Severe Heavy Duty

Bearing Cup Installer

10218

Safety Warning

Read all instructions and safety warnings prior to operation. Failure to do so could

result in equipment damage, personal injury or even death.

CAUTION: FAILURE TO CHECK THE SPHERICAL THRUST WASHER AND REPL ACE AS NECESSARY MAY RESULT

IN UNREPAIRABLE DAMAGE TO YOUR U-JOINT PULLER GLOVE CASTING. PREVENTATIVE MAINTENANCE AS

OUTLINED BELOW WILL ENSURE MANY YE ARS OF USE FROM YOUR TIGER TOOL PULLER. FAILURE TO PERFORM

PREVENTATIVE MAINTENANCE WILL VOID YOUR WARRANT Y.

•

Stay Alert! Watch what you are doing and use common sense when

operating this tool.

•

Inspect product for damage prior to using; do not use if product is

in unsafe condition.

•

Do not operate tool while under the influence of drugs, alcohol

or medication.

•

Always use safety equipment to prevent injuries. Approved face

and eye protection must always be worn by the operator, as well

as others in the work area.

•

Do not overreach. Keep proper footing and balance at all times.

•

Dress properly. Do not wear loose clothing or jewelr y.

Keep your hair, clothing and gloves away from moving parts.

•

Keep your work area clean and well lit.

Have Wh at It Takes

NOTE: HAMMERING THIS TOOL WILL VOID YOUR WARRANTY.

View demonstration videos and a

complete product list at tigertool.com

Technical Support

1.800 .661.46 61

Severe Heavy Duty

Bearing Cup Installer

10218

Operating Instructions

1 Clean bearing cup bores of all rust and debris.

2 Select & install the correct anvil for the driveline being

worked on:

A For the Spicer driveshaft – use the “SPL 350” anvil

B For the Meritor driveshaft – use the “RPL 35” anvil

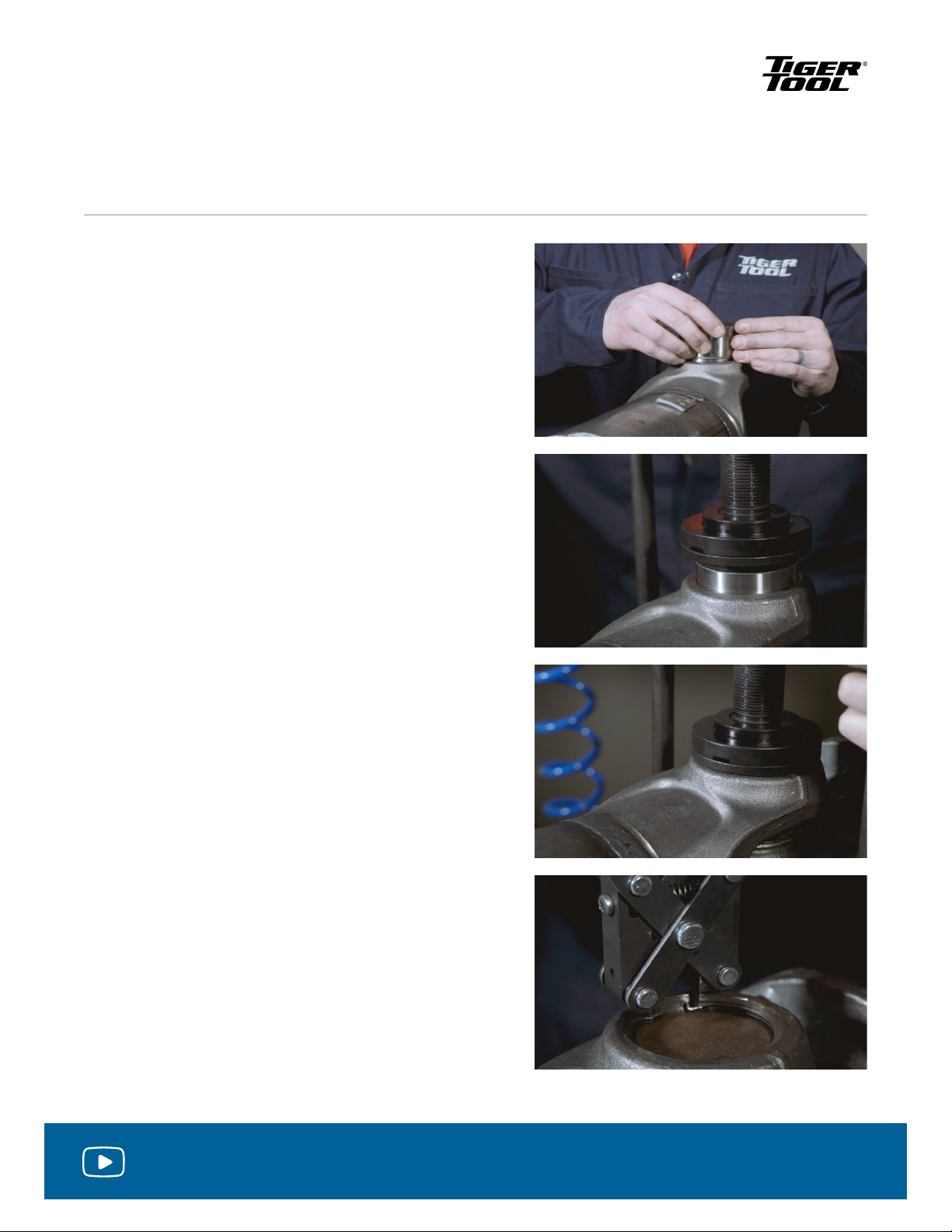

3 Press one bearing cup into the yoke by hand, then place

the tool over top of the yoke/protruding bearing cup.

(Figure 1)

4 Using a wrench or ratchet, turn the forcing screw and

press the bearing cup in to the yoke until the bottom of

the cup is flush with the underside of the yoke.

(Figure 2)

5 Rotate the driveshaft 180 degrees and place the U-joint

cross in to the half-installed bearing cup.

Have Wh at It Takes

1

2

6 Repeat steps 3 and 4 on the opposing yoke, making

sure the needle bearings stay in place and the u-joint

cross rotates freely inside the cups.

7 Rotate the driveshaft 180 degrees and press the half-

installed bearing cup down to the installed depth.

(Figure 3)

8 Install new retaining rings. (Figure 4)

Here at Tiger Tool, your satisfaction is our number one

priority. Should you have any questions about this or any

of our products, please call us at 1.800.661.4661.

3

4

View demonstration videos and a

complete product list at tigertool.com

Technical Support

1.800 .661.46 61

Severe Heavy Duty

Bearing Cup Installer

10218

Parts Breakdown

Have Wh at It Takes

1

2

3

4

5

6

Item No.

1

2

3

4

5

6

View demonstration videos and a

complete product list at tigertool.com

Part Number

90150-13

10218-14

10218-1

90150-14

10218-3

10218-13

Description

Forcing Screw - Short

SHCS

Installer Top Plate

O-Ring

Installer Anvil

Adapter

Qty.

1

2

1

1

1

1

Technical Support

1.800 .661.46 61

Severe Heavy Duty

Bearing Cup Installer

10218

Parts Breakdown

Have Wh at It Takes

7

Item No.

7

8

9

10

11

Part Number

10100-5

10218-4

10218-12

10218-5

10218-2

10

Description

FHMS

Anvil End Plate - SPL 350

O-Ring

Anvil End Plate - RPL 35

Installer Bottom Plate

8

9

11

Qty.

1

1

2

1

1

View demonstration videos and a

complete product list at tigertool.com

Technical Support

1.800 .661.46 61

Loading...

Loading...