Tilia Maxi 80 - 200, CTC Maxi 80, CTC Maxi 100, CTC Maxi 120, CTC Maxi 140 Installation, Operating And Maintenance Instructions

...

161 505 07 02-01

Maxi 80 - 200

CAST-IRON BOILERS

TECHNICAL MANUAL

Installation, operating and maintenance instructions

EKSKLUZIVNI UVOZNIK IN ZASTOPNIK:

TILIA d.o.o., Lju bljanska c est a 89, 8000 Nov o m esto;

tel : 07/ 3324 442; fax: 07/ 3323 209; e-mail: info@ti li a.si; www.t ilia.si

A TTENTION!

The boilers in this series must keep

within the limits they are designed

for.

Any other use is to be considered

as improper and consequently

dangerous.

This limits are indicated on the

manufacturer´s data decal.

- Boiler type.

- Serial number.

- Max boiler power.

- Max boiler pressure.

- Max working temperature.

- Supply voltage.

• This manual is an integral and

esential part of delivery of the

boiler and must be given to the

User.

• If the boiler is transferred or sold

to other Users (change of destination or relocation)make sure that

the Installation, Operating and

Maintenance Manual is also

transferred so that it can be

consulted by the installer, the

maintenance technician and by

the new owner.

• Read the warnings and

procedures with care before

installing, filling or starting-up the

system and and before any

maintenance. The manual gives

important information regarding

system safety and protction of

DEFINITIONS

The terms A TTENTION, WARNING

and NOTE have been used when

draving up the manual to underling

instructions or information

that are considered to be critical

or unusual.

The conditions that dictate use of

these terms are defined as follows:

A TTENTION!

Information or procedures which

can cause danger situations if they

are not complied with.

WARNING

Information or procedures which can

cause damage to the machine or to its

components if they are not complied

with.

NOTE

Information or procedures which can

simplify or facilitate maintenance

procedures or important parts of the

text that need to be emphasised.

WARNINGS or REQUIREMENTS

This installation, Operating and

Maintenance manual is applicable for

all series

CTC Maxi cast-iron boilers designed to produce hot water (at temperatures below the boiling point and

atmospheric pressure) in central

heating systems.

Their operating pressure are up to 5

bar (test pressure: 7.5 bar).

Thermal power ranges go from 80 kW

to 200 kW.

1

persons.

• Installation must be done in

accordance with Current Law,

following the instructions given in

this manual.

Installation must be performed by

professionally qualified and

certified persons.

• Never permit the appliance to be

used or operated by inexpert

persons.

Erroneous installation or inadequate use and maintenance

of the boiler can cause harm to

persons or property for which the

manufacturer declines all

responsibility.

DEFINITIONS................................................1

1 TECHNICAL DATA

1.1 General characteristics..................................................4

1.2 Delivery contents............................................................ 4

1.3 Dimensions......................................................................5

1.4 T echnical data................................................................. 6

2 ASSEMBLY

2.1 Boiler assembly .............................................................. 7

2.2 Burner installation........................................................... 7

2.3 Insulation and shell installation...................................... 8,9

3 INST ALLA TION

3.1 Plumbing system............................................................ 10

3.2 Pipeline system standards............................................ 11

3.3 Heating water delivery and return pipelines................ 11

3.4 Safety , control and adjustment devices........................11

3.5 Water characteristics..................................................... 11

3.6 Electrical connections, system......................................12

3.7 Wiring diagram............................................................... 13

3.8 Heating plant................................................................... 14

3.9 Connection to the smokestack..................................... 14,15

4 OPERA TION

4.1 Control panel...................................................................16

5 SYSTEM START-UP, OPERATION

AND MAINTENANCE

5.1 Filling the heating system.............................................. 17

5.2 First start-up and preliminary checks........................... 17

5.3 Data for checking combustion...................................... 18

5.4 General boiler operating regulations............................18

5.5 Safety regulations and periodic checks.......................19

5.6 General maintenance standards.................................. 20

5.7 Inspection and maintenance......................................... 20

5.8 Checking hatchway seal................................................ 20

3

TABLE OF CONTENTS

1. TECHNICAL DATA

1.1GENERAL TECHNICAL

CHARACTERISTICS

CTC Maxi cast-iron boilers are high

efficiency (superior to 90%) generators

of hot water up to 90°C for central

heating. The high efficiency of this type

of system also achieves extremely

LOW NOx emission to the atmosphere.

