Tiger-Vac B-8 HEPA, 2D-15 HEPA, B-8 (A) HEPA (SCVP), 2D-15 (2+2) HEPA (SCVP) Instruction Manual

Page 1

INSTRUCTION MANUAL

INDUSTRIAL VACUUM CLEANERS

WITH INTERNAL HEPA FILTER

FOR DRY RECOVERY AND SANDING

(SELF CLOSING VACUUM PORT)

MODELS:

B-8 (A) HEPA (SCVP)

2D-15 (2+2) HEPA (SCVP)

TO ENSURE A SAFE WORKING ENVIRONMENT,

CAREFULLY READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Page 2

TABLE OF CONTENTS

1 INSPECTION ................................................................................................................................... 3

2 PRE-USAGE NOTES AND TESTING PROCEDURES .................................................................. 3

2.1 GROUNDING INSTRUCTIONS ............................................................................................... 3

2.2 IMPORTANT SAFETY PRECAUTIONS .................................................................................. 4

3 FILTRATION SYSTEM .................................................................................................................... 6

4 OPERATING INSTRUCTIONS ....................................................................................................... 7

4.1 OPERATING INSTRUCTIONS FOR DRY RECOVERY .......................................................... 7

4.2 OPERATING INSTRUCTIONS FOR VACUUM SANDING KITS ............................................ 8

5 MAINTENANCE .............................................................................................................................. 9

5.1 CLEANUP PROCEDURE AFTER USE ...................................................................................... 9

5.2 STORAGE ................................................................................................................................... 9

5.3 INSTALLING AND REPLACING THE INTERNAL HEPA FILTER AND SAFETY FILTER ..... 10

August 23, 2013

Page 2 of 13

Page 3

1 INSPECTION

Carefully unpack and inspect your Tiger-Vac vacuum cleaner. Each vacuum cleaner is tested and

thoroughly inspected before being shipped; therefore, any damage is the responsibility of the

delivering carrier, who should be notified.

2 PRE-USAGE NOTES AND TESTING PROCEDURES

POWER SUPPLY CORD

Should the power supply cord be replaced, carefully study the wiring diagram supplied with the

instruction manual.

NOTE: As the colors of the wires in the mains load of this appliance may not correspond

with the colored markings identifying the terminals in your plug, proceed as

follows:

- The wire which is colored green must be connected to the terminal in the plug which is marked with

the letter E or by the earth symbol, or colored green.

WARNING: THIS APPLIANCE MUST BE EARTHED.

- Dispose of a plug that has been cut from the power supply cord.

2.1 GROUNDING INSTRUCTIONS

This vacuum cleaner must be grounded. If it should malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce the risk of electric shock.

WARNING: This vacuum cleaner is equipped with a cord having an equipment-grounding

conductor and grounding plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in accordance with all local codes

and ordinances. Ensure that the fuse/breaker on the electrical panel is of the

correct rating and exceeds the maximum current rating shown on the technical

data sticker of the vacuum unit.

WARNING: DO NOT OPERATE UNIT WITHOUT A PROPER GROUND SOURCE.

DANGER: Improper connection of the equipment-grounding conductor can result in a risk

of electric shock. Check with a qualified electrician or service person if you are in

doubt as to whether an outlet is properly grounded. Do not modify the plug

provided with the vacuum cleaner. If it will not fit the outlet, have a proper outlet

installed by a qualified electrician. No adaptor should be used with this vacuum

cleaner.

Page 3 of 13

Page 4

2.2 IMPORTANT SAFETY PRECAUTIONS

WARNING: If vacuum cleaner is used to recover toxic or hazardous substances such as:

asbestos, silica, lead, pesticides, etc., the following safety precautions must be

taken:

1. Vacuum cleaner must be equipped with a HEPA filter.

2. Service and operation should only be carried out by trained personnel wearing appropriate

clothing and breathing apparatus.

3. Dispose of collected materials responsibly. Follow government regulations for the disposal of

hazardous materials.

NOTE: Any health hazard associated with the use of this vacuum cleaner in conjunction

with the recovery of asbestos and other hazardous substances has not been

investigated.

WARNING: To reduce the risk of fire, electrical shock or injury:

4. Do not leave vacuum cleaner when plugged in. Unplug from outlet when not in use and before

servicing.

5. Do not allow vacuum cleaner to be used as a toy. Close attention is necessary when used near

children.

6. Use only as described in this manual. Use only with recommended attachments.

7. Do not use with damaged cord or plug. If vacuum cleaner is not working as it should, has been

dropped, damaged, left outdoors or dropped into water, return it to a service centre.

