Page 1

Steadicam

®

Volt

™

LIT-817001, RevA

Page 2

Introduction 1

Volt Components 2

Get Started 7

Neutral Balance 8

Powering On 11

Operating with Volt 15

Control Box settings 19

Installing the Volt 25

Control box 27

Gimbal prep 29

Mounting Volt motors 35

Flip button 37

Adding Belts 39

Upgrading gimbals

Archer/Archer2 gimbal 45

Ultra2/Shadow gimbal 49

PRO gimbals 53

Balance Ultra2/PRO 57

Troubleshooting and Notes 61

Wiring and pin-outs 63

Contact Tiffen 65

The Tiffen Company

90 Oser Avenue

Hauppauge, NY 11788

Visit us at tiffen.com

Table of Contents

Page 3

1 2

The Steadicam® Volt™

Welcome to the future of professional Steadicam® stabilizer operating!

Working with the sled’s inertia and neutral balance, the Volt generates

an “articial bottom-heaviness” to keep the horizon level and headroom

stable. With the Volt, the operator can concentrate on precise framing,

timing, navigating, and other more interesting aspects of operating.

The strength of the roll and the tilt assistance can be individually

ne-tuned to suit the operator’s preferences, and easily adjusted for

different shots. The assistance can feel like operating a sled with a very

long drop time – easy to tilt or roll – to full gyro-simulation, with the

sled locked hard to the horizon in roll or tilt or both!

Because the sled is always balanced neutrally top-to-bottom, all

pendular effects from acceleration and deceleration are eliminated. Plus,

there is no re-balancing needed when switching to low mode!

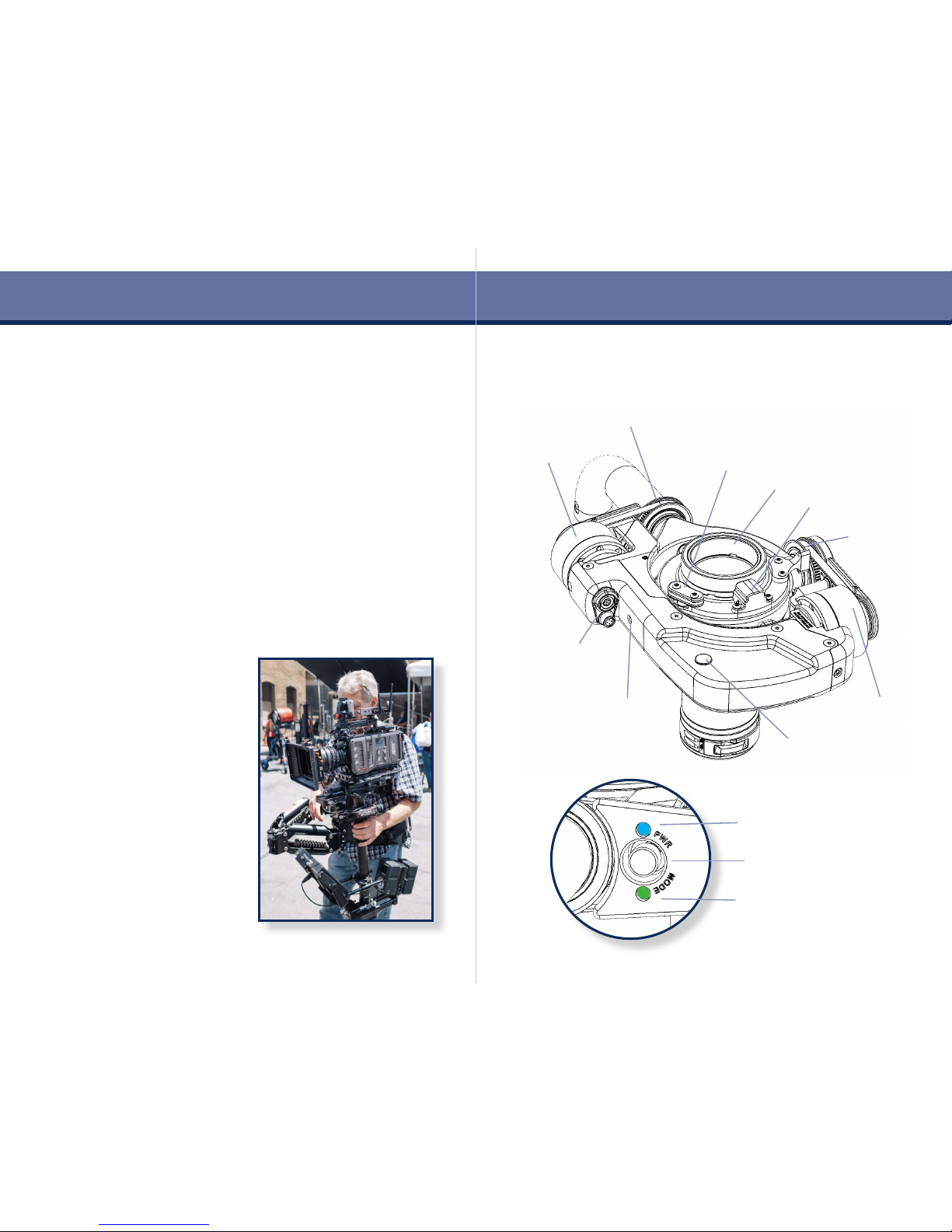

Introduction Components

Trunnion

pulley

Handle pulley

Trunnion motor

and belt

Pan encoder

Pan encoder ring

Steadicam® Volt™ shown on M-1™ gimbal

Main power/

control input &

Encoder jack

Handle motor

and belt

Power LED (blue)