When LOW - NOx burners are installed

this boiler meets the most restrictive

European air pollution Standards.

The boiler body (made of modular castiron wet-chamber components)

functions in depression for the entire

range of admissible power ratings.

The boiler body is composed of:

a. Front component with inspection

hatchways and support for the

blown-air burner.

b. Intermediate elements with

shapes designed for high thermal

exchange even when operating at

LOW temperatures.

The number of elements can vary

depending on the thermal

capacity of the boiler.

c. End element that connects to the

delivery and return pipelines and

to the smoke exhaust system.

4

All elements are connected together

by twin-taper connection nipples.

Structural rigidity is achieved by tierods, which also function to carry loadbearing parts of the shell. Boiler

insulation is obtained by a thick layer

of glass wool applied directly to the

boiler body and the rear element. The

shell, made of stove enamelled steel

sheet, is quite simple, efficient and

modular and permits access to

inspection and maintenance

hatchways by simply removing

(without any tool) the front panel. The

shell also covers and protects the

control board which is furnished tested

and already wired.

Specific boiler data are given on the

data-decal applied to the back section

of the right side.

1.2 DELIVERY CONTENTS

Delivery consists of 6 packages:

1 - Pallet with boiler components

.

2 - Box with putty for seals between

modular component surfaces.

Putty applicator and twin-taper

connection nipples.

3 - Tie-rods for assembly .

4 - Box containing the front

hatchways, the hinge for the

lower door, front plugs,

connection flanges and seals,

sheath for control instrument

probes and baffles.

5 - Box containing the shell,

insulation, spacers for positioning

the shell, installation screws,

nuts and washers, technical and

guarantee documents.

6 - Box containing the control panel,

complete

7 - Assembly tools for boiler body

assembly (optional equipment)

