Page 1

USE AND MAINTENANCE MANUAL

YEAR OF MANUFACTURE: ______________

TIGER 370 CNC--MR

EN

Page 2

Page 3

EN

”CE” CONFORMITY DECLARATION

(according to EEC MACHINES DIRECTIVE 2006/42/CE annex II A)

The manufacturer:

SPA

SEGATRICI

Via Enzo Magnani, 1

61045 Pergola (PU) ITALIA

Tel. 072173721--Fax 0721734533

Hereby declares that the circular sawing machine:

Machine model:

Serial number:

Year of manufacture:

TIGER 370 CNC--MR

is in specification with the following directives:

• DIRECTIVE EEC MACHINES DIRECTIVE 2006/42/CE

• DIRECTIVE 2006/95/CE ”LVD”

• DIRECTIVE 2004/108/CE ”EMC”

• D. Lgs. 17/2010

Responsible of a Technical File

(Walter Di Giovanni)

c/o MEP SPA

Via Enzo Magnani, 1

61045 -- Pergola -- PU -- ITALY

Pergola, lì

Managing Director

(William Giacometti)

Page 4

Page 5

5

Introduction and technical specifications 1--1..........

Foreword 1--1...................................

Machine presentation 1--1..........................

Machine specification 1--2.........................

Technical Data 1--2...............................

Technical Data 1--4...............................

Dimensions 1--4.................................

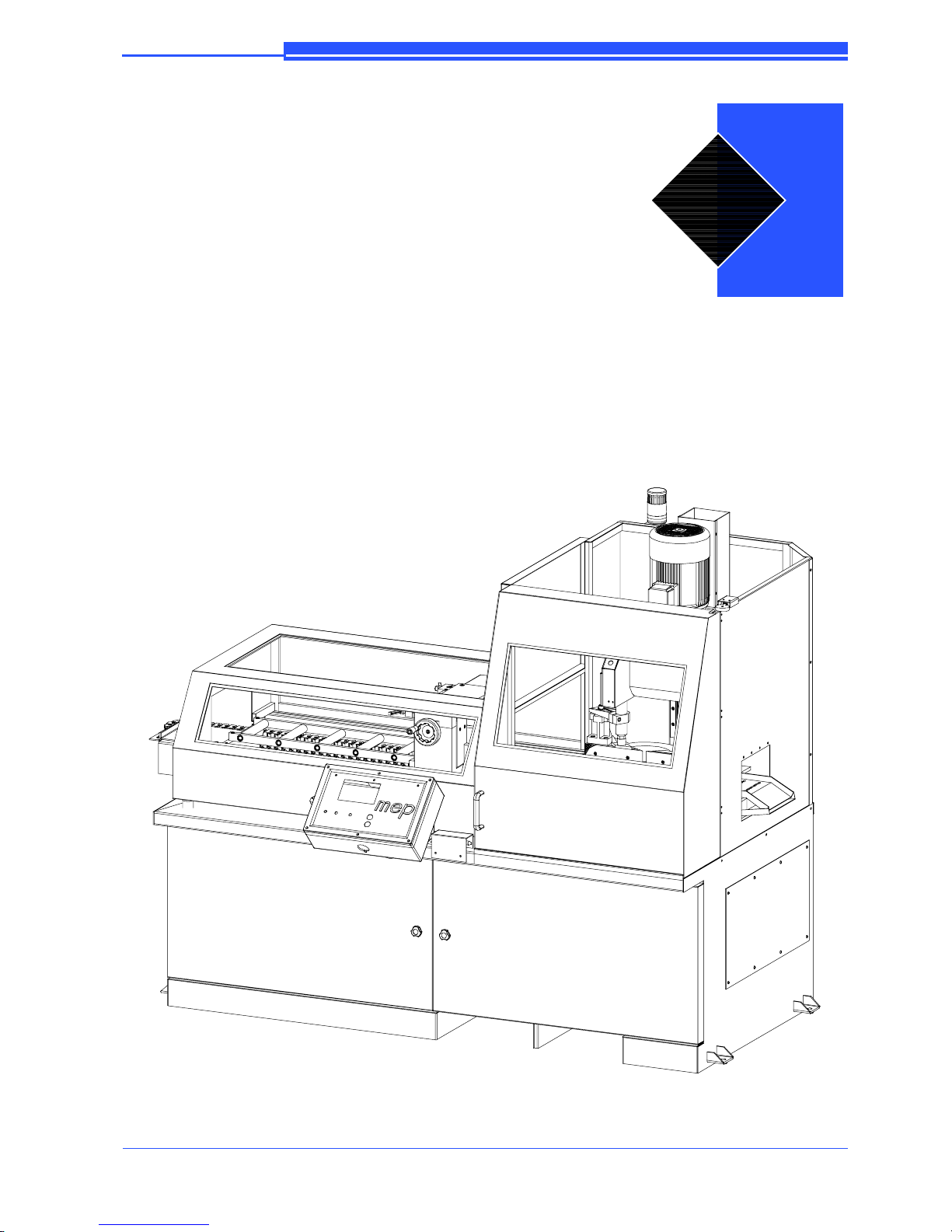

Functional parts 2--1..............................

TIGER 370 CNC--MR model 2--1...................

Cutting head 2--2.................................

Cutting vice 2--2.................................

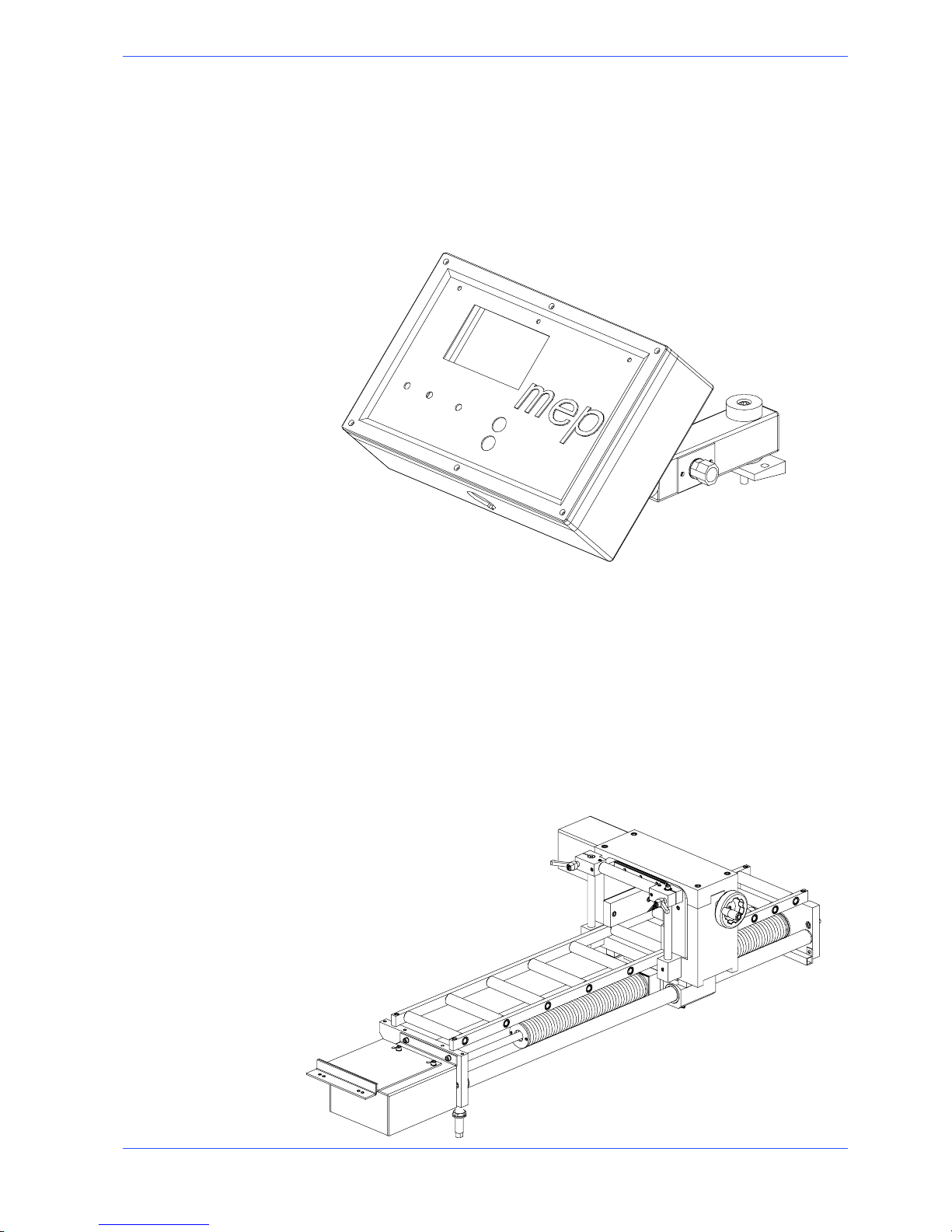

Control Panel 2--3................................

Feeder 2--3......................................

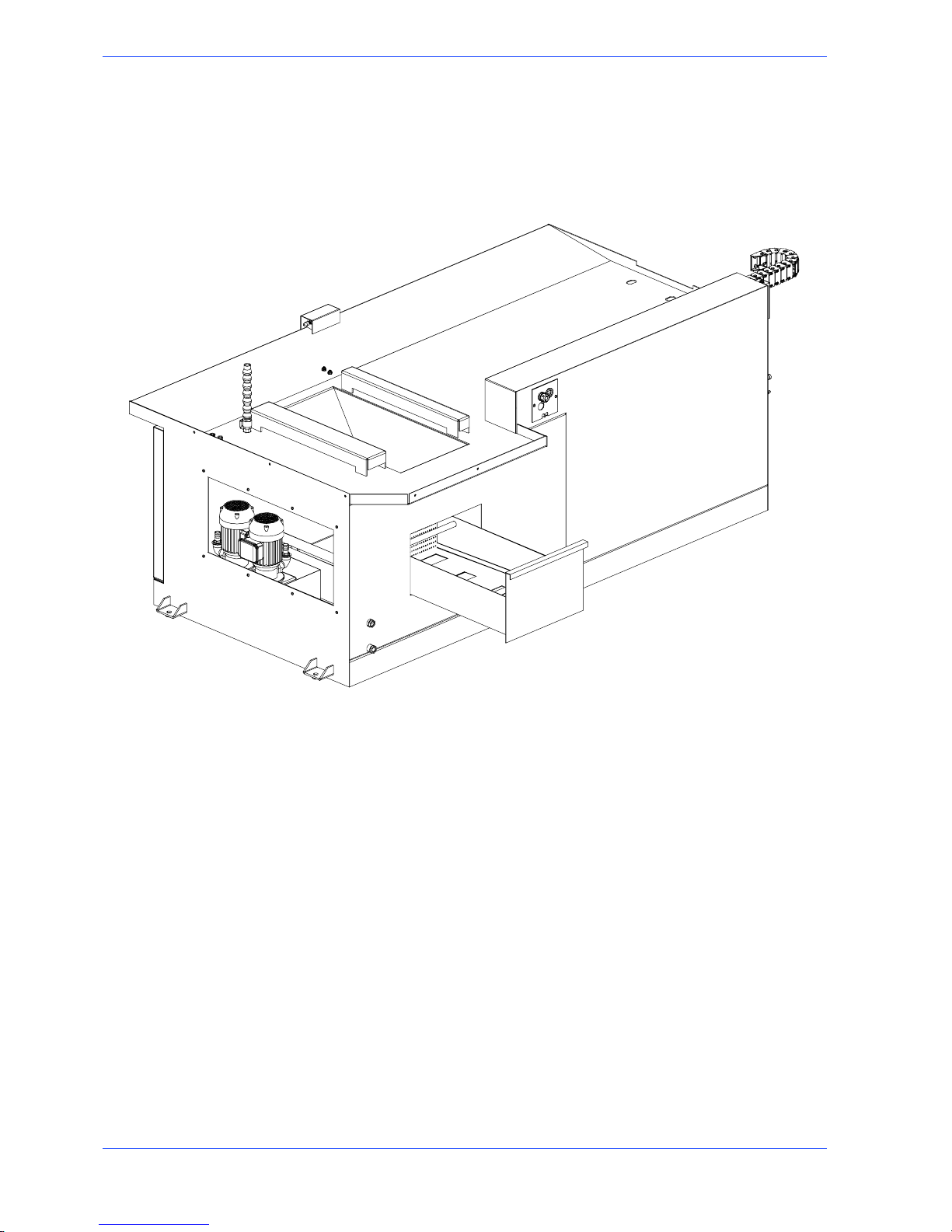

Base 2--4.......................................

