Page 1

INSTALLATION INSTRUCTIONS

700-Series Hydraulic Release Bearing (Acura/Honda)

Tilton's Acura/Honda hydraulic release bearing assembly installs easily into any late model

(92'-on) hydraulic transmission when converting to a Tilton 2-plate 7.25" Carbon/Carbon or

Cerametallic clutch. Carbon/Carbon clutches use assembly 61-772 and Cerametallic clutches

use assembly 61-777. These assemblies eliminate the stock mechanical release bearing link-

age, slave cylinder, and all of its components. The Tilton hydraulic release bearing is ideal

for racing and high performance use. Our release bearing components are machined out of

billet aluminum, which results in a higher strength and lighter weight design. Each hydraulic

assembly comes complete with hydraulic lines and ttings.

The hydraulic release bearing assembly is self-adjusting in that the bearing stays close to the

clutch spring at all times even though the spring changes position with clutch wear. There is

no extra return spring that pulls the piston back all the way to the bottomed position. In this

respect, the piston in the hydraulic bearing assembly works like the piston in a disc brake

caliper, returning only as far as forced. This is why with a Tilton Hydraulic Release Bearing

assembly the clutch pedal feel does not change with clutch wear allowing the driver to make

more consistent shifts.

INSTALLATION

1. Remove the original equipment (OE) from the front of the gearbox, including the release

fork, release fork pivot, and slave cylinder.

2. Apply a small amount of grease to the pilot nose to allow the o-ring located in the inter-

nal bore to slide on easily.

3. Install the Tilton bearing assembly onto the front of the gearbox so that both hydraulic

lines can be routed out the existing clutch release fork hole in the gearbox.

