Page 1

P/N 92209201 • Rev H• 8/28/2008

Warranty: If this unit fails during the warranty period, contact tii customer service to authorize return. Unit may be returned prepaid.

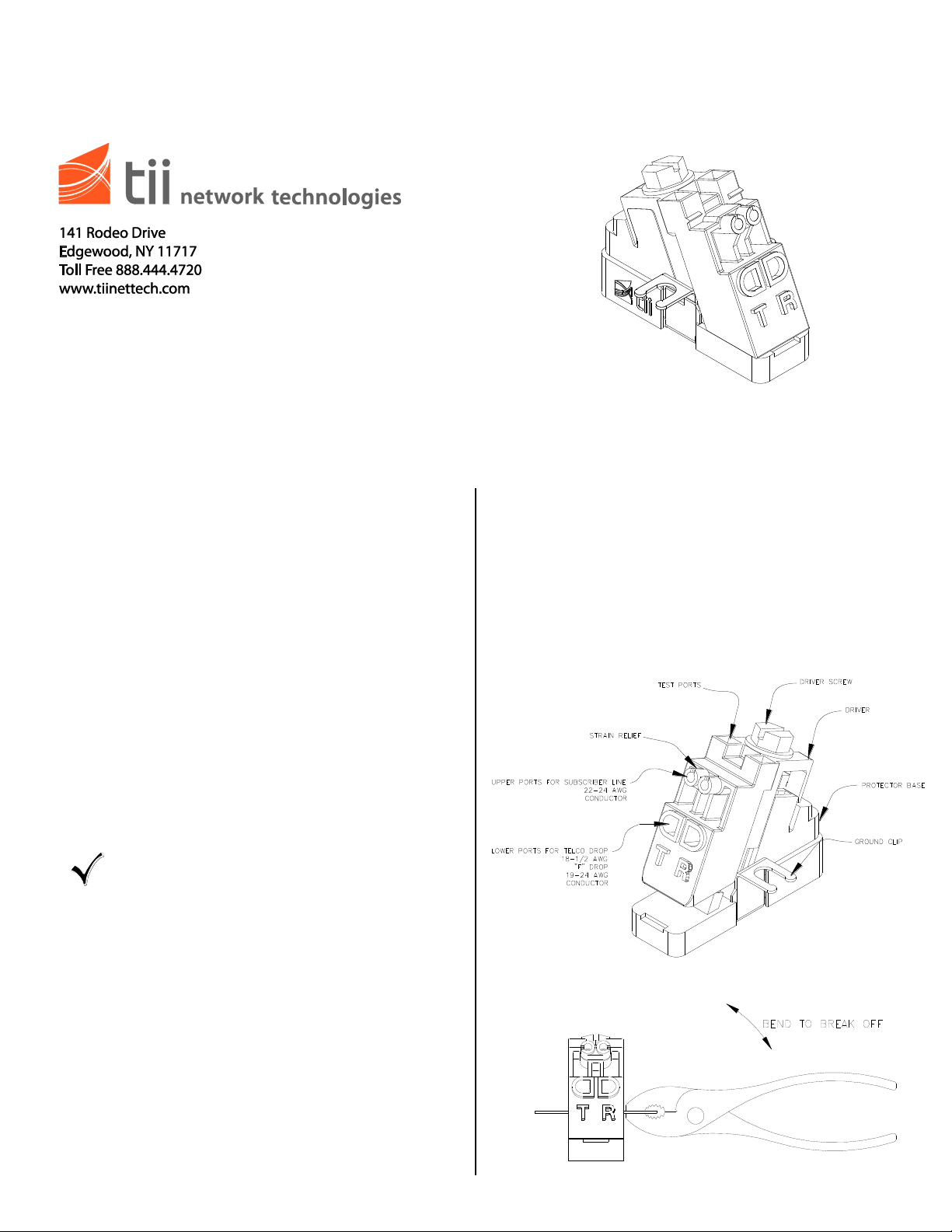

Model AD-SERIES Angle Driver Module with Surge Protection

ADX-SERIES Angle Driver Module without Surge Protection

Installation Note

Description

Installation

1. The AD-Series & ADX- Series Station

Protector modules may be installed in a wide

variety of station protector and network

interface housings.

2. The AD-Series & ADX- Series Station

Protector Modules provides one upper and

two lower ports per line for ease of wiring and

termination. It is equipped with a universal

grounding and mounting tab.

3. All ports utilize tool-less IDC rockers. The

upper ports accept 22-26 awg wire, the lower

ports terminate 18.5 ”F” drop - 24 awg wire.

Both ports are terminated by the driver bolt

mechanism.

4. The AD-Series & ADX- Series modules are

equipped with integral sealed test points for

ease of troubleshooting.

NOTE

National Electric Code Requirement. The

protector shall be installed per National

Electric Code ANSI/NFPA 70, Article

800, Section C, and shall meet all

applicable local safety codes.

These modules shall be installed in NID

enclosures evaluated to the requirement

of UL497.

1. The Angle Driver is delivered with a universal

grounding and mounting tab (See Figure 1). If

installing a new module into a NID, break

away the unwanted ground tab from the

module using a pair of pliers and discard (See

Figure 2). Install module on desired NID

ground post and secure with washer and nut.