Safety and accident prevention 3--1..................

Use of the machine 3--1...........................

General recommendations 3--1......................

Recommendations to the operator 3--2................

Machine safety devices 3--4........................

Reference standards 3--4...........................

Protection against accidental contact with the blade 3--5..

Electrical equipment 3--5..........................

Emergency devices 3--5...........................

Noise level of the machine 3--6......................

Noise level measurement 3--6.......................

Noise level values 3--7............................

Vibration emission 3--7............................

Electromagnetic compatibility 3--7...................

Machine installation 4--1...........................

Packaging and storage 4--1.........................

Anchoring the machine 4--4........................

Minimum requirements 4--4........................

Check list 4--4...................................

Connection to the compressed air supply 4--6..........

Connection to the power supply 4--6.................

Description of machine operation 5--1................

Description of the control panel 5--1.................

Page 6

6

Key for control console keyboard 5--1................

Basic instructions for carrying out a cutting cycle 5--4...

Manoeuvring the cutting head 5--4...................

Access to the cutting head 5--4......................

Manoeuvring the feeder 5--4........................

Clamping the work piece in the vice 5--4..............

Lubricant/coolant fluid supply 5--6...................

Preliminary check list for cutting operation 5--6........

Starting up the machine 5 --7........................

Semi--automatic operating cycle 5--8.................

Automatic operating cycle 5--12......................

Single program 5--15...............................

Multiple programming 5--22.........................

Multiple programming cuts 5--29.....................

Automatic loop operating cycle 5--30..................

Diagrams, exploded views and replace--

ment parts 6--1...................................

Pneumatic diagram TIGER 370 CNC--MR 6--1.........

Pneumatic diagram TIGER 370 CNC--FE HR 6--2......

APS/P drive for step motors 6--3....................

MEANING OF THE PARAMETERS IN THE TABLE 6--3

SCHEMATIC CONFIGURATION

OF INPUTS / OUTPUTS 6--7......................

LAYOUT OF APS/P DRIVE COMPONENTS 6--8.....

How to read the wiring diagrams 6--9.................

D2--Letter codes used to designate the type

of component 6--11................................

Standardised Wiring Diagrams TIGER 370 CNC--MR

(IEC 750 EN 60204--1 Standard) 6--14.................

List of cables 6--29................................

List of components 6--34............................

List of terminals 6--37..............................

List of IUD--IUV Card I nputs and Outputs 6--39.........

IUD: Digital Inputs and Outputs 6--39.................

IUV card: Miscellaneous Inputs and Outputs 6--39.......

CN 1 VICE 6--40..................................

CNSL card: Console Inputs and Outputs 6--41...........

Exploded views 6--42..............................

Page 7

7

Base 6--42.......................................

Fixed worktable 6--44..............................

Turntable 6--46...................................

Vice assembly 6--48...............................

Head unit 6--50...................................

Motor assembly 6-- 52..............................

Blade guard unit 6--54..............................

Electro--cylinder unit 6--56..........................

Supply carriage unit 6--58...........................

Supply roller unit 6--60.............................

Control panel 6--62................................

Guard rail 6--64...................................

Adjustments 7--1.................................

Displaying and editing the set--up parameters 7--1.......

Set language parameter 7--1........................

Set parameter for machine type 7--2..................

Set parameter for step motor 7--2....................

Setting blade characteristics, head downstroke

speed and bar initializing 7--5.......................

Blade motor and supply unit setting 7--5..............

Set minimum blade tension threshold 7--6.............

Optional settings 7--6.............................

Cutting head setting 7--7...........................

Head transducer calibration Set--up 7--7...............

Electronic systems 7--9............................

Replacing the microchip C8 on the control console 7--9..

Machine parameters Eeprom memory 7--9.............

Replacing the MEP 24 controller Eprom 7--10..........

Adjusting the display br ightness 7--11.................

Mechanical systems 7--12...........................

Cutting head stroke 7-- 12...........................

Adjusting the position of the blade--cleaning brush 7--12..

Replacing tool 7--14...............................

Feeder 7--15......................................

Vice 7-- 17.......................................

Adjusting the vice play 7--17........................

Adjusting the anti--chip device 7--18..................

Maintenance and choice of consumables 8--1...........

Page 8

8

The role of the operator 8--1........................

Maintenance requirements 8--2......................

General maintenance 8--2..........................

Daily 8--2.......................................

Weekly 8--2.....................................

Monthly 8--3....................................

Maintenance of working parts 8--3...................

Transmission box 8--3.............................

Consumable materials 8--4.........................

Oils for transmission box 8--4.......................

Oils for lubrication/coolant liquid 8--4................

Oils for spray mist system (optional) 8--4..............

Cutting speed and choice of tools 9--1................

Cutting speed 9 --1................................

Basic version 9--1................................

Choice of blade 9--2..............................

Tooth pitch 9--2..................................

Types of swarf: 9--3...............................

Cutting and feeding speed 9--3......................

Lubricant/coolant 9--4.............................

Blade structure 9--4...............................

Types of blades 9--5..............................

Tooth shape 9--5.................................

Blade selection table with respect to cutting speed and

downstroke speed 9--8.............................

Classification of steels 9--9.........................

Classification of steels 9--10.........................

Troubleshooting 10--1..............................

Troubleshooting blade and cutting problems 10--1........

Troubleshooting (control console diagnostics) 10--3......

Displaying the diagnostics menu 10--3.................

Diagnostics 10--4..................................

Error messages, alarm and emergency 10--7............

Optional 11--1....................................

Accessories available on request 11--1.................

Chute type bar loader CB 6001 11--1..................

Optional 11--3....................................

Blade 11--3......................................

Page 9

9

Roller table 11--3..................................

Can of emulsible oil 11--3...........................

Adattatore pianale a rulli lato scarico 11--3.............

Feed side roller table support 11--4....................

Motor chip discharger unit 11--4......................

Page 10

Page 11

1--1

Introduction and

technical

specifications

Foreword

We have decades of experience in the construction of the best metal ---cutting

machines. Our experience, our knowledge of our customers and constant

technological development of design and production equipment allow us to offer

a specific solution for every type of cutting need. This work tool has been

designed as a simple and reliable answer to the wide range of cutting needs of the

modern workshop. TIGER 370 CNC--- MR is rugged, quiet and safe. It cuts

various kinds of material, with very little scrap and great applicative flexibility

for

cutting copper, brass and bronze.

Congratulations for having chosen this product which, by following the instructions contained in this user and maintenance handbook, will guarantee you years

of dependable service.

This band saw has been exclusively designed to cut metals.

Machine presentation

TIGER 370 CNC---MR is an electromechanical pneumatic saw, which cuts metal

profiles and solids. It can operate in SEMIAUTOMATIC or AUTOMATIC

mode. In Semiautomatic mode, after setting the cutting head stroke and the head

downstroke speed on the control panel, position the vice 2÷3 mm from the

material being processed and press the start button on the control panel to

activate the disk (or foot pedal if supplied);

1.Thecuttervicecloses

2. The head lowers until the cut is made

(FCTA)

3. The head returns to

start position (FCTI)

4. The cutter vice

opens

In Automatic mode, after setting the cutting head stroke and the head downstroke speed on the control panel, position the vice 2÷3 mm from the material being

processed and press the start button on the control panel to activate the disk (or

foot pedal if supplied):

Warning

1

Page 12

MEP S.p.A.

1--2

2

Use and maintenance manual TIGER 370 CNC --MR

1.Thecuttervicecloses 2. The head lowers until the cut is made

(FCTA)

3. The head returns to

start position (FCTI)

4. The feed vice closes

5.Thecutterviceopens 6. The cutting material

is fed

7. The cuttingvice closes 8. The feed vice opens

and the cutting cycle

starts up

Machine specification

Theanodisedaluminiumnameplateisrivetedonthesideofthemachine;the

same data are reproduced on the declaration of conformity included with this use

and maintenance manual.

TIGER 370 CNC--FE MR

When communicating with the Technical Service department, the model, serial

number and year of manufacture of the machine must be quoted.

Tech n ical Data

WORKING PRESSURE

Max. working pressure for opening/closing vice Bar 6

Air consumption for a complete cycle Nl/min 5,74

The “air consumption” value refers to standard conditions (temperature 0° and

pressure 1.013 bar, i.e. density 1.3 x 10

-- 3

Kg/l) where 1 Kg/min. = 772 Nl/min.

N.B.

N.B.

Page 13

1--3

3

Introduction and technical specifications

LUBRICANT/COOLANT FLUID AND OIL

Lubricant/coolant fluid (oil concentration 5--- 6%) capacità Lt. 105

Oil for transmission box capacità Lt. 10

VICE

Vice max. opening mm 190

CUTTING CAPABILITY

Model Blade diameter

0° 370 120 100 180 x 100

45° ' 370 70 70 70 x 100

45° a 370 70 70 70 x 100

60° a 370 50 50 50 x 100

CUTTING CAPABILITY

Model Blade diameter

0° 370 120 100 180 x 100

45° ' 370 115 100 120 x 100

45° a 370 115 100 120 x 100

60° a 370 115 90 90 x 100

PACKED WEIGH T

Wooden cage and pallet Kg 250

Wooden pallet Kg 100

2600

1800

2100

Page 14

MEP S.p.A.

1--4

4

Use and maintenance manual TIGER 370 CNC --MR

Tech n ical Data

CUTTING SPEEDS

Speed rpm 900

Speed (optional) rpm 600900

Disk blade (HSS type)

External disc diameter mm 370

Internal hole diameter mm 32

Blade thickness mm 3

RATED ELECTRICAL POWER

Head spindle motor Kw 3

Electric coolant pump motor Kw 0,09 x 2

Feed step motor Kw 0,44

Step head motor kW 0,048

Max installed power kW 3.668

SPINDLE MOTOR

No.of poles Current (Volts) Absorption (Amps) Power (Kw) rpm

6 380 8,4 3 940---1130

Stator wound with enamelled copper wire, class H 200° C.

Class F insulation (limit temperature TL 155° C).

IP 54 protection rating (total against contact with live parts, water sprayed from all directions, with shaft oil

seal).

Conforming to CEI norms, publication: IEC 34 of 01/07/1985.