Gimbal button

Mode LED (green)

Trunnion screw

access

Invert button access

The Volt also allows behaviors

that were impossible before. Like

“friction mode” which emulates a

uid head with tilt hold and a xed

horizon, bringing you new control

options for each and every shot.

In use, the Volt is completely

transparent to the operator, and it

feels exactly like regular Steadicam

operating – with perfect horizons.

The operator is always in full

and direct control of framing,

and can easily override the Volt’s

assistance.

Encoder cable guide

Page 4

3 4

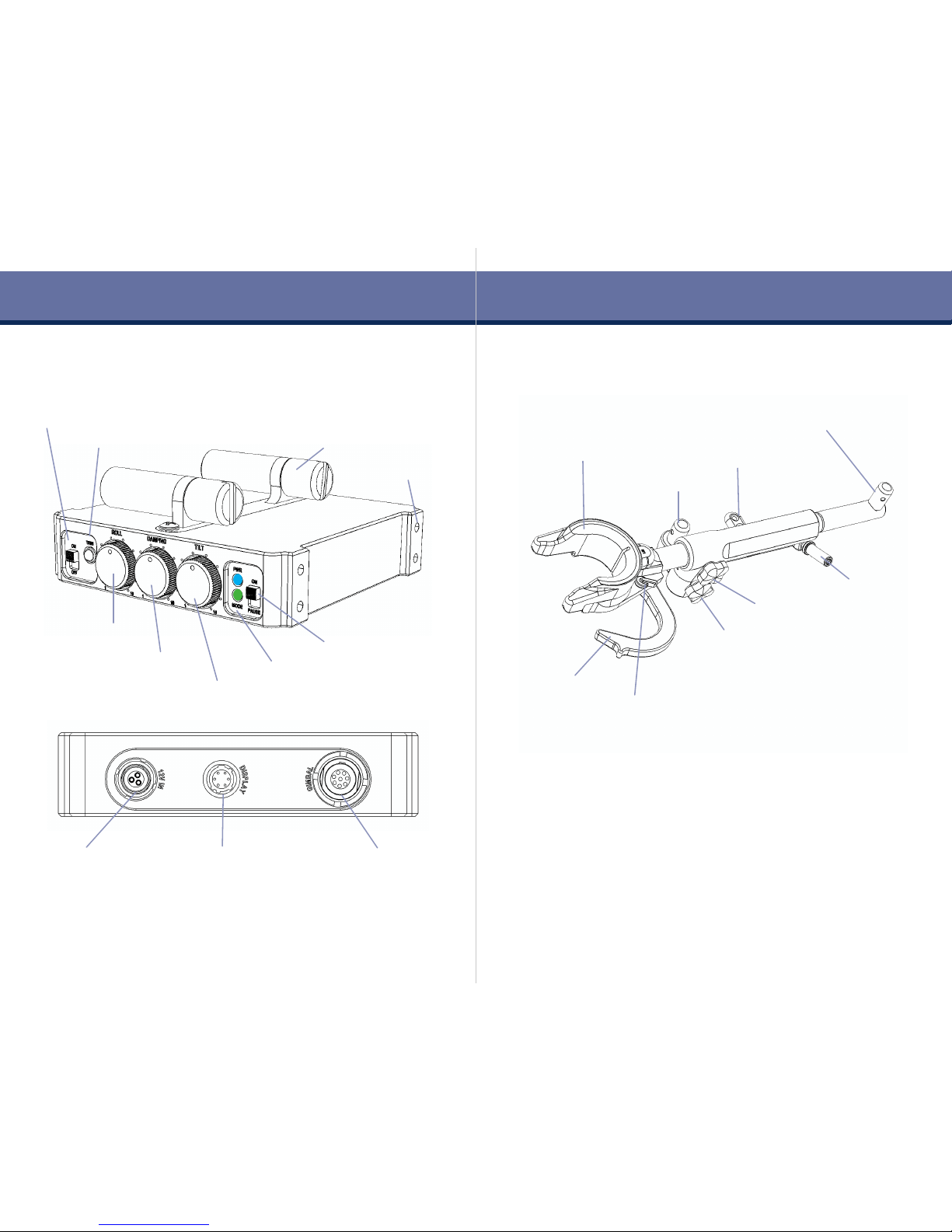

Components

Nose box rods

Power and Mode LEDs

Run/pause switch

Steadicam® Volt™ Control Box

Main power switch

Level trim button

Power input jack

from sled power

Display jack

(RESERVED)

Main power/control

output to Volt

Roll strength dial

Tilt strength dial

Damping adjuster

Steadicam® Padded Dock

The new dock

The padded dock is designed to protect the Volt electronics as well as

make docking and balancing easier. The low-prole design ensures

nothing contacts the Volt gimbal motor assembly when docked, and

the “over-center” arm swings into place to secure the sled. Docking

on the gimbal also reduces shock loads on your gimbal bearings. You’ll

note a low, primary balance stud on the side, which is barely higher

than your gimbal handle, making it a simple task to lift for balancing

regardless of the sled build.

