Page 1

INSTALLATION INSTRUCTIONS

9000-Series Hydraulic Release Bearing

DESCRIPTION

Tilton's 9000 series hydraulic release bearing is a compact assembly that is adaptable for

many dierent applications. The bearing is self-adjusting for clutch wear maintaining "near

zero" clearance at all times. There is no extra return spring that pulls the piston back to the

bottomed position. In this respect, the piston works like the piston in a disc brake caliper,

returning only as far as forced. This is why with a Tilton hydraulic release bearing assembly

the clutch pedal feel does not change with clutch wear allowing the driver to make more

consistent shifts.

Note: The ports are -3AN that can accept straight or banjo ttings with

either a tapered seat or crush washer.

Note: If you need to take any measurements for clearance purposes fully

compress the piston. It is now partially extended.

INSTALLATION

There are a few dierent ways that the assembly can be mounted depending on the

particular part number and application. It is important to know that both ports are identi-

cal. It does not matter which port you use for the bleed port or the ll port. Position the

assembly in one of the two positions shown in Proper Bleed Port diagram to set up proper

bleed orientation.

1. In many applications the assembly and adapter bolt in place of the existing pilot tube

or in place of the original hydraulic release bearing.

2. For custom applications where you will make your own adapter see Figure 1 for the

mounting conguration. The two holes in the base are sized for both 1/4" and 6 mm

fasteners. You will want to locate (center) the assembly using the inner diameter of the

base. If there is an existing pilot tube it must be removed or trimmed to below the top

of the hydraulic release bearing base. Make sure that the adapter allows the HRB to be

installed in one of the two positions shown in the Proper Bleed Port diagram for cor-

rect bleed port set up.

If you are installing this assembly into a known application where the bearing clearance

and mounting conguration have already been determined proceed to the Hydraulic

Lines section.