Dimensions

MACHINE INSTALLED

Work tabl e hei g ht mm 1000

Weight Kg 1060

Page 15

1--5

5

Introduction and technical specifications

Page 16

2--1

Functional parts

TIGER 370 CNC--MR model

In order for the user to move towards a full understanding of how the machine

works, which is described in detail in the chapter 5, this chapter deals with the

main units and their locations.

2

Page 17

MEP S.p.A.

2--2

7

Use and maintenance manual TIGER 370 CNC --MR

Cutting head

The cutter head makes the cut. It is contained inside guards preventing accidental

contact with the tool and moving parts. It is moved by an electro--- mechanical

cylinder (step motor), and runs on a twin linear guide with ball---bushing sliding

blocks. This system makes the structure highly rigid, providing a better cutting

finish with less vibration and noise.

Cutting vice

The vice is the unit that clamps the workpiece during cutting; it consists of a vice

support, commonly known as a “lead nut” fixed to the work table on which a

mobile jaw is mounted. The vice is operated manually by a handwheel and locked

by a Pneumatic cylinder.

Page 18

2--3

8

Functional parts

Control Panel

The control panel has a protection rating of IP 54 and contains the electronic

equipment. Access to the control panel is protected by a safety panel mounted on

hinges and fastened with screws, specially designed to prevent tampering. The

control panel swivels on two articulated joints so that it can be positioned by the

operator for greater ease---of---use and safety.

Feeder

The material, locked by means of the pneumatic vice, is delivered by a carriage

which conveys it along ground guides. The numeric check controls, with great

precision, the step motor of the infeed carriage, enabling the operator to set, on

the same bar, 32 batches of pieces to be cut, each with different amounts and

lengths.The material, locked by means of the pneumatic vice, is delivered by a

carriage which conveys it along ground guides. The numeric check controls, with

great precision, the step motor of the infeed carriage, enabling the operator to

set, on the same bar, 32 batches of pieces to be cut, each with different amounts

and lengths.

Page 19

MEP S.p.A.

2--4

9

Use and maintenance manual TIGER 370 CNC --MR

Base

This unit features a large coolant collection surface which conveys the coolant to

the rear tank via the tank cover, and a swarf collection drawer. An electric pump

is housed inside the tank which draws the clean fluid from the filter system.

Page 20

3--1

Safety and accident

prevention

The TIGER 370 CNC---MR has been designed and produced in accordance with

European standards. For the correct use of the machine we recommend that the

instructions contained in this chapter are carefully followed.

Use of the machine

The TIGER 370 CNC---MR circular saw is designed to cut exclusively non---fer-

rous profiles and solid metal sections. Other types of material and machining are

not compatible with the specific characteristics of the saw. The employer is

responsible for instructing the personnel who, in turn, are obliged to inform the

operator of any accident risks, safety devices, noise emission and accident

prevention regulations provided for by international standards and national laws

regardingtheuseofthemachine.Theoperatormustbeperfectlyawareofthe

position and function of all the machine’s controls.The instructions, warnings and

accident prevention standards in this manual must be respected without question

by all those concerned.The following definitions are those provided for by EEC

MACHINES DIRECTIVE 2006/42/CE :

H “Danger zone”: any zone in and/or around a machine in which the presence of a

person constitutes a risk for the safety and health of that person.

H “Person exposed”: any person finding himself either completely or partly in a

danger zone.

H “Operator”: the person or persons given t he responsibility of installing, operating,

adjusting, maintaining, cleaning, repairing or transporting the machine.

The manufacturer declines any responsibility whatsoever, either civil or criminal, should there be unauthorised interference or replacement of one or more

parts or assemblies on the machine, or if accessories, tools and consumable

materials are used that are different from those recommended by the manufacturer itself or if the machine is employed in a plant system and its proper

function is thereby altered.

General recommendations

LIGHTING

Insufficient lighting for the types of operation envisaged could constitute a safety

hazard for the persons concerned. For this reason, the machine user must provide

lighting in the working area sufficient to eliminate all shadowy areas while also

avoiding any blinding light concentrations. (Reference standard ISO 8995--- 89

”Lighting in work environments”).

CONNECTIONS

Check that the power supply cables and pneumatic feed systems comply with the

maximum machine absorption values listed in the “Machine Specification” tables;

replace if necessary.

Attention

3

Page 21

MEP S.p.A.

3--2

11

Use and maintenance manual TIGER 370 CNC --MR

EARTHING

The installation of the earthing system must comply with the requirements set out

in IEC STANDARD 204.

OPERATOR POSITION

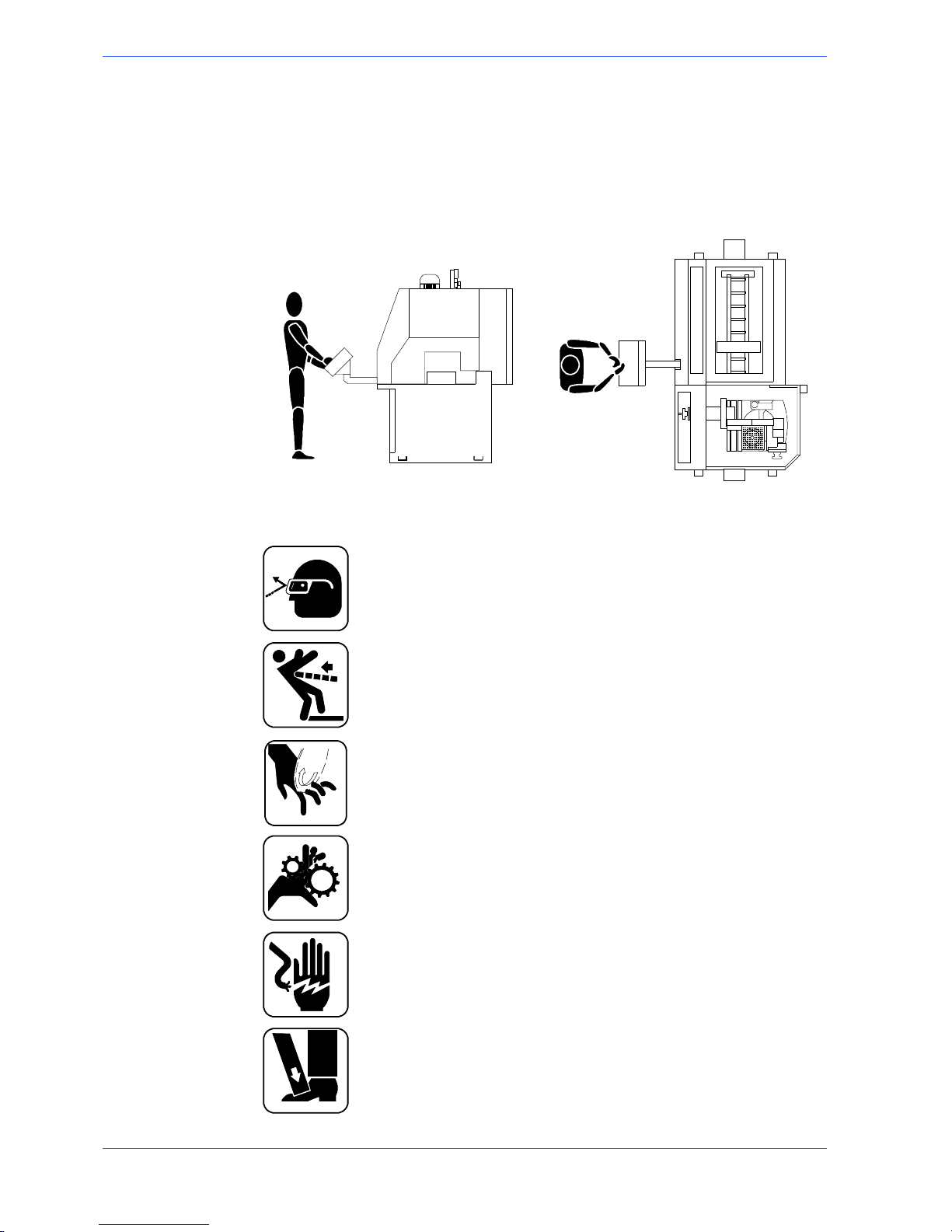

The position of the operator controlling machine operations must be as shown in

the diagram below.

Recommendations to the operator

Always wear proper goggles or protective glasses.

Do not use the machine without the guards in position. Replace the polycarbonate windows , if subject to corrosion.

Do not allow hands or arms to encroach on the cutting zone while the

machine is in operation.

Do not wear oversize clothing with long sleeves, oversize gloves, bracelets, necklaces or any other object that may become entangled in the machine during working; long hair must be tied back and bunched.

Alwaysdisconnectthepowersupplytothemachinebeforecarryingout

any maintenance work whatsoever, including in the case of abnormal

operation of the machine.

Before starting cutting operations, support the material at both e nds of

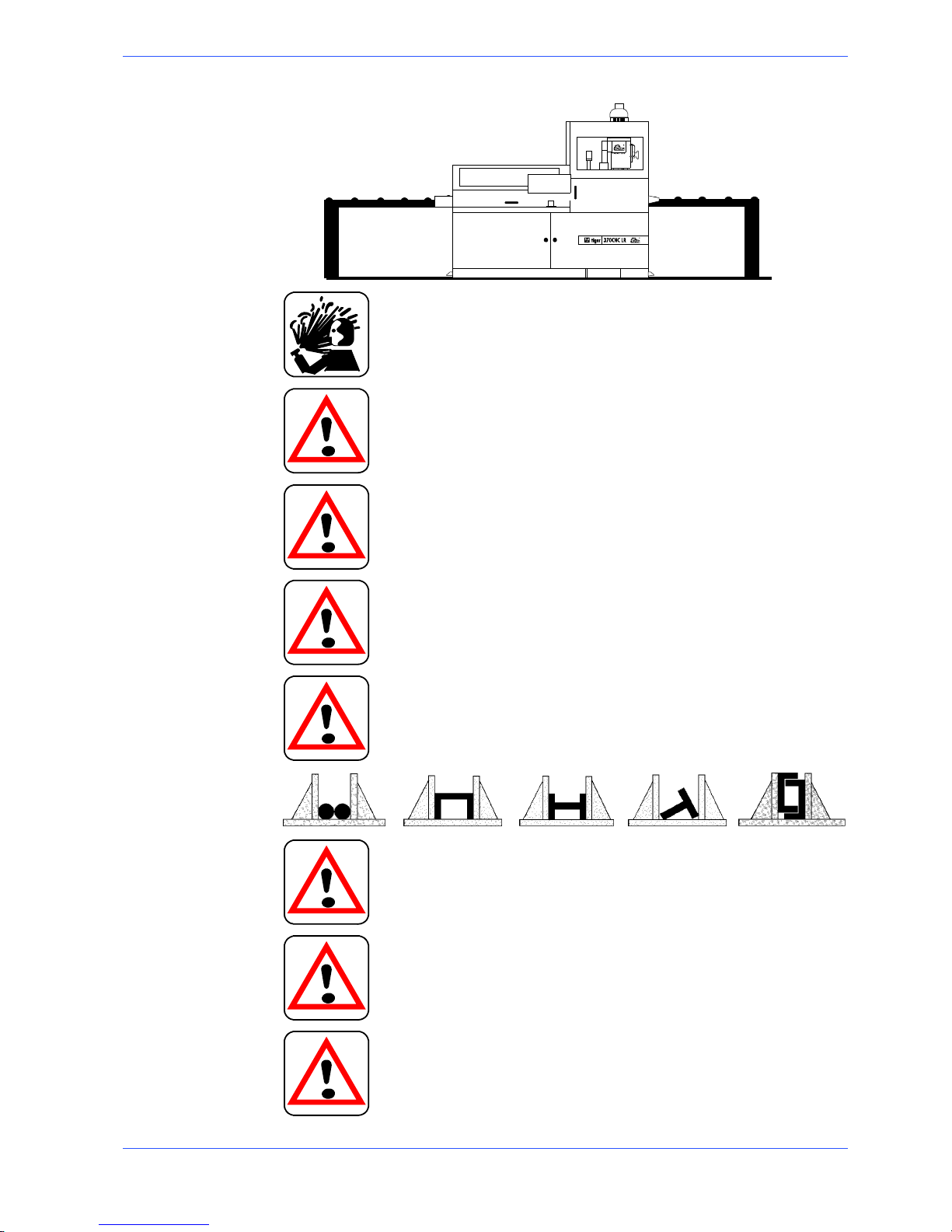

the machine using the support arm --- standard, or OPTIONAL accessories such as the feed and discharge roller tables shown in the diagram

below.

