Page 1

P/N 92242001 • Rev A • ECN 14-119 • 5/7/2014

Warranty: If this unit fails during the warranty period, contact tii customer service to authorize return. Unit may be returned prepaid.

Model FDT1 Series

Fiber Distribution Terminal

Installation Note

Description

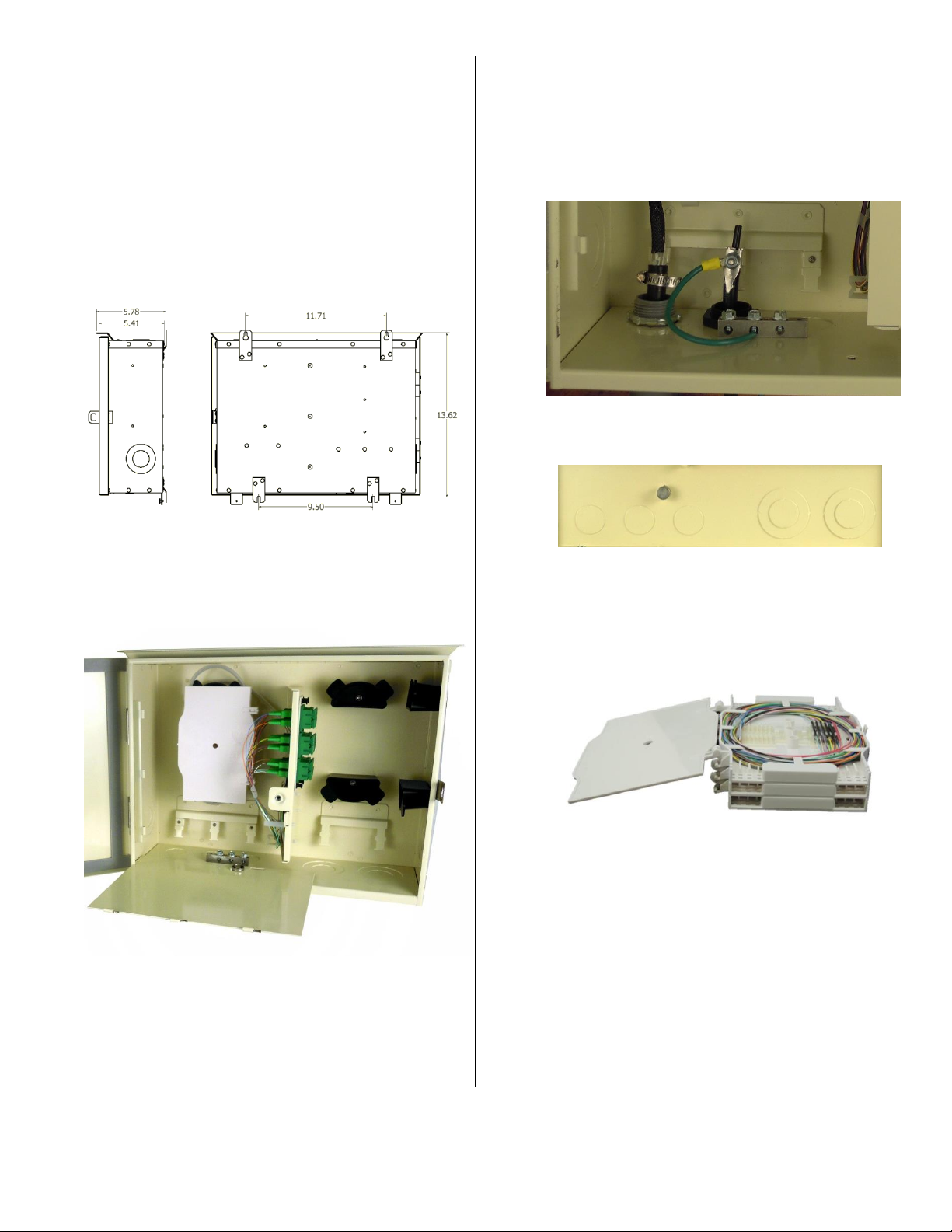

Splice

Compartment

Customer

Drops

Inner Door

Outer Door

Installation

The FDT Series Fiber Distribution Terminals

provide splicing connectivity to the OSP feeder

fiber and a point of demarcation for customer drop

terminations.

Features

Up to 24 fiber drops.

Top, bottom and side 1” and 2” conduit knockouts

Removable and lockable inner and outer doors

Inner door converts to work surface

Optional protective bottom cable entry skirt

The FDT is designed for outdoor or indoor installation.

It can be ordered empty and configured on-site or

factory loaded with adapter plates, pigtails, and splice

trays to reduce installation time.

1. Verify contents and inspect for damage

2. Select installation site:

Vertical wall surface

Easily accessible

Adequate clearance from electric light

fixtures, equipment and power circuits.

Near suitable earth ground

Figure 1

Figure 2

Page 2

3. Knock out required cable entry conduit ports.

Top – 2 ea combination 1” / 2”

Side – 1 ea combination 1” / 2 “

Bottom – 2 ea combination 1” / 2”

3 ea 1”

4. Trim and install conduit fittings or NPT

compression couplings as needed.

5. Mark and install appropriate wall hanging

hardware and secure unit.

Figure 3

6. The inner door can be used as a work surface

in remote or confined space installations. Lift

the inner door from hinges and use 216 tool to

secure 3/8” bolt to bottom of enclosure.

7. Cut excess feeder cable to length leaving a

minimum of 3 ft. of slack from point of entering

splice bay. Location to perform fusion splicing

will dictate exact length necessary of slack.

Remove protective jacketing material to

expose fiber cable subunits and secure to

cable entry point. Ground and bond armored

or tonable cable using provided ground bar.

Figure 5

8. Ground the FDT enclosure to a suitable earth

ground using the external ground stud.

Figure 6

9. Splice feeder fiber to pigtails using the FST

modular splice tray. The trays are stackable

and have 3 attaching points to secure one tray

to the other. Each tray can splice up to 24

single fusions or 6 mass fusions.

Figure 4

Figure 7

10. Store feeder fibers and pigtail slack in

provided slack management rings.

11. Customer drops are routed from the cable

entry ports to the patch panel and slack is

stored in the provided slack management

rings.

Loading...

Loading...