Page 1

INSTALLATION INSTRUCTIONS

B

A

6000-Series Hydraulic Release Bearing

The hydraulic release bearing assembly is self-adjusting in that the bearing stays

close to the clutch spring at all times, even though the spring changes position with

clutch wear. There is no extra return spring that pulls the piston back all the way to

the bottomed position. In this respect, the piston in the hydraulic bearing assembly

works like the piston in a disc brake caliper, returning only as far as forced. This is

why with a Tilton hydraulic release bearing assembly the clutch pedal feel does not

change with clutch wear allowing the driver to make more consistent shifts.

The piston of this assembly has .700” of total stroke. Precision measurement of clear-

ances and the correct adjustment of the pedal stop are extremely important to the

correct function of this unit.

FREE PLAY AND HEIGHT ADJUSTMENT

1. Disconnect and remove any existing meachanical clutch linakge, fork and bearing.

2. Install the ywheel, clutch and bellhousing onto the engine. Tighten all com-

ponents in place following their respective manufacturer’s instructions. Do not

install the transmission at this time.

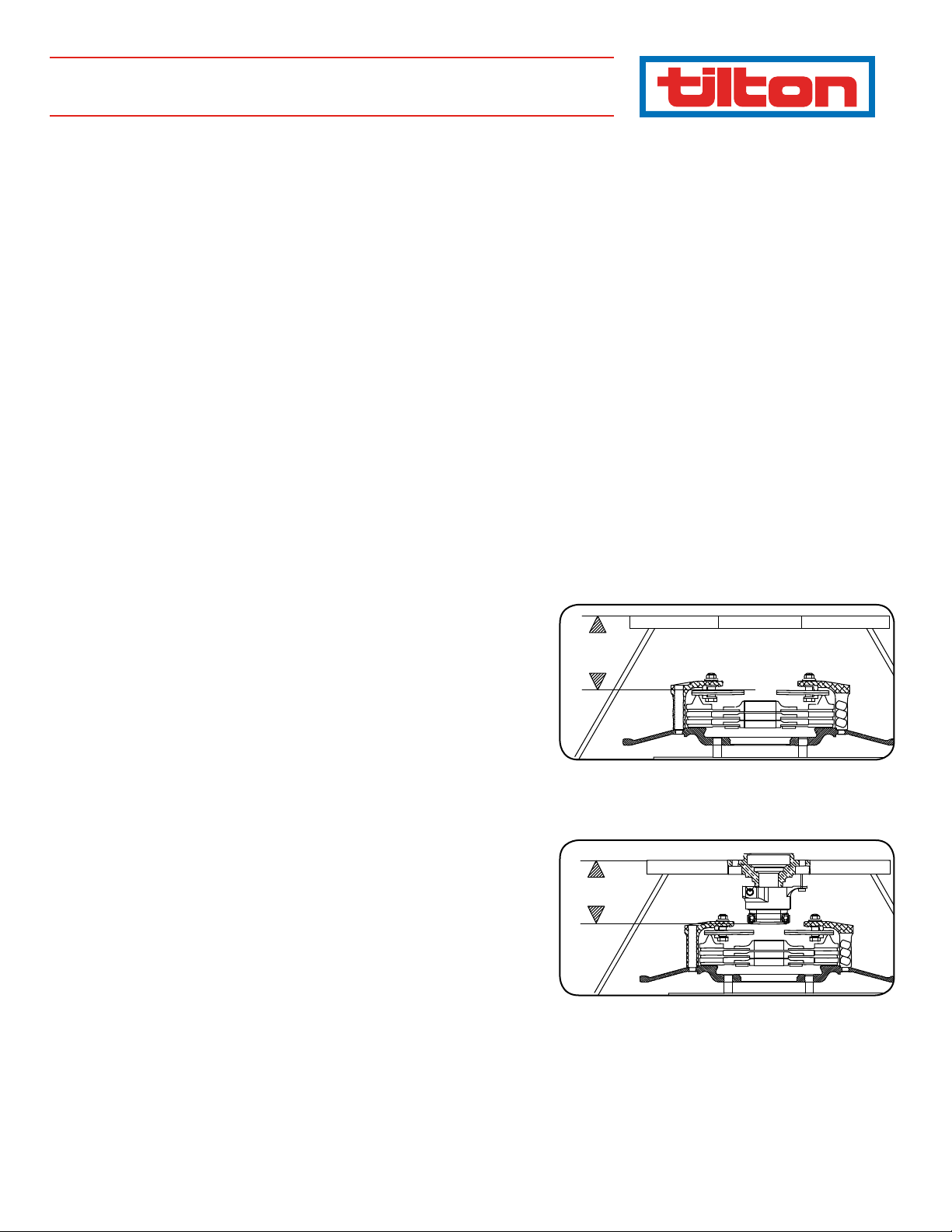

3. Using a pair of dial calipers or a depth micrometer, measure the distance from the

transmission face of the bellhousing to the bearing contact point of the clutch

spring. Record this distance as “Dimension A”. See Diagram 1.