MDR-3 mount

Dynamic balance stud

Tool holder

Arm holder

Padded dock insert

specic for your gimbal

Static balance stud

Over-center hook

Hook lock lever

Dock tilt lock knob

Stand lock knob

Note: The Lemo connectors rotate up to 90˚ in the control box chassis

to allow you more options when running cables.

Page 5

5 6

Included with Steadicam® Volt™ for M-1

• Volt Gimbal Motor Assembly (hockey stick) and pulleys

• Volt Control Box (mustache box)

• Pan encoder assembly and pan encoder ring for gimbal

• 12V power cable (817-0131)

• Gimbal cable, short (817-0135)

• Padded Dock (with insert for your gimbal) and case (817-7980)

• Nose box mounting rods

• Spare adhesive tapes for pan encoder ring

• This operation manual (LIT-817001) on USB drive

Included with Upgrade Kits for other gimbals

• Volt compatible yoke and mounting kit

• Power cable for your rig

• Blue pin wrench for your gimbal

• Mounting options you selected

• Upgrade kit details start on page 45

Tools required for installation

• Blue “whale” gimbal tool for your gimbal.

• Imperial Allen key set for install and belt adjustment.

• Flat screwdriver for nose box rods.

• Loctite® 222™ for post top screws and upgrade kits.

Components Mount options

Nose box adapter

U2, Shadow, Clipper, Archer

MDR-3 adapters

PRO or any other MDR setup

Page 6

7 8

Balance

Neutral balance

In order for the motors to exert maximum balancing assistance to

the roll and tilt axes, we balance the sled completely neutral. No drop

time at all! This also eliminates any pendulum effect when accelerating

or stopping the sled. Static and dynamic balance are now even more

critical, so panning the camera will not create diagonal forces and the

sled can easily be held at any angle without rotating.

Before you begin

The two major components of Steadicam® Volt™, the motor assembly

and the control box, contain advanced sensors and electronics.

Each may be mounted left or right, to optimize the controls for your

operating, but you must be aware of the differences these choices

present for the Volt electronics.

• The control box may be mounted for regular or goofy operators.

If your knobs are to the right of the sled (regular operator), you’ll

align the gimbal handle to the rear of the post on power up.

If your knobs are to the left of the sled (goofy operator) you’ll

align the gimbal handle to the front of the post on power up.

See page 11 about powering on.

Right knobs = REAR, Left knobs = FRONT

• Similarly, the Volt motor assembly may be mounted left or right

on the gimbal. If you’re doing this yourself, be aware that left

side is default mode and right side mounting requires pressing

the internal “ip” button once to reorient the Volt. See page 39

to learn about the ip button. If the system was installed at your

dealer, the ip procedure will have been performed already.

• We strongly encourage professional installation of the Volt

components onto your system by an authorized dealer.

• Installation instructions for Volt compatible gimbals, and upgrade

kits for other gimbals, are provided later in this manual.

• For more information visit tiffen.com/steadicam/voltsystem/

Let’s get started!

Page 7

9 10

Then, change the balance to

be completely neutral top-to

bottom. It should hold any post

angle and not rotate.

TIP: For a refresher on

dynamic balancing, see

Section One of The Steadicam

Operator’s Handbook.

Balance the sled with a normal

to long drop time. BOTH static

and dynamic balance are

important here. You know how

to dynamic balance, right?

NOTE: You may wish to

temporarily unplug the gimbal

cable while dynamic balancing

to allow multiple rotations.

Make sure the sled does not

pan when holding a tilt. If so, a

tiny adjustment to your side-

side balance should correct this.

Otherwise, go back and re-

check your dynamic balance.

TIP: When you change

anything ABOVE the gimbal and

re-balance at the top stage,

dynamic balance is maintained!

When changing accessories

above the gimbal, like lenses

or lters, re-balance on the pin

with a normal drop time and

then go fully neutral again.

