Page 1

P/N 92242801 • Rev A • ECN 14-215 • 9/29/2014

Warranty: If this unit fails during the warranty period, contact tii customer service to authorize return. Unit may be returned prepaid.

Model 312 Series

Station Protector

Installation Note

Description

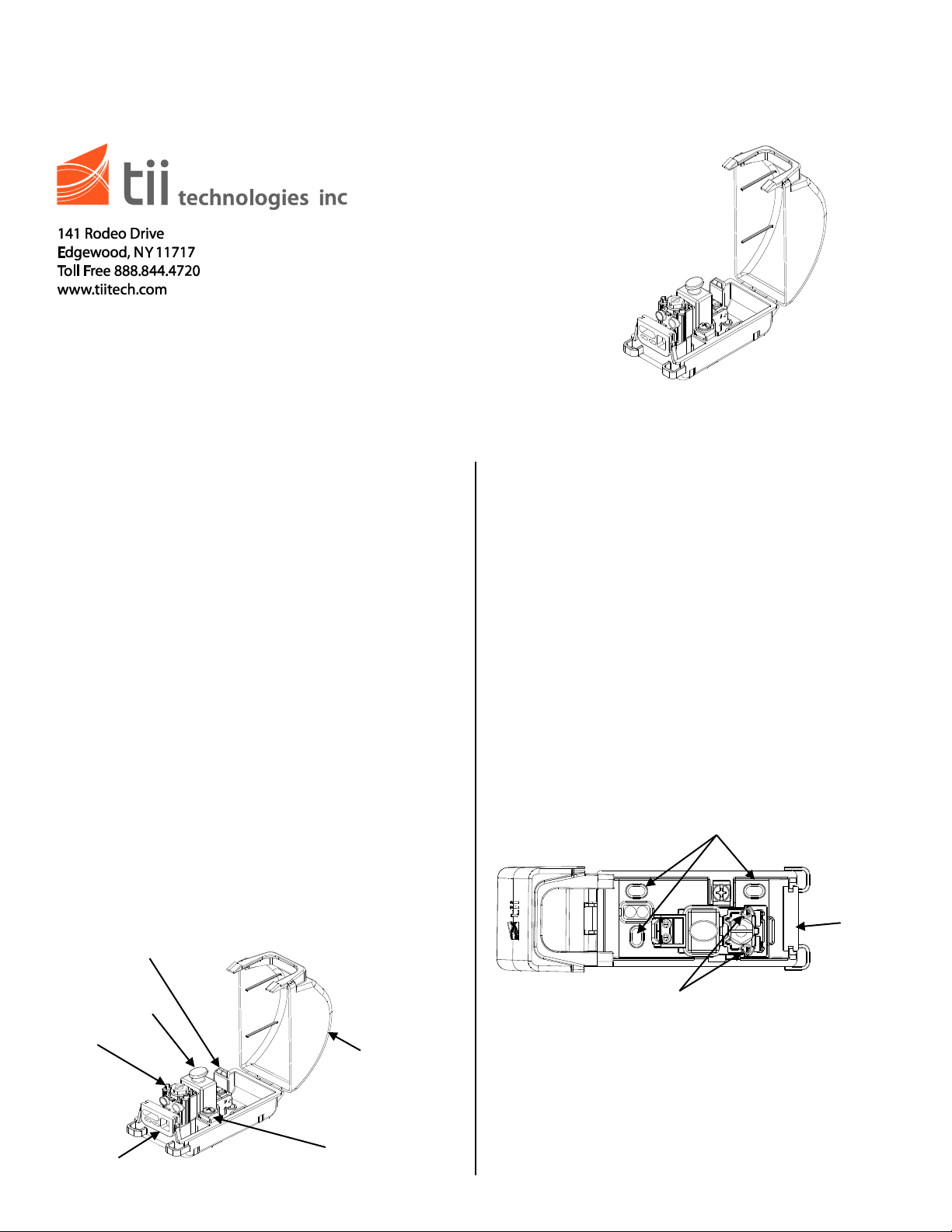

Mounting holes

Grommet

Test Ports to check dial tone

Protector

(Optional)

Ground Screw/

Retaining Post

Protector

Module

Grommet

312 Station

Protector

Tool-less IDC

Rocker

Installation

1. The TII 312 Series is a Station Protector which

consists of a DRM Series Surge Protector

Module in a 312 Protector Enclosure with a

molded in ground stud.

2. The 312 Protector Enclosure has a removable

grommet located in the center of the base lip

to allow Telco cable, customer cable and

grounding conductor penetration. It is

equipped with a universal grounding and

mounting tab. (See Figure 1).

3. The TII DRM Series Station Protector Module

utilizes gel-sealed screw drive IDC input

connections & tool-less output IDC rockers.

They are also equipped with integral sealed

test points for ease of troubleshooting.

4. All ports accept .4mm to 1.5mm awg wire.

5. The TII DRM Series Station Protector Modules

are equipped with removable 5 pin protector

modules and are available in non-protected

and protected versions.

Features

Figure 1

1. Mount the station protector so as to minimize

the possibility of dirt or moisture getting into

the protector.

2. Station protectors mounted side-by-side or

end-to-end should be placed so covers can be

easily removed.

3. Where protection for multiple services is

required, it is recommended that a protected

building terminal in an interior terminal box be

installed in place of station protectors.

4. Mount the station protector vertically on a flat

surface utilizing the mounting holes shown in

Figure 2 and using the appropriate hardware

(the length of the mounting screws should

allow for 1/8” of length within the protector).

Figure 2

Wire Entry

Page 2

Wiring

Drive Screw – open to

terminate wires

Insert ground

wire here

Ground Screw

Insert input

wires here

Insert output

wires here

Rocker – open to

to terminate wires

Testing

1. Insert input, output & ground wires through the

grommet as required.

2. Do not strip wire insulation. Make certain wire

ends are cut flush with insulation for all input

and output connections.

3. Unscrew Protector Module Driver Screw to the

full upright position (See Figure 3).

4. Fully insert the two input wires into their

respective tip and ring (color-coded) ports.

5. Insert while holding the two input connection

wires in place. Ensure wires are fully inserted

beyond the IDC connector. Tighten the Drive

Screw to the full down position (See Figure 3).

Pull on wires to ensure proper connection.

Wires should remain securely in place.

6. Lift rocker to the full up position (See Figure

3).

7. Hold the wires between thumb and index

finger (approx. 1/8” separation between wires).

8. Fully insert the output wires into wire their

respective tip and ring (color-coded) ports at

the same time until they bottom out.

9. While holding wires in the wire guides,

terminate rocker by lowering rocker all the

way.

10. Assure the rocker is in the down position (See

Figure 3). Pull on wires to ensure proper

connection. Wires should remain securely

in place.

1. Insert test probes into test ports (See Figure 2)

to check for dial tone.

11. Unscrew the ground screw and insert the

ground wire into the grounding retainer post.

Once inserted, tighten the ground screw to

hold the ground wire firmly in place (See

Figure 3). Be sure the other end is attached to

an appropriate ground source.

insert wires- close to

Figure 3

insert wires- close

Loading...

Loading...