Page 1

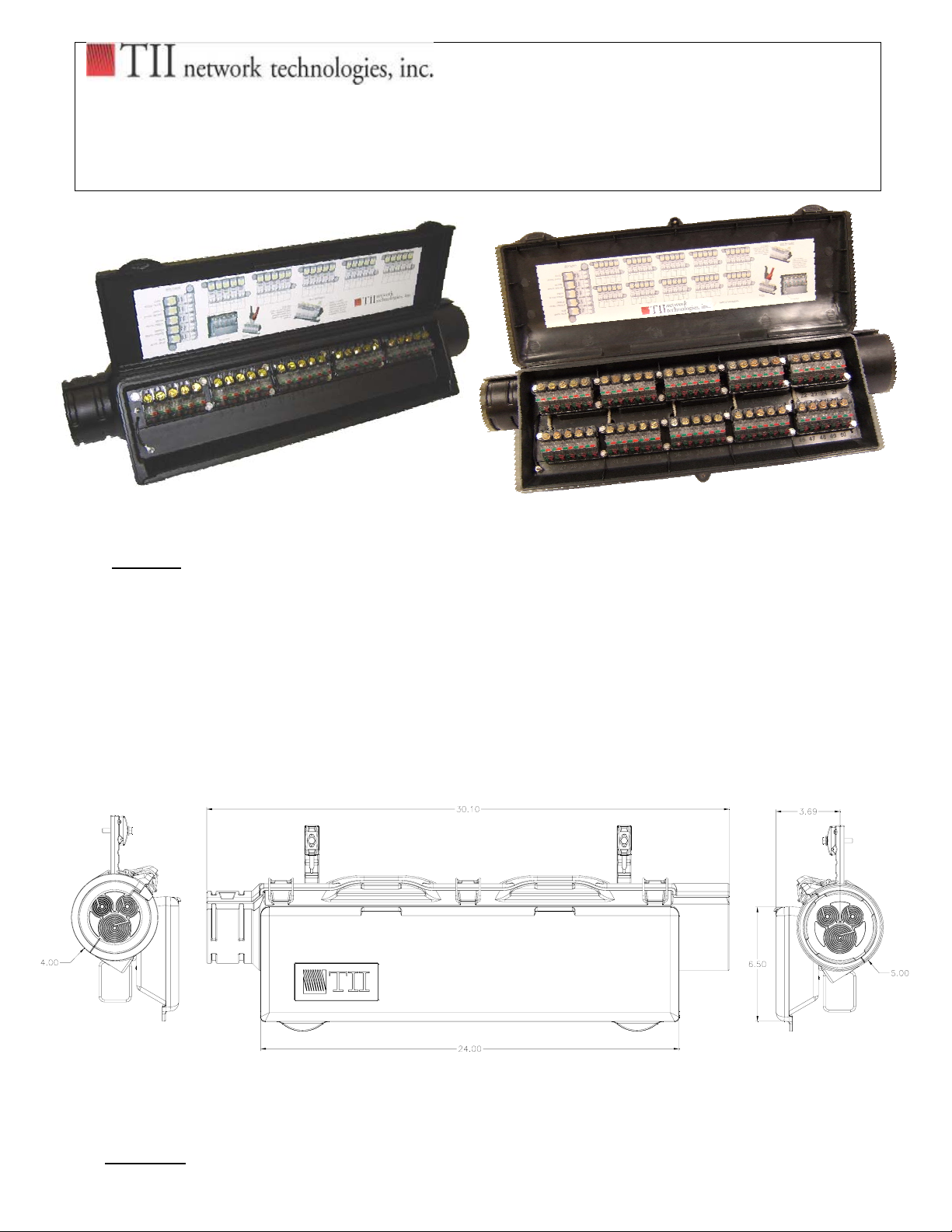

1385 Akron Street TII 605 Series

Copiague, NY 11726 Aerial Terminal Enclosure

Customer Service/Sales 888-844-4720 Pat. Pending

Rev D 11/06

INSTALLATION NOTE

Model 605-5

Model 605-50

1. General

1.1 The Series 605 Aerial Terminal Enclosure with external bonding hanger brackets are

designed for fixed count terminating, non-protected up to 50 pair. The 5” x 30” (127mm x

762mm) terminal is available empty to handle configurations of 5 thru 50 pair. It can

accommodate a 3” (76mm) diameter splice bundle and cable up to 1.75”(44mm) diameter.

