Tiffin Motorhomes PowerGlide 2019 Owner's Manual

ALLEGRO BUS POWERGLIDE CHASSIS MANUAL

TTIIFFFFIINN MMOOTTOORRHHOOMMEESS,, IINNCC..

105 2nd Street NW Red Bay, Alabama 35582 U.S.A.

2019 PowerGlide

Owner’s Manual

®

WARNING: Breathing diesel engine exhaust exposes you to chemicals known to the

State of California to cause cancer and birth defects or other reproductive harm.

• Always start and operate the engine in a well-ventilated area.

• If in an enclosed area, vent the exhaust to the outside.

• Do not modify or tamper with the exhaust system.

• Do not idle the engine except as necessary.

For more information go to www.P65warnings.ca.gov/diesel.

DISCLAIMER

ALLEGRO BUS POWERGLIDE CHASSIS MANUAL

TIFFIN MOTORHOMES, INC.

Allegro Bus Chassis Owner’s Manual

2019

Tiffin Motorhomes, Inc.

nd

105 2

Street NW, Red Bay, AL 35582 U.S.A.

Telephone 256.356.8661 • Facsimile 256.356.8219

E-Mail: info@tiffinmotorhomes.com

Many of the features and appliances described in this manual may or may not be reflected in the

actual motor home purchased, depending on the options and models selected by the motorhome

owner. All items, materials, instructions, and guidance described in this manual are as accurate

as possible at the time of printing. However, because of Tiffin Motorhomes’ ongoing and

dedicated commitment to excellence, improvement of Tiffin motorhomes is a continuing process.

Consequently, Tiffin Motorhomes reserves the right to make substitutions and improvements in

its makes and models of motorhomes without prior notification. Substitutions of comparable or

better materials, finishes, appliances, instrumentation, and instruction may be made at any time

it is deemed prudent to provide the customer with the best possible motorhome meeting the

customer’s requirements.

Copyright © 2018 by Tiffin Motorhomes, Inc. -- all rights reserved

Printed in the United States of America: Sixth U.S. Printing: June 2018

[20180601]

Tiffin Allegro Bus - PowerGlide Chassis

If you should require chassis service, you should first contact your nearest Tiffin

Customer Support

256-356-0261

Monday-Friday

6 a.m. - 4:30 p.m. CST

Powerglide®Chassis service center. Use

https://tiffinmotorhomes.com/locate_dealer/map.php to find an authorized warranty

service facility. If for some reason this is not possible or if you would like to call the

manufacturers direct, you can contact them at the following telephone numbers:

TIFFIN POWERGLIDE CHASSIS

256-356-0261

(Please have your VIN# ready)

SAFE RIDE

(Nights and weekends)

1-877-276-0619

CUMMINS ENGINE COMPANY

1-800-CUMMINS (800-286-6467)

ALLISON TRANSMISSIONS

1-800-524-2303

MICHELIN TIRE

800-TIRE-HELP (800-847-3435)

Visit our website at www.tiffinmotorhomes.com

ii

ALLEGRO BUS POWERGLIDE CHASSIS MANUAL

Table of Contents

Chapter 1

Tire Care

Tire Care 1-2

Correct Tire Pressure 1-3

Chapter 2

Allison Transmission Operation

Driving Considerations 2-2

Fluid Level Check 2-3

Chapter 3

Brake System

Brake System 3-2

Compressed Air System 3-4

Air Dryer 3-6

Engine Compression Brake 3-7

ATS Warning Lamps 4-5

DPF Maintenance 4-6

Aftertreatment Operation 4-6

Engine Indicator Lamps 4-8

Engine Starting 4-12

Cold-Weather Starting 4-13

Engine Braking (optional) 4-13

Cruise Control 4-14

Engine Shutdown 4-15

Diagnostic Fault Codes 4-15

Towing Hitch 4-16

Chapter 5

Scheduled Maintenance

Scheduled Maintenance Chart 5-2

Fluids 5-5

Lubrication Points 5-8

Maintenance Parts 5-13

Tiffin Assistance 5-15

Chapter 6

Chapter 4

Cummins Engines

Engine specs and maint. 4-2

EPA Mandates 4-4

Pre-Trip Inspection

Pre-Trip Inspection 6-2

ii

ALLEGRO BUS POWERGLIDE CHASSIS MANUAL

Chapter 7

Instruments & Controls

Graphical Instrument Cluster

Operation Guide 7-2

Overview 7-5

Indicator Quick Reference 7-6

Gauge Quick Reference 7-8

Navigation 7-9

Indicators 7-10

Gauges 7-14

Selectable Display 7-18

Alarm Messages 7-23

Menu Map 7-28

Parts Gallery 7-31

Smart Wheel Steering Wheel 7-33

Chapter 11

Allegro Club

Allegro Club Information 11-2

Chapter 8

Air Supply

Air Supply 8-2

Chapter 9

Tag Axle

Tag Axle Operation 9-2

Chapter 10

Warranty

Chassis Warranties 10-2

iii

TIRE CARE

Chapter

1

TIRE CARE

1-1

1-2

Tiffin Motorhomes: “Wherever you go…we go”

TIRE CARE

TIRE CARE

• What is the most important component of tire care?

TIRE PRESSURE

o Why?

Improved Ride

Improved Tire Wear

Improved Road Handling

Improved Braking

Tire Care

Maintaining the proper tire inflation pressure is the most important thing you can do to maximize the life of

your tires. An under-inflated tire can build up excessive heat that may go beyond the prescribed limits of

endurance of the rubber and the radial cords. Over-inflation will reduce the tire’s footprint on the road,

reducing the traction, braking capacity, and handling of your vehicle. An over-inflated tire will also cause a harsh

ride, uneven tire wear, and will be more susceptible to impact damage.

Keep in mind that the pressure rating on the side wall of your tire is the maximum pressure for that tire. This is

not necessarily the correct pressure for the tires when installed on your vehicle. Maintaining the correct tire

pressure for your vehicle’s loaded weight is extremely important and must be a part of regular vehicle maintenance.

1-3

Correct Tire Pressure

PSI=>

90

95

100

105

110

115

120

125

130

KPA=>

620

660

690

720

760

790

830

860

900

TIRE CARE

• How to determine the correct pressure:

Weigh each wheel position

Set tire pressure according to chart

Single LBS

Dual LBS

Single KG

13,340

24,280

6,060 6,300

13,880

25,580

* This Chart Shows Cold Inflation Pressures

315/80 R22.5 LRL X LINE ENERGY Z COACH

Load per Wheel-end

22.5 X 9.00” Wheel

14,380

26,180

6,520

14,880

27,760

6,740

15,220

27,760

6,900

15,840

28,840

7,180

16,540

30,440

7,500

17,380

31,640

7,880

18,180

33,080

8,250

Max

Load per

Tire

9,090

8,270

4,125

Dual KG

11,000

11,600

11,880

12,280

12,600

13,080

13,800

14,360

15,000

3,750

1-4

To determine the correct air pressure for your tires, load your motor home as you would normally travel,

including water and fuel. Go to a truck scale as found at most major truck stops and weigh each wheel

position independently, with driver and passenger(s) in the vehicle as described in the

Vehicle T ire Guide

wheel position. Then use the charts in the guide and adjust the pressure accordingly when the tires are cool or

have not been driven for more than one mile. You may call 1-800-847-3435 for a copy of the

Recreational Vehicle Tire Guide

bulletins-and-warranties/load-and-inflation-tables/#/

NOTE: Never reduce the air pressure in a hot tire.

REMEMBER: For control of your RV, it is critical that the tire pressure be the same on both sides of the axle.