Balance

Page 8

11 12

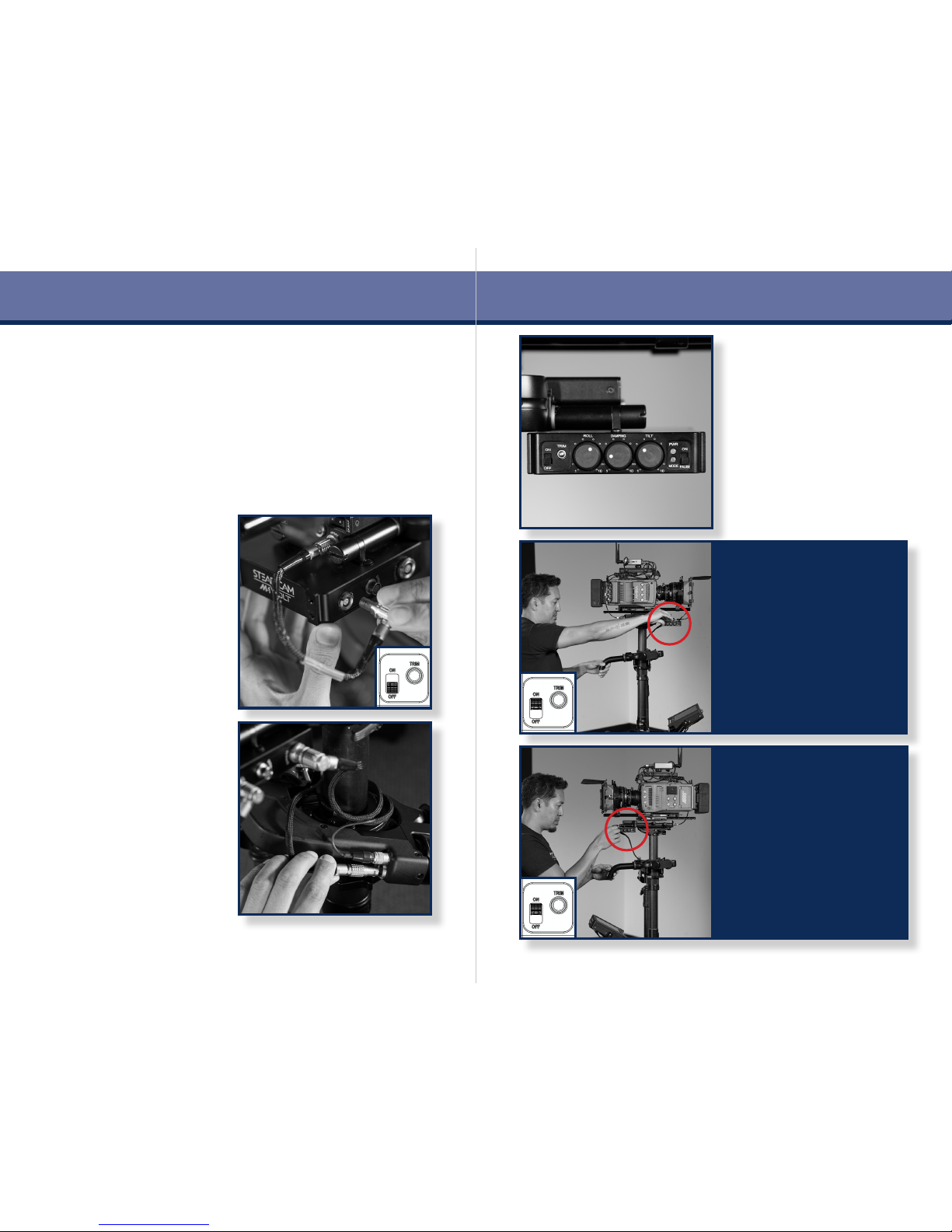

Powering up

Adding the Steadicam® Volt™ to your system requires an extra step

when powering up, and when picking up your sled. First, you’ll align

the pan encoder while powering on, and later you’ll run the system

when you want the Volt motors active. It’ll become second nature, but

pay close attention while you’re getting started for best results.

