Tilton Floor-Mount User Manual

INSTALLATION INSTRUCTIONS

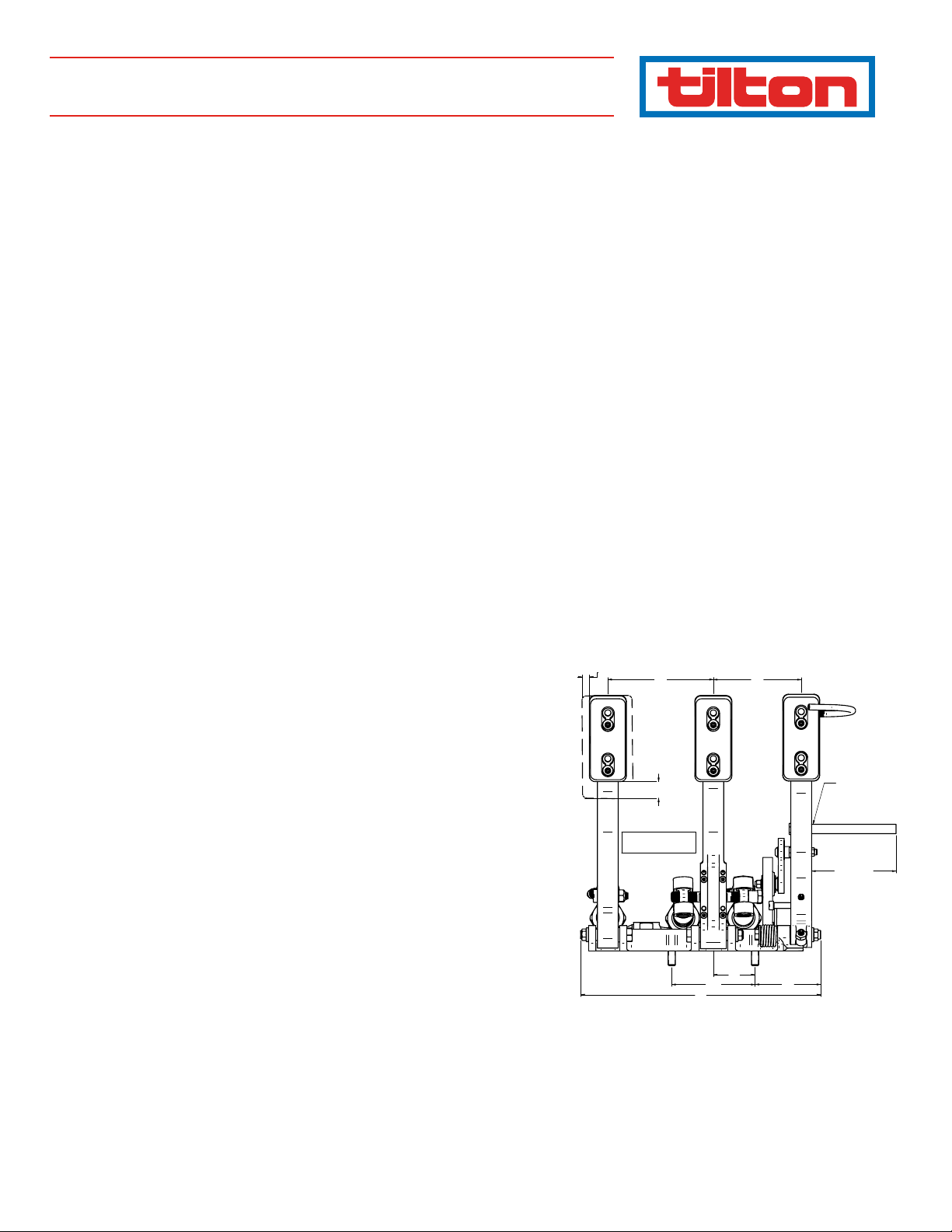

900 Series Floor-mount 3 Pedal Assembly

Description

Minimizing friction and ex in the pedal assembly and the master cylinders maximizes driver

control. The Tilton oor mount pedal assembly with forward mounted pivot type master

cylinders eectively handles these critical issues. In addition this assembly is highly adjust-

able for dierent drivers and tracks, easy to install and maintain, and does all of this in a very

lightweight package.

Master cylinDer & peDal asseMbly installation

1. A pedal assembly can only be as rigid as its mounting system in the car.

Flex in the supporting structure reduces braking control as much as air in the lines. See the

drawing on page 4 for the mounting bolt pattern. Multiple holes in two tubes running fore/aft

in the car can allow multiple mounting positions.

2. Select the brake pedal pivot position (high or low motion ratio).

The overall pedal ratio is dependent on the pivot position combined with the foot pad

position, and the ratios are marked on the brake pedal. Tighten the four fasteners to

46 in-lbs using a 3mm hex wrench.

3. The balance bar clevises are of two dierent lengths; The longer clevis is to be used with

the master cylinder for the front brake system and should stay on the right-hand side of

the brake pedal. This conguration ensures the best remote adjuster cable clearance to

the throttle pedal.

4. Set the center-to-center distance on the two balance bar clevises at 2.60". A good place to

start is with both clevises equally spaced from the pedal (middle balance bar position).

5. Remove the long bolt that mounts the three master cylinders. Remove the four master

cylinder spacers from the frame.

6. Reinstall the two center master cylinder spacers in the frame. A small amount of RTV will

keep the spacers in place during assembly.