8. Do not: pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around

sharp edges or corners. Do not run vacuum cleaner over cord. Keep cord away from heated

surfaces.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

Page 4 of 13

Page 5

10. Do not handle plug or appliance with wet hands.

11. Do not put any object into openings. Do not use with any openings blocked; keep free of dust, lint,

hair and anything that may reduce air flow. Poor ventilation will result in overheating of motor.

12. Keep hair, loose clothing, fingers and all parts of body away from openings and moving parts.

13. Do not pick-up anything that is burning or smoking such as: cigarettes, matches or hot ashes, etc.

14. Do not use without appropriate filters in place.

15. Turn of all controls before unplugging.

16. Use extra care when cleaning on stairs.

17. Do not pick-up flammable or combustible liquids such as gasoline, or use in areas where they

may be present.

18. Never operate unit unless the power-head is securely fastened to the recovery tank with latches.

19. Connect to a properly grounded outlet only. See grounding instructions.

Page 5 of 13

Page 6

3 FILTRATION SYSTEM

1 Paper filter bag

2 Main cloth filter

3 Safety filter

4 HEPA filter

Page 6 of 13

Page 7

4 OPERATING INSTRUCTIONS

(Refer to section 3.0 Filtration System for illustrations)

WARNING: The vacuum cleaner is designed dry recovery. The appropriate filters must be

installed in the vacuum cleaner.

4.1 OPERATING INSTRUCTIONS FOR DRY RECOVERY

1. Disengage the latches and remove the power head from recovery tank.

WARNING: Make sure that the HEPA FILTER is properly installed prior to use.

2. Ensure that no liquids are present in the recovery tank.

3. Connect the PAPER FILTER BAG (item 1) to the inlet inside of the recovery tank. Make sure that

the rubber collar of the paper filter bag fits snugly around it.

4. Install the main cloth filter in the recovery tank. Make certain that the filter’s gasket covers the

entire circumference of the recovery tank lip.

5. Place the power head on the recovery tank and fasten the lid to the tank with the latches.

6. Plug in the power cord into a grounded electrical outlet.

7. Fasten hose to suction intake on side of recovery tank

8. Attach desired tools to the hose. Use only the recommended cleaning tools supplied with each

unit.

9. To operate unit, depress switch in the ON position.

10. To shut off unit, depress switch in the OFF position. Disconnect power cord when not in use.

Page 7 of 13

Page 8

4.2 OPERATING INSTRUCTIONS FOR VACUUM SANDING KITS

WARNING: Always wear eye protection when sanding or grinding even if using vacuum

assisted tools.

WARNING: It is the users responsibility to determine the type of protective clothing and

respiratory equipment required.

IMPORTANT: Carefully read and follow the instructions provided with the vacuum assisted

sander or grinder to ensure proper operation.

1. Disengage the latches and remove the powerhead from the recovery tank.

WARNING: Make sure that the HEPA FILTER is properly installed prior to use.

2. Ensure that no liquids are present in the recovery tank.

3. Connect the PAPER FILTER BAG (item 1) to the inlet inside of the recovery tank. Make sure that

the rubber collar of the paper filter bag fits snugly around it.

4. Install the main cloth filter in the recovery tank. Make certain that the filter’s gasket covers the

entire circumference of the recovery tank lip.

5. Place the power head on the recovery tank and fasten the lid to the tank with the latches.

6. Plug in the power cord into a grounded electrical outlet.

7. Fasten hose to suction intake on side of recovery tank

8. Connect sander or grinder to the suction supply hose. Follow the instructions provided with the

sander or grinder to ensure proper operation.

9. To operate unit, depress switch in the ON position.

10. To shut off unit, depress switch in the OFF position. Disconnect power cord when not in use.

Page 8 of 13

Page 9

5 MAINTENANCE

5.1 CLEANUP PROCEDURE AFTER USE

1. Disconnect power cord from electrical outlet.

2. Disengage latches and remove power head from recovery tank.

3. Remove the main cloth filter and paper filter bag from recovery tank.

4. Empty collected materials into suitable container.

5. Clean the main cloth filter periodically. A clogged filter restricts the air flow and reduces the

vacuum’s performance. The main cloth filter may be washed in lukewarm water.

NOTE:

cleaner.

6. Paper filter bags may not be reused once full, they must be discarded.

Ensure that main cloth filter assembly is completely dry before reinstallation in vacuum

NOTE: Ensure that main cloth filter assembly is completely dry before reinstallation in vacuum

cleaner.