Page 22

3--3

12

Safety and accident prevention

mm. 1500 mm. 1500

FEED ROLLER TABLE

DISCHARGE ROLLER TA-

BLE

Any maintenance work on the hydraulic or pneumatic systems must be

carried out only after the pressure in the system has been released.

The operator MUST NOT perform any risky operations or those not

required for the machining in course (e.g. remove swarf or metal shavings

form the machine while cutting).

Remove equipment, tools or any other objects from the cutting zone; always keep the working area as clean as possible.

Do not use the machine for cutting pieces which exceed the cutting capacity described in the technical specifications or are less than 5 mm

Before starting any cutting operations, ensure that the workpiece is securely held in the vice and the machine has been set correctly. A number

of examples of how to clamp the different profiles correctly in our machines are shown below.

Never move the machine while it is cutting.

Do not use blades of different sizes to those recommended in the machine’s specifications.

When cutting very short pieces, make sure that they are not dragged behind the support shoulder, where they could jam in the blade.

Page 23

MEP S.p.A.

3--4

13

Use and maintenance manual TIGER 370 CNC --MR

When using the pneumatic vice (version MA) check that the jaws actually

move right up to and effectively block the piece, as the maximum travel

in only 6 mm, and check that the clamping pressure is correct.

When working on the bandsa w, only wear gloves when handling materials

and tool change or adjustment operations. Only carry out one operation

at a time and do not hold more t han one ite m or operate more than one

device simultaneously. Keep hands as clean as possible.

Warning: if the blade jams in the cut, press the emergency stop pushbutton immediately. If this does not free t he blade, slowly release the vice,

remove the piece and check that the blade or its teeth for damage, if

need be replace the blade.

Before carrying out any repair works on the machine, consult the MEP

Technical Service; this can also be done through an agency in the country

in which the machine is being used.

Machine safety devices

This use and maintenance manual is not intended as purely a guide for the use of

the machine in a strictly productive environment, it is instead an instrument

providing information on how to use the machine correctly and safely. The

following standards are those specified by the EEC Committee in the directives

regarding safety of machinery, health and safety at work, personal protection and

safeguarding of the environment. These standards have been applied to the

TIGER 370 CNC---MR band saw.

Reference standards

MACHINE SAFETY

H EEC MACHINES DIRECTIVE 2006/42/CE ;

H EEC directive no. 2004/108/CE “EMC -- Electromagnetic Compatibility”;

H EEC Directive No. 2006/95/CE known as “Low voltage directive”.

HEALTH AND SAFETY AT WORK

H EEC Directive No. 80/1107; 83/477;86/188;88/188; 88/642 for the protection of

workers against risks caused by exposure t o physical, chemical and biological agents during working;

H EEC Directive No. 89/391 and Special EEC Directives No. 89/654 and No. 89/655

for improvements in health and safety at work;

H EEC Directive No. 90/394 for the protection of workers against risks deriving from

exposure at work to carcinogenic substances;

H EEC Directive No. 77/576 and No. 79/640 on safety signs at work.

PERSONAL PROTECTION

H EEC Directive No. 89/656 and No. 89/686 on the use of personal protection de-

vices.

ENVIRONMENTAL PROTECTION

H EEC Directive No. 75/442 on waste disposal.

H EEC Directive No. 75/439 on the disposal of used oil.

Page 24

3--5

14

Safety and accident prevention

Protection against accidental contact with the blad e

1. Metal disc cover fixed to the cutting head;

2. mobile protection of the disc attached to the guard, in order to guarantee

cover of the blade and to leave only the part of the disc used for cutting free

as required by President’s Decree 547/55 article 108;

3. vice with double ---blocking anti ---burr device to securely grip the workpiece;

4. the cutting and infeed vice is controlled by pneumatic devices, with maximum

6 mm stroke; the jaw which clamps the piece must be aligned to the part to be

processed at a distance of 2÷3 mm;

5. Access to the cutting zone is bounded by a door fitted with a timed lock,

which allows it to be opened only 5 or 10 seconds after the processing cycle

has stopped;

6. the cutting material supply is protected by a sheet ---metal casing, which can be

opened, that is fitted with a Perspex window to check the cutting operations.

1

6

2

5

3

4

Electrical eq u ip ment

In accordance with Italian standard CEI 60204---1, April 1998, derived from

European Standard EN 60204 ---1 publication IEC 204 ---1, 1997:

H 24 Vac Control voltage for actuators, in accordance with chapter 6 of European

Standard “Control and indication circuits” paragraph 2 “Control Circuits” sub-- section 1 “Preferential voltage values for control circuits”;

H plant protected against short circuits by quick blowing fuses and earthing of all

work and accidental contact parts;

H Protection from accidental start--up by a minimum voltage relay in the case of

power failure.

Emergency devices

In accordance with Standard CEI 204---1:

H Chapter 5 Section 6 Sub--section 1 ”Emergency stop device”: “the emergency

stop device immediately stops all t he dangerous and other functions of the machine”.

H Chapter 6 Section 2 Subsection 4 point 7 “Safety guards”: “the removal of

safety guards protecting dangerous parts or zones of the machine causes the machine to shut down immediately. When the guards are returned to their original

position the machine must be reset in order to resume work”.

...Emergency devices applicable to the TIGER 370 CNC ---MR:

1. Emergency stop: a non--- return mushroom---head pushbutton, colour red on

yellow background, is located on the control panel of the machine. To release

the pushbutton, the actuator must be rotated 45° . After the emergency situation has been resolved, the machine must be reset.

Page 25

MEP S.p.A.

3--6

15

Use and maintenance manual TIGER 370 CNC --MR

2. Thermal--- magnetic circuit breaker: this device incorporates two power fail-

ure protection systems. In fact, in the event of a power failure, it disconnects

all the electrical components, causing the machine to shut down immediately

and prevents it from automatically starting up again when power is restored.

The device also resets the thermal relay fitted to protect against current overloads.

3. Head casing safety switch: to access the cutting zone it is necessary to open

the front door, pressing the relevant button on the control console. This device cannot be removed and has timed opening; therefore, it can only be

opened 5 or 10 seconds after the processing cycle has stopped.

4. Feeder casing safety switch: to access the cutting material feeder, it is necess-

ary to open the casing, with a safety limit switch that stops all machine operations that must be reset to continue processing.

2

3

1

4

Noise level of the machine

Noise can cause hearing damage and represents one the problems faced by many

countries who adopt their own standards. In accordance with the EEC MA-

CHINES DIRECTIVE 2006/42/CE , we are listing the standards that specify noise

levels for machine tools. This chapter also reports the noise levels produced by

the TIGER 370 CNC---MR during its various operating phases and the methods

used for measuring these levels. The Italian standard governing this aspect is

D.M.n.277/91 drawn from EEC Directives 80/1107, 82/605, 83/477, 86/188, 88/642,

UNI EN ISO 4871 (1998).

Noise level measurement

Noise levels are measured using an instrument known as an Integrator noise--meter which registers the equivalent continuous acoustic pressure level at the

work station. The damage caused by noise depends on three parameters: level,

frequency and duration. The equivalent level concept Leq combines the three

parameters and supplies just one indication. The Leq is based on the principle of

equal energy, and represents the continuous stationary level containing the same

amount of energy, expressed in dBA, as that actually fluctuating over the same

period of time. This calculation is made automatically by the integrator noise --meter. The measurements are taken every 60 seconds, in order to obtain a

stabilised value. The reading stays on the display for a sufficient time to enable a

reading to be taken by the operator.Measurements are taken by holding the

instrument at approximately 1 metre from the machine at a height of 1.60 metres

above the platform at the operator’s work s tation. Two measurements are taken:

the first while the machine operates without cutting anything, the second while

cutting in manual mode.

Page 26

3--7

16

Safety and accident prevention

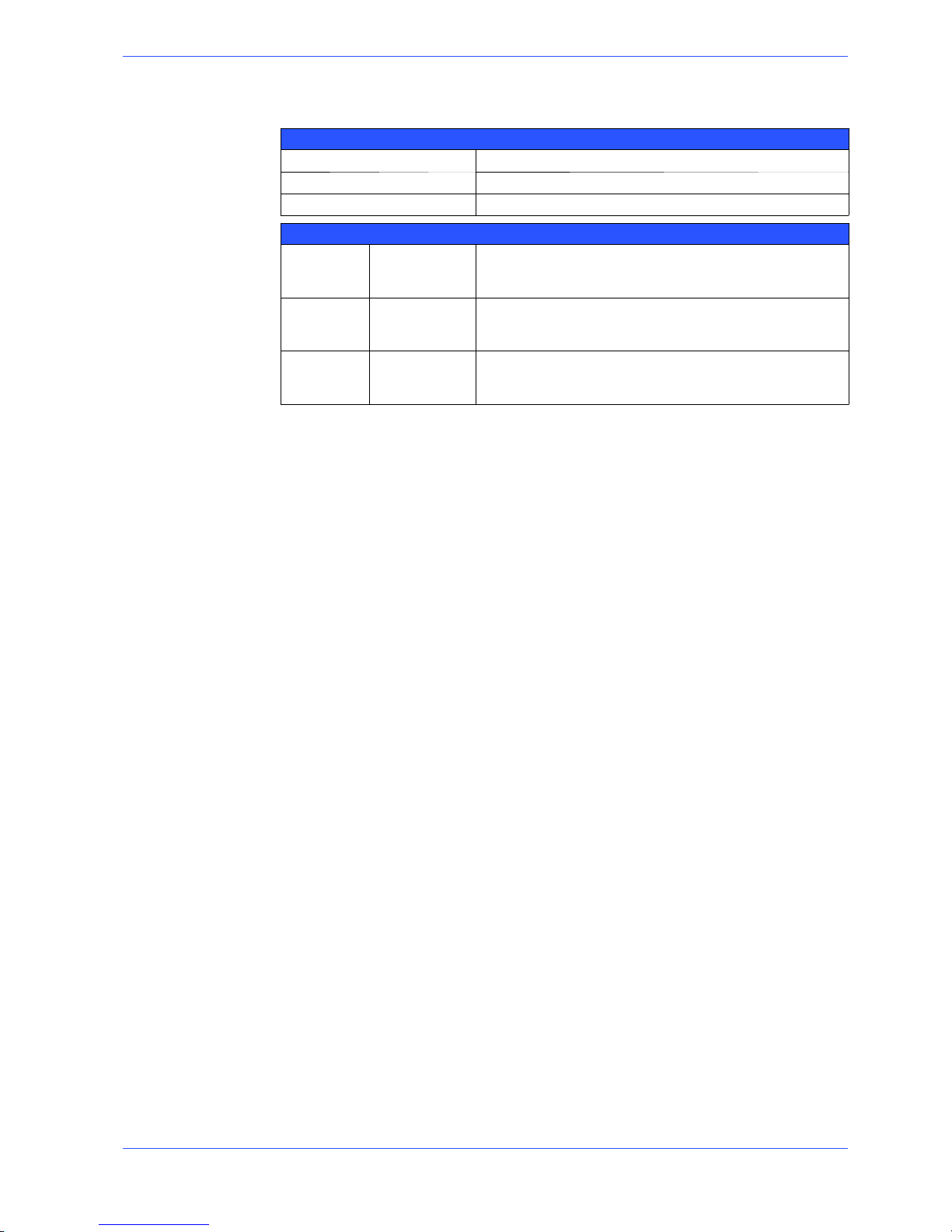

Noise level values

Identification

Machine type

Circular sawing machine

Model

TIGER 370 CNC--- MR

Reference standard ISO 3746

Results

Te st 1st

Results

Mean sound level (Leq) 67,7 dB (A)