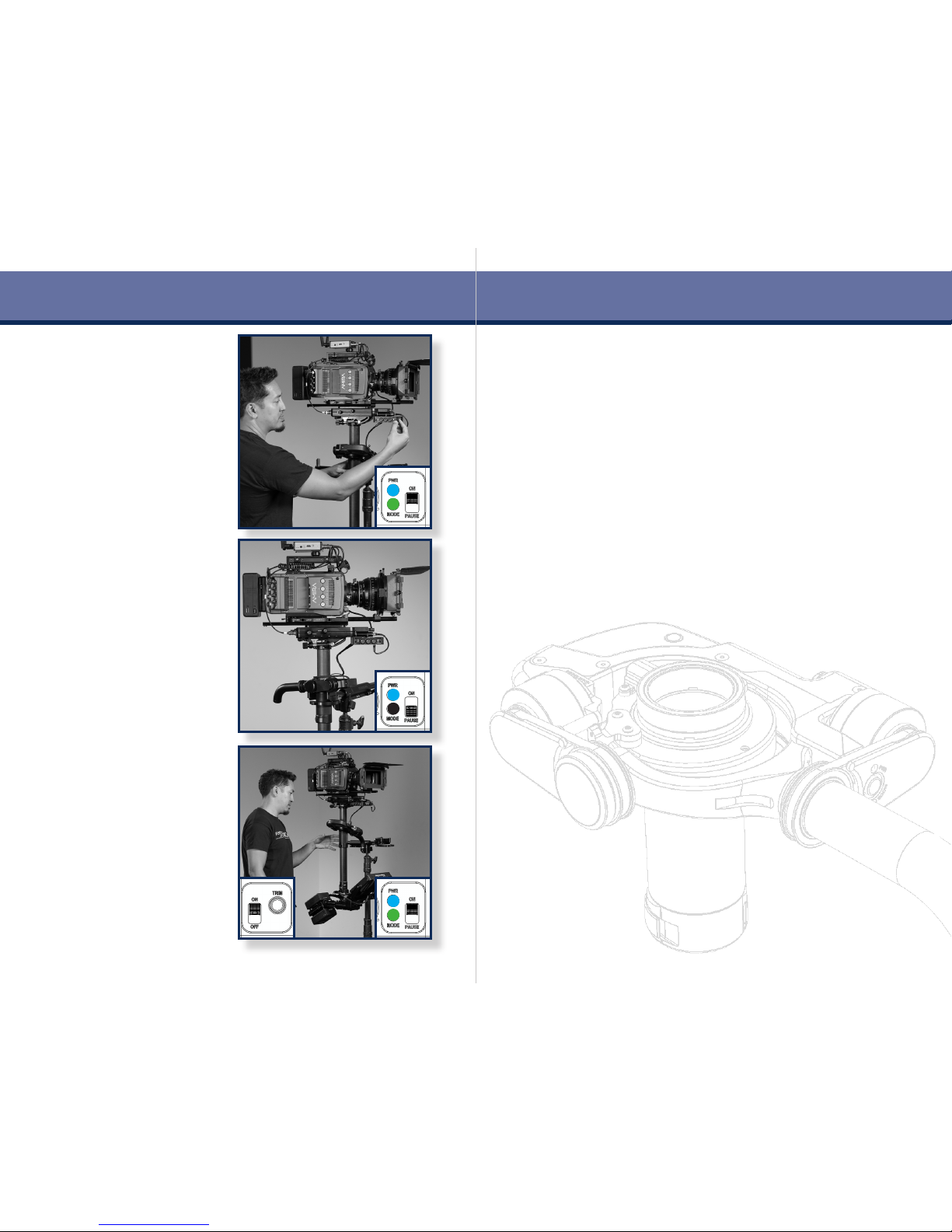

IF the control box is mounted

for regular operators (knobs

on the RIGHT) align the gimbal

handle with the REAR of the

post and simultaneously power

on the Volt. Wait 2.5sec while

the system registers the pan

encoder position.

The blue LEDs glow.

You’ll do this EVERY TIME you

power on the Volt.

Before powering on the system,

double check that the PAUSE

switch is engaged.

TIP: Consider using the Roll,

Damping and Tilt settings

shown here as a starting point.

More suggestions on page 21.

Make sure the power switch is

in the OFF position and plug in

the power cable from your sled

to the Volt control box.

NOTE: If you’re using an

aftermarket power cable,

conrm the polarity is correct.

Volt is protected against reverse

voltage, but won’t work very

well without power.

Plug in the Volt gimbal cable and

wrap a couple of loops around

the post as needed to control

any slack.

NOTE: The Volt control box will

not power up without the gimbal

cable properly connected.

IF the control box is mounted

for goofy operators (knobs

on the LEFT) align the gimbal

handle with the FRONT of the

post and simultaneously power

on the Volt. Wait 2.5sec while

the system registers the pan

encoder position.

The blue LEDs glow.

You’ll do this EVERY TIME you

power on the Volt.

Power on

Page 9

13 14

Powering on the system sets

the roll and tilt trims to default

horizon for a vertical post with

level tilt head.

In the next section, we’ll

explore trimming and modes.

Pick up the sled on your arm or

use the balance pin.

With the post vertical, ip the

pause switch to ON and the Volt

becomes active.

The green LEDs glow.

You should now feel the horizon

assistance and articial bottom-

heaviness of normal mode.

Power on

The Volt only needs to have

the post encoder aligned when

powering on.

Pausing and activating the Volt

can be toggled with the handle

in any orientation.

If you do power down,

remember to align the handle

again when powering back up.

Page 10

15 16

To trim, tilt the sled to any

angle and SHORT-press the

gimbal handle (thumb) button.

The new trim angle is set

immediately.

In normal mode, the articial

bottom-heaviness will return

the sled to THIS angle.

This can be done on the y,

during the shot - a huge

advantage to your operating.

Operating with the Steadicam® Volt™

The best thing about adding this tool to your system is that you’re still

operating a mechanical stabilizer, and using your skills and years of

experience to craft each shot. Here are some tips on how to optimize

the Volt, starting with trimming the post angle and the two operating

modes. We’ll adjust the control box dials later.

DO NOT TRIM with your top

stage balance like you used to...

Leave the sled in perfect neutral

balance at all times!

The two operating modes are

toggled with a LONG press of

the gimbal button.

In normal mode, the sled will

return to your trimmed tilt

angle, simulating a normally

balanced Steadicam sled.

Normal mode is always default

and displays SOLID green LEDs.

Operating

The second mode is called the

“Friction mode” and displays

PULSING green LEDs.

