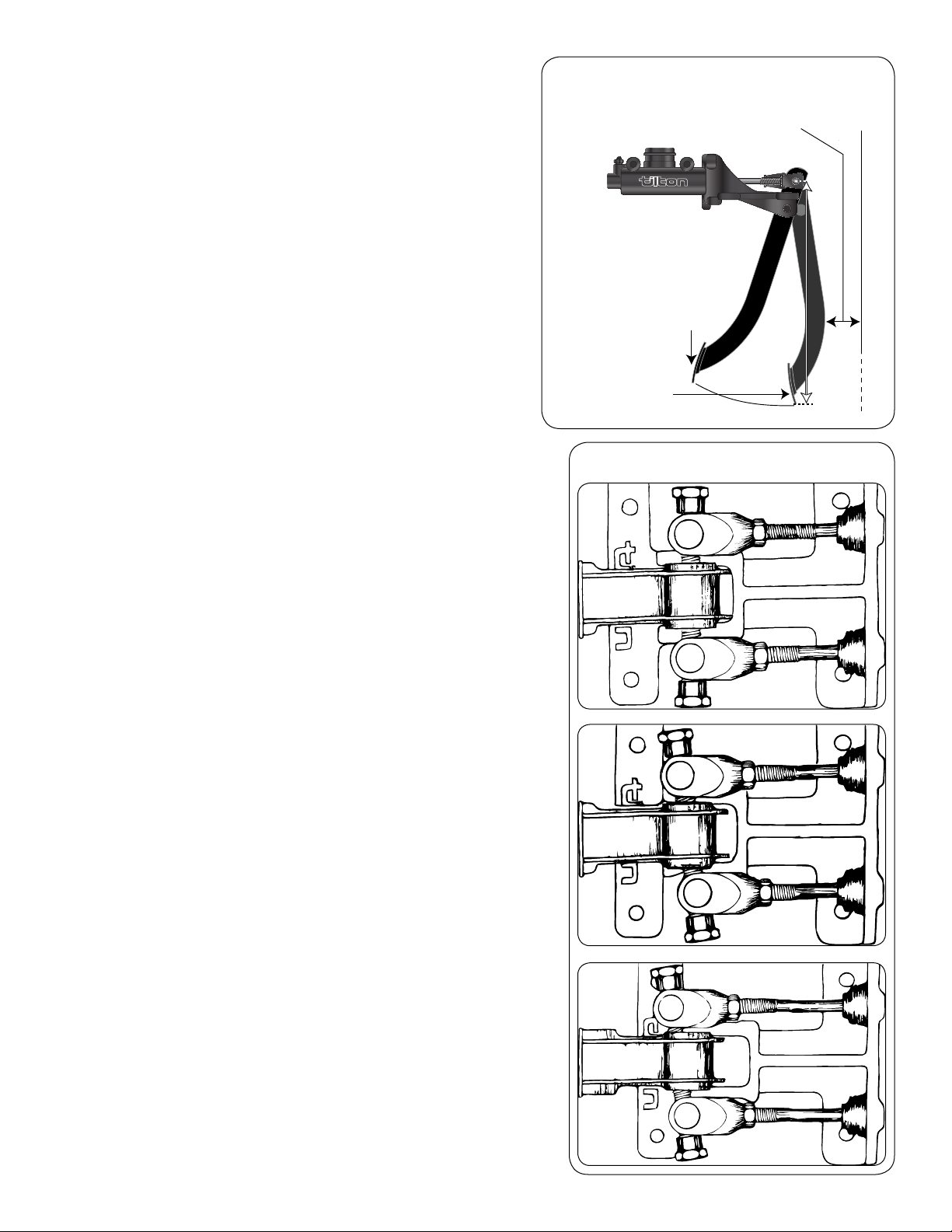

Diagram 2

Distance from the rewall must be great enough

that a full stroke of the master cylinder is possible.

FIREWALL

PEDAL AT REST

11.75"

MASTER CYLINDER

BOTTOMED

Diagram 3

3.1

Pedal Depressed

Balance Bar

not at an angle

(Correct)

3.2

Pedal Depressed

Balance Bar

at an angle

(Incorrect)

3.3

Pedal Relaxed

Balance Bar

may or may not

be at an angle

Page 3

FIREWALL

BA

.25"

clutch peDal setup

1. Install the clutch master cylinder using the supplied 5/16"-24 serrated ange

nuts. Make sure that there is a jam-nut on the pushrod.

2. Thread the pushrod into the rod end on the clutch pedal until the pedal

is in the desired position, which is usually a matter of driver preference. A

minimum of .25" thread engagement (6 threads) is recommended. You may

need to shorten the pushrod for some positions.

3. Tighten the master cylinder pushrod jam-nut against the spherical rod end.

4. Connect the hydraulic line to the master cylinder.

5. Fill the master cylinder reservoir with brake uid. Do not use a silicone-

based uid.