(MWL43146 Rev. 03/12) to determine the correct air pressure for the weight on each

, or visit: https://www.michelintruck.com/reference-materials/manuals-

TIRE CARE

Michelin Recreational

Michelin

Emissions and Fuel Efficiency

Compliance

Your chassis was designed, and built, with components including, but not limited to, low rolling resistance tires

specifically designed and manufactured to exacting standards for regulatory fuel efficiency and greenhouse gas

emissions compliance. The vehicle owner is responsible for being sure these components are replaced with

the same or equivalent components that maintain compliance with federal and local regulations.

For help with determining tires that are the same or equal in regards to rolling resistance for maintaining

compliance with the regulatory standards, please contact Michelin at 1-800-947-3435.

2-1

Chapter

2

ALLISON TRANSMISSION OPERATION

Allison Transmission Operation

2-2

ALLISON TRANSMISSION OPERATION

Driving Conditions

• Normal driving – best fuel economy

o Select “D” and “Mode On”

• Performance

o “Mode Off”

o For mountain driving, select lower gears to maintain 2000+ engine RPM

• Hill climbing on hot days

o Keep RPMs high to cool engine

Driving Tips with the Allison 3000MH or 4000MH Transmission:

The points at which shifts occur depend upon predetermined speeds and other operating conditions. A

transmission “shift calibration” includes several sets of shift points used according to current or anticipated

operating conditions, such as engine or transmission fluid temperature. You can change shift schedules using

the MODE button.

The transmission control module (TCM) includes the capacity for two separate and distinct shift calibrations,

one for use in “Primary Mode” of operation and one in “Secondary Mode.”

Primary – This shift schedule is typically used for all normal vehicle operations.

Secondary – This is an alternate shift schedule that the TCM uses upon request. This is operatorcontrolled using the MODE button.

When you are driving under normal road conditions, the DRIVE mode is recommended for the best

performance and fuel economy. The MODE switch should be set to ON for economy mode, but MODE off

should be used when climbing hills and when extra performance is required.

The display screen on the shift control pad will indicate the highest selected gear for the transmission. When

mountainous or up-and-down terrain conditions are encountered, you should manually select a lower gear,

preferably lower than 5th gear. This can be done at any road speed by pressing the down arrow repeatedly until

the desired gear is indicated in the window of the shifter pad. When your road speed decreases to a safe point,

the transmission will downshift at a higher RPM than normal. This will decrease the use of overdrive while

pulling hills, which can result in excessive heat build-up in the transmission, and keeps the engine operating at

peak horse power and performance.

When ascending a grade, maintain engine speed to within 400-500 RPM of governed engine speed. Governed

speed will be 2200 RPM on the Cummins ISL engine model. Road speed may decrease, but the engine will be

at its peak in the power curve.

It is especially pertinent to monitor your water temperature gauge when climbing steep grades. Keep in mind

that it is not uncommon for the temperature to increase, especially in hot weather. If the gauge reaches the end

2-3

ALLISON TRANSMISSION OPERATION

zone or if the temperature warning light on the gauge panel should come on, reduce your road speed, shift to

the next lower gear and keep your tachometer within 500 RPM of engine governed speed. In many cases this

will stabilize the water temperature. If the temperature gauge continues to rise, pull to the side of the road and

shift the transmission into neutral. Bring the engine RPM to 1,700—2,000 RPM until the temperature drops

down into the normal range. This should occur in a relatively short period of time. If the temperature gauge does

not begin to drop, stays in the red zone, or continues to rise, shut down the engine and allow it to cool. After the

engine is allowed to cool check the fluid level in the reservoir and add coolant if needed.

A good “rule of thumb” for descending grades is to never use a higher gear than was used to climb the same

or similar grade. Try to keep the engine within 500 RPM of governed speed. This will give the best engine

braking and reduce the need to use the service brakes. Select a gear that will keep you at a safe speed with

minimal brake application. Never ride your brakes when descending a grade since excessive brake heat will

build up and your brakes could fade, leaving you with little or no braking power.

Your vehicle is equipped with an engine brake. The engine brake will assist in slowing your vehicle on a

downhill grade. With the engine brake switch in the ON position, release the accelerator and depress the

service brake to activate the engine brake. When the engine brake is activated the transmission will pre-select a

lower gear to aid in braking. This is indicated by a “2” in the left hand pane of the transmission shift selector.

The transmission will begin to down-shift as soon as the road and engine speed will safely allow. This will

produce a slowing effect and will remain engaged until either the exhaust brake switch is turned off, the

accelerator is pressed, or the engine speed drops to 800 RPM. If your initial speed is high, you may have to

step on the brake to slow the vehicle before the transmission will down-shift from 6th gear to 5th gear. This is

normal.

Always select (N) neutral on the transmission shift pad prior to turning off the vehicle engine.

Fluid Level Check

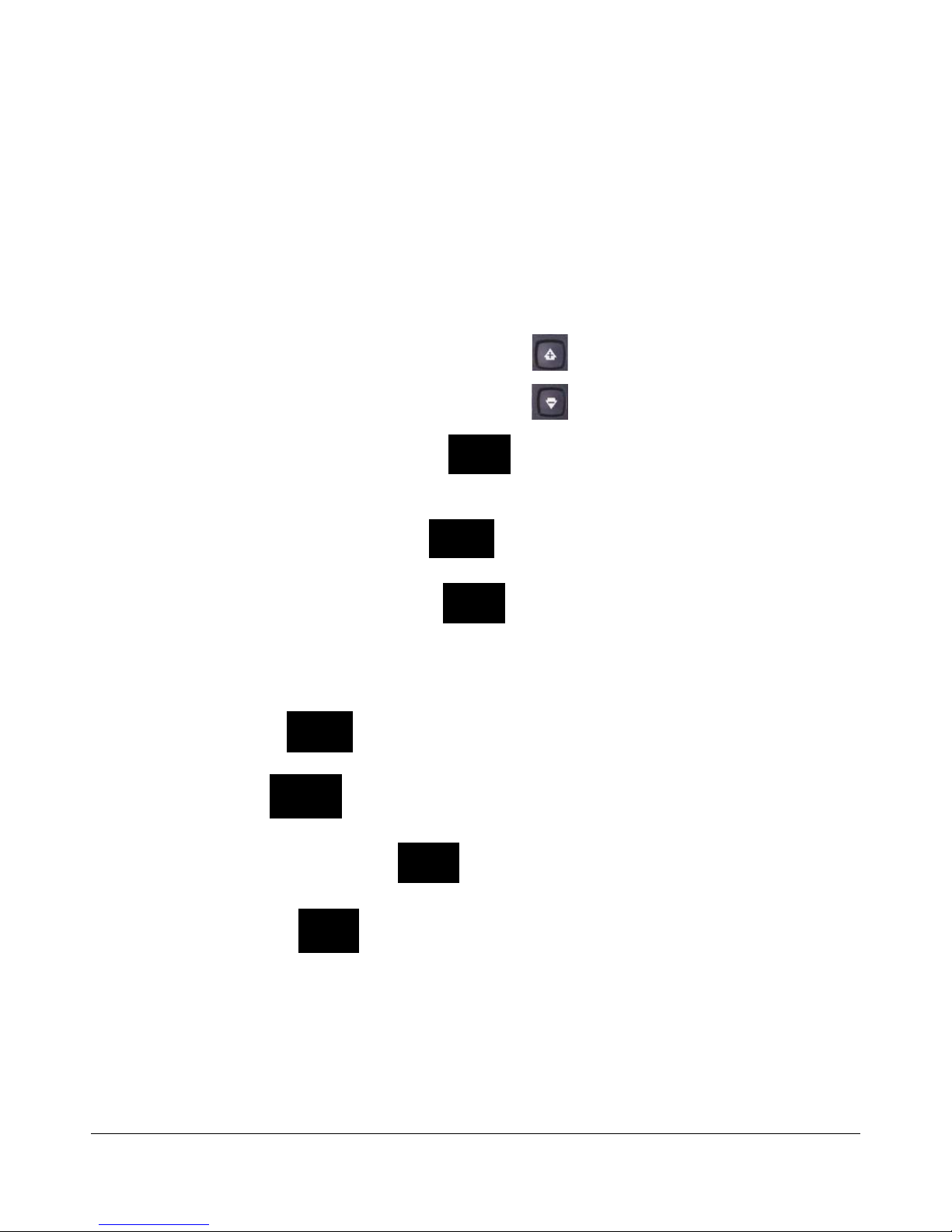

Use the transmission shift pad for best results in checking the transmission fluid level. The transmission will

not reach operating temperature until the coach has been driven for at least 15 miles. Therefore, it may be best

to check transmission fluid level at the end of your driving day.