1.2 The ADX-5T terminal block is filled with a gel sealing compound to provide environmental

protection.

1.3 Dimensions:

2. Warranty

TII P/N: 92221501

Page 2

2.1 See TII Warranty. If this unit fails during the warranty period, the factory should be

requested to authorize return. Return the unit prepaid. Units that fail due to normal wear or

abuse should be discarded.

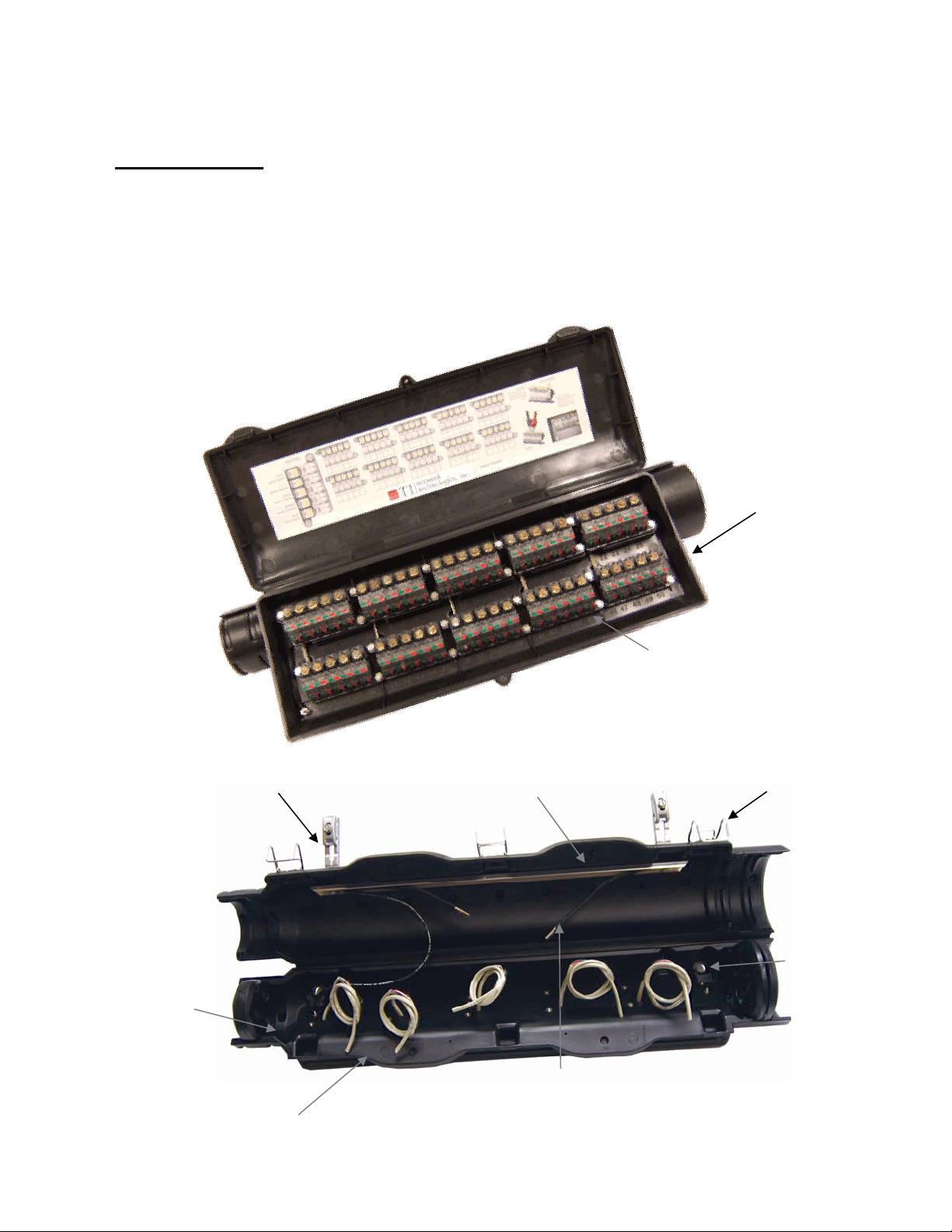

3.0 Carton Contents

3.1 Product Contents are as follows: 3.2 Additional Materials Required

(1) Sealed Aerial Terminal Body • Cable Ties

(1-10) Sealed Termination Blocks (ADX-5T) • Cable Spacers

(2) Aerial Hangar Straps • Vinyl Tape

(3) Stainless Steel Latches • Moisture Resistant Splicing

Connectors

(2) Entry Cable Grommets

(2) Ground Braid Assembly

(1) Cable Ground Bar

(1-5) Service Cable’s

(2) Vent’s

Aerial Hangar Strap (X2)

Cable Entry Grommets

(X2)

Model 605-50

Aerial Cable Ground Bars

Terminal Housing

ADX-5T Sealed Termination

Blocks (5-Pair Blocks)

Stainless Steel Latches (X3)