5.2 STORAGE

It is recommended that the inside of the recovery tank be cleaned and dried before storing the vacuum

cleaner.

Page 9 of 13

Page 10

5.3 INSTALLING AND REPLACING THE INTERNAL HEPA FILTER AND SAFETY FILTER

HEPA filters are designed for filtration of ultra-fine particles. A clogged HEPA filter will restrict the air

flow thereby reducing the vacuum's performance.

Depending upon operating conditions, it is recommended that the HEPA filter and the safety filter be

replaced at least once a year.

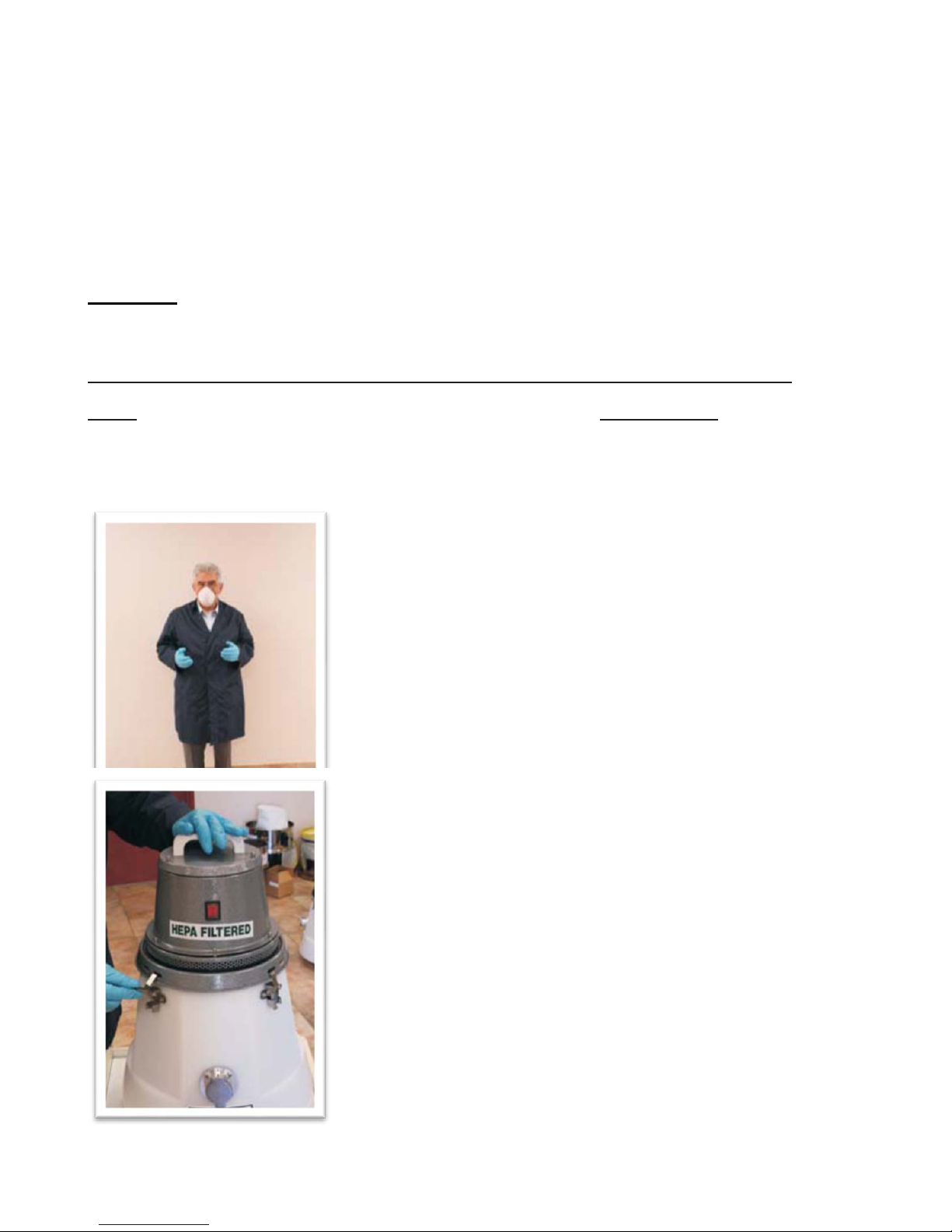

WARNING: If vacuum is used for the recovery of toxic materials proper clothing and the use

of an appropriate breathing apparatus is necessary when replacing the HEPA

filter, the safety filter or any other contaminated part of the vacuum cleaner.