Transmissions do not consume fluid. If your transmission shows to be low of fluid, it should be inspected for

leaks.

2-4

TRA NS OIL

LEVEL OK

TRA NS OIL

2QT LOW

TRA NS OIL

3QT HI

OIL TEMP

TOO LO

MUST BE IN

NEUTRAL

SETTLING

:62

ENG RPM

TOO HI

ALLISON TRANSMISSION OPERATION

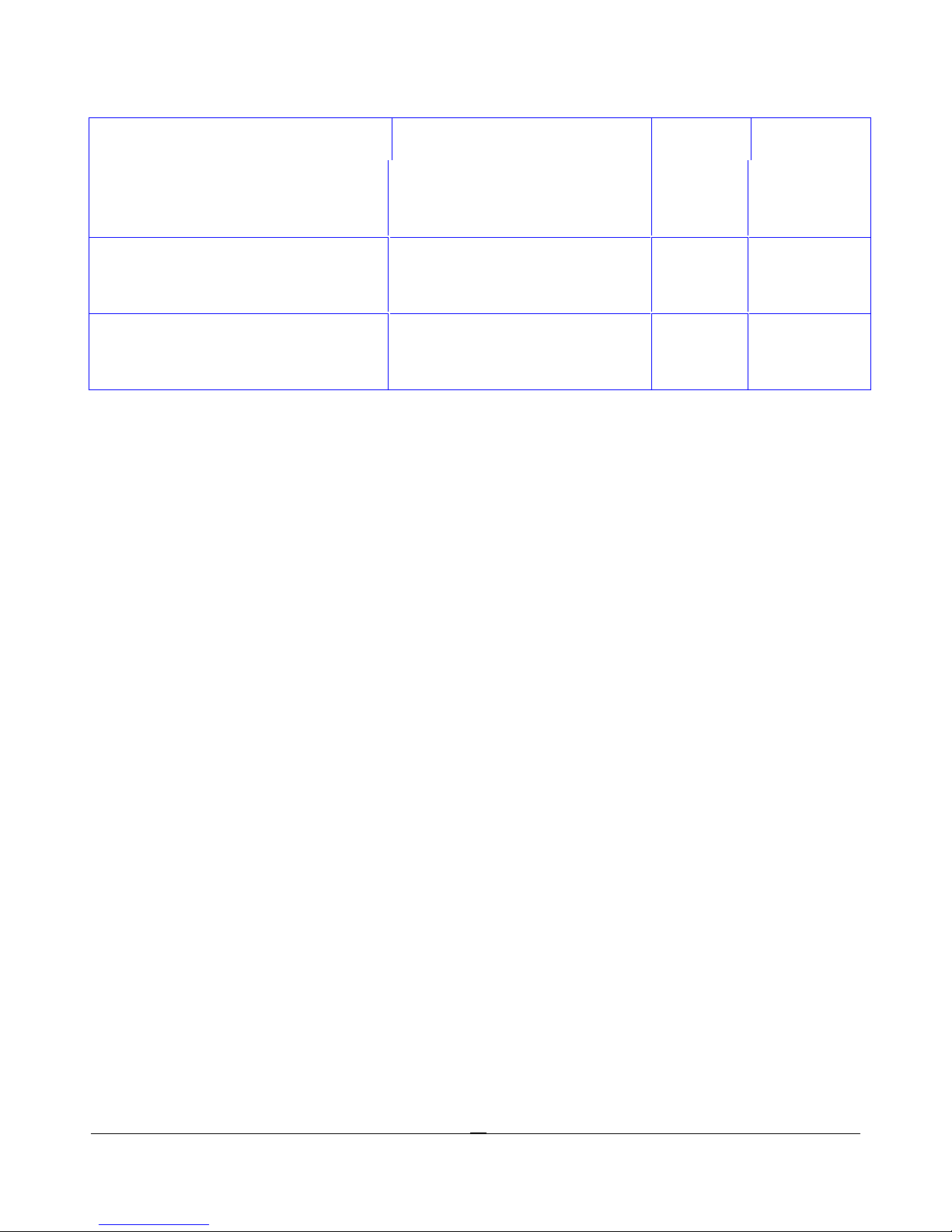

Check the transmission fluid level with the following steps:

Conditions that must be met

• Be sure transmission is at operating temperature (104° to 220° F)

