TigerStop TigerStop Installation Manual

2017 TigerStop, LLC

TigerStop

®

February 2017 Mk1

Register warranty and enable TigerStop

Optimizer BEFORE installation!

See Page 14!

1

Serial Number

Safety First!

WARNING: Installation of your TigerStop Product must be done by a person trained in the safe

design and installation of automation products, and in the safe operation of power equipment. Ensure

that such installation meets all legally required safety requirements and guidelines, and that proper

guarding and safety devices are provided on all sides of the equipment to preclude unintended access

during operation. Consult with and follow the recommendations of a qualifi ed safety engineer.

WARNING: TigerStop Products are components intended for use in conjunction with potentially

dangerous machinery. The use of TigerStop Products does not make other machinery safe. TigerStop

Products are not intended to substitute, in any manner, for safe operating practices in general, or for

safety features present in other machines designed to make those machines as safe as possible.

TIGERSTOP PRODUCTS, IF USED OR INSTALLED IMPROPERLY, MAY CAUSE PERSONAL

INJURY OR DEATH AND SHOULD ONLY BE OPERATED BY PERSONS TRAINED IN THEIR

SAFE OPERATING PROCEDURES. Illustrations of TigerStop Products in use do not show, and are

not intended to show, all safety features and practices necessary for their safe operation.

GENERAL

WARNINGS

IMPORTANT SAFETY INFORMATION. READ ALL WARNINGS BEFORE OPERATING THIS PRODUCT.

WARNING: TigerStop Products must be installed in accordance with all local, state, and federal

regulations. Only personnel properly trained in the safe design and installation of automation

machinery and related power equipment should install TigerStop Products onto other equipment, to

ensure a safe and proper work station. TigerStop Products should not be operated without proper

training, both in the operation of TigerStop Products, and in the operation of related equipment.

INSTALLATION

WARNINGS

IMPORTANT CAUTION:

The motor box (compartment) contains DC voltage with potentially FATAL amperage. NEVER attempt

any unauthorized actions inside the motor box.

WARNING: Using a TigerStop interconnect does not relieve you of the responsibility for making sure

that your saw or other tool has all the necessary safety equipment in place. All installations must

meet all legally required safety requirements and guidelines. Installation and training should be done

following the recommendations of a qualifi ed safety engineer.

INTERCONNECTS

DANGER: This machine can start, move and stop automatically. Keep hands and loose clothing

clear of moving parts while operating. Moving parts can crush and cut. When used with a saw or

other cutting equipment, bodily injury and death may result if operated without safety guards on

all machines. Do not operate with guards removed. Operators must wear adequate eye and ear

protection.

OPERATION

DANGER! Don’t get pinched by the push feeder. Keep your hands away when in motion!

Controller

Controller

Stand

FlipAway

Stop

Nut Pack

Quick Reference

Cards

Power CableController Cable

Standard Interconnect Kit

Mini Gang Stop

2

Safety First!

WARNINGS

INSTALLATION

WARNINGS

INTERCONNECTS

OPERATION

IMPORTANT SAFETY INFORMATION. READ ALL WARNINGS BEFORE OPERATING THIS PRODUCT.

WARNING: Installation of your TigerStop Product must be done by a person trained in the safe

design and installation of automation products, and in the safe operation of power equipment. Ensure

that such installation meets all legally required safety requirements and guidelines, and that proper

guarding and safety devices are provided on all sides of the equipment to preclude unintended access

during operation. Consult with and follow the recommendations of a qualifi ed safety engineer.

GENERAL

WARNING: TigerStop Products are components intended for use in conjunction with potentially

dangerous machinery. The use of TigerStop Products does not make other machinery safe. TigerStop

Products are not intended to substitute, in any manner, for safe operating practices in general, or for

safety features present in other machines designed to make those machines as safe as possible.

TIGERSTOP PRODUCTS, IF USED OR INSTALLED IMPROPERLY, MAY CAUSE PERSONAL

INJURY OR DEATH AND SHOULD ONLY BE OPERATED BY PERSONS TRAINED IN THEIR

SAFE OPERATING PROCEDURES. Illustrations of TigerStop Products in use do not show, and are

not intended to show, all safety features and practices necessary for their safe operation.

WARNING: TigerStop Products must be installed in accordance with all local, state, and federal

regulations. Only personnel properly trained in the safe design and installation of automation

machinery and related power equipment should install TigerStop Products onto other equipment, to

ensure a safe and proper work station. TigerStop Products should not be operated without proper

training, both in the operation of TigerStop Products, and in the operation of related equipment.

IMPORTANT CAUTION:

The motor box (compartment) contains DC voltage with potentially FATAL amperage. NEVER attempt

any unauthorized actions inside the motor box.

WARNING: Using a TigerStop interconnect does not relieve you of the responsibility for making sure

that your saw or other tool has all the necessary safety equipment in place. All installations must

meet all legally required safety requirements and guidelines. Installation and training should be done

following the recommendations of a qualifi ed safety engineer.