In friction mode, the sled

will remain tilted where the

operator places it and require

force to change tilt position.

It’s like having a uid head on

your Steadicam!

Using your sled’s integrated

tilt head maintains the vertical

post, ideal for panning.

First, pause the system, change

the tilt and re-balance the sled.

Then run the Volt and set a new

tilt trim by short pressing the

gimbal button.

Page 11

17 18

Operating

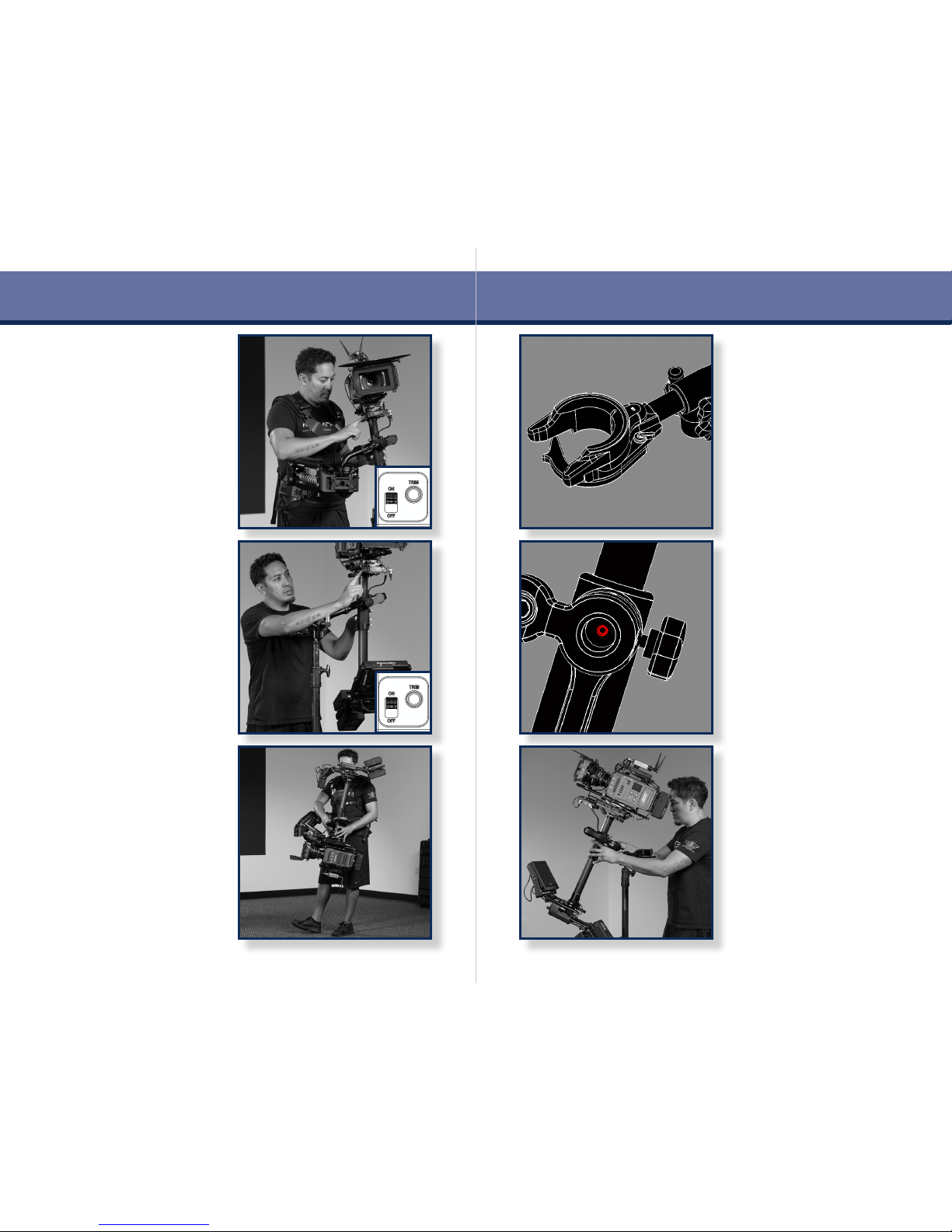

Quick low mode is now easier

than ever! When ipping,

there is no need to re-balance

because the sled is neutral.

Simply invert the sled

and rotate the monitor for

viewability.

NOTE: If you tilt the head,

make sure to set a new trim.

To reset the roll horizon to

default, LONG-press the trim

button on the control box for 6

seconds until both LEDs on the

control box turn off and pulse

back on.

Horizon is now reset.

Any previous TILT trim will be

maintained.

Should you wish to set the

ROLL trim, SHORT-press the

trim button on the control box

and position the sled to the new

level position while the LEDs

blink for 5 seconds.

When LED blinking stops,

your new horizon position (or

Dutch angle!) is now stored in

memory.

The dock offers the ability to

tilt the gimbal up to 30˚ while

remaining docked and secure.

To enable this feature, remove

the set screw from beneath the

stand mount with a 1/8” Allen

ke y.