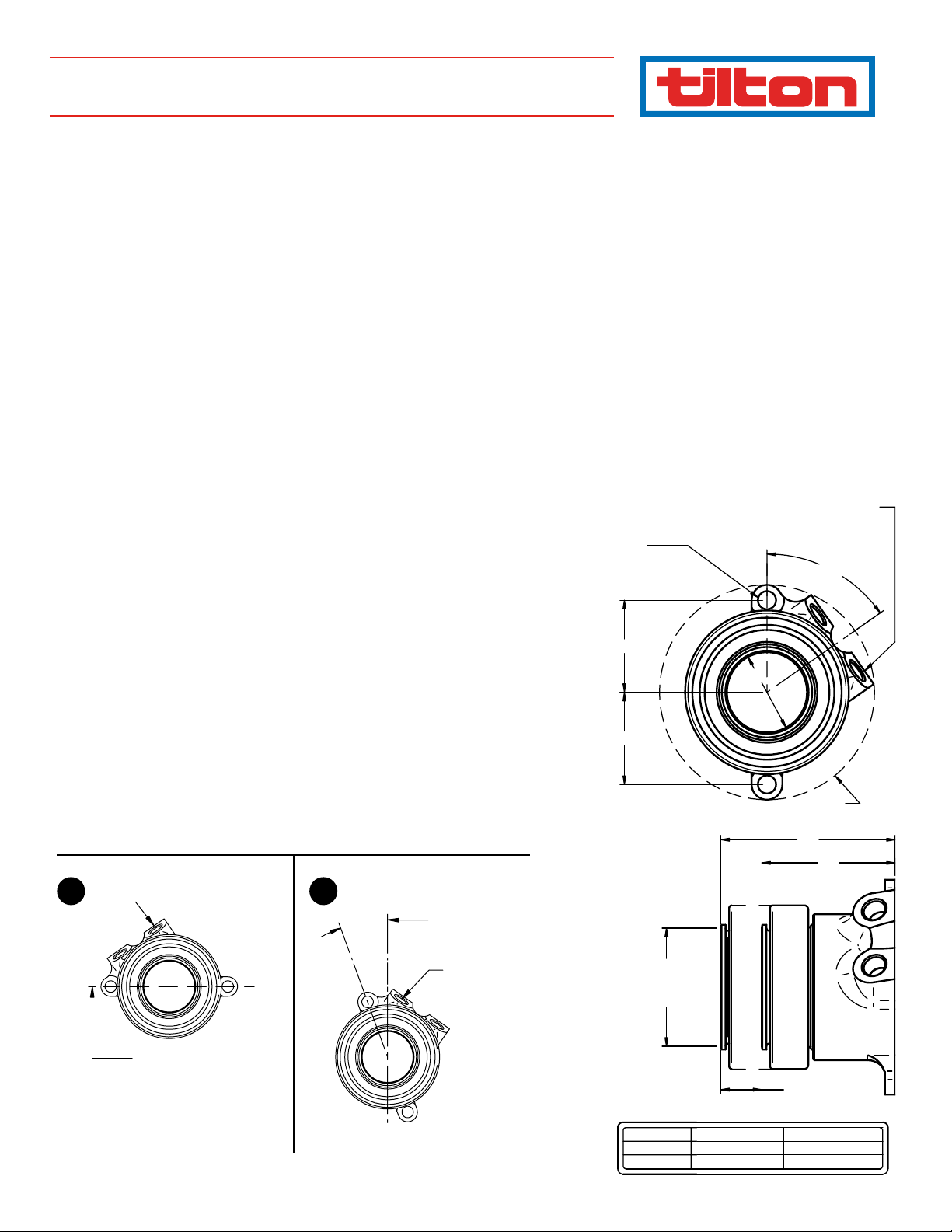

PROPER BLEED PORT SET UP.

Position in one of two orientations for proper bleed port set up.

O

.266

ACCEPTS 1/4 AND

6mm FASTENERS

1.35

1.35

98 -1121

Figure 1

AN-3 PORT, 3/8-24 UNF THREADS.

PORTS WILL ALLOW STRAIGHT AND

BANJO FITTINGS. 2 PL.

55°

O 1.175

O 3.15

B

A

BLEED PORT

BOLT HOLE

±5

°

FROM

HORIZONTAL.

2.1.

20° ±5°

FROM VERTICAL

BLEED PORT

CONTACT

DIAMETER

1.73 (44mm)

PART NUMBER

61-9002

61-9012

SET UP HEIGHT "A"

1.95 2.55

2.02 2.67

.600

MAX. STROKE

EXTENDED HEIGHT "B"

Page 2

MEASURING BEARING CLEARANCE

For new applications with unknown clearance

1. Install the ywheel and new clutch assembly as explained in their instructions. Worn friction

discs will generate false readings.

2. Press with a rm and even force to make sure that the piston in the hydraulic release bearing

is fully retracted.

3. Measure the distance "A" as shown in Figure 2. This is the distance from the engine/trans-

mission housing interface to the top of the hydraulic release bearing with the piston fully

retracted.

4. Measure the distance "B" shown in Figure 3. This is the distance from the engine/transmis-

sion housing interface to tips of the spring ngers on the clutch.

5. C=A-B. This is your bearing clearance. It should be in the range of .170 to .230" for Tilton 5.5"

and 7.25" clutches and .150" to .230" for The Tilton 4.5" clutch. This will allow the full wear

range of the clutch. If the clearance is outside of this range you will need to modify the posi-

tion of the hydraulic release bearing assembly.

HYDRAULIC LINES

Some assemblies include hydraulic lines. Cut braided line to length and attach ttings.

1. The ports are -3AN (3/8-24). Depending on the assembly part number the ttings could be

-3AN male or -3AN banjo style. The male ttings are made to seal on the taper and not the

threads. Do not use pipe tape or other sealants on any of the ttings.

2. The port coming out of the top must be connected to the bleed line. Route the bleed line

outside of the housing for easy access.