Environmental correction (K) 0,6 dB(A)

Peak sound power (Lw) 85,0 dB(A)

Test 2nd Results

Mean sound level (Leq) 65,2 dB(A)

Environmental correction (K) 0,6 dB(A)

Peak sound power (Lw) 82,6 dB(A)

Test 3rd Results

Mean sound level (Leq) 68,8 dB(A)

Environmental correction (K) 0,6 dB(A)

Peak sound power (Lw) 86,2 dB(A)

Vibration emission

This sawing machine complies with the norms EN1299 and EN1033, as the

machine vibration emission on the devices controlled by the operator does not

exceed the threshold of 2.5 m/s

2

Electromagnetic compatibility

As from 1 January 1996 all electrical and electronic appliances bearing the CE

marking that are sold on the European market must conform to Directive

2004/108/CE e 2006/95/CE and 2006/42/C

EE. The prescriptions regard two

specific aspects in particular:

1. “EMISSIONS: during its operation, the appliance or system must not emit spurious

electromagnetic signals of such magnitude as to contaminate the surrounding

electromagnetic environment beyond clearly prescribed limits”;

2. “IMMUNITY: the appliance or system must be able to operate correctly even when

it is placed in an electromagnetic environment that is contaminated by disturbances

of defined magnitude”.

The following text contains a list of the applied standards and the results of the

electromagnetic compatibility testing of machine model TIGER 370 CNC ---MR;

Test report no. 120101.

Emissions

H CEI EN 61000--6--4 (2002) Electromagnetic Compatibility (EMC) -- Generic stan-

dard regarding emissions. Part 6--4: Industrial Environment.

H EN 55011 (1999) Industrial, scientific, and medical radio frequency appliances

(ISM). Characteristics of radio frequency disturbance -- Limits and methods of

measurement.

H EN 55014--1 (2002) Electromagnetic Compatibility -- Prescriptions for domestic

appliances, electric power tools, and similar equipment. Part 1: Standard Emission

in relation to product family.

Page 27

MEP S.p.A.

3--8

17

Use and maintenance manual TIGER 370 CNC --MR

CONDUCTED EMISSIONS

Gate A Freq. ( MHz) Q --- p e a k l i m i t ( d B u V ) Mean value limit (dBuV) Result

A.C. power supply

input

0.15 --- 0.5

0 . 5 --- 5

5 --- 3 0

79 --- 73

(linear reduction with

log of frequency)

73

73

66 --- 60

(linear reduction with log of fre-

quency)

60

60

Complies

CONDUCTED EMISSIONS --- ANALYSIS OF INTERMITTENT DISTURBANCES

Gate Result

A.C. power supply input Not applicable

IRRADIATED EMISSIONS

Gate Freq. ( MHz) Q--- peak limit (10 m)

(dBuV/m)

Result

Enclosure 30 --- 230

230 --- 1000

40

47

Complies

Immunity

H CEI EN 61000--6--2 (2000) Electromagnetic Compatibility (EMC) -- Generic stan-

dard on immunity. Part 6 --2: Industrial Environment.

H EN 61000--4--2 + A1 (1996--1999) Electromagnetic Compatibility (EMC) -- Part 4:

Test and measurement techniques -- Section 2: Electrostatic discharge immunity

tests -- Basic publication.

H EN 61000--4--3 Electromagnetic Compatibility (EMC) -- Part 4: Test and measure-

ment techniques -- Section 3: Radiated, radio-- frequency, electromagnetic field immunity test.

H EN 61000--4--4 (1996) Electromagnetic Compatibility (EMC) -- Part 4: Test and

measurement techniques -- Section 4: Fast transients/bursts immunity tests -- Basic

publication.

H EN 61000--4--5 (1997) Electromagnetic Compatibility (EMC) -- Part 4: Test and

measurement techniques -- Section 5: Surge immunity test.

H EN 61000--4--6 (1995) Electromagnetic Compatibility (EMC) -- Part 4: Test and

measurement techniques -- Section 6: Immunity to conducted interference, induced

by radio frequency fields.

H EN 61000--4--11 (1977) Electromagnetic Compatibility (EMC) -- Part 4: Test and

measurement techniques -- Section 11: Voltage dips, short interruptions and voltage

variations immunity tests.

IMMUNITY TO ELECTROSTATIC DISCHARGES

Gate T est levels Evaluation criterion Result

Enclosure contact 4 kV

steel plate 4 kV

in air 8 kV

B Complies

IMMUNITY TO VOLTAGE (BURSTS)

Gate T est levels Evaluation criterion Result

A.C. power supply in-

put

2kV B Complies

IMMUNITY TO CONDUCTED ELECTROMAGNETIC FIELDS

Gate T est levels Evaluation criterion Result

A.C. power supply in-

put

10V A Complies

IMMUNITY TO IRRADIATED ELECTROMAGNETIC FIELDS

Gate T est levels Evaluation criterion Result

Enclosure 10 V/m A Complies

Page 28

4--1

Machine installation

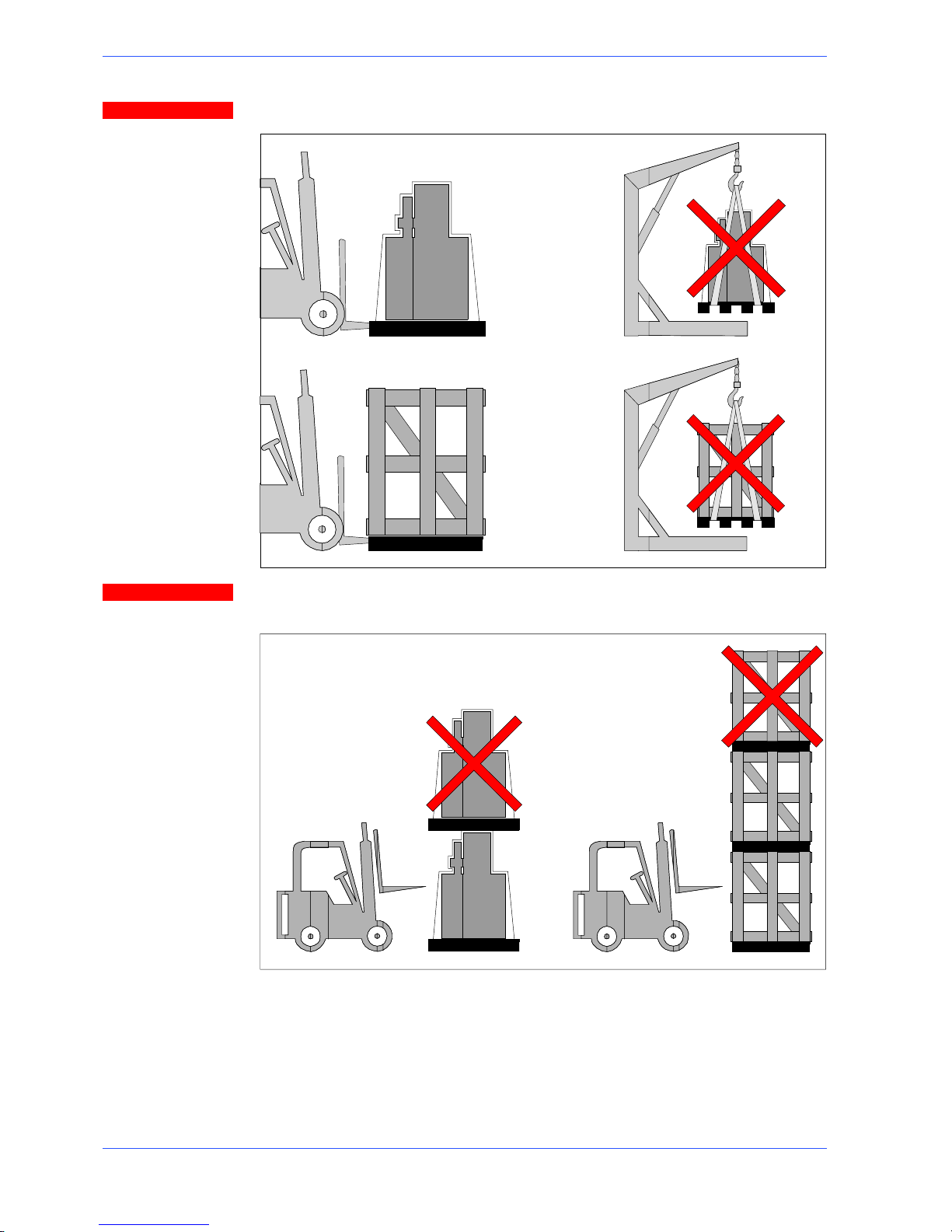

Packaging and storage

MEP S.p.A. use packing materials that guarantee the integrity and protection of

the machine during its transport to the customer.

The type of packing differs according to the size, weight and destination.

Therefore the customer will receive the machine in one of two following ways:

1. on a pallet with straps and heat---shrink plastic;

2. on a pallet with straps, heat--- shrink plastic and a wooden crate.