• Vehicle is parked on level ground with the parking brake is set

• Transmission in neutral and engine at idle

• Wait until vehicle has been stationary for two minutes

• Simultaneously press the up and down arrow keys

• Correct fluid level will be indicated by

• Low fluid level will be indicated by

• High fluid level will be indicated by

If conditions are not met one of the following messages will be displayed

• Oil temp too low

• Not in neutral

• Not stationary for two minutes

• Engine not at idle

BRAKE SYSTEM

Chapter

3

Brake System

3-1

3-2

BRAKE SYSTEM

Brake System

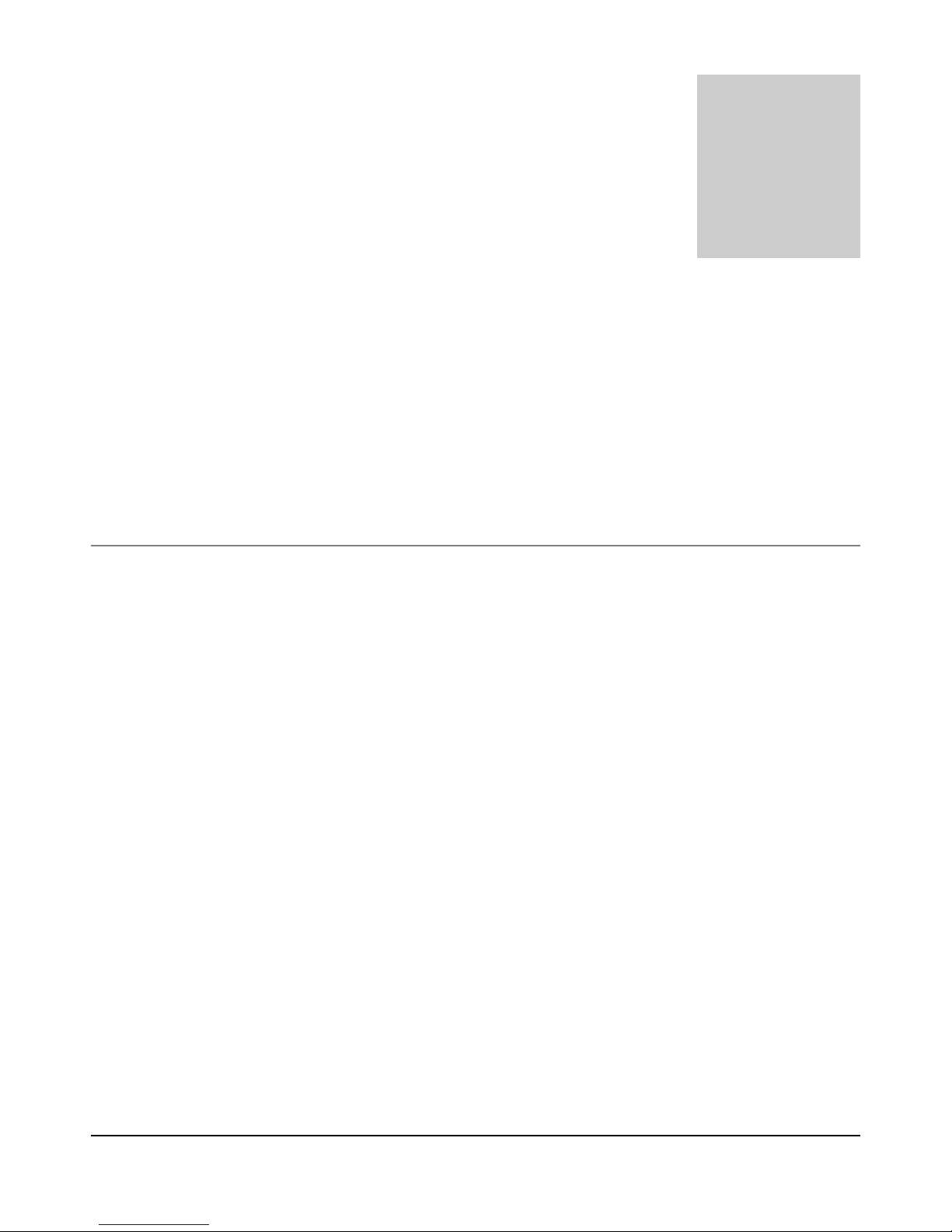

Figure 3-1: Rear Brakes

Front brakes are 17” air applied disc

Rear brakes (Figure 3-1) double as parking brake

- Park brakes are spring applied – air released

- Two large 16.5 x 7” drum brakes

- Park brake remains applied even if air pressure is lost

If air pressure is lost

- A buzzer and warning lamp will alert you

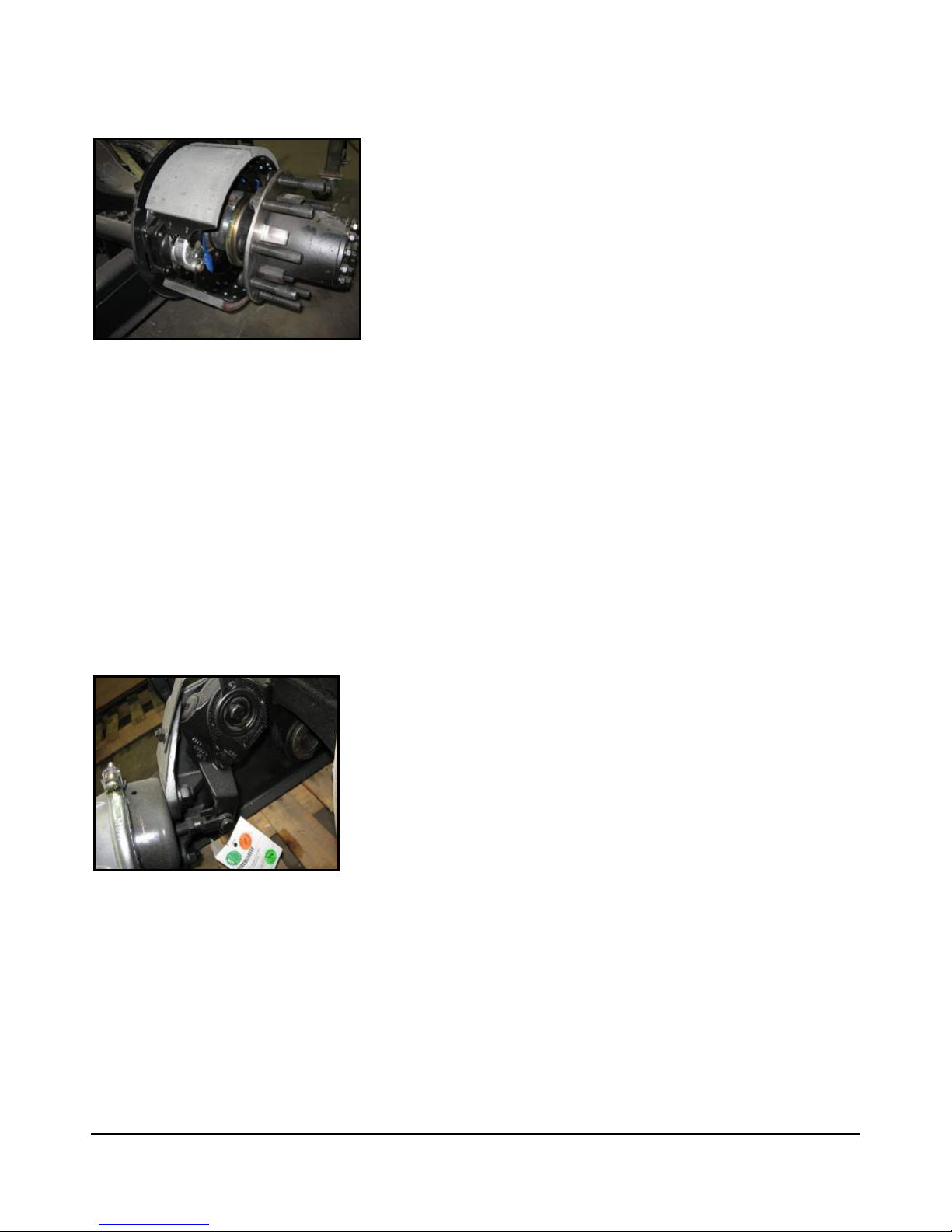

Chassis is equipped with automatic slack adjusters (Figure 3-2)

- No brake adjustment required

Figure 3-2: Automatic Slack Adjuster

The rear brakes on the PowerGlide chassis are also used as the parking brakes. This provides you the holding

power of two large drum brakes to prevent your coach from rolling, even when fully loaded on a 20% grade.

A decrease in air pressure while driving will not cause an immediate loss of brakes. If a significant leak develops

in the air system, at approximately 60 PSI you will be alerted by a lamp on the instrument panel, and by an

audible alarm. As you apply the brakes, the air supply holding the park brakes in the released position will

gradually be depleted. When system pressure drops to approximately 40 PSI the rear brakes will set. This allows

you sufficient time to pull over to the side of the road.

3-3

BRAKE SYSTEM

NOTE: The rear brakes have dual chambers – one for the service brakes and one for the park brake. The

service brakes are air applied and spring released. The park brake is spring applied and air released.

The brake system is equipped with automatic slack adjusters that avoid the need to manually adjust your brakes.

Each time you step on the brake pedal, if adjustment is needed, the adjusters will take up the slack.