DANGER: This machine can start, move and stop automatically. Keep hands and loose clothing

clear of moving parts while operating. Moving parts can crush and cut. When used with a saw or

other cutting equipment, bodily injury and death may result if operated without safety guards on

all machines. Do not operate with guards removed. Operators must wear adequate eye and ear

protection.

DANGER! Don’t get pinched by the push feeder. Keep your hands away when in motion!

3

IMPORTANT SAFETY INFORMATION. READ ALL WARNINGS BEFORE OPERATING THIS PRODUCT.

Keep the work area clean and well lighted to avoid accidental injury.

Do not use TigerStop machines in a dangerous environment. Using power tools in damp or wet

locations or in rain can cause shock or electrocution.

Do not operate near fl ammable liquids or in gaseous or explosive atmospheres!

Wear proper apparel, no loose clothes, long hair or jewelry which could get pulled into moving

machinery or materials.

Wear non slip footwear, safety glasses, ear protection and a dust mask.

Use only 3- wire extension cords that have 3-prong grounding type plugs and 3-pole receptacles that

accept the tools plug for 120VAC. Use only 5-wire cords and plugs when using 3 phase.

Do not open motor compartment or controller keypad. DC Voltage with potentially FATAL amperage!

Disconnect power before servicing. No user-serviceable parts inside.

DO NOT operate this or any machine under the infl uence of drugs or alcohol!

No one should operate this machine except for fully qualifi ed personnel.

Read the manual!

4

Table of Contents

Table of Contents

Installation Requirements..............................................................................................6

TigerStop Installation....................................................................................................7

TigerStop Anatomy

Installation

Mounting TigerStop on the Right Side of your Tool

Install Flipaway Stop

Install Mini Gang Stop

Install Controller Stand

Install Standard Interconnect Kit

Final Connections

Enable Code..............................................................................................................14

Enabling Dynamic Optimization

First Power Up...........................................................................................................15

Calibration Settings

Set Zero End

Find the End Limits

Calibrate TigerStop

Set Kerf

Set Units

Set Optimizer Settings

Basic TigerStop Functions............................................................................................21

Entering Decimals

Entering Fractions

Calculator Mode

Jog

Increment

Preset

Quick Calibration

Working with Part Lists...............................................................................................25

Programing a List

Creating a Backboard Defecting & Optimizing List

Maintenance Schedule................................................................................................29

5

Installation Requirements

Installation Requirements

TigerStop Power Requirements

110 VAC 15 Amps

208 VAC 20 Amps

240 VAC 20 Amps

TigerStop must have a dedicated circuit. No other equipment or devices should be on the same circuit.

WARNING! Do NOT use a high leg delta circuit to power TigerStop.

If you are not sure what kind of circuit you are using, STOP! Have a qualified electrician confirm the main power circuit.

Do NOT drill or tap into the TigerStop beam!

Drilling holes into the TigerStop beam may damage the drive system. All fastening or

attachment to the fence beam must be made by inserting T-bolts or T-nuts with washers.

Do NOT over tighten mounting hardware!

It is critical, especially if not using the TigerStop Universal Attachment brackets, that the

bolts are prevented from over tightening and driving into the fence beam. Always use washers.

ALWAYS evenly tighten mounting hardware!

Uneven tightening of mounting hardware can introduce a slight twist or other deformation in the beam.

This will result in inaccurate measurement and premature failure of the drive belt or other components.

The motor box compartment contains DC voltage with potentially FATAL amperage.

6

NEVER open TigerStop Motor Box!

NEVER attempt unauthorized actions inside the motor box!