Tilt angle is now secured with

the tilt lock knob pictured.

The included padded dock is

essential to protect the Volt’s

motors and electronics. Other

methods of docking may

damage the unit.

Always use the over-center

hook while docked.

TIP: You can remove

unnecessary docking rings and

gain precious gimbal height!

TIP: Instead of using the tilt

dock, you can also place the rig

on the balance stud and engage

the Volt motors.

Setting trim will hold the shot

with next to no operating

required!

Page 12

19 20

The pause switch is there to

keep the Volt powered on and

tracking the encoder and motor

positions.

Pausing does NOT require you

to align the gimbal handle

again, and your previous trim

setting will be maintained.

It’s great for quickly re-

balancing or standing by.

The trim button on the control

box has two functions:

• SHORT-press sets ROLL trim

to the current post angle.

• LONG-press of 6 seconds

reverts roll trim to default.

Control box settings

The three dials on the control box allow you to customize the behavior

of the Volt in two axes, roll and tilt, independently. Additionally, the

damping dial controls how the system returns the sled to vertical. Here

are some general guides to all of the control box switches and knobs.

Settings

The ROLL dial controls the

strength of the motors in the

roll axis. This equates to how

strongly the rig seeks a level

horizon side-to-side.

To help retain subtlty of control,

start with low assist levels and

add strength as needed for each

shot.

More isn’t always better!

Damping works like friction to

keep the sled from oscillating.

Set the damping in proportion

to your TILT strength, but use

as little as possible.

The operator should do most

of the damping (like normal

operating) rather than letting

the electronics do it.

The TILT dial controls the

strength of the motors in the tilt

axis. This alters the behavior:

In normal mode, more tilt

strength equates to stronger

articial bottom-heaviness.

In friction mode, more tilt

strength equates to rmer hold

at the operator’s set post angle,

like drag on a uid head.

Page 13

21 22

ROLL Dampen TILT

Recommended settings

Try these settings for the different situations listed. These recipes are

just a starting point; experiment, starting with reduced strength and

nd exactly what works best for you, for each shot.

TYPICAL MODE

Every day operating, easy tilt.

ROCK AND ROLL

Free to tilt or roll Dutch angles.

GYRO SIMULATOR

Tilt and roll set to 11.

WHIP PANS

Roll/tilt equal, vertical post.

VEHICLE MODE

High roll/tilt resistance.

FRICTION MODE

Fluid head sim, TILT is drag.

SO MANY TILTS

Normal mode, when tilting more

than 60˚ from vertical.

Additional thoughts on settings:

• Use higher motor strength in both axes for heavier rigs and rigs

with more inertia, like long mode. Less strength for lighter rigs.

• Full tilt assist is available to 22.5 degrees from vertical, HALF

assist at 45 degrees, and ZERO assist beyond 67.5 degrees,

allowing extreme tilts and a natural rest position without the

motors intervening.

• When using friction mode, increasing the TILT strength enables the

sled to “stick” to a tilt angle with more authority. It’s like the drag

setting on a uid head.

• Damping becomes LESS effective with increased motor strength

settings. Tune this to taste.

• Share settings with other Volt operators as we all explore the

future of Steadicam® operating!