6. Open the bleed tting at the master cylinder, or loosen the line.

7. Gently depress and release the clutch pedal until uid emerges.

8. Tighten the bleed tting or line.

9. Fill the reservoir with brake uid.

10. Place a light force on the pedal. You want enough to hold the bearing out

against the clutch diaphragm spring but not enough to compress it.

11. Open the bleed screw for the hydraulic release bearing.

12. Completely stroke the pedal.

13. Close the bleed screw.

14. Let the pedal return to its natural position and wait 4 seconds.

15. Repeat steps 10-14 until all air has been removed from the system.

16. Proceed directly to setting the pedal stop before stroking the pedal

again or the clutch could be damaged. A pedal stop is usually required

for small diameter racing clutches and/or hydraulic release bearings with

limited stroke.

Diagram 4

clutch peDal stop setup

(For use with Tilton style hydraulic release bearings)

NOTE: For assemblies that do not have a built in positive clutch pedal

stop, you will need to fabricate one on the oor/rewall.

1. Raise the vehicle onto jack stands or a hydraulic lift.

2. With the engine o put the transmission into 1st gear and have someone

attempt to rotate one of the drive wheels.

3. Depress the clutch pedal slowly until the clutch disengages and the drive

wheel can be rotated.

4. Note the clutch pedal position at this point. This is labeled A in Diagram 4.

5. Adjust the pedal stop bolt to allow an additional 1/4" of pedal travel at the

foot. This is labeled as point B in Diagram 4. Secure the pedal stop bolt with

jam-nut once the position has been set.

6. Adjust the pedal stop so the pedal cannot travel past point B.

Maintenance

Periodic inspections of the brake and clutch pedal assemblies should be

conducted routinely. Pay particular attention to the balance bar and pivot

areas.

Note: DO NOT reuse the snap rings found on the pedal pivot pins. These

snap rings will yield when removed from the pivot pins if spread too far

open. If replacements are needed, please order part number N5100-37

from your Tilton dealer.

Diagram 5

Diagram 6

Page 4

Balance Bar aDjustMent anD operation

LOW FRICTION

DRY LUBE AND

HARD COATING

ON CLEVISES

2.62 ±.04

SET TO

1/4-20 UNC AUXILIARY

MOUNTING HOLES

3.750

2.120

2.630

When running on pavement, you want the front tires to lock-up with slightly less

pedal force than the rear tires. This will help to keep the car stable and prevent it from

going into a spin.

1. Loosen the jam-nut on the adjusting shaft (Item 3 in Diagram 10). A jam-

nut is not used with a remote adjuster.

2. Turn the adjusting shaft (Item 8 in Diagram 10) by hand or with the

remote cable adjuster so that it advances the spherical bearing closer

to the selected master cylinder, increasing the braking force produced

by that master cylinder (Diagram 9). The balance bar must be adjusted

with the pedal in the relaxed position (Diagram D). It will not rotate while

depressing the pedal.

3. The balance bar has a fairly large adjustment range. However, if you nd

that what you need is outside of the adjustment range, you will need

to make a master cylinder bore size change. There are three possible

changes that can be made (See below). All will allow the spherical joint to

move back towards the center position.

a) Decrease the bore size of the master cylinder closest to the

spherical joint by 1/8". This will decrease the amount of pedal force

required from the foot and increase the amount of pedal travel.

b) Increase the bore size of the master cylinder farthest from the

spherical joint by 1/8". This will increase the amount of pedal force

required by the foot and decrease the amount of pedal travel.

c) Increase the bore size of the master cylinder farthest from the

spherical joint by 1/16". Decrease the other master cylinder bore

size by 1/16". This will maintain the amount of force and pedal

travel while making a relatively large change to the front/rear

brake bias.

4. Whenever making an adjustment, remember to tighten the jam-nut (Item

3 in Diagram 10) afterwards. A jam-nut is not required when a Remote

Brake Bias Adjuster is used.

Diagram 7

Diagram 8

Diagram 9

Spherical Joint Position Left Clevis Right Clevis

3/8" left-of-center 64.3% 35.7%

1/4" left-of-center 59.5% 40.5%

1/8" left-of-center 54.8% 45.2%

Centered 50.0% 50.0%

1/8" right-of-center 45.2% 54.8%

1/4" right-of-center 40.5% 59.5%

3/8" right-of-center 35.7% 64.3%

Force Distribution (2.62" Clevis Center-to-Center)

Tilton Engineering, Inc. 25 Easy Street • PO Box 1787 • Buellton, CA 93427 • www.tiltonracing.com

Diagram 10

7

5

6

8

1. Clevis 4. Retaining Ring Clips 7. Pushrod

2. Barrel Nuts 5. Pivot Sleeve 8. Adjusting Shaft

3. Jam-nuts 6. Spherical Bearing 9. Jam-nuts (Pushrod)

9

4

1

Center

2

3

Adjustment

Loading...

Loading...