Figure 1

Figure 2

Page 2

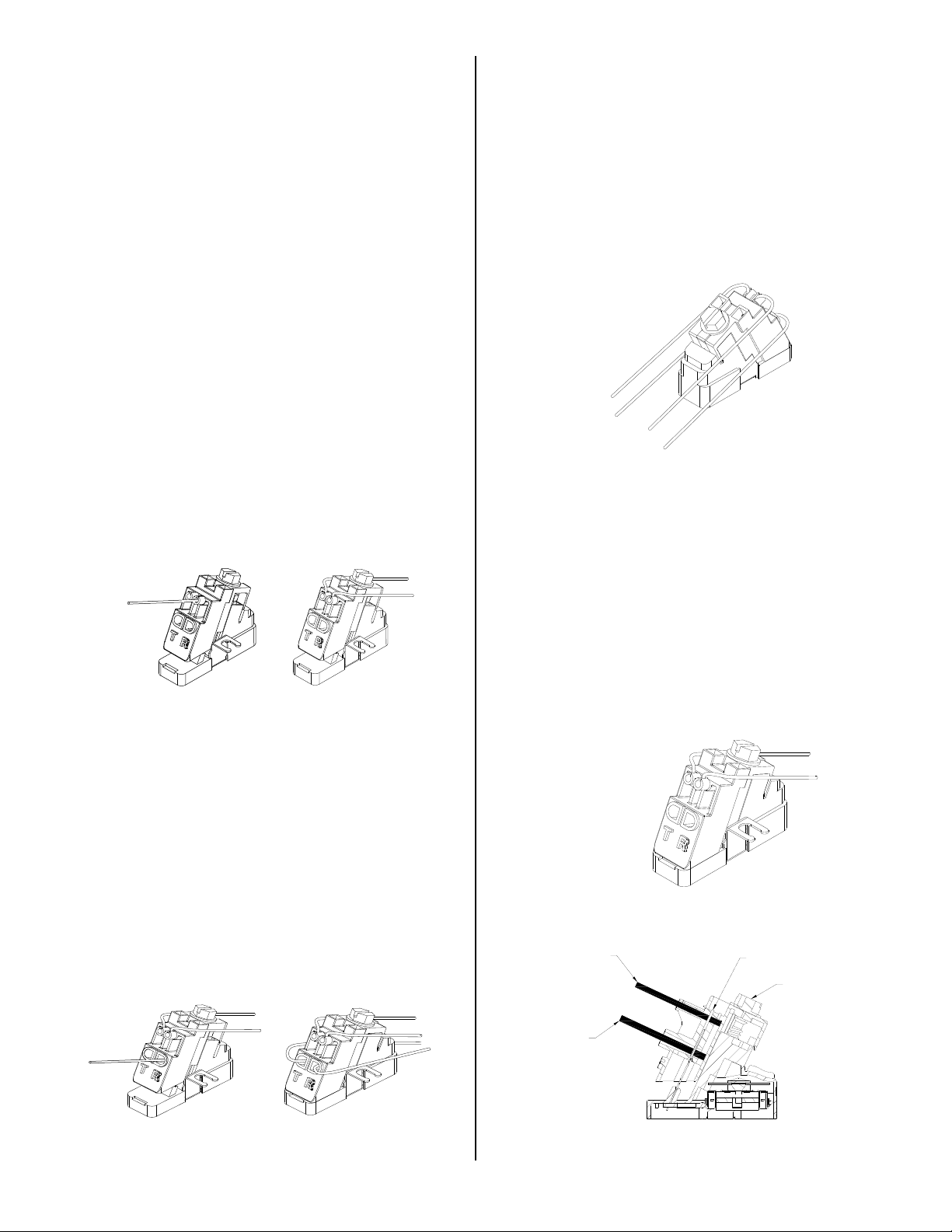

Wiring

IDC

SUBSCRIBER

CONNECTION

WIRE

TELCO

WIRE

DRIVE SCREW

Testing

1. The two upper ports of the Angle Driver are

intended to terminate subscriber (customer)

wires. Telco drop (feeder) wires must be

terminated in the two lower ports of the Angle

Driver.

2. Upper Port Subscriber Connections (See

Figure 3) Subscriber terminations are already

made at the factory. If it is necessary to reterminate a subscriber wire, do so as follows:

3. Do not strip wire insulation. Make certain wire

ends are cut flush with insulation.

4. Unscrew Angle Driver screw to the full upright

position.

5. Fully insert the two subscriber wires into their

respective tip and ring (color-coded) ports.

6. Insert while holding the two subscriber

connection wires in place. Ensure wires are

fully inserted beyond the IDC connector

(See Figure 7). Tighten Drive Screw to the full

down position. Pull on wires to ensure

proper connection. Wires should remain

securely in place.

7. Dress the wires through the strain relief slots

to hold them in place (See Figure 3).

Figure 3

Lower Port Telco Connections

(See Figure 4)

1. Feeder and subscriber wires must be

segregated between the upper and lower ports

to facilitate isolation testing (See Figure 5).

Upper and Lower Port Connected

1. With Driver in the fully closed position, insert

test clips into tip/ring test port access holes

located at top of driver. Perform customary

tests.

Figure 5

Testing Subscriber Connections

(See Figure 6)

1. Loosen drive screw so driver is in the full

upright position.

2. Remove telco wires from lower ports of driver.

3. Tighten drive screw so driver is in the full

down position.

4. With Driver in the fully closed position, insert

test clips into tip/ring test port access holes

located at top of driver. Perform customary

tests.

1. Do not strip wire insulation. Make certain wire

ends are cut flush with insulation.

2. Unscrew Angle Driver screw to full upright

position.

3. Fully insert the two feeder (telco) wires into

their respective tip and ring (color-coded)

ports. Ensure wires are fully inserted

beyond the IDC connector (See Figure 7).

4. While holding the two telco wires in place,

tighten Drive Screw to full down position. Pull

on wires to ensure proper connection.

Wires should remain securely in place.

Figure 4

Figure 6

Figure 7

Loading...

Loading...