Vent

Terminal Block Cable Stubs

Ground Braid Assembly

TII P/N: 92221501

Page 3

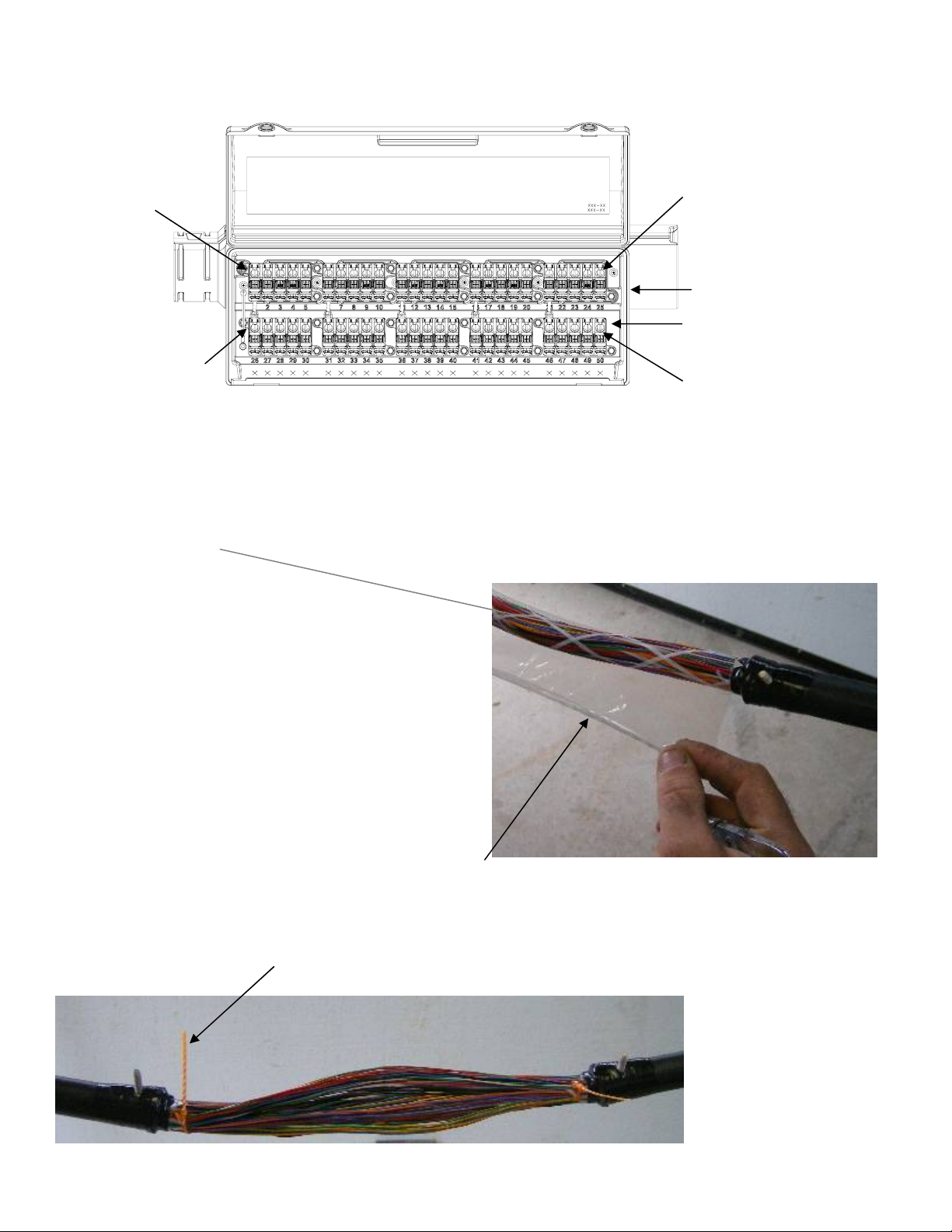

4.0 Cable Preparation

4.1 Prepare cable and strand as shown in Figures 1 & 2.

Figure 1

Note: Suggested method in preparing the outer sheath on both single and double sheath

cables.

Single Sheath Cable

Cable Sheath

Core Wrap

Slit for Ground Stud Installation

Cable Sheath

1" (25mm)

Slit Slit

1/2" (13mm)

Figure 2

Double Sheath Cable

1/2" (13mm)

Cable Sheath

Inner Sheath

Slit On Cables Less Than 3/4" In Diameter

Cable Sheath

1 1/2" (38mm)

Core Wrap

1/8" (3mm)