3-4

Compressed Air System

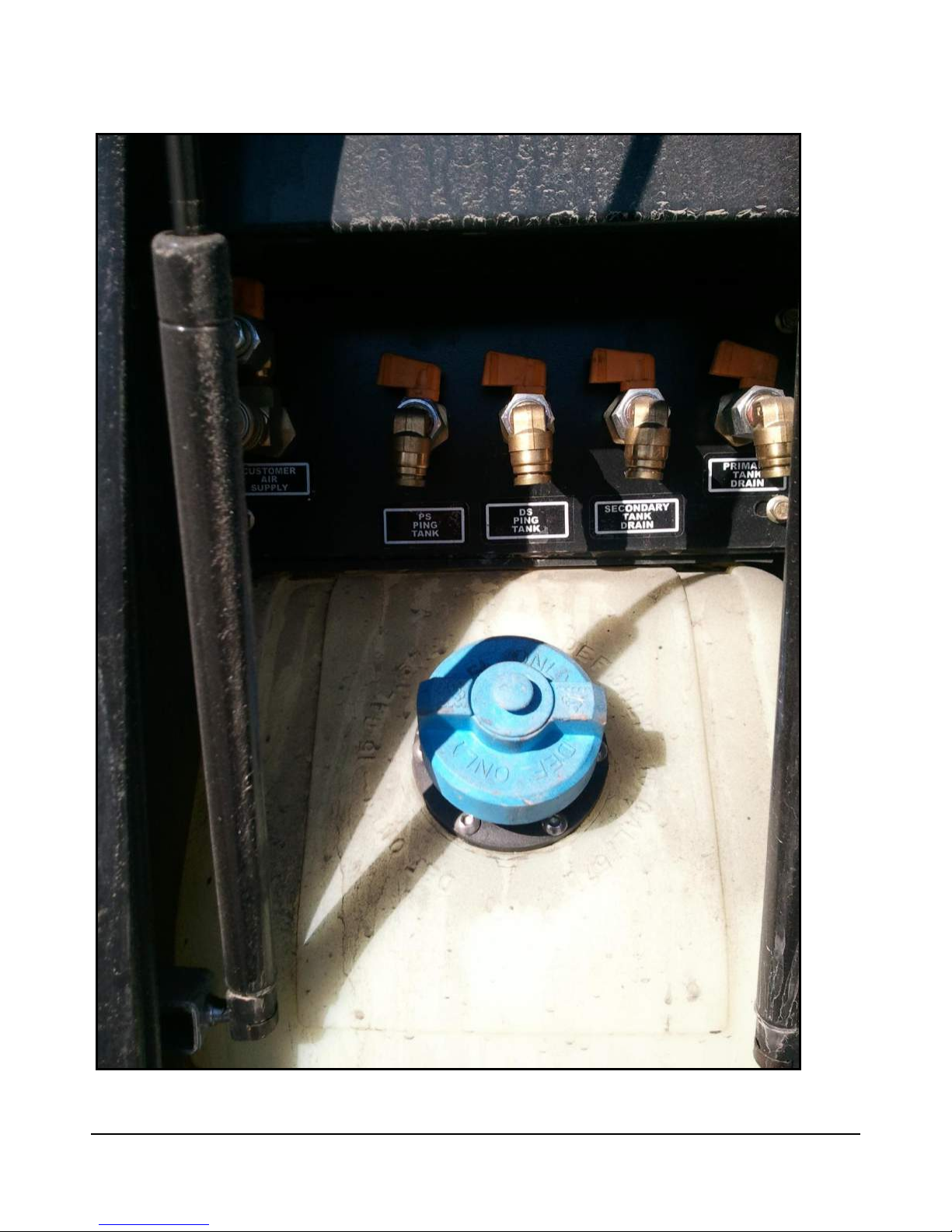

36’ and 40’ Bus Non-Tag Tank Drains

BRAKE SYSTEM

3-5

43' Bus Tag Tank Drains

BRAKE SYSTEM

3-6

Warning

Air tanks should be bled of all pressure any time you perform work on the air system.

BRAKE SYSTEM

Compressed Air System

The compressed air system is comprised of multi-air storage tanks. The primary tank stores and supplies

air for the rear brakes, the secondary tank stores and supplies air for the front brakes.

When air is compressed it becomes hot. As it cools, condensed moisture forms in the system. The air system is

equipped with an air dryer to remove most of this moisture. The dryer has an automatic moisture ejector that

releases the trapped moisture back into the atmosphere. However, some moisture will form in the system

beyond the dryer, and make its way into the storage tanks. As moisture collects in the primary and secondary

tanks, it displaces the area needed for air storage, thus requiring that the tanks be drained periodically.

The air system is equipped with air tank drains conveniently located in the compartment with the DEF tank.

Each drain is attached to a different tank. These drains should be opened regularly for a few seconds to

remove any moisture trapped in the tanks.

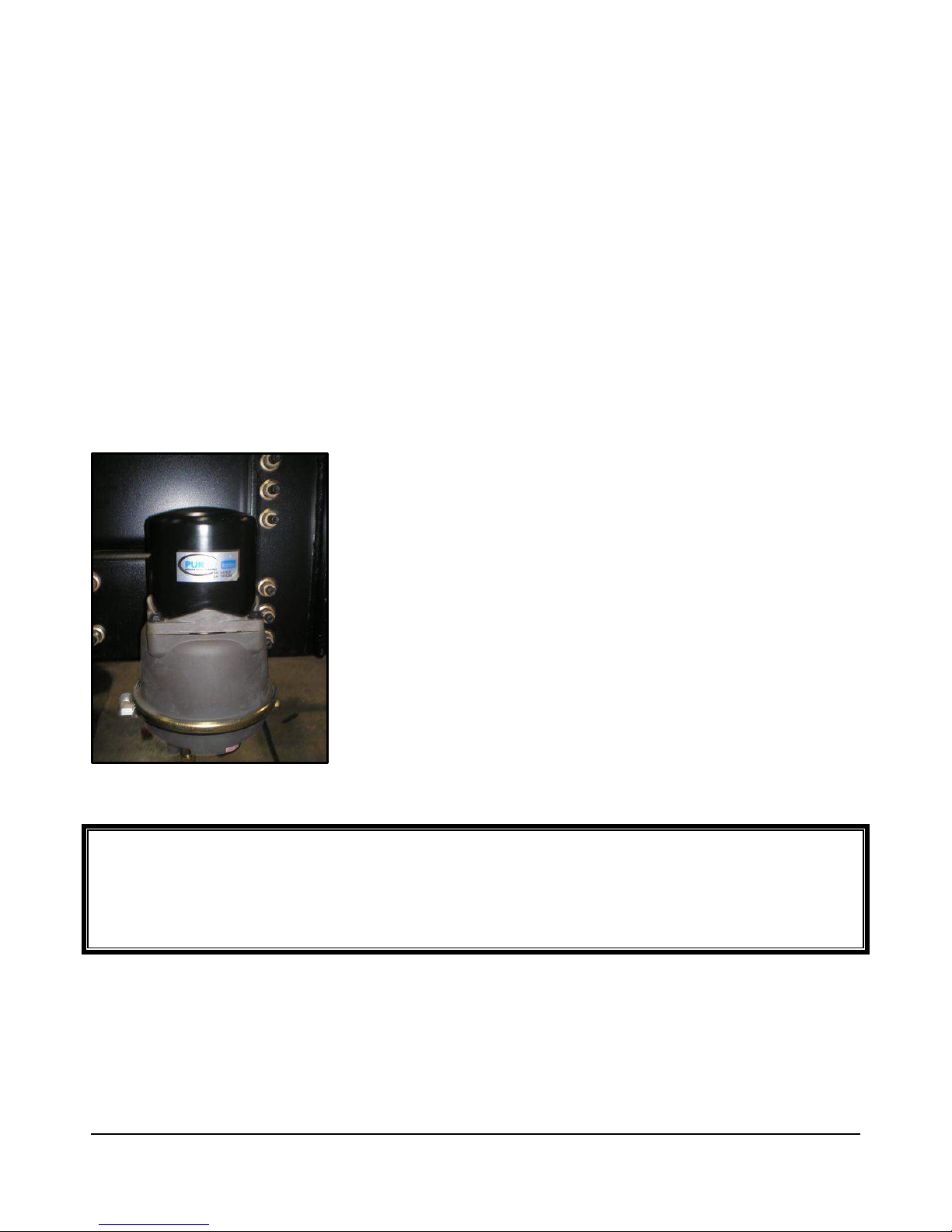

Air Dryer

Figure 3-3: Haldex Purest Air Dryer

The Tiffin PowerGlide chassis air brake system features a Haldex Purest air

dryer (Figure 3-3), which removes the condensed moisture from

compressed air. The air dryer is equipped with a desiccant cartridge that

needs to be changed every 36 months. The dryer is located on the driver's

side (LH) frame rail (behind the rear axle).