TigerStop Installation

TigerStop Installation

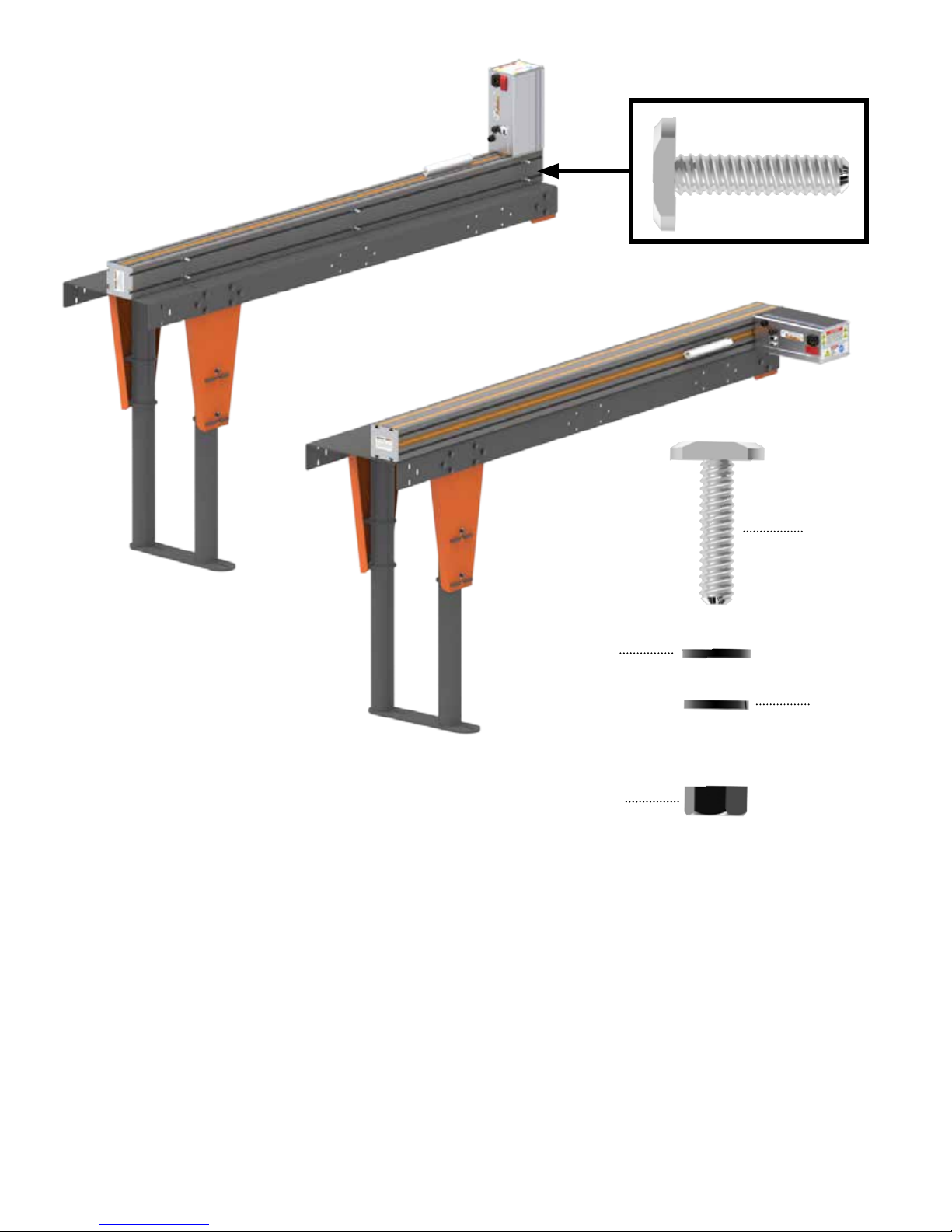

TigerStop Anatomy

Motor Box

Flip away Stop

End Cap

Controller

TigerStop

Serial Number

Installation

Orange

Trim Strips

Attachment

Mounting Slots

Controller

Stand

Power Switch

&

Incoming Power

TigerStop

Mounting Slots

(Underside)

1. Unpackage and place TigerStop on the mounting surface with the motor box facing up.

2. Insert the T-Bolts from the hardware pack into the TigerStop mounting slots.

3. Rotate TigerStop so that the T-Bolts go through the holes in the mounting surface.

4. Attach the washer, lock washer and nut on each T-Bolt. Tighten evenly.

7

T-Bolt

Washer

Lock Washer

Nut

Mounting TigerStop on the Right Side of your Tool

From the factory, TigerStop is built to be installed on the left side of your tool. With very little

configuration, you can install TigerStop to the right side of the tool. The TigerStop has mounting slots on

both the top and the bottom of the beam. The top slots are filled with orange trim strips from the factory.

To mount TigerStop on the right side of your tool, simply remove the orange trim strips from the top

mounting slots, flip the machine over 180 degrees, and mount as normal.

8

Install Flip Away Stop

Threaded

1. Place the flip away stop on the TigerStop carriage.

2. Insert a nylon washer between the carriage hinge and flip away stop hinge, one on each end.

3. Insert the threaded rod into the flip away stop.

4. Screw the locking nuts on each end of the threaded rod. Tighten so that when raised slightly, the flip

away stop says up.

Rod

Locking Nut

Nylon Washer

Nylon Washer

Locking Nut

9

Install Mini GangStop

The Mini GangStop extends the reach of TigerStop so that you can reach the zero point of your tool.

Being able to reach 0 is essential for getting the best material yield when using your TigerStop Dynamic

Optimization feature.

The stop plate at the front of the Mini GangStop can be adjusted, by loosening the bolt, to

accommodate very thin materials or the PVC foot can be removed and the stop plate can be adjusted

to push materials that are stacked up.

1. Attach PVC foot to Mini GangStop stop plate.

2. Slide two T-Nuts into the lower channel of the flip away stop.

3. Connect the two tube retention blocks to the T-Nuts using two cap head screws.

4. Slide the Mini GangStop assembly into the tube retention blocks. Tighten down the locking handles.

10

Loading...

Loading...