7. Install the master cylinders. It is best to install the master cylinders on the pedal assembly

before placing the assembly in the car. Reinstall the mounting bolt through the three

master cylinders, and tighten the nut to 120 in-lbs.

8. Thread the three pushrods into the clevises .710" (about seventeen (17) revolutions).

This will position the pedals as shown in the drawings. Final pedal position adjustment

will be made later.

9. Since the brake pushrods are threaded equal amounts and the clevises have two dierent

lengths, the balance bar will be at a 5˚ angle. This is by design and will be addressed in the

Pedal Positioning section.

10. Mount the pedal assembly into the car. Be sure to use high quality 5/16" or 8mm Allen

head bolts of the appropriate length with a supplied AN washer under the head of each

bolt.

Note: For clearance reasons, Allen mounting bolts must be installed with the

head recessed in the counterbore of the frame. Do not be tempted to use

a large OD washer and a hex bolt that will not sit in the counterbore of the

frame, as interference to critical moving parts will occur.

FOOT PAD SID E ADJUSTM ENT: THREE PO SITIONS, .290 INCREMENTS

4.56

ALL 3 PEDALS, .75 0 TOTAL

FOOT PAD HEIGHT ADJUSTMENT

FOUR POSITIONS, .250 INCREMENTS

BILLET AL UMINUM PEDALS ARE

OPTIMIZED FO R STRENGTH,

WEIGH T AND STIFFNESS

1.80

3.600

10.4

98 -12 0 7

3.80

THROTT LE CABLE STANDOFF

FOR REAR E NGINE CAR S.

UNFIN ISHED END C AN BE MODIFIED

BY CUSTOME R TO ACCEPT A

VARIETY OF C ABLE AT TACHMENTS

CUT TO LENGT H

3.65

AS SUPPL IED

2.84

peDal positioning

1. With the system properly bled, and the brake pedal depressed, the straight portion of

the brake pedal beam should be close to square with the master cylinder pushrods as

viewed from the side. To achieve this, adjust the brake pedal height by threading both

brake master cylinder pushrods in or out of the clevises equal amounts. Keep at least

.300" of pushrod threaded into the clevises. With the pedal depressed, check the driver’s

reach. The driver must not be stretching toes to reach the depressed pedal, and the knee

must be slightly bent. Open a bleeder screw and conrm that the driver can fully stroke

the brake pedal in event of uid boiling, or a brake line failure. Move the entire assembly

in the car if a coarse adjustment is necessary. Small adjustments in pedal position may

be made by threading the pushrods in or out of the clevises. Tighten the two pushrod

locknuts once the proper pedal position is achieved. The pushrod has two ats to accept

a 5/16" wrench.

2. The front master cylinder will require more stroke to operate than the rear once the sys-

tem has been bled. After bleeding, check to make sure the balance bar is parallel with the

rewall when the brakes have been applied with the normal wheel locking force. If not,

loosen the locknuts, readjust, and retighten the locknuts.

3. Thread the clutch master cylinder pushrod in or out until the desired pedal height is

achieved relative to the brake pedal. Keep at least .300" of pushrod threaded into the

clevis. Tighten the pushrod locking nut.

4. If your hydraulic release bearing requires the use of a positive stop, a stop threading into

the frame and a locking nut have been provided. See your hydraulic release bearing

instructions for adjusting the pedal stop.

5. Set the throttle return stop according to driver preference. If you are unsure, a good start-

ing point for the throttle is to have it even with the depressed brake pedal. This allows

a driver who is completing his braking maneuver with the right foot to quickly change

back to the throttle.

6. For rear/mid engine cars, modify the throttle cable stando on the right side of the

throttle pedal to accept your particular cable or linkage. For front engine cars, bell crank

P/N 72-791 is useful.

7. Set the throttle depressed stop so that the engine’s throttle is fully open without strain-

ing the cable or linkage. If an alternate amount of throttle pedal throw or progression is

desired, a wide variety of mounting holes on the pedal and P/N 72-791 can be selected.

8. The toe clip allows the driver to pull closed a throttle that would otherwise be stuck in the

open position. It also provides a rest to keep the driver’s foot well supported with high

lateral loading. It can be re-bent as desired, rotated up or down, and moved left and right

via the threaded portion. Position it so that it does not interfere with normal pedal use,

yet can be easily reached should the need arise.

9. The footpad positions can be adjusted left and right in three .29" increments. The foot-

pad position can be adjusted vertically in four .25" increments. The vertical bolt pattern

is oset, so, turning the pedal pad over allows four positions with only 2 bolt patterns.

Always use both mounting screws per pad and a removable thread locking compound.

5 THROT TLE

STANDOFF OR

BELLCRANK LINKAGE

MOUNTING POSITI ONS

2 POSITION

ADJUS TABLE

PEDAL RATIO.

ADJUSTABLE

THROTT LE

PEDAL RETU RN STOP

OPTION AL BELL-CRANK THROTTLE

LINKAGE ASSEM BLY P/N 72-79 0

FOR FRON T ENGINE CA RS.

FULLY ADJUS TABLE FOR T OTAL THROW

AND PR OGRESSION

77 SERI ES MASTER CY LINDER

SOLD SEPARATELY

5/8" TO 1" B ORE AVAIL ABLE

ADJUSTABLE THROTT LE

PEDAL STOP

Loading...

Loading...