TII P/N: 92221501

Page 4

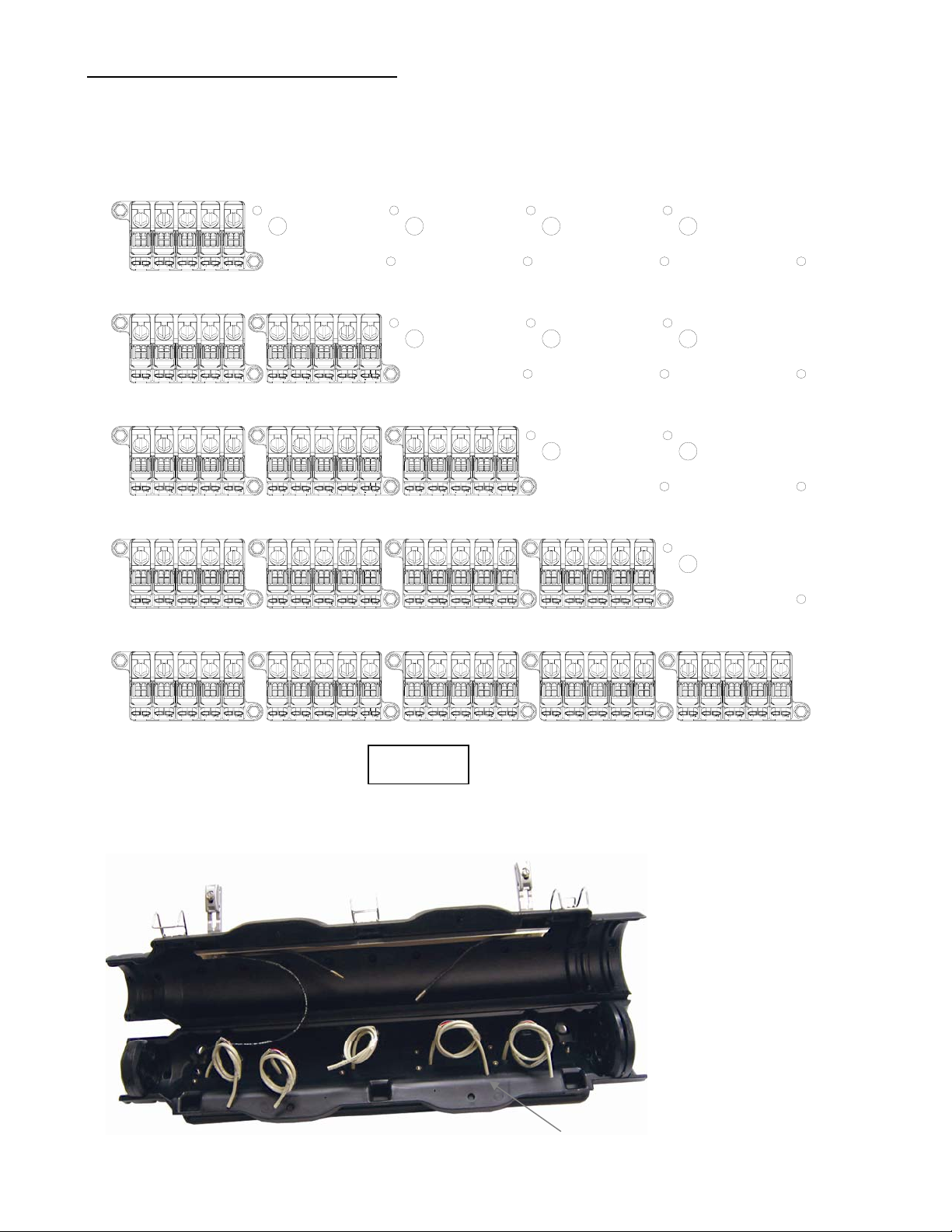

5.0 ADX-5T Terminal Block Installation

5.1 Select the proper mounting configuration in the terminal housing for the desired terminal block

locations (See Figure 3).

Note: Feed hole for the Terminal Block Tails is larger and sits to the far left.

5 PAIR BLOCK

10 PAIR BLOCK USING TWO 5 PAIR BLOCKS

15 PAIR BLOCK USING THREE 5 PAIR BLOCKS

20 PAIR BLOCK USING FOUR 5 PAIR BLOCKS

25 PAIR BLOCK USING FIVE 5 PAIR BLOCKS

Figure 3

Note: Any combination can be configured up to 50 pair.

5.2 Feed terminal block stub through appropriate hole(s) in box leading to the splice chamber.

Model 605-5

Terminal Block Stubs In Splice Chamber

TII P/N: 92221501

Page 5

5.3 Mount the terminal block(s) in multiple of five as required.

ADX-5T

TERMINAL BLOCK

#1

ADX-5T

TERMINAL BLOCK

#6

ADX-5T

TERMINAL BLOCK

#5

5-25 Pair Positions

30-50 Pair Positions

ADX-5T

TERMINAL BLOCK

#10

5.4 The Model 605-50 is equipped for mounting up to (10) ADX-5T sealed terminal blocks.

6.0 Terminal Installation, Bonding and Splicing

6.1 Bond the cable shield with approved shield bond connectors

Per approved practice.

6.2 Apply 4 – 5 wraps of vinyl tape around bond clamps then

Remove the pair protector

6.3 Select binder group to be spliced, and mark using standard practice.

TII P/N: 92221501

Page 6

6.4 Mount terminal to strand. Terminate shield bond connectors to terminal closure ground bond

straps; ensure bond clamps are pointing forward.

6.5 Using rip cord remove necessary amount of jacket from tail of ADX-5T blocks.

TII P/N: 92221501

Page 7

6.6 Splice as per standard practice.

6.7 Cable should be tie wrapped to the ground bar at each end for strain relief.

6.8 Install cable spacers as per standard practice.

TII P/N: 92221501

Page 8

7.0 Cable Entry Grommet Installation

7.1 Cut the cable entry grommet from the outside edge

to the appropriate ring diameter that matches the

Aerial Cable Diameter.

1

1¼” Maximum Diameter

1¾” Maximum Diameter

¼” Maximum Diameter

7.2 The Grommet is labeled 1 thru 7, the diameters

are listed per the drawing to the right. For best results cut out circumference

template at the bottom of the sheet. Wrap the template around

the cable using the start point as your reference point.

