Page 1

TII 347-07-2-1

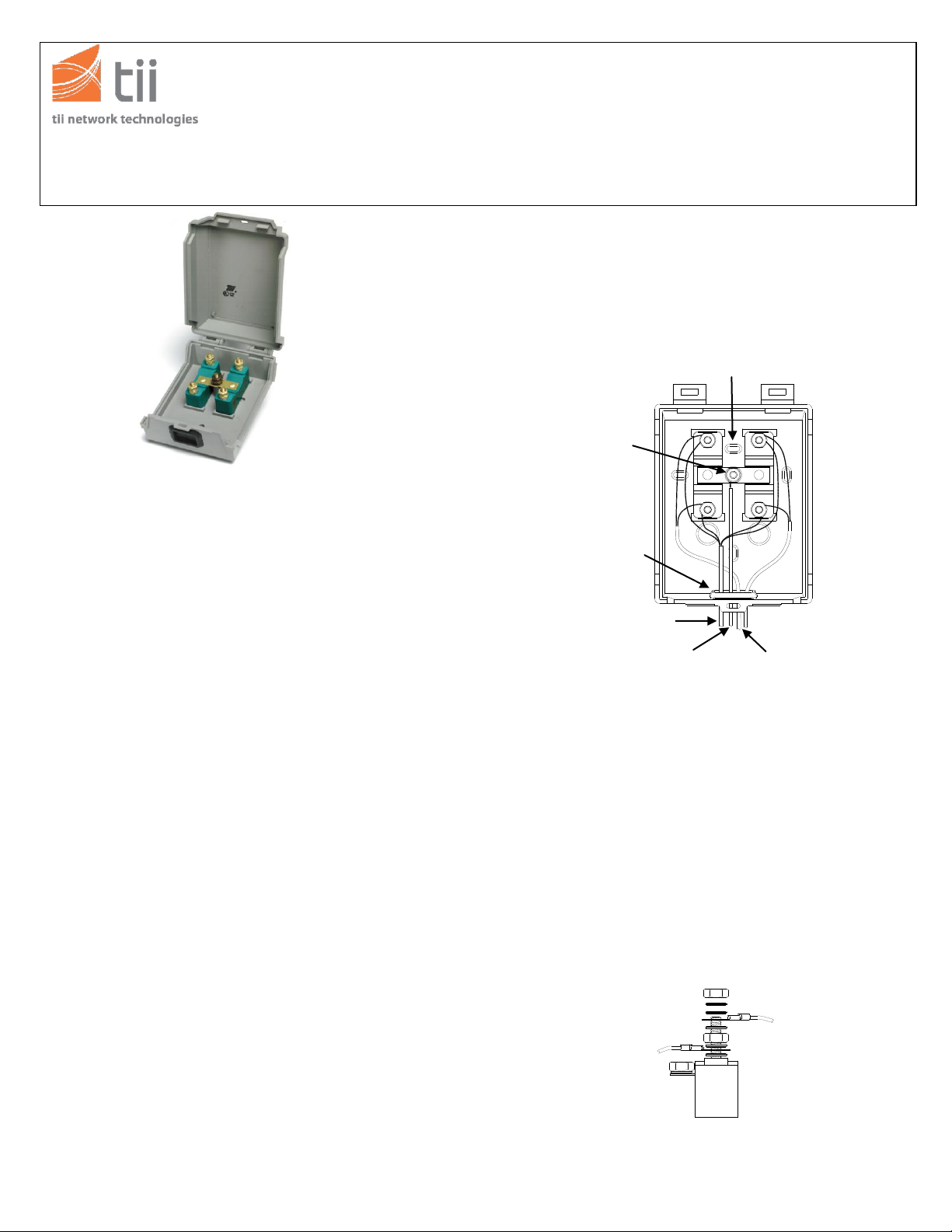

Figure 2

Customer Side Cable

Telco Side Cable

Figure 1

Customer Side Cable

Line 1 and Line 2

Telco

Side Cable

Ground Stud /

Binding Post

Grounding

Conductor

Grommet

Knockout (Typical)

TII 347 Series

141 Rodeo Drive Station Protectors

Edgewood, NY 11716 TII P/N: 92223701

Customer Service/Sales 888-844-4720 INSTALLATION NOTE 11/07 Rev B

1. GENERAL

1.1 The TII 347 Series Station Protectors consist of one or two

Protector Modules in a top hinged enclosure with integral

ground stud (See Figure 1).