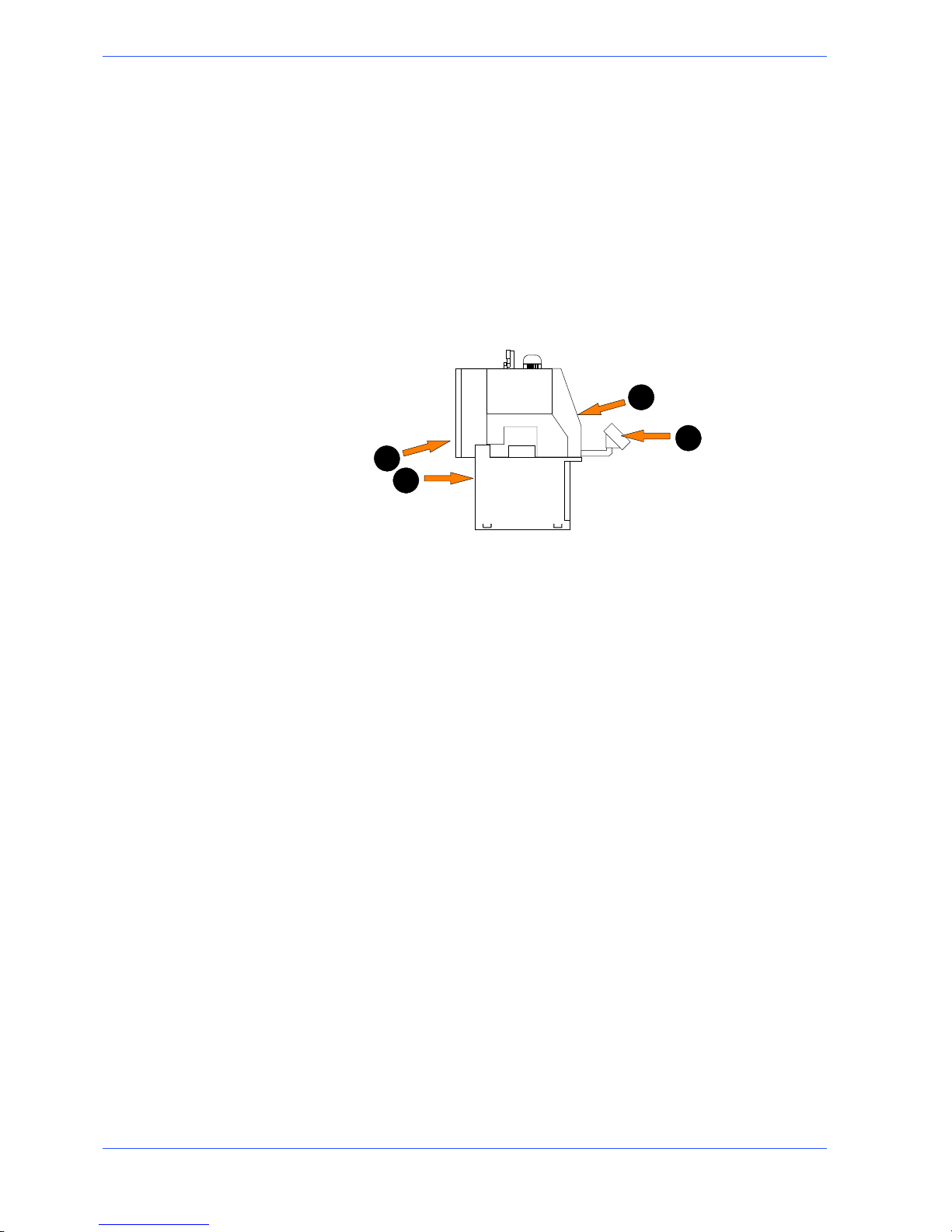

In both cases, for correct balancing the machine must be handled using a

fork-- lift truck, inserting the tines at the points indicated by the arrows, using

the reference marks on the crate itself.

Before carrying out lifting operations, make sure that the weight of the machine, as indicated on the crating or other packaging, is within the forklift truck

load limit.

Warning

Attention

4

Page 29

MEP S.p.A.

4--2

19

Use and maintenance manual TIGER 370 CNC --MR

Do not handle the packed machine using slings.

When storing, machines palletized and shrink--wrapped must not be stacked

two high, and machines pallettized and crated must not be stacked three high.

To install the machine, first remove the packing, paying particular attention not to

cut any electric wires or hydraulic hoses; if necessary use pliers, a hammer and a

cutter.

Open crate in the illustrated order:

Attention

Attention

Page 30

4--3

20

Machine installation

1. remove nails and lift the top of the cage;

2. remove nails and lower walls;

2

2

2

2

1

3. remove heat--- shrink covering;

4. remove the straps;

5. remove nails from pallet securing planks and remove planks;

6. remove the front panel and insert fork tines.

3

4

5

6

To locate the machine in the workplace, the machine dimensions and necessary

operator working space, including the spaces laid down in safety standards, must

be taken into account.

Page 31

MEP S.p.A.

4--4

21

Use and maintenance manual TIGER 370 CNC --MR

Anchoring the machine

The base of the machine is anchored to the floor by two permanent studs located

on the sides of the base. The studs are screwed into nuts previously sunk into the

concrete, and tightened from above with lock nuts. The schematic specifications

set out in Chapter 1 should be taken into account when positioning the machine.

2226

747,5

Minimum requirements

For the machine to function correctly, the room in which it is to be installed must

satisfy the following requirements:

H power supply voltage/frequency: refer to the values on the rating plate;

H working pressure not less than 6 Bar and not greater than 8 Bar;

H temperature of machine location: from --10 to +50° C;

H relative humidity: not more than 90%;

H lighting: not less than 500 Lux.

The machine is already protected against voltage variations, but will only run

trouble--free if the variations do not exceed ± 10%.

Check list

Before starting installation, check that all the accessories, whether standard or

optional, supplied with the machine are present. The basic version of the TIGER

370 CNC ---MR is supplied complete with:

CHARACTERISTICS

Multi --- microprocessor with two controlled axes that permits programming 32

batches of workpieces with different lengths and quantities on the same bar

n

Three--- stage drive system to ensure a high level of rigidity and precision, and to

attain a great capacity for removal

n

Warning

Page 32

4--5

22

Machine installation

CHARACTERISTICS

Fully encased model to provide operator safety, sound insulation and the possibility

of working with large quantities of liquid

n

HSSdiskø370x32x3forsteel n

HM disk ø 400 x 32 x 3.6 for aluminium and light alloys n

Cabinet for electric and electronic equipment with fully identifiable wiring, door---

locking switch with padlockable device, emergency device, motor overload cut --- out,

minimum voltage coil and protection against a missing phase

n

Activation and control systems protected by input and output electric and electronic devices

n

Low tension control panel: softkey polyester keypad with thermo---moulded touch

sensitive buttons and acoustic signal when the machine is started

n

48 character x 16 li ne display showing technical parameters such as: number of cuts

programmed and executed, blade thickness, single forward movement measure,

cutting time, ammeter, display of diagnostic messages (approx. 80) and warnings in

the language chosen

n

Four controls to program the cutting head stroke limits, according to the dimensions of the bars to be cut

n

Programming and control console with LCD display comprehensive of self--- diagnosis messages

n

Blade rotation with motor at a speed, together with an electronic variable speed

drive, making cutting possible from 15 to 150 rpm to always accomplish the best

efficiency

n

Spray gun to wash the work surfaces n

Pneumatic clamp with adjustable steel gib n

Acoustic and flashing light signal in case of machine stop n

Infeed unit with step motor; screw/nut with ball bushing (length 1000 mm) n

Vice with rag prevention device and double workpiece clamping feature n

Swing feeder vice to deliver even deformed bars n

Coolant tank obtained in the pedestal with a pair of motor pumps for a total deliv-

ery of 120 l/min

n

Chip drawer n

Electric pump to lubricate and cool the disk n

Blade cleaning brush n

Upright pneumatic vice for cutting more than one bar n

Cutting head moving on twin linear guide with pre--- loaded double ball--- bushing

sliding blocks

n

Head movement with electro--- mechanical cylinder to provide the greatest cutting

rigidity

n

Rotating pin with pre--- loaded thrust bearing to ensure precision and reliability n

Machine set for handling with pallet truck n

Keys, user manual and manual for ordering spare parts in the language used n

Motor chip discharger n

Roller platform adapter on loading and unloading side n

Emulsifiable oil 5 l n

MEP slide bar loader for high production (CB6001)* n

*ACCESSORIES AVAILABLE ON REQUEST

Accessory kit is placed before the packaging inside the machine; it contains the

following items:

H 3, 4, 5, 6, 8 and 10 mm Allen keys;

H open 19 mm wrench;

Page 33

MEP S.p.A.

4--6

23

Use and maintenance manual TIGER 370 CNC --MR

H this Use and Maintenance Manual.

Connection to the compressed air supply

To ensure perfect operation and a long service life, it is recommended that the

machine is connected to a compressed air system having the characteristics

reported in the diagram below.

1

2

3

4

5

6

KEY

1 - DOWN PIPE

2 - CONDENSATE COLLECTOR

3 - DRAIN COCK

4 - AIR FILTER

5 - DRAIN COCK

6 - CONNECTING HOSE

Connection to the power supply

Before connecting the machine to the power supply, check that the socket is not

connected in series with other machines. This requirement is fundamental for the

good operation of the machine.To connect the machine to the power supply,

proceed as follows:

" connect the power supply cable of the machine to a plug which matches the

socket to be used. (EN 60204---1; par. 5.3.2).

CONNECTION FOR ”5-CORE” WIRE SYSTEMS WITH NEUTRAL

R=L1

S=L2

T=L3

PE = GND

N = NEUTRAL

CONNECTION FOR ”4-CO

R

E” WIRE SYSTEMS WITH NEUTRAL

S=L2

T=L3

PE = GND

R=L1

When using systems with a neutral wire, special care must be taken when connecting the blue neutral wire, in that if it is connected to a phase wire it will discharge the phase voltage to the equipment connected for voltage: phase--

neutral.

Attention

Page 34

4--7

24

Machine installation

" Insert the plug in the socket, ensuring that the mains voltage is the same as

that for which the machine has been setup.

VOLT ?VOLT ?

" To switch on the machine, turn the main switch located at the rear, on the

right---hand side of the electric cabinet;

" press the ON button on the control console;

" press RESET twice.

The above sequence (ON and RESET buttons) must be performed each time the

machine is switched on.

Make sure that the disk rotates properly. To do this, proceed as follows:

" make sure the machine is not in emergency status (red mushroom head but-

ton released); otherwise, release the emergency stop button and press

RESET;

" set the cutting head downstroke adjuster by means of the specific selector;

" set the speed of the disc by means of the relevant potentiometer;

Page 35

MEP S.p.A.

4--8

25

Use and maintenance manual TIGER 370 CNC --MR

" enable motor rotation by activating the blade motor selector on the control

console;

" start disc rotation using the start pushbutton on the control panel or the pedal

control (if machine is equipped);

" if all the above operations have been carried out correctly, the disc motor will

start up and the disc will start to turn.

Ensure that the blade moves in the correct direction as shown in the

above figure. If it does not, simply reverse two of the phase wires on the ma-

chine’s power supply input.

The sawing machine is now ready to start the work for which it was designed.

Chapter 5 provides a detailed description of the various functions of the machine

and its operating cycles.

Attention

Page 36

5--1

Description of

machine operation

This chapter analyses all the machine functions. We begin with a description of

the pushbuttons and other components on the control panel.

Description of the control panel

The control console is housed inside the control panel in an IP 54 rated housing

which is tamperproof and resistant to dust and moisture. The control panel

swivels on two articulated joints so that it can be positioned by the operator for

greater ease of use and safety. The figure below shows the control panel of

TIGER 370 CNC---MR:

Key for control console keyboard

On key: enables machine operation Cutting vice closure

5

Page 37

MEP S.p.A.

5--2

27

Use and maintenance manual TIGER 370 CNC --MR

Cutting vice opening

RESET key: resets the machine after an

emergency condition or conflicting commands.

Blade motor selector: during normal

operation of the machine, this enables or

disables the cutting cycle start button

(START)

Start button: starts the cutting cycle

STOP button: stops the machine in the

automatic cycle only

Speed de--- selection key (zero)

Head lowering speed potentiometer Cutting force control potentiometer

Disk rotation speed potentiometer

Function key:

In automatic work mode, allows you to enter

programming and return to execution

In programming work mode, allows you to

switch between the program cuts and select

program displays

Function Key:

Calling up program No.