3-7

Warning

DO NOT USE the compression brake on wet roads, hazardous, or slippery conditions.

As with any motorized vehicle, practice safety when on the road.

BRAKE SYSTEM

Engine Compression Brake

Figure 3-4: Compression Brake

The engine compression brake (Figure 3-4):

Improves braking power

Reduces the chance of overheating brakes on steep grades

Works in conjunction with the transmission to help slow the vehicle

Has two stages (low and high) for varying terrain

All brakes will build up heat when being used due to friction – this is normal. However, excessive use of the

brakes when descending a grade can result in excessive heat and can cause “brake fade” or a loss of braking

power, even with disc brakes. The proper way to use your brakes is to go slowly enough that a fairly light,

occasional use of the brakes will keep your speed from increasing.

NOTE: DO NOT maintain continual brake pedal pressure when descending a hill with any type of brake

system.

Rather, down-shift the transmission to slow the vehicle and make light, intermittent brake applications to

control downhill speeds. By utilizing the transmission gears and compression brake, continual use of the brakes

will not be necessary. When using the transmission’s lower gears to slow the vehicle on hills, be careful not to

exceed the governed speed of your engine. If engine-governed speed is exceeded, the transmission will shift up

to the next range, rapidly increasing the speed of your vehicle. If you find that you are continually using the

brakes to maintain a safe speed and to keep the RPM within this range, slow the vehicle down even further and

shift the transmission to a lower gear.

3-8

BRAKE SYSTEM

4-2

Configuration

Inline 6

Displacement

543 CU IN

8.9 L

Lube Oil Capacity

24-28 QT

23-26 L

Idle Speed

700-800 RPM

Optional Compression Brake

Up to 370 HP @ 2600 RPM

No Load Governed Speed

2400 RPM

Engine Weight (Dry)