1.2 The TII 347 is available with a variety of protector modules

with standard binding post termination or sealed IDC

termination.

1.3 The plastic base is molded with knock out holes for

mounting. A captive nylon insulated nut may be provided to give

a degree of tamper proofing, and for easy installation and

removal as an option (See Figure 1).

1.4 A flexible grommet is located in the center of the base to

provide a seal for Telco cable, customer cable and grounding

conductor wiring. (See Figure 1.)

National Electric Code Requirement

The protector shall be installed per National Electric Code

ANSI/NFPA 70, Article 800, Section C, and shall meet all

applicable local safety codes.

2. WARRANTY

2.1 See TII Warranty. If this unit fails during the warranty

period, the factory should be requested to authorize

return. Return the unit prepaid. Units that fail due to

normal wear or abuse should be discarded.

3. INSTALLATION

3.1 Precautions

3.1.1 Mount the station protector so as to minimize the

possibility of dirt or moisture getting into the protector.

3.1.2 Station protectors mounted side-by-side or end-to-end

should be placed so covers can be easily removed.

3.1.3 Where protection for multiple services is required, it is

recommended that a protected building terminal in an interior

terminal box be installed in place of station protectors.

3.2 Mounting

3.2.1 Mount the station protector vertically on a flat surface

using appropriate hardware (the length of the mounting screws

should allow for 1/8” of length within the protector.

4. WIRING

4.1 Ground

4.1.1 Insert the grounding conductor, the customer side

cable and the Telco side cable through the grommet in the

base of the protector (See Figure 1).

4.1.2 Terminate one end of the grounding conductor (No. 6

AWG) on the ground stud / binding post and the other end to

an appropriate ground source. (See Figure 1.)

4.2 STATION PROTECTOR WIRING

(If equipped with binding post protection)

4.2.1 For binding post termination type protectors; terminate

the Customer Side cable in between the bottom set of washer

and bottom nut of the appropriate stud (one conductor to Tip

and one to Ring) and tighten down. (See Figure 2.)

4.2.2 Terminate the Telco Side Cable under the top set of

washers and the top nut of the appropriate stud (one

conductor to Tip and one to Ring) and tighten down. (See

Figure 2).