Scrollimg the cursor

Storing data

Storing programs

Selecting programs

Storing parameters

Function Key:

In automatic work mode, allows you to delete

the last program carried out by loading the new

one to be carried out

In programming work mode, allows you to delete existing or incorrect data

When entering cutting or machine parameters,

allows you to delete existing or incorrect data

Manual movement of feed carriage foreward

Manual movement of feed carriage

backward

Head up key Head down key

Main vice closure Main vice opening

EMERGENCY mushroom: pressing this

button all the operations of the machine

stop immediately. To reset the emergen-

cy, rotate the actuator by 45

°

Gun sprays lubricant/coolant fluid even

when the machine is stopped

Page 38

5--3

28

Description of machine operation

Jet of lubricant/coolant fluid from taps,

only when the cycle has started

No lubricant/coolant fluid jet

Button for memorizing the FCTI (Head

Upstroke Limit)

Button for memorizing the FCTA (Head

Downstroke Limit)

Button to open and close the timed door

of the cutting head

Chip discharger unit in manual mode

Chip discharger unit deactivated Chip discharger unit in automatic mode

Decimal point for entering numerical

values in tenths of a millimetre or thousandths of an inch when programming

parameters and cutting lenghts.

Selecting operating mode

F0: Function Key:

Takes you from single to multiple programming in automatic work mode

F1: function key

At machine start up, it allows programming the setup parameters.

F2: Function key not operational

F3: Function Key:

Selects semi---automatic work mode in

the main menu

F4: Function Key:

Selects Automatic work mode in the

Main menu

F5: Function Key:

Resets total cutting time counter in

semi--- automatic work mode

F6: Function Key:

Selects diagnostic work mode in the

main menu

zeroing command

Enables step=length check in automatic

work mode

F7: function key

in automatic mode it enables the selection of the single cycle i.e. the basket

change cycle, or the continuous cycle

F8: Function Key:

--- Allows operator to enter blade thick-

ness value in automatic work mode

F9: Function Key:

Takes you from the first display to the

zero--- setting display

Takes you from the zero---setting display

to the main menu

Takes you back to the main menu

Page 39

MEP S.p.A.

5--4

29

Use and maintenance manual TIGER 370 CNC --MR

Basic instructions for carrying out a cutting cycle

Manoeuvring the cutting head

In the TIGER 370 CNC---MR model, it is possible to move the cutting head with

up and down buttons, shown in the key of the control panel in this chapter.

Head up key Y+ Head down key Y --

Access to the cutting head

To ensure operator safety, the machine is entirely enclosed by safety guards that

prevent accidental contact with the tool and moving parts. To access the cutting

zone it is necessary to unlock the device closing the door.

Button to open/close the door of the cutting head

Manoeuvring the feeder

The power supplier can be moved with the buttons reported on the diagram

below, only after having reset the power supply (as explained in the “machine

start up” paragraph).

Forward key X+ Back key X--

Clamping the work piece in the vice

Vice opening and closure, for the cutting vice and the feeder vice, are controlled

by the corresponding buttons on the control console.

Cutting Vice close button Cutting vice open button

Feeder vice close button Feeder vice open button

Page 40

5--5

30

Description of machine operation

However, to ensure that the workpiece is securely clamped in the vice, proceed as

follows:

" make sure the workpiece dimensions do not exceed the machine’s cutting ca-

pacity;

" make sure the piece is correctly supported on both sides of the machine;

" move the vice to within 2÷3 mm of the workpiece using the handwheel. Press

the vice closure button on the console;

2--3 mm

" make sure that the material is well blocked by trying to move it manually, as

thevicecylinderhasastrokeof6mmonly.

Page 41

MEP S.p.A.

5--6

31

Use and maintenance manual TIGER 370 CNC --MR

Lubricant/coolant fluid supply

It is possible to select the operating mode of the coolant by means of the specific

buttons on the control panel:

Technological control parameters

The following table indicates the control parameters which are shown on the

displays of the semi ---automatic, automatic and Automatic Loop operating cycles.

X =1000,5

X--- axis dimension (position of feeder carriage)

θ =00,00

Nonoperating

W =000.0

Nonoperating

F=0

Cutting head descent speed potentiometer

S=15

Disc rotation speed (rpm)

Kg=000

Nonoperating

DL=0

Nonoperating

SL= 3

Blade thickness (depends upon machine model)

AM=5,8

Max. blade motor absorption

A =0,7

Amperometer

T =00,00

Partial cutting time

TT=00,00

Total machine time for the cutting cycle

Preliminary check list for cutting operation

To guarantee complete safety during cutting cycles, the operator should work

through a check list of the entire apparatus, checking:

" ensure that the disk guard completely surrounds the tool when it is not in use;

" that the work piece is properly clamped in place;

" ensure that the blade teeth are appropriate for the material being cut;

" that the speed selected is right for the kind of piece to be cut;

" that all protections are in place and correctly locked;

" lubricant/coolant level and activation of the electropump;

" the blade downstroke speed must be correct.

Page 42

5--7

32

Starting up the machine

When switching on the machine, proceed as follows:

" press the ON button.

" Press RESET twice.

The display shows the introductory and starting SCREEN.

" To c o n ti n u e p r e s s F 9 .

" The display suggests ZERO SETTING the machine. To carry out this opera-

tion,pressF6. Togotothemainmenu,pressF9.

During zero setting, the display will read ZERO SETTING IN PROGRESS,

which will continue to be displayed until the operation has been completed. While

zero setting is taking place, only the EMERGENCY button is active.

" When ZERO SETTING has been completed, the display will show the

COUNT STARTING VALUE for the X axis. Press F9 to continue.

Page 43

MEP S.p.A.

5--8

33

Use and maintenance manual TIGER 370 CNC --MR

Semi--automatic operating cycle

" Starting from the main menu, press F3 to put the machine in SEMI ---AUTO-

MATIC mode.

MAIN MENU

F3 = SEMI-AUTOMATIC

F4 = AUTOMATIC

F5 = AUTOMATIC-LOOP

F6 = DIAGNOSTICS

F9 = ZERO SETTING MENU

" The display will show the screen for the SEMI ---AUTOMATIC cycle.

SEMI-AUTOMATIC

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CURRENT CYCLE

F9 = MAIN MENU

F5 = RESET TT

Technological control parameters

X =1000,5

Nonoperating

θ =00,00

Nonoperating

W =000.0

Nonoperating

F=0

Cutting head descent speed potentiometer

S=15

Disc rotation speed (rpm)

Kg=000

Nonoperating

DL=0

Nonoperating

SL= 3

Blade thickness

AM=5,8

Assorbimento motore

A =0,7

Amperometer

T =00,00

Partial cutting time

TT=00,00

Total machine time for the cutting cycle

Clamping the work piece in the vice

" Release the protection by pressing the relevant key;

Page 44

5--9

34

" open the vice by rotating the handwheel anti ---clockwise and position the

workpiece between the jaws.

" Bring the moveable jaw to within 2÷3 mm of the workpiece by rotating the

handwheel clockwise.

2 --- 3 m m

" Block the piece by means of the pneumatic cutting vice block, by pressing the

close cutting vice button.

" Check that the workpiece is effectively locked in positon!

If the vice was already closed by the pneumatic piston, it may not block the

piece. In this case it is necessary to repeat the operation, i.e.: open the vice by

pressing the specific button, bring the moving jaw near to the piece and block

it again with the closing button, bearing in mind that the stroke of the pneumatic piston is approx. 6 mm.

Cutting stroke adjustment

" Once the workpiece is locked in position, the cutting stroke must be adjusted.

When the head down button is pressed, the cutting head is automatically lowered.

N.B.

Page 45

MEP S.p.A.

5--1035Use and maintenance manual TIGER 370 CNC --MR

" Keep the button pressed until the disk is at 5/10 mm from the material to be

cut.

" Memorize the FCTI (Head Upstroke Limit) by pressing the specific button;

" after pressing the FCTA memorizing button, the display will indicate that it

has been memorized.

SEMI-AUTOMATIC

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CURRENT CYCLE

F9 = MAIN MENU

F5 = RESET TT

FCTI

" The FCTI (Head Downstroke Limit) will be restored at the end of the cut.

Preparing to cut

" Select the fluid for automatic operation by pressing the specific button. The

led of the relative button will light up.

" Adjust the head descent speed potentiometer to 0 to avoid undesirable start-

ing speeds.

Cutting

" Close the protection and press the reset button;

" Enable motor rotation by activating the blade motor selector on the control

console;

Page 46

5--11

36

" start operation.

At this stage it is possible to adjust, according to the type of material, the 2

parameters which influence the cut: the disk rotation speed and the head

downstroke speed, through the relative potentiometers on the control panel.

Now the blade starts, the cutting cylinder is under pressure and the lubricant/

coolant supply starts.

In this phase, pressing the head dowstroke button, the FCTA spot is deleted.

" When the machine arrives at the end of the cut it is necessary to memorize

the FCTA position, by pressing the relative button;

" when the machine reaches the position to start cutting again, the symbol to

indicate the FCTA upstroke limit will re ---appear on the display.

SEMI-AUTOMATIC

CURRENT CYCLE

FCTA

" At the same time, the disk will stop and the cutting head will return to the

start of cut position (FCTI).

" When the head arrives at the start of cut position, the display will indicate the

FCTI position.

SEMI-AUTOMATIC

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CURRENT CYCLE

F9 = MAIN MENU

F5 = RESET TT

FCTI

" Next, the machine automatically opens the cutting vice.

The machine is ready to carry out a new cutting cycle.

N.B.

N.B.

Page 47

MEP S.p.A.

5--1237Use and maintenance manual TIGER 370 CNC --MR

Automatic operating cycle

" Return to the main menu to change the operating mode. To return to the

MAIN MENU press F9.

MAIN MENU

F3 = SEMI-AUTOMATIC

F4 = AUTOMATIC

F5 = AUTOMATIC-LOOP

F6 = DIAGNOSTICS

F9 = ZERO SETTING MENU

" Now press the F4 button to go to the AUTOMATIC cutting cycle.

" The AUTOMATIC screen shows the parameters inserted for the last opera-

tion completed.

AUTOMATIC

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

CUTS

EXEC.

θ CUTS

PROG.

SINGLE CYCLE

RUN/PROG=PROGRAMMING

PGR. NO MEASUR. CUTS PROG.

10 512,8 2343

OPERATING CYCLE

PROGRAMME DATA

PGR. NO. = When the AUTOMATIC cycle screen switches on, the programme

number for the last programme memorised is displayed, irrespective of whether it was

totally or partially completed or only saved. The control memory allows 32 programmes to be memorised as well as the single programme. The latter programme is

indicated by the number 0.

MEASUREMENT = As for the situation described above, the MEASUREMENT

value displayed also relates to the last programme memorised. The control memory

allows cutting lengths of up to 9999,9 mm. to be memorised. The cutting length can be

programmed to an accuracy of a tenth of a millimeter. PRECISION ±0.1 mm. 0÷1000

mm (Precision as regards the position of the feeding car and not to the cut part)

CUTS PROG. = In the case of the number of CUTS PROGRAMMED, the same information as above appli es. It is possible to set a maximum number of cuts of 9999

pieces for each programme.

CUTS EXEC. = The number of CUTS EXECUTED displayed relates to those effectively completed before the machine was last switched off. These will remain in the

memory until they are replaced by further cuts carried out using the same programme,

or until they are zero set or modified by a new programme.

OPERATING BUT-

TONS ACTIVE DUR-

ING THE AUTOMATIC

CYCLE

F0 = SINGLE PROGRAMME: Press this button to access the single programme.

Using this option, programming can be done directly on the work screen. The single

programme allows 1 MEASUREMENT and 1 QUANTITY of cuts to be carried out.

This possibilty has been included to avoid multiple programming procedures when

these are not necessary.