HOW TO PROPERLY DISPOSE OF THE INTERNAL HEPA FILTER AND SAFETY FILTER

NOTE: A second vacuum cleaner sprays or other power sources are not required for this type of

operation in our industry. Proper clothing is, however, required by OSHA for the health and

safety of the operator.

In the Controlled Environment Industry for the recovery of

designated substances, changing a filter is considered a low to

moderate risk. However, a protective mask and gloves should be

worn. The following procedure is valid for both electrically and

pneumatically (air) operated vacuum cleaners.

In order to change the HEPA filter, leave the vacuum

cleaner running and remove the powerhead from the

recovery tank by detaching the latches.

Page 10 of 13

Page 11

The HEPA filter and safety filter are attached to the

lid of the powerhead.

Stop the vacuum cleaner and carefully place the

powerhead of the vacuum cleaner on a poly liner on the

ground.

Place a poly liner in the recovery tank inside of the

main cloth filter.

Page 11 of 13

Page 12

Place the powerhead on the edge of the recovery

tank on top of the poly liner.

Carefully remove the safety filter and place it gently

into the poly liner.

Unscrew the hex nut located under the HEPA filter using a

5mm (5/6” #8) tool and carefully lower the HEPA filter into

the poly liner.

Page 12 of 13

Page 13

The HEPA filter and safety filter are now sealed inside of the

poly liner and can be disposed of according to local

governmental laws. (Conductive poly liners are available.)

Gently lift up the poly liner and seal it with a tie wrap.

Following the above operations:

1. Place a new HEPA filter under the lid and fix it with the hex nut using a 5mm (5/6” #8) tool

2. Place and fasten a new safety filter around the HEPA filter.

NOTE: It is recommended that an aerosol leak test, or particle count test be performed

before use to ensure that HEPA filter has been properly installed.

Page 13 of 13

Page 14

Page 15

Two Year Warranty

Tiger-Vac warrants that its equipment will be free of defects in workmanship or material for a

period of Two year from the date of delivery. Should any failure to conform to this warranty

appear Tiger-Vac shall upon notification within such time period, correct such non-conformity, at

its option, either by repairing any defective part or parts, or by replacing a part or parts provided

that the equipment is returned to an authorized Tiger-Vac service facility. In all cases freight

both ways will be at the expense of the customer. Equipment shall not be returned without

advance notice to, and consent of Tiger-Vac.

Except as specifically set forth herein, Tiger-Vac makes no warranties, either expressed or

implied as to any matter whatsoever, including without limitation any and all warranties of

merchantability, fitness for purpose, or other warranties, all of which are expressly disclaimed

and excluded. Neither party shall be liable to the other for special, indirect, incidental or

consequential damages, including but not limited to loss of production, loss of time, loss of

profits or any other similar indirect losses which might occur as a result of defects partial or total

failure of the product to perform as specified.

Correction of non-conformities or defects in the manner and for the period of time provided

above, shall constitute fulfillment of all liabilities of Tiger-Vac to the customer whether based on

contract, negligence or otherwise with respect to, or arising out of such equipment. The remedies

set forth herein are exclusive, and the liability of Tiger-Vac with respect to this sale or anything

done in connection therewith, whether in contract, in tort, under any warranty, or otherwise, shall

not, except as expressly provided herein, exceed the price of the equipment or part on which such

liability is based.

This warranty does not cover repairs due to normal wear and tear, accident, neglect, misuse or

abuse, incorrect installation or use other than as described in the instruction booklet. Breaks in

hoses and cables are not covered. This warranty is rendered void if the motor plate is removed or

defaced or if repairs are made or attempted by persons not authorized by Tiger-Vac.

Some states do not allow exclusions of implied warranties or limitation on how long an implied

warranty lasts so the above exclusions or limitation of implied warranties may not apply. Some

states do not allow exclusion or limitation of incidental or consequential damages so the above

exclusion or limitation of incidental or consequential damages may not apply. Limited warranties

set forth above give specific legal rights. Customer may have other rights which vary from state

to state.

Tiger-Vac Inc. (USA)

73 S.W. 12 Ave. Bldg. 1, Unit 7

Dania, FL 33004 USA

Tel: (954) 925-3625

Fax: (954) 925-3626

Tiger-Vac International Inc.

2020 Da gena is West

Laval, Qc H7L 5W2 Canada

Tel: (450) 622-0100

Fax: (450) 625-3388

e-mail: support@tiger-vac.com

web-site: www.tiger-vac.com

Loading...

Loading...