1,695 LB

769 KG

Aftertreatment Weight

132-179 LB

60-81 KG

Chapter

4

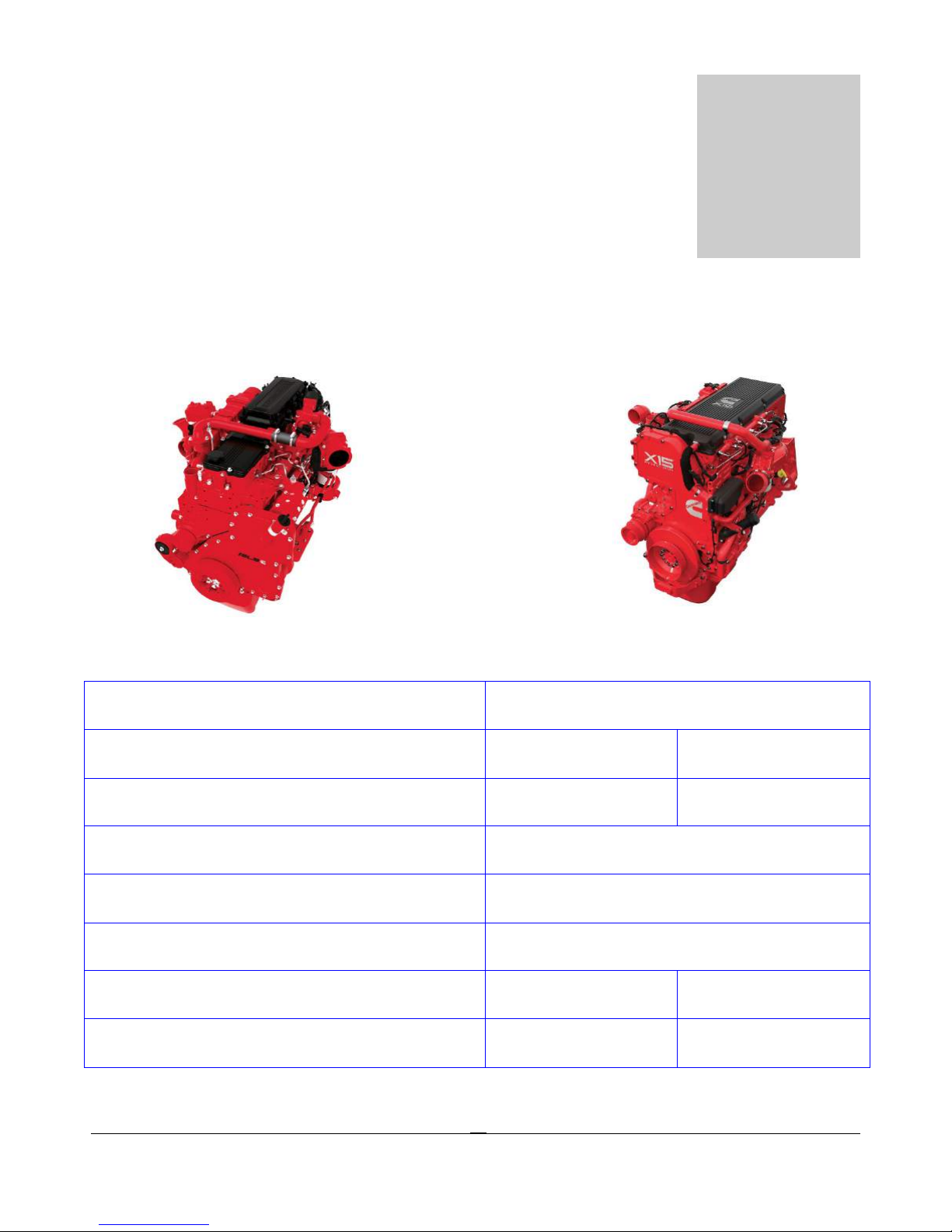

CUMMINS ENGINES

Cummins ISL & X15 Engine

________________________________________________________________________________________________________________________

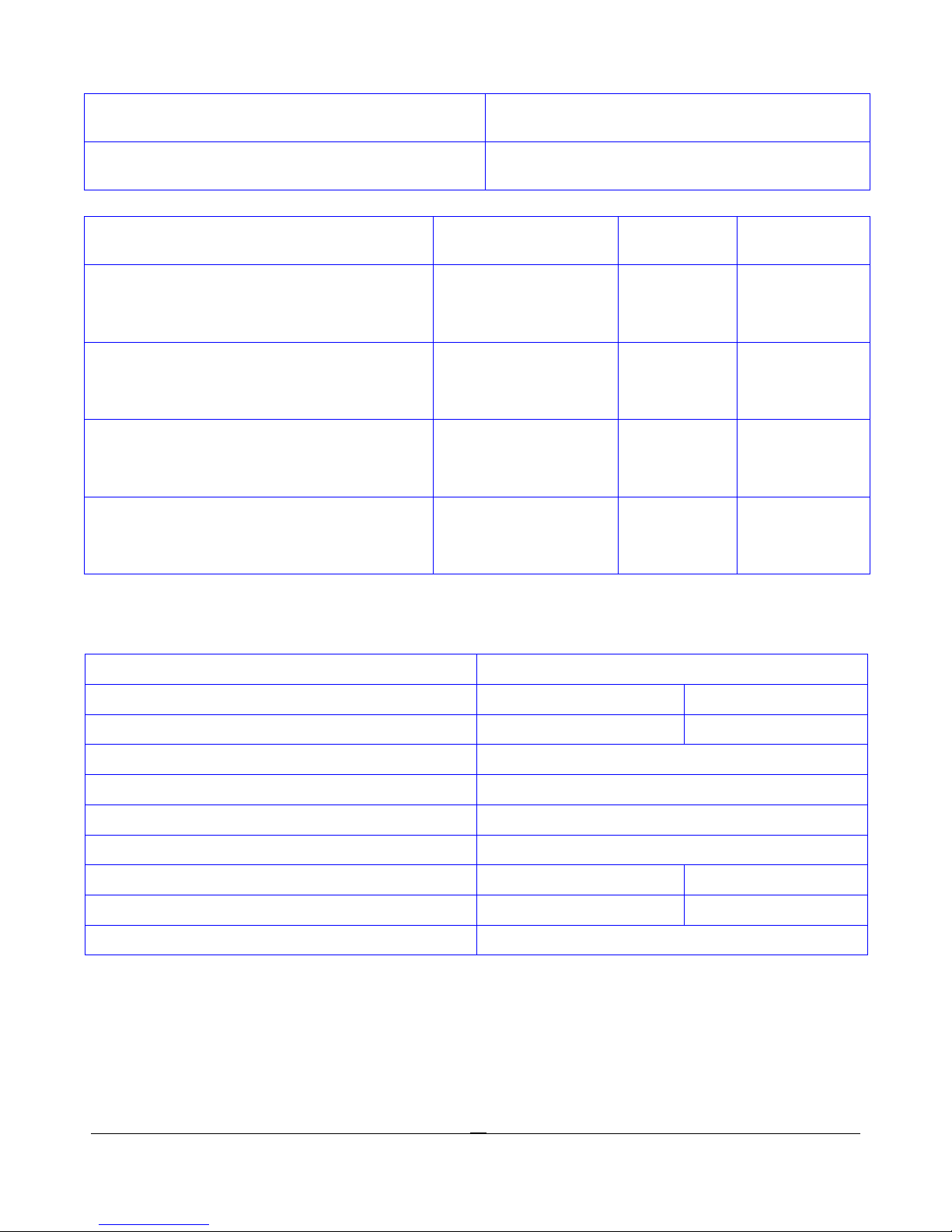

Cummins ISL9 Specifications

4-3

Injection Pressure

32,000 PSI

Biodiesel Compatibility

Up to B20

Maintenance Item

Miles/Kilometers

Hours

Months

32,000 KM

32,000 KM

240,000 KM

96,000 KM

Configuration

Inline 6

Displacement

912 CU IN

14.9 L

Lube Oil Capacity

44 QT

41.6 L

Biodiesel Compatibility

Up to B20

Engine Braking Horsepower

Up to 605 HP @ 2100 RPM

Idle Speed

600-800 RPM

No Load Governed Speed

2130 RPM

Engine Weight (Dry)

2,964 LB

1,344 KG

Aftertreatment Weight*

173-211 LB

78-96 KG

Injection Pressure

32,000 PSI

Maintenance

CUMMINS ENGINES

Oil and Filter 20,000 MI

Fuel Filter 20,000 MI

Overhead Adjustment 150,000 MI

Coalescing Filter 60,000 MI

Cummins X15 Specifications

500 12

500 12

5,000 48

2,000

*Depending on configuration

4-4

Miles/Kilometers

Maintenance

CUMMINS ENGINES

Maintenance Item

Oil and Filter

Fuel Filter

Overhead Adjustment

Consult your engine Owners Manuals for more information

15,000 MI

24,000 KM

15,000 MI

24,000 KM

150,000 MI

240,000 KM

Hours Months

500 12

500 6

5,000 48

EPA Mandates

The Environmental Protection Agency (EPA) mandates that all engines built after December 31, 2009 must

reduce the level of emissions exhausted by the engine to the following levels.

Nitrous Oxides (NOx) – 0.2 g/bhp-hr

Particulate Matter (PM)- .01 g/bhp-hr

To meet EPA guidelines, diesel engines installed in Tiffin Motorhomes PowerGlide chassis for domicile

in Canada and the USA use an after treatment system (ATS) with a diesel particulate filter (DPF)to reduce

particulate matter, and selective catalytic reduction (SCR) technology to reduce NOx downstream of the

engine.

Using non-specification fluids can result in serious damage to the ATS. It is extremely important that the

following guidelines be met for vehicles with EPA10 thru EPA2017 compliant engines, or damage may

occur to the ATS, and the warranty may be compromised.

• Use "ultra-low sulfur diesel (ULSD)" with 15 ppm sulfur content or less.

• Do not use fuel blended with used engine lube oil or kerosene.

• Engine lube oil must have a sulfated ash level less than 1.0 wt %, currently referred to as CJ-4 oil.

• Use only API certified diesel exhaust fluid (DEF) in the DEF tank.

Notice

4-5

CUMMINS ENGINES

The ATS is comprised of a diesel oxidation catalyst (DOC), and a diesel particulate filter (DPF). The

DPF traps soot particles, and exhaust heat converts the soot to ash in the DPF in a process called

regeneration (re-gen). The harder an engine works, the better it disposes of soot. When the engine is

running under load and re-gen occurs without input, it is called passive re-gen. If the engine isn’t running

hot enough, the electronic controls may initiate an active re-gen, whereby extra fuel is injected into the

exhaust stream before the DPF, to superheat the soot trapped in the filter and burn it to ash. Both types

of re-gen occur without driver input.

Operating at reduced engine load will allow soot to accumulate in the DPF. When this occurs, the DPF

lamp illuminates, indicating that a re-gen must be performed, and the driver must bring the vehicle

up to highway speed to increase the load. Driving at highway speeds for 20 minutes should allow for a

re-gen to take place, and turn off the DPF lamp.

After the exhaust stream passes through the DPF, it flows through a second canister housing which is the

SCR device. A controlled quantity of diesel exhaust fluid (DEF) is injected into the exhaust stream where

heat converts it to ammonia (NH3) gas. This mixture flows through the SCR device where the ammonia

gas reacts with the NOx in the exhaust to produce harmless nitrogen (N2) and water vapor (H2O), which

then exits out of the tailpipe.

ATS War ning Lamps

Warning lamps in the driver’s message center alert you of situations with the after-treatment system.

• An illuminated DPF lamp indicates a re-gen is needed. Driving at highway speeds for 20

minutes should correct this condition.

o A blinking DPF lamp indicates the need for a re-gen is more urgent. Again, driving the

vehicle at highway speeds for 20 minutes should correct this condition.

o A blinking DPF lamp along with a check engine light indicates that the engine is unable to

effectively regenerate, and you should immediately seek service at the nearest Cummins

Authorized Dealer.

• An illuminated High Exhaust Temperature (HEST) lamp alerts the operator of elevated exhaust

temperatures while the engine is performing an active re-gen. Do not operate, or park the

vehicle near flammable objects while the HEST lamp is illuminated.

• An illuminated DEF warning lamp indicates that the DEF tank should be refilled at the next

opportunity. This light will illuminate when the tank level is at approximately 10%.

o A blinking DEF warning lamp indicates the tank level has dropped to approximately 5%.

o A blinking DEF lamp along with the check engine lamp indicates the tank level has

dropped to approximately 2.5%. A 25% reduction in engine torque will be applied with

this condition.

4-6

CUMMINS ENGINES

o When the tank is empty the Stop Engine Light will be illuminated and the vehicle speed

will be limited to 5 MPH. Filling the tank with new DEF will remedy this condition.

DPF Maintenance

Eventually ash will accumulate in the DPF and the filter will require servicing. DPF servicing must be

performed by an authorized technician, following the engine manufacturer’s instructions. DPF cleaning

will be required at approximately 200,000 miles of service. A record must be maintained for warranty

purposes, which includes:

• Date of cleaning or replacement

• Vehicle mileage

• Particulate filter part number and serial number

Aftertreatment Operation

Diesel Particulate Filter

Soot is composed of the partially burned particles of fuel that occur during normal engine operation

(black smoke).

Ash is composed of the partially burned particles of engine oil that occur during normal engine operation.

Over time, both soot and ash accumulate in the DPF and must be removed. Soot is removed by a

process called regeneration. Ash is removed by removing the DPF and cleaning it at specified intervals.