P/N: 92223701

Page 2

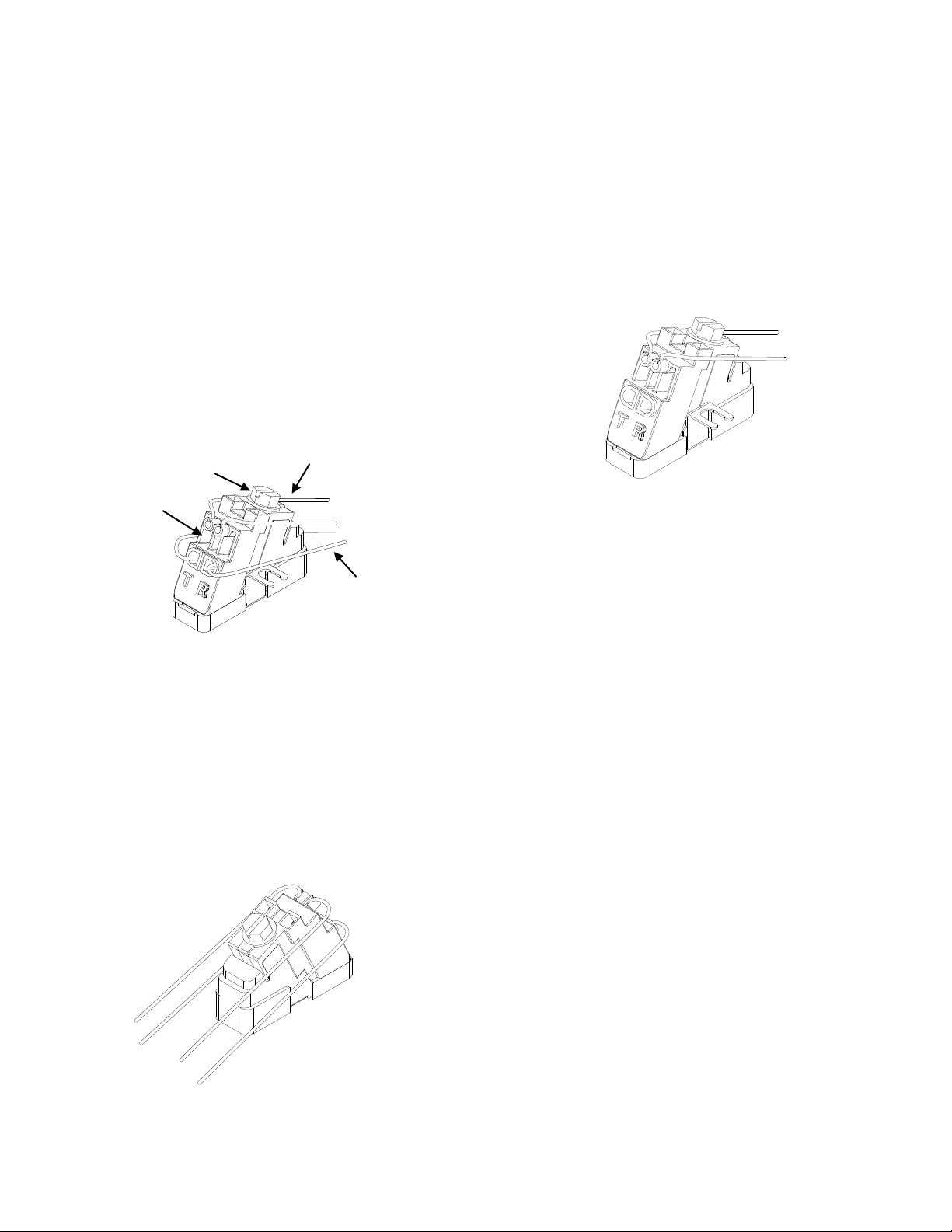

Figure 3

Strain

Relief

Drive

Screw

Telco Side Cable

Customer Side Cable

Figure 4

Figure 4

Figure 5

4.3 STATION PROTECTOR WIRING

(If equipped with angle driver module)

4.3.1 For sealed IDC termination type protectors; terminate

the Telco Side Cable by loosening the drive screw and pulling

up the driver and insert un-stripped Telco Side Cable in the

bottom ports (one conductor to Tip ‘T’ and one to Ring ‘R’)

until they are seated at the bottom of the ports. (See Figure 3.)

4.3.2 Insert un-stripped Customer Side Cable in the top ports

(one conductor to Tip ‘T’ and one to Ring ‘R’) until they are

seated at the bottom of the ports. (See Figure 3.)

4.3.3 Re-tighten the drive screw bring the driver down to

the protector base. (See Figure 3.)

4.3.4 Set the Customer Side Cables into the strain relief

cutouts on the sides of the Customer Side Cable

ports. (See Figure 3.)

4.3.5 Loop back unused station wire conductors and coil

around the station wire jacket or store in such a

manner as to prevent them from coming in contact

with protector terminals or bare wires.

5. Angle Driver Testing

Upper and Lower Port Connected

5.1.1 Feeder and subscriber wires must be segregated between

the upper and lower ports to facilitate isolation testing (see

Figure 4).

5.1.2 With Driver in the fully closed position, insert test clips into

tip/ring test port access holes located at top of driver. Perform

customary tests.

Testing Subscriber Connections

5.2.1 Loosen drive screw so driver is in the full upright

position.

5.2.2 Remove Telco wires from lower ports of driver.

5.2.3 Tighten drive screw so driver is in the full down position.

5.2.4 With Driver in the fully closed position, insert test clips

into tip/ring test port access holes located at top of driver.

Perform customary tests.

P/N: 92223701

Loading...

Loading...