3. The other port connects to the master cylinder.

4. Route both lines clear of heat sources such as the exhaust system. Also make sure that the

lines will stay clear of the clutch and y wheel.

MASTER CYLINDER SELEC TION AND PRIMING

1. The 9000 Series is intended to be used with a 5/8" master cylinder and a Tilton 7.25" Clutch.

A 7/10" master cylinder can also be used. It will take a greater force at the pedal and require

less stroke to release the clutch.

2. Fill the master cylinder with a DOT 3 or Dot 4 compatible uid. DOT 5 (silicone-based. uids

are not compatible with the seals. Special high temperature uids are not required and usu-

ally shorten the seal life.

3. Have a port or bleed tting open at the master cylinder and depress the pedal.

4. Close the master cylinder port and bleed screw and let the pedal return.

5. Repeat steps 3 and 4 until the emerging uid is free of air.

HYDRAULIC RELEASE BEARING BLEEDING

1. Fill the master cylinder reservoir with DOT 3 or DOT 4 compatible uid.

2. Open the bleed screw for the hydraulic release bearing.

3. Take the clutch pedal to full stroke.

4. Close the bleed screw after uid stops owing out.

5. Let the pedal return to its natural position and leave it there for at least 3 seconds.

6. Repeat steps 3 through 5 until the emerging uid is free of air.

7. Do not stoke the pedal again until the pedal positive stop has been set.

Figure 2

"A"

Distance from spring ngers to housing mounting

Figure 3

"C"

Distance from engine mounting surface to top of bearing

"B"

Page 3

CLUTCH PEDAL STOP

A positive clutch pedal stop must be used to prevent over-stroking the hydraulic release bearing

piston and the clutch. For access reasons, in many cars it is not easy to determine how far the

master cylinder is being stroked.

The method listed below provides a very eective method for adjusting the pedal stop:

1. Lift the drive wheels o the ground and support the car on jack stands.

2. With the engine o, place the gearbox in rst gear and have someone attempt to rotate the

drive wheels.

3. Depress the clutch pedal slowly until the clutch disengages and the drive wheels can be

rotated.

4. Adjust pedal stop to allow another 1/4" of pedal travel. This should provide clean release of

the clutch. Do not stroke the pedal any further than this point throughout this procedure,

otherwise you will over-stroke the clutch.

MAINTENANCE

A few basic procedures will help to ensure that your hydraulic release assembly will provide a long

and dependable life.

1. Spin the bearing race and check how it feels. If it has a higher than normal resistance or feels

rough, replace the bearing.

2. The piston can be removed and replaced without breaking the hydraulic seal or requiring

bleeding. Periodically, remove the piston and check for any scores in the bore or on the piston

surface. Wipe the piston and orange dust wiper seal before reinstalling. You may nd that the

piston is not dry. This could be the rubber grease used when installing the new seal. Do not

mistake this for brake uid.

3. If the seal needs replacing, order Tilton’s replacement seal kit (P/N 62-905). Instructions and

the correct installation grease are included in the kit. We also recommend the use of a seal

installation tool (P/N 96-002) to prevent damaging the seal during installation.

SERVICE INFORMATION

1. Contact Tilton’s Repair Department (805-688-2353) and describe the problem or the service

that is required.

2. If the bearing assembly needs to be sent in, a Returned Merchandise Authorization (RMA)

number is required and will be provided by a Tilton representative.

3. Write the RMA number on the outside of the package and ship to:

Tilton Engineering

25 Easy Street

Buellton CA 93427

Adjustable

Pedal stop

FIREWALL

Figure 3

Pedal position wher e

pedal stop shoul d be set.

Never travel clutch

pedal past thi s point!

Pedal position wher e

clutch breaks fre e.

1/4" additional travel

(exaggerated for clarity)

Tilton Engineering, Inc. 25 Easy Street • PO Box 1787 • Buellton, CA 93427 • www.tiltonracing.com

Loading...

Loading...