A vehicle with an ATS has up to four additional indicator lamps on the dashboard. These additional

lamps, along with the check engine lamp, alert the operator of the status of the ATS.

Ultra low sulfur diesel fuel is required for an engine equipped with a DPF. If ultra low sulfur diesel is not

used, the engine might not meet emissions regulations, and the DPF or DOC can be damaged.

To maximize the maintenance intervals of the DPF, Cummins Inc. recommends the use of a lubricating

engine oil meeting Cummins Engineering Standard 20081. The use of oil meeting CES 20081 also

requires the use of ultra low sulfur diesel fuel to maintain the specified oil drain interval without risk of

engine damage.

Regeneration

4-7

CUMMINS ENGINES

Regeneration is the process of converting the soot collected in the DPF into ash.

Under some operating conditions, such as low speed, low load, or stop and go duty cycles, the engine

may not have enough opportunity to regenerate the DPF during normal vehicle operation. When this

occurs, the engine will illuminate the DPF lamp to inform the vehicle operator that assistance is required,

typically in the form of operating the vehicle at highway speeds for approximately 20 minutes.

Heat is required for the regeneration process to occur. Regeneration can be classified into two different

types: passive regeneration and active regeneration.

Passive Regeneration

Passive regeneration occurs when the exhaust temperatures are naturally high enough to oxidize the soot

collected in the DPF faster than the soot is collected.

Passive regeneration typically occurs when the vehicle is driven at normal highway speeds and/or under

heavy loads.

Active Regeneration

Active regeneration occurs when the exhaust temperatures are not naturally high enough to oxidize the

soot in the DPF faster than it’s collected.

Active regeneration requires assistance from the engine in to increase the exhaust temperature. This is

typically accomplished by the engine injecting a small amount of diesel fuel into the exhaust stream,

which is then oxidized by the DOC, and creates the heat needed to regenerate the DPF.

Active regeneration will occur more frequently in vehicles operated at low speed, low load, or stop and go

duty cycles. Active regeneration only occurs if the engine ECM has detected that the DPF restriction has

reached a specified limit, and may only occur if the vehicle is moving above a preset speed threshold. The

engine ECM will activate and de-activate active regeneration as needed.

Active regeneration is largely transparent to the vehicle operator, the vehicle operator may notice an

increase in turbocharger noise during an active regeneration event, and may notice that the high exhaust

temperature lamp is illuminated, if the vehicle is so equipped.

During active regeneration, the exhaust temperature can be hotter than when the engine is operating at

full load. The exhaust temperature during a normal active regeneration event could reach 1100°F, and

possibly 1500°F under certain conditions.

4-8

CUMMINS ENGINES

Warning

Active regeneration can occur any time the vehicle is moving, and the exhaust temperature can remain

hot after the vehicle has stopped moving. The exhaust temperature could reach 1500°F, which is hot

enough to ignite or melt common materials, or to burn people. If the HEST lamp is illuminated do not

operate or park the vehicle with the exhaust near people, or flammable materials.

Aftertreatment Warm-up

The ATS warm up function is used to help prevent the buildup of water condensation in the ATS during

extended idle operation.

After approximately four hours of engine idle operation, the engine speed will increase to around 1100

RPM, and remain at this speed for 10 minutes. During this time the ATS is warmed up enough to

evaporate any water that has condensed in the system.

The ATS warn-up function can be stopped by depressing the throttle, clutch, or brake pedal. If the

engine continues to idle, the ATS warm-up function will try to raise the idle speed until the ATS

temperatures are suitable.

Engine Indicator Lamps

General Information

The following engine indicator lamps cover only the lamps controlled by the engine ECM.

Wait to Start Lamp

The WAIT TO START lamp illuminates when the intake air heater needs to warm the intake air prior to

starting the engine. The WAIT TO START lamp on time will vary depending on the ambient air

temperature.

The WAIT TO START lamp is amber and looks similar to this:

.

Check Engine Lamp

4-9

CUMMINS ENGINES

The CHECK ENGINE lamp illuminates when the engine needs to be serviced at the first available

opportunity.

The CHECK ENGINE lamp is amber, and looks similar to this:

Another function of the CHECK ENGINE lamp is to flash for 30 seconds at key-on when one of the

following occurs. This flashing function is referred to as the MAINTENANCE lamp. The

MAINTENANCE lamp could flash for any of the following reasons:

o Maintenance required (if the Maintenance Monitor is enabled).

o Water-in-fuel is detected.

o Coolant level is low.

Stop Engine Lamp

The STOP ENGINE lamp indicates, when illuminated, the need to stop the engine as soon as it can be

safely done. The engine must remain shut down until the engine can be repaired.

For engines with the Engine Protection shutdown feature enabled, if the STOP ENGINE lamp begins to

flash, the engine will automatically shut down after 30 seconds. The flashing STOP engine lamp alerts the

operator to the impending shut down.

The STOP ENGINE lamp is red in color, and looks similar to this:

Malfunction Indicator Lamp (MIL)

The engine in this vehicle is required to conform to EPA Heavy Duty On-Board Diagnostic (OBD)

regulations. OBD exist to make sure the engine is operating within the prescribed emissions limits. The OBD

system monitors the ATS to detect malfunctions that adversely affect emissions. If a malfunction is detected

the malfunction indicator lamp (MIL) will illuminate, and a diagnostic fault code will be logged in the engine

control module.

The MIL lamp is amber, and looks similar to this:

Diesel Particulate Filter (DPF) Lamp

The DPF lamp indicates, when illuminated or flashing, that the DPF needs to be regenerated.

The DPF lamp is amber, and looks similar to this:

4-10

CUMMINS ENGINES

An illuminated DPF lamp indicates that the DPF needs to be regenerated at the next possible

opportunity. This can be accomplished by:

1. Changing to a more challenging duty cycle, such as highway driving, for at least 20 minutes.

2. Have a Cummins authorized repair location perform a stationary regeneration.

NOTE: Stationary regeneration is considered a normal maintenance practice and is not covered by

Cummins Inc. warranty.

A flashing DPF lamp indicates that the DPF needs to be regenerated at the next possible opportunity.

Engine power may be reduced automatically.

When the DPF lamp is flashing, the operator should:

1. Change to a more challenging duty cycle, such as highway driving, for at least 20 minutes.

2. Have a Cummins authorized repair location perform a stationary regeneration.

A flashing DPF lamp combined with an illuminated CHECK ENGINE lamp indicates that the DPF

needs be regenerated immediately. Engine power will be reduced automatically. When these lamps are

illuminated together you should immediately seek service from a Cummins authorized repair location.

NOTE: If the engine is unable to complete a DPF regeneration cycle, the STOP ENGINE lamp will

illuminate and the vehicle will have to be towed to a Cummins authorized repair location.

High Exhaust Temperature (HEST) Lamp

The HEST lamp is amber, and looks similar to this:

The HEST lamp indicates, when illuminated, that exhaust temperatures are high due to regeneration of

the DPF. The lamp could illuminate during normal engine operation or during stationary regeneration.

NOTE: The OEM determines whether or not the HEST lamp is installed on the vehicle. The OEM also

specifies the temperatures, vehicle speeds, and other conditions at which the lamp illuminates. Refer to

the OEM service manual for additional information regarding this lamp.

When this lamp is illuminated, make sure the exhaust pipe outlet is not directed at any surface or material

that will melt, burn, or explode.

o Keep the exhaust outlet away from people, and anything that can burn, melt, or explode.

o Nothing within 0.6 m [2ft] of the exhaust outlet

o Nothing that can burn, melt, or explode within 1.5 m [5ft] (such as gasoline, wood, paper, plastics,

fabric, compressed gas containers, or hydraulic lines).

o In an emergency, turn off the engine to stop the flow of exhaust.

Loading...

Loading...