Page 48

5--13

38

OPERATING BUT-

TONS ACTIVE DUR-

ING THE AUTOMATIC

CYCLE

F9 = MAIN MENU: press this button to return to the working mode selection menu.

F8 = BLADE THICKNESS: this option gives access to programming of the BLADE

THICKNESS. This parameter is very important because the bar infeed system operates in zero setting mode, therefore the value of the scrap produced by the disk must

be added to the size of the piece to be processed. Adding and subsequent division by

the number of runs necessary to obtain the required measurement, will be carried out

independently on the control console.

F7 = SING/CONT CYCLE: this operation is more easily understood if the SINGLE

CYCLE is called the CHANGE TOTE --- BOX cycle. In practice, when a number of

measurements and pieces are programmed for the same bar, this option allows them

to be kept separate, stopping the machine at the end of each programme.

Inserting and locking the workpiece

Initially the machine could be configured in any way, therefore the first series of

operations to be carried out is to set the machine for the material to be cut.

" Bring the cutting head to the upstroke limit, using the manual head lift but-

ton;

" Release the protection by pressing the relevant key;

" open the cutting vice and the infeed vice by rotating the relative handwheels;

then adjust the position of the anti---chip vice indicated by the arrow.

" After this second operation, check that the pneumatic piston is in open posi-

tion. To do this, use the supply vice and cutting vice opening buttons.

It is advisable to use the buttons a number of times, to be totally familiar with

operation.

Page 49

MEP S.p.A.

5--1439Use and maintenance manual TIGER 370 CNC --MR

" The second series of operations are to fit the material to be cut: place the ma-

terial between the vice jaws, and draw one end under the blade in order to

perform an initial cut to initialize the cuts.

" After inserting the material, bring the moving jaws for the cutting and feeder

vices to within 2

÷3 mm of the workpiece;

" activate the automatic pneumatic vices to block the piece, using the two vice

closing buttons;

" check that the piece is well blocked;

to avoid deformation when the tubes are thin walled, or the blocking force of the

vices is not sufficient for materials which are particularly hard or with articulated

sections, adjust the vice pressure by means of the regulator located inside the

base.

Preparing to cut

" Close the protection and press the reset button;

" adjust the cutting stroke by memorizing the head upstroke limit (FCTI): bring

the cutting head near the material using the head downstroke button.

" Memorize the cutting start position by pressing the FCTI (Head Upstroke

Limit) button. The FCTI indication will appear at the top of the display on

the right hand side.

AUTOMATIC

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

CUTS

EXEC.

θ CUTS

PROG.

SINGLE CYCLE

RUN/PROG=PROGRAMMING

PGR. NO MEASUR. CUTS PROG.

10 512,8 2343

OPERATING CYCLE

FCTI

Programming cuts

Once the material to be cut has been inserted and blocked, bring the cutting head

to the FCTI (Head Upstroke Limit) position, set the cutting dimension indicated

Page 50

5--15

40

on the display as Measure, and the amount of pieces to be cut Prog. cuts.

AUTOMATIC

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

CUTS

EXEC.

θ CUTS

PROG.

SINGLE CYCLE

RUN/PROG=PROGRAMMING

PGR. NO MEASUR. CUTS PROG.

10 512,8 2343

OPERATING CYCLE

FCTI

For the cutting program it is necessary to set the following parameters:

H PGR. N. = PROGRAM NUMBER: this value identifies all existing programs, the-

refore it is possible to select a program previously memorized by setting a number,

or the number proposed by the controller can be accepted.

H MEASUREMENT = MEASUREMENT OF PIECES: This value is keyed in, using

the numeric keys, in mm and tenths of a mm, or in inches and thousandths of an

inch, relates to the selected programme.

H PROGRAMMED CUTS = NUMBER OF PIECES TO BE CUT PER MEASURE:

set this value using the numeric keys in relation to the PGR. N. and MEASURE

set.

The machine’s control console allows cuts to be programmed in two ways:

H SINGLE PROGRAMME: This option enables programming on the work screen,

setting the measurements and number of pieces to be obtained from the workpiece.

H MULTIPLE PROGRAMMING: With this programming system 32 cutting lengths

can be set with relative number of pieces to be cut for each dimension. Furthermore, selecting the programs, it is possible to set cutting sequences with different

measures on the same bar.

Single program

" To set the measure and number of pieces in the single program, press F0.

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

MEASUR.

AUTOMATIC

OPERATING CYCLE

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CUTS

EXEC.

θ CUTS

PROG.

SINGLE PROGRAM

RUN/PROG=PROGRAMMING

PGR. NO CUTS PROG.

0 512,8 2343

FCTI

" When the F0 button has been pressed, the display reads:

PGR. NO. 0

MEASUREMENT The last measurement programmed

CUTS PROG. The last number of cuts programmed

CUTS EXEC. The portion of the last job executed. The type of pro-

Page 51

MEP S.p.A.

5--1641Use and maintenance manual TIGER 370 CNC --MR

gramme in use will appear in the first square: SINGLE PGR. To begin programming, press RUN/PROG.

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

MEASUR.

AUTOMATIC

OPERATING CYCLE

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CUTS

EXEC.

θ CUTS

PROG.

SINGLE PROGRAM

RUN/PROG=PROGRAMMING

PGR. NO CUTS PROG.

0 512,8 2343

FCTI

" When the RUN/PROG button has been pressed, the measurements will be

reversed, indicating that they can be changed. To set new measurements, key

in using the NUMERIC KEYS. Enter the measurement 905,7 (for example).

To do so the following keys must be pressed: “9” “0” “5” “.” “7”

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

MEASUR.

AUTOMATIC

OPERATING CYCLE

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CUTS

EXEC.

θ CUTS

PROG.

SINGLE PROGRAM

RUN/PROG=PROGRAMMING

PGR. NO CUTS PROG.

0 905,7 2343

FCTI

" Pressing the numeric keys, the numbers are displayed from right to left. If you

make a mistake when writing the measure, press CLEAR to delete the value;

0.0. will appear. After entering the measure, press ENTER. With this operation you will obtain two results:

1) the new value is memorized;

2) the reverse moves to PROG. CUTS to set the desired number of cuts.

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

MEASUR.

AUTOMATIC

OPERATING CYCLE

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CUTS

EXEC.

θ CUTS

PROG.

SINGLE PROGRAM

RUN/PROG=PROGRAMMING

PGR. NO CUTS PROG.

0 905,7 2343

FCTI

" With the reverse on PROG. CUTS, set the number of cuts to be executed

using the numeric keys as for the previous operation. Digit 100, pressing in

order buttons “1” “0” “0”; then press ENTER again. With this operation you

will obtain two results:

Page 52

5--17

42

1) the new value is memorized;

2) the reverse moves to NR PGR.

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

MEASUR.

AUTOMATIC

OPERATING CYCLE

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CUTS

EXEC.

θ CUTS

PROG.

SINGLE PROGRAM

RUN/PROG=PROGRAMMING

PGR. NO CUTS PROG.

0 905,7 2343

FCTI

" End of programming. Press RUN/PGR to return to execution.

Whenever CLEAR is pressed in the single program automatic mode, when the

machine is stopped, the count of the cuts executed previously is reset.

" After pressing RUN/PGR, the reverse will disappear from the display; this

indicates that the machine is ready for operation. To confirm the new program, press CLEAR; this will produce two results:

1) confirmation of the program to be executed

2) count reset of cuts executed previously.

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

MEASUR.

AUTOMATIC

OPERATING CYCLE

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CUTS

EXEC.

θ CUTS

PROG.

SINGLE PROGRAM

RUN/PROG=PROGRAMMING

PGR. NO CUTS PROG.

0 905,7 2343

FCTI

" Enter the value BLADE THICKNESS which must be programmed every ti-

me the tool is changed. It is necessary to add also the blade thisckness to the

cutting measure, because the bar supply system works when the carriage is at

zero, i.e. after being cut, the piece is on the right of the blade, and this value

is subtracted from the total length of the finished piece. Press F8 to enter this

value.

RUN/PROG = PREVIOUS MENU

BLADE THICKNESS = 3

RESIDUAL

PROGRAMMED = 1547 m

BLADE LIFE = 952 m

MAXIMUM BLADE MOTOR CURRENT

TORTOISE 1ST SPEED AMP. = 12.5

SPEED HEAD AP MPP = 1

BAR INITIALIZING SIZE = 170

N.B.

Page 53

MEP S.p.A.

5--1843Use and maintenance manual TIGER 370 CNC --MR

" After pressing F8 the display will show BLADE THICKNESS. To enter the

value press in order the numeric keys and the decimal point. To memorize the

new value press ENTER again. Of course, in case of a typing error, it is possible to correct it by pressing CLEAR. Once the operation is complete, press

RUN/PROG to return to the operating display screen.

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

MEASUR.

AUTOMATIC

OPERATING CYCLE

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CUTS

EXEC.

θ CUTS

PROG.

SINGLE PROGRAM

RUN/PROG=PROGRAMMING

PGR. NO CUTS PROG.

0 905,7 2343

FCTI

" Now it is possible to start operation. To check the measure of the piece cut,

press F6; in the first box the indication STEP will appear.

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

MEASUR.

AUTOMATIC

OPERATING CYCLE

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CUTS

EXEC.

θ CUTS

PROG.

SINGLE PROGRAM

RUN/PROG=PROGRAMMING

PGR. NO CUTS PROG.

0 905,7 2343

FCTI

" After pressing F6, the machine proceeds as follows:

--- S TA RT

--- INITIAL CUT

--- B A R S U P P LY

--- C U T I N A U T O M AT I C M O DE

--- S T OP.

Themachineperformsthefirstcycleofoperations,tocuttosizethefirstpiece. This enables a precise check of the measure of the piece. If the size is correct, press F6 again to deactivate the check cycle, then press START.

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

MEASUR.

AUTOMATIC

OPERATING CYCLE

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CUTS

EXEC.

θ CUTS

PROG.

SINGLE PROGRAM

RUN/PROG=PROGRAMMING

PGR. NO CUTS PROG.

0 905,7 2343

FCTI

Page 54

5--19

44

" If the size is not correct, use the BLADE THICKNESS parameter to enter

the correction value. Repeat the cut with the check cycle activated. In this case the machine will perform the following operations:

--- S TA RT

--- B A R S U P P LY

--- C U T I N A U T O M AT I C M O DE

--- S T OP.

In other words, the machine starts again where it had stopped, automatically

changing the size with the set adjustment, and supplying the bar with the new

measure. Check the size again, and if it is correct, press F6 to delete STEP,

then press START.

F0 = PGR. SINGLE

F9 = MAIN MENU

F8 = BLADE THICKNESS

F7 = SING/CONT CYCLE

F6 = EXEC. STEP/CONT

MEASUR.

AUTOMATIC

OPERATING CYCLE

X=

θ° =

W=

F = 153

S=

kg= 10

DL= 0

SL= 3

AM= 0.0

A = 0.1

T= 0:0

TT= 0:10

CUTS

EXEC.

θ CUTS

PROG.

SINGLE PROGRAM

RUN/PROG=PROGRAMMING

PGR. NO CUTS PROG.

0 905,7 2343

FCTI

" Select the cutting speed.

" Select the fluid for automatic operation by pressing the specific button. The

button led will light up.

" Set the head descent speed regulator to 0 to prevent inadvertent movement of

the cutting head, once the cycle starts.

Cutting

" Enable motor rotation by activating the blade motor selector on the control

console;

" start operation.

Now the blade starts, the cutting cylinder is under pressure and the lubricant/