4. Insure that the assembly is seated ush with the bottom of the pilot tube.

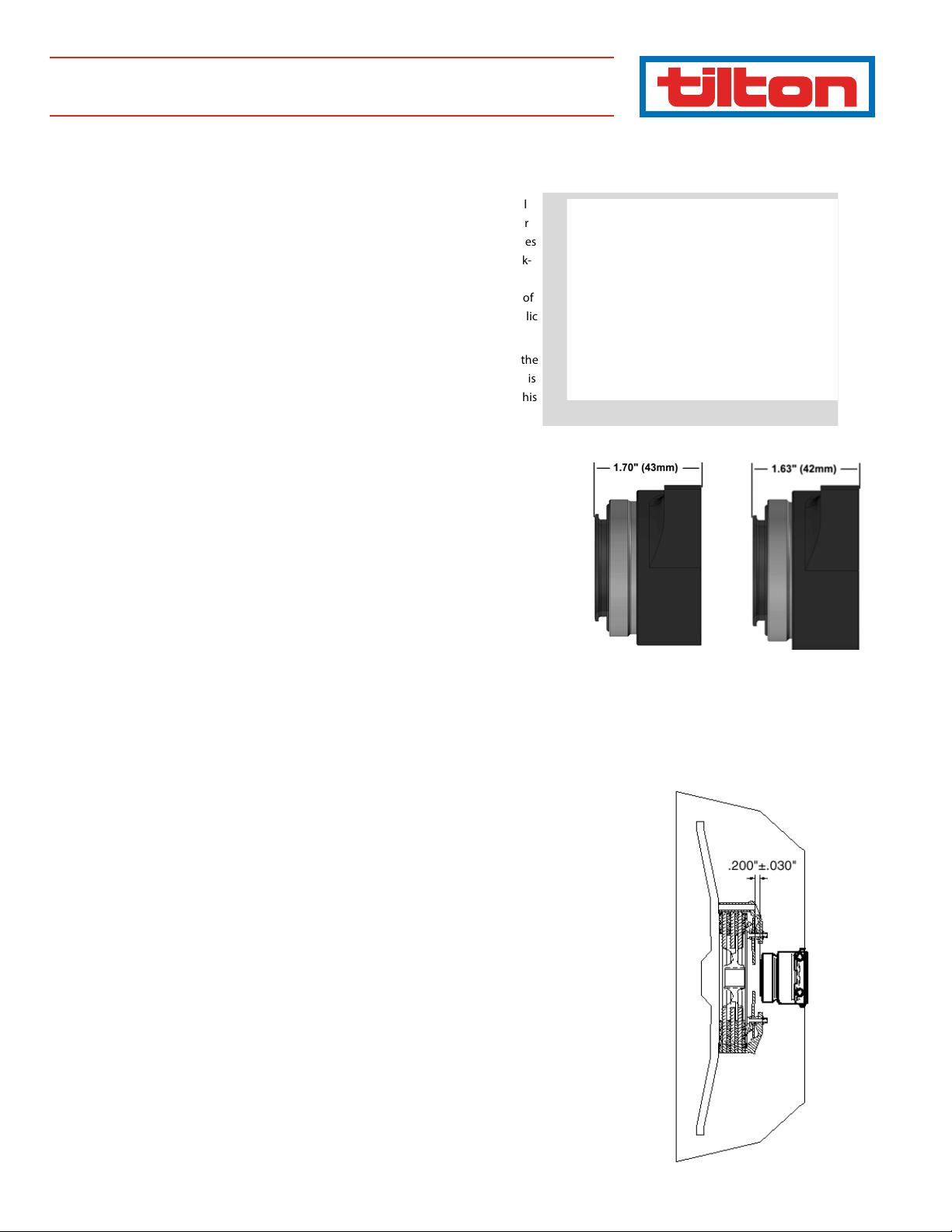

5. The heights of the installed assemblies are 1.63" for P/N 61-772 and 1.70" for P/N 61-777

when the piston is fully retracted as seen in Diagram 1. These heights are measured from

the bearing face to the ange mounting surface.

Note: The mounting surface is not the lower-most surface on the Honda

HRB's, it is the smaller ring recessed .100" from the bottom.

6. Please verify that there is approximately .200" clearance between the bearing face and

the clutch diaphragm spring upon installation, as seen in Diagram 1.

Note: Compression of the bearing piston into the bearing base, prior to

installation, to seat the seal may be required to achieve the set-up height

dimension.

7. A pedal stop must be installed on the clutch pedal to prevent over stroking the hydraulic

release bearing and damaging the clutch (see Pedal Stop section).

HYDRAULIC LINE INSTALLATION

Note: Fittings supplied in kit are -3AN 90˚ banjo ttings. It is important that

the crush washers used with the banjo ttings are replaced if the banjo ttings are removed from this hydraulic base. DO NOT use PTFE tape or thread

sealer. The single hydraulic line included in the kit is to be used to make both

the supply line and bleed lines.

61-772

(2-Plate Cerametallic)

98 -1115

61-777

(2-Plate Carbon)

Diagram 1

Page 2

SUPPLY LINE ASSEMBLY

1. Assemble one of the banjo ttings with the supplied crush washers and banjo bolt

loosely onto the supply port of the hydraulic assembly (see Diagram 2).

Note: a crush washer needs to be placed on either side of the banjo tting

for proper installation.

2. Trial t the line in place and determine the length required for the supply line to reach

the master cylinder. Route the supply line clear of any obstructions to prevent damage

and away from heat sources to prevent pedal fade.

3. Cut braided line to length and attach ttings.

4. Leave the banjo tting loose for the supply line at this time.

BLEE D LINE A SSEM BLY

1. Assemble the second banjo tting with crush washers and banjo bolt and loosely place

the tting into the bleed port.

2. Trial t the remainder of the line, selecting a location for the bleed tting that is outside

of the transmission housing.

3. Thread the supplied bleed screw into the newly attached tting on the bleed line.

FINAL A SSEM BLY REFER TO DIAGRAM 3

1. With supply and bleed line assembled, clock banjo ttings inward, toward each other

leaving a small gap in between.

2. Tighten banjo ttings.

DRIVELINE ASSEMBLY

1. While installing the transmission, carefully route both lines through the release fork

window.

2. Once the transmission is seated, conrm that all parts of the release bearing and hydrau-

lic lines clear the clutch and ywheel.

3. Complete the driveline installation.

MASTER CYLINDER SELECTION

The recommended master cylinder bore diameter for use with this hydraulic release bear-

ing assembly and a 7.25" clutch is 3/4". If you are using the OEM clutch master cylinder,

please check the bore diameter.

MASTER CYLINDER PRIMING

1. Fill the master cylinder with brake uid. Use a DOT 3, DOT 4 or other non-silicone based

uid. Avoid DOT 5 (silicone based) uids since they are not compatible with the seals.

2. Open the bleed tting (if equipped) at the master cylinder while the line port is closed.

3. Gently depress the clutch pedal, close the bleed screw and release the clutch pedal.

4. Repeat Steps 1 and 2 until uid free of air bubbles emerges.

Do not stroke a Tilton master cylinder more than 1".

HYDRAULIC RELEASE BEARING BLEEDING

1. Fill the master cylinder reservoir with DOT 3 or DOT 4 brake uid.

2. Apply approximately 3 lbs of force on the clutch pedal. You want enough force to hold

the bearing out against the clutch diaphragm spring, but not enough to actually move

the spring.

3. Open the bleed screw that is attached to the bleed line on the hydraulic release bearing.

4. Completely stroke the pedal.

5. Close the bleed screw.

6. Let the pedal return to its relaxed position and wait a few seconds.

7. Repeat Steps 2 through 6 while keeping an eye on the uid level until all air is removed

from the system.

Note: You do not want to stroke the clutch during the bleeding process.

All you are trying to do at this point is get all of the air out of the system.

Do not stroke the clutch until the pedal stop is set!