1. TECHNICAL DATA

5

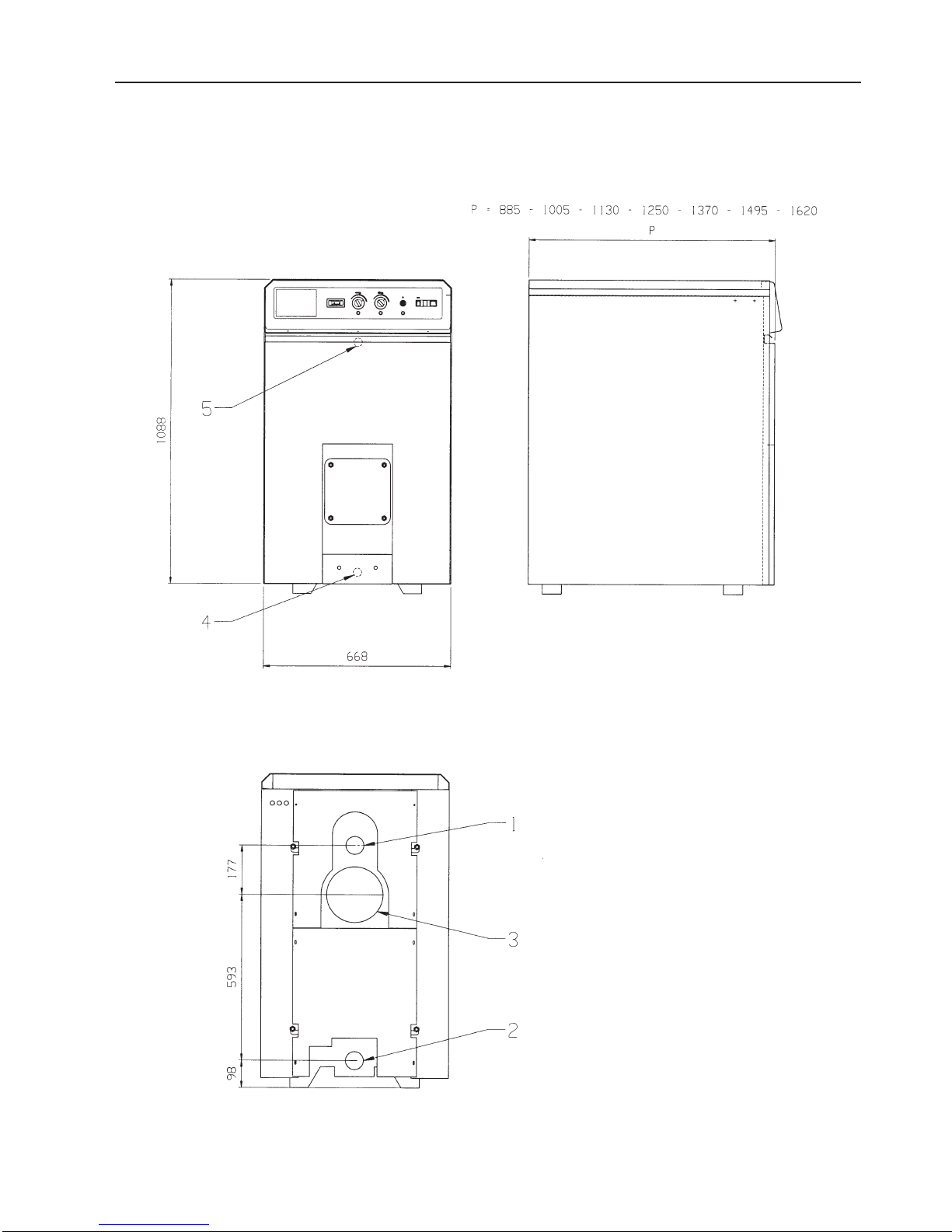

1.3 DIMENSIONS

1. Heating flow

2. Heating return

3. Flue gas connection

4. Drain

5. Sensortube

6

1. TECHNICAL DATA

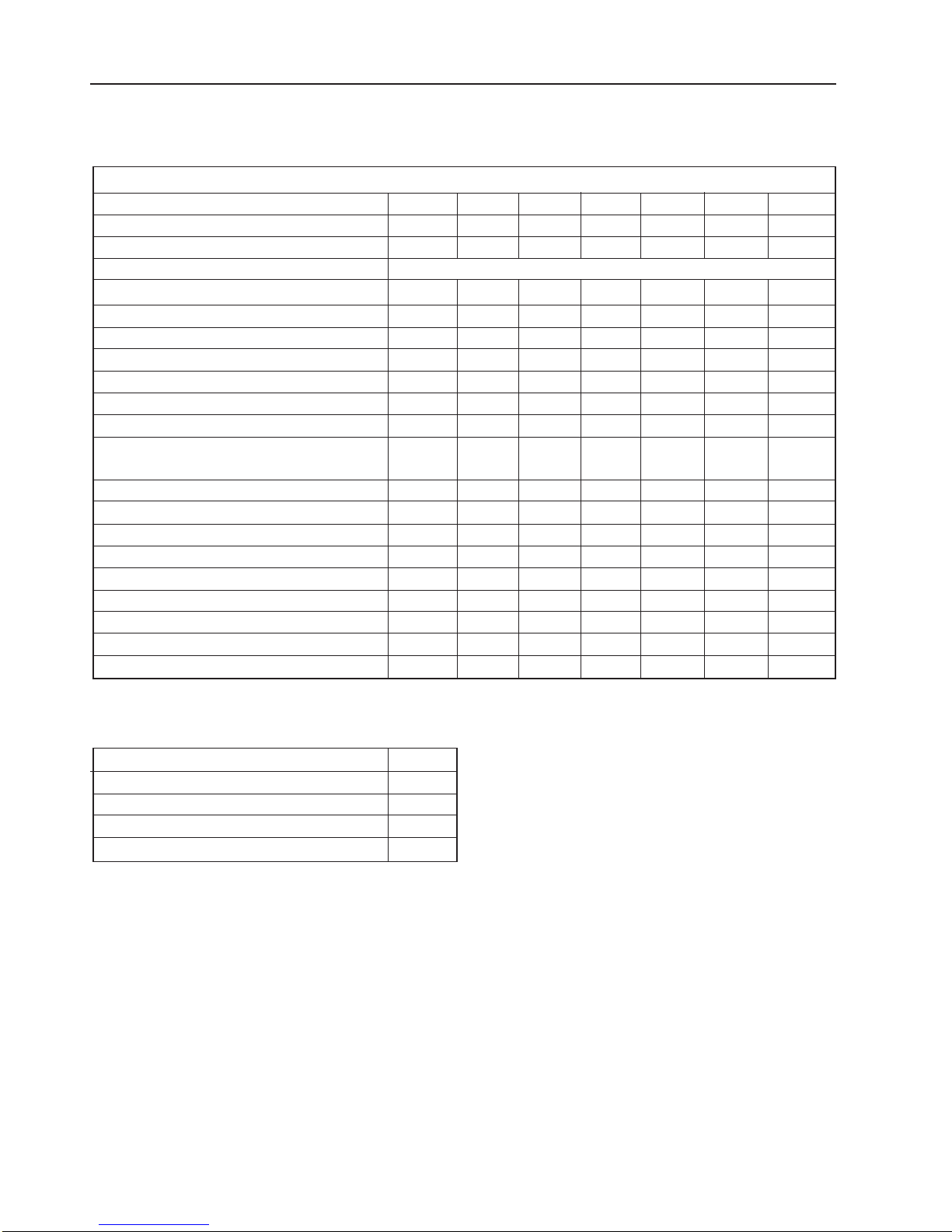

BOILER CTC Maxi80100120140160180200

Number of elements 6 7 8 9 10 1 1 12

Max output power kW 80 10 0 12 0 14 0 16 0 18 0 200

Max input power kW 88,9 1 11,1 133,3 155,6 177,8 200,0 222

Fuel Gas/Fuel-oil

Working efficiency % 90,0 90,0 90,2 90,4 90,4 90,5 90,6

Efficiency at 30% capacity % 88 88 88 88 88 88 88

Loss at the smokestack % 8,4 8,2 8,4 8,4 8,2 8,2 8,2

Smoke temperature* °C 205 20 0 202 202 200 20 0 20 0

Gas smoke flow rate kg/h 13 7 171 206 240 274 309 342

Fuel oil smoke flow rate kg/h 13 1 165 198 231 264 297 33 0

Smoke load losses mbar 0,10 0,15 0,28 0,30 0,40 0,55 0,66

Dimensions of the combustion chamber:

Length mm 565 686 807 928 1049 1 170 1291

Diameter mm 380 380 380 380 380 38 0 380

Volume of the combustion chamber dm

3

72 86 101 116 131 145 159

Smokestack connection mm 200 20 0 200 2 00 20 0 200 200

Water contents l 66,0 76,5 87,0 97,5 108,0 118,5 129,0

Water side load loss Dt = 15°C mbar 9 12 18 28 35 45 60

Delivery connection “G 2 ½” 2 ½” 2 ½” 2 ½” 2 ½” 2 ½” 2 ½”

Return connection “G 2 ½” 2 ½” 2 ½” 2 ½” 2 ½” 2 ½” 2 ½”

Boiler depth P mm 8 85 1005 1 130 1250 1370 1495 1620

Weight of empty boiler kg 41 0 465 520 57 5 63 0 68 5 740

* with CO2% = 13 for Fuel Oil and 10 for Gas

Max. operating pressure ba r 5

T est pressure ba r 7,5

Control thermostats ° C 21-85

Safety thermostat °C 1 10

Code PIN CE 0063/ ...

1.4 TECHNICAL DA T A

Loading...

Loading...