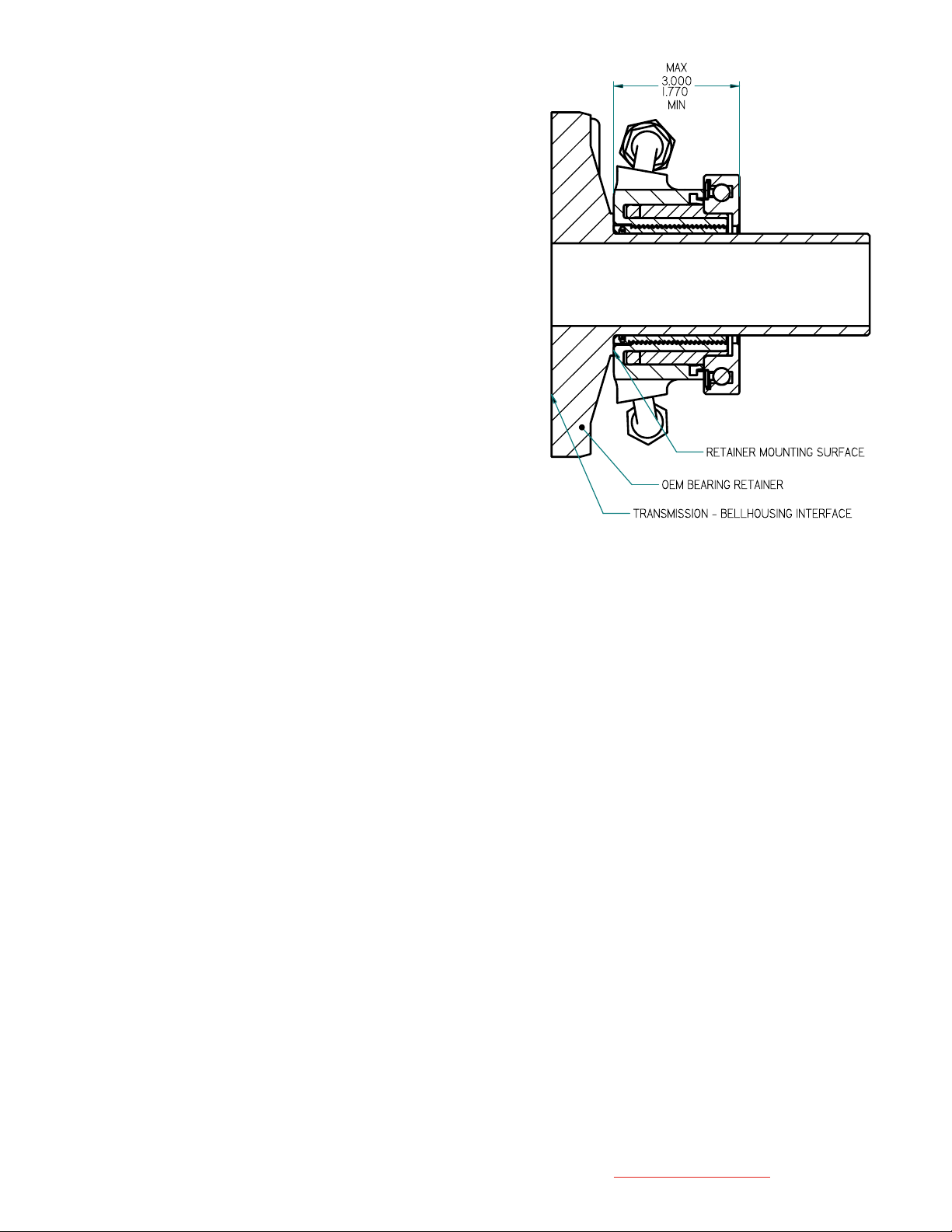

4. Subtract .125” from Dimension A. This should be the installed distance from the

face of the release bearing to the face of the transmission (with the bearing and

piston completely compressed into the hydraulic base). See “Dimension B” in

Diagram 2.

5. Install the supplied o-ring into the supplied threaded sleeve and push these onto

the bearing retainer on the front of your transmission. A small amount of petro-

leum jelly may be used during assembly. The o-ring end of the sleeve should be

towards the transmission.