Ø

Ø1

Ø1

Ø1

(1)

3

Ø

8

(2)

5

Ø

8

(3)

3

4

(4)

(5)

1

8

(6)

3

8

(7)

5

Ø1

8

3

Ø1

4

Max Diameter

*The template has been perforated for easy removal, please tear down perforated lines.

Circumference Template

Start Point

1 2 3 4 5 6 7

4

3

2

1

7

6

5

4

3

2

1

1

Max Diameter

Ø1

4

Ø1

4

3

2

1

3

Ø

4

5

Ø

8

3

Ø

8

TII P/N: 92221501

Page 9

7.3 Cut end caps to fit cable, install in each end of terminal, and ensure a snug fit around cable.

A wrap of vinyl tape should be placed around each unit.

7.4 Install Cable Entry Grommets on the end of each cable

and position in body enclosure.

TII P/N: 92221501

Page 10

8.0 Adding or Changing Terminal Blocks

8.1 Using standard 7/16” terminal wrench remove existing ADX-5T block by backing out 2 nuts

on each side of block.

8.2 Remove block by pulling straight out.

8.3 Open new ADX-5T block and inspect. Insert tail of ADX-5T block into hole in terminal, left of

mounting space.

TII P/N: 92221501

Page 11

8.4 Align block with mounting holes in terminal housing

8.5 Tighten mounting nuts one half turn past tight, do not over tighten.

TII P/N: 92221501

Page 12

9.0 Replacement of Gel-filled ADX driver.

9.1 Using standard 7/16” terminal wrench, back driver nut off all the way out.

9.2 Using either your thumb and forefinger or a flat screwdriver, lift the back lock of the driver

off of the glide plate.

9.3 Remove the defective driver.

TII P/N: 92221501

Page 13

9.4 Remove a new driver from its packaging and inspect it. Place the new driver over the glide

plate, align with driver hole and snap into place.

9.5 Using standard 7/16’ terminal wrench, fully tighten the driver into the down position, ensure

driver is all the way down as it will affect the functionality of the tool-less connector if it is

not.

TII P/N: 92221501

Page 14

10.0 Drop Wire Termination

10.1 Open terminal box door.

10.2 Prepare Wire / Cable Per Standard Practice.

10.3 Using needle-nose pliers, push up through bottom

of terminal to accommodate wire installation.

10.4 Route wire through wire guides outside terminal.

10.5 Insert prepared wire/cable through access holes in the aerial enclosure. Use locking clip or tape

to eliminate pull out of drop

.

TII P/N: 92221501

Page 15

10.6 Tool-less rocker accepts 22-24awg wire, lower ports

To terminate 18.5-24 AWG wire (driver bolt actuated).

Upper Ports

Tool-less IDC Rockers

Lower Ports

Driver Bolt Mechanism

10.7 Upper Ports of tool-less IDC rockers accept 22-24

AWG wire. Lift rocker to full upright position. Insert wires.

Lower rocker to full down position.

Note: There is no need to open the driver to terminate 22-24

AWG wire.

10.8 Lower Ports terminate 18.5-24 AWG wire. Raise

Driver bolt mechanism to full up position by turning driver

bolt counter-clockwise. Insert Tip/Ring pair into lower

ports. Lower Driver to Fully seated position.

10.9 Complete termination log.

10.10 Close door and check for proper sealing.

TII P/N: 92221501

Page 16

11.0 Testing

11.1 Insert test clips into test ports and follow company

procedure for testing.

12.0 Accessories

• TII ADX-5T 5-Pair Gel Filled Terminal Block 20

• 00193501 Special Service Red Marker Tag

• 00193601 Replacement Gel Filled Drivers

5 sleeves (5pcs / sleeve)

• 00194101 Replacement Rubber End Seals

(Pair) 20 pairs.

Sealed Test Point Access

Tip/Ring (Butt Set Accessible)

Blocks

For ADX-5T,

20 bags (100pcs / bag).

TII P/N: 92221501

Loading...

Loading...