Upper Port

(Bleed Line)

Diagram 2

Lower Port

(Supply Line)

Diagram 3

Crush Washer

Banjo Fitting

Crush Washer

Banjo Bolt

-3AN Line

Page 3

CLUTCH PEDAL STOP

A positive clutch pedal stop must be used to prevent over-stroking the

hydraulic release bearing piston and the clutch. For access reasons, in

many cars it is not easy to determine how far the master cylinder is being

stroked.

The method listed below provides a very eective method for adjusting

the pedal stop:

1. Lift the drive wheels o the ground and support the car on jack

stands.

2. With the engine o, place the gearbox in rst gear and have someone

attempt to rotate the drive wheels.

3. Depress the clutch pedal slowly until the clutch disengages and the

drive wheels can be rotated.

4. Adjust pedal stop to allow another 1/4" of pedal travel. This should

provide clean release of the clutch. Do not stroke the pedal any

further than this point throughout this procedure, otherwise you will

over-stroke the clutch.

MAINTENANCE

A few basic procedures will help to ensure that your hydraulic release

assembly will provide a long and dependable life.

1. Spin the bearing race and check how it feels. If it has a higher than

normal resistance or feels rough, replace the bearing.

2. The piston can be removed and replaced without breaking the

hydraulic seal or requiring bleeding. Periodically, remove the piston

and check for any scores in the bore or on the piston surface. Wipe

the piston and orange dust wiper seal before reinstalling. You may

nd that the piston is not dry. This could be the rubber grease used

when installing the new seal. Do not mistake this for brake uid.

3. If the seal needs replacing, order Tilton’s replacement seal kit (P/N

62-905). Instructions and the correct installation grease are included

in the kit. We also recommend the use of a seal installation tool (P/N

96-002) to prevent damaging the seal during installation.

SERVICE INFORMATION

1. Contact Tilton’s Repair Department (805-688-2353) and describe the

problem or the service that is required.

2. If the bearing assembly needs to be sent in, a Returned Merchandise

Authorization (RMA) number is required and will be provided by a

Tilton representative.

3. Write the RMA number on the outside of the package and ship to:

Tilton Engineering

25 Easy Street

Buellton CA 93427 hydraulic seal. Inspect the piston and

hydraulic assembly bore for scratches. To remove the hydraulic seal

from the release bearing assembly block one hydraulic port and

apply 5 PSI of air pressure to the other port. Wear safety glasses and

point the seal exit path away from you! Never try to pry the seal out

of the assembly. Refer to Diagram 7 when installing the new seals and

ensure that the at side of the main hydraulic seal rides against the

piston. Always use rubber grease, such as Tilton part number RG-17,

when installing the seal. Take care not to damage the seals during

installation.

FIREWALL

Adjustable

Pedal stop

Diagram 4

Pedal position where

pedal stop should be set.

Never travel clutch

pedal past this point!

Pedal position where

clutch breaks free.

1/4" additional travel

(exaggerated for clarity)

Diagram 5

Bearing

Piston

Main Seal

(Black)

Bearing

Base

Page 4

ECN

21

2.20

ENGINEERING INC. is strictly forbidden."

disclosure, or use without specific written authorization of TILTON

manufacture, use or sell anything it may describe. Reproduction,

convey the rights to reproduce, disclose its contents, or to

ENGINEERING, INC., and its receipt or possesion does not

R

"This document contains proprietary information of TILTON

4972

DWG

FAX 805/688-2745

2.25O

3/8-24 UNF

ACCEPTS BANJO (INCLUDED)

OR STRAIGHT FITTINGS.

2 PL.

1.70

1.94

1.80

.500

MAX STROKE

: 1

1

HONDA B/K SERIES, ULTRA SHORT

INSTALLATION DRAWING, HRB

CHAMBERS

1

1

SHEET OF

6/13/05

DATE

61-777

1.73O

ZONE CHKD DATE REV CHANGE OR ADDITION

44mm CONTACT DIAMETER

2.64

34

O 1.38

2.67

25 EASY STREET, P.O. BOX 1787, BUELLTON, CA 93427 805/688-2353

TITLE:

TILTON ENGINEERING, INC.

MAT'L

HARD

SPEC

COND

+.003/-.001

+.001/-.001

+.002/-.001

DRILL HOLES

.013-.040:

.041-.130:

TOLERANCES:

.020

.X ±

.010

.XX ±

.131-.229:

.005

1/32

.XXX ±

FRACT ±

UNLESS SPECIFIED OTHERWISE

P/N

DRAWN BY CHKD SCALE

SPEC

FINISH

+.004/-.001

+.005/-.001

+.007/-.001

.230-.500:

.501-.750:

.751-1.000:

1/2°

.005

(TIR)

ANGLE ±

CONC

NOTES:

D

C

B

A

Tilton Engineering, Inc. 25 Easy Street • PO Box 1787 • Buellton, CA 93427 • www.tiltonracing.com

1. DIMENSIONS IN INCHES EXCEPT WHERE NOTED.

2. MUST SET POSITIVE STOP ON CLUTCH PEDAL

PER INSTRUCTIONS.

Loading...

Loading...