6. Thread the bearing onto the threaded sleeve until Dimension B is achieved.

7. There is a small ear and slot machined into the hydraulic base. The supplied shoul-

der screw ts through this to provide anti-rotation. Once the correct installed

height has been achieved, locate and remove the transmission bearing retainer

bolt closest to the ear. Replace this bolt with the supplied Tilton retainer bolt

using Loctite 272 (red) thread locking compound. Torque to 16 foot-pounds. DO

NOT OVERTIGHTEN. Align the ear over the bolt and install the supplied shoulder

screw using thread locking compound. Ensure that the head of the screw does

not touch the bearing assembly.

8. The hydraulic lines supplied have been installed at the factory using the proper

tooling and assembly lubricant. They are designed to rotate once while installed.

There is no need to remove these prior to assembly.

9. Double check that the bearing to clutch clearance is .125” (tolerance +/-.025”).

DRIVELINE ASSEMBLY

1. While installing the transmission, carefully route both lines through either the

release fork window or holes that have been drilled to accommodate the lines.

2. Ensure that the lines do not interfere with the clutch or ywheel. A string may be

used to help guide the lines around any obstacles during installation.

3. Once the transmission is seated, conrm that all parts of the release bearing clear

the clutch and ywheel. Complete the driveline installation.

Diagram 1

Diagram 2

98 -1110

Distance from Spring Fingers to Bellhousing Face

Installed Distance

Page 2

MASTER CYLINDER SELECTION

Most 10.5” or 11.0” clutches will require a 7/8” bore master cylinder when used with this

hydraulic release bearing and a clutch pedal ration between 5:1 and 7:1.

HYDRAULIC LINES

This bearing is supplied with two identical lines installed for the supply and bleed ports.

Both lines are sized AN-4 and should only be used with AN type ttings. It is important

that whichever line is on the bottom is used as the supply line (connected to the master

cylinder) and whichever line is on top is used as the bleeder.

1. Attach the supply line to the master cylinder using your choice of rigid or exible line.

If using a Tilton master cylinder (which have AN-3 outlets) you will need a AN-3 male to

AN-4 male adapter (such as Earl’s part number 963243).

2. Attach the supplied bleed adapter and bleed tting to the bleed line.

HYDRAULIC RELEASE BEARING BLEEDING

1. Fill the master cylinder reservoir with DOT3 or DOT 4 brake uid. Do not use DOT 5,

silicone based or high temperature resistant brake uids designed for more than 550ºF

as some will cause the seals to swell.

2. Apply light force on the clutch pedal. You want enough force to hold the bearing out

against the clutch diaphragm spring, but not enough to compress the clutch dia-

phragm spring.

3. Open the bleedscrew that is attached to the bleed line on the hydraulic release bear-

ing.

4. Completely stroke the pedal and hold the pedal down.

5. Close the bleedscrew that is attached to the bleed line on the hydraulic release bearing.

6. Let the pedal return to its relaxed position and wait a few seconds.

Repeat Steps 2 through 6 until all air is removed from the system.

Note: Do not stroke the pedal again before the pedal stop is set.

SETTING THE CLUTCH PEDAL STOP

You MUST use a pedal stop to limit the amount of bearing travel. Failure to do this WILL

result in clutch, bearing and/or transmission damage!

1. Lift the drive wheels o the ground and support the car on jackstands.

2. With the engine o, put the transmission into 1st gear and have someone attempt to

rotate the drive wheels.

3. Depress the clutch pedal slowly until the clutch disengages and the drive wheel can be

rotated. Do not push it any further.

4. Note the clutch pedal position at this point. Adjust the pedal stop bolt to allow an ad-

ditional 1/4” of pedal travel.

MAINTENANCE

Spin the bearing race and check how it feels. If it has a higher than normal resistance or has

a slightly notchy feel, replace the bearing. The replacement bearing is Tilton part number

62-618.

The piston can be removed and replaced without having to break the hydraulic seal or per-

forming the bleeding procedure. Remove the piston assembly and check for any scoring in

the bore or on the piston surface. Wipe the piston and orange wiper seal before installing.

You may nd that the piston is not dry. This could be the rubber grease used when install-

ing the new seal at the factory. Do not mistake this for brake uid.

If the seal needs to be replaced, the seal replacement kit is Tilton part number 62-905.

Remove the piston assembly to access the hydraulic seal. Inspect the piston and hydraulic

assembly bore for scratches. To remove the hydraulic seal from the release bearing assem-

bly, block one hydraulic port and apply 5 PSI of air pressure to the other port. Wear safety

glasses and point the seal exit path away from you! Never try to pry the seal out of the

assembly. Refer to Diagram 4 when installing the new seals and ensure that the at side of

the main hydraulic seal rides against the piston. Always use rubber grease, such as Tilton

P/N RG-17, when installing the seal. Take care not to damage the seals during installation.

Tilton Engineering, Inc. 25 Easy Street • PO Box 1787 • Buellton, CA 93427 • www.tiltonracing.com

Loading...

Loading...