• For more information visit tiffen.com/steadicam/voltsystem/

Settings

Page 14

23 24

Page 15

25 26

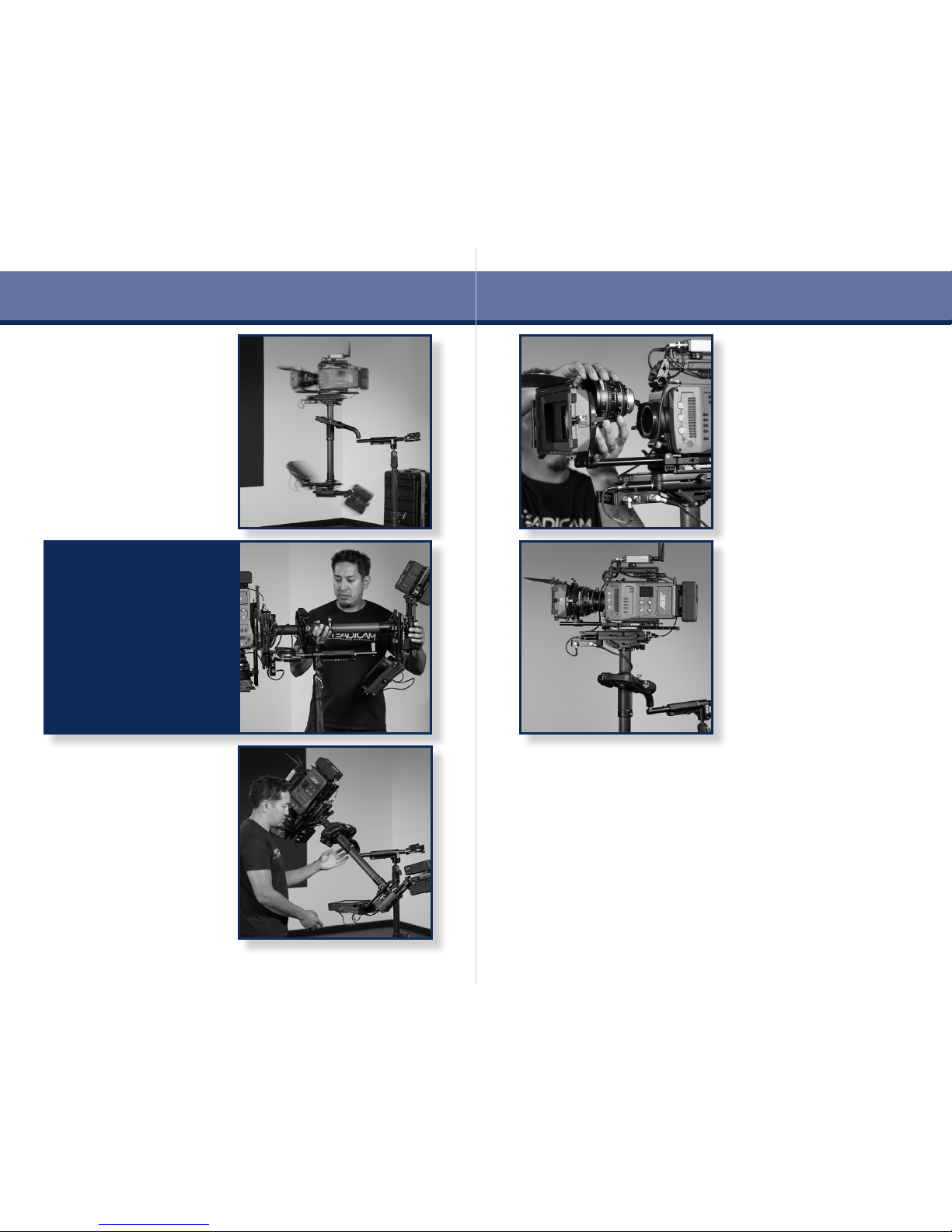

Installation

Installing Steadicam® Volt™ yourself

Professional installation is recommended, but a mechanically inclined,

professional Steadicam® Operator such as yourself should be able to

install a Volt in roughly an hour. But unlike other “horizon” gadgets,

you’ll probably never want to take it off!

The steps involved are:

• Before beginning you should decide two details:

1. Which side of the sled you’ll mount the control box knobs.

2. Which side you’ll mount the gimbal motors.

• Add the control box to the top stage.

• Upgrade and balance the gimbal if your gimbal is not Volt

compatible from the factory. Kits start on page 49.

• Prepare the gimbal for Volt.

• Install the gimbal motor assembly.

• Install power and gimbal cables.

• If mounting the gimbal motors on the RIGHT side of gimbal, press

the FLIP button one time while powered on.

• Sit down for a moment to mentally prepare yourself for more

creative, accurate and consistent shots!

NOTE: This portion of the manual takes you through a detailed

RIGHT-side install on an M-1 gimbal, with special notes for upgraded

gimbals and LEFT-side installs. The two sides are essentially mirror

images with minor differences.

Because specications are subject to change, visit tiffen.com/

steadicam/voltsystem/ for the latest.

Note about choosing sides

The Volt gimbal motor assembly, casually referred to as the hockey

stick, may be mounted to either side of your gimbal yoke. In general,

regular operators prefer to mount it to the left and goofy operators

mount it to the right. This allows maximum viewability of the monitor

and places the gimbal button conveniently near your thumb. However,

broadcast users may wish to test t their zoom controller onto the

handle to ensure access to the gimbal button. Also, keep in mind your

rest position may need to change if the Volt gimbal motor assembly

contacts your shoulder. The choice of side is up to you!

RIGHT side mount

(typically goofy)

LEFT side mount

(typically regular)

Page 16

27 28

Add the included short rod

extensions to the nose box of

your M-1 top stage and tighten

with a at head screwdriver.

Slide on the control box and

secure with the threaded rod

caps. Tighten with a at head

screwdriver.

Other Tiffen rigs can utilize the

nose box adapter.

Remove the three Allen screws

from the top of your nose box,

slide the adapter onto the rig

and fasten with the included

Allen screws.

Snug down the assembly by

tightening the two set screws

on the bottom.

Installing the Control Box

The control box can be mounted to the nose of your sled with the

knobs facing either side, to accommodate regular or goofy operators.

Mounting to an integrated rod system, like on the M-1 nose, is easy. If

you’re using rod adapters or MDR plates on other rigs, make sure the

control box is afxed rigidly to the sled.

Installation Control Box

Ensure the power switch is in

the OFF position and connect

the short power cable from sled

power to the 12V IN port.

NOTE: If you use an

aftermarket power cable,

conrm the polarity is correct.

Volt is protected against reverse

voltage, but won’t work very

well without power.

REMEMBER: If your box is

mounted with the knobs to the

RIGHT (regular), you’ll align

the gimbal handle to the REAR

when powering on later.

However, if your box is mounted

with the knobs to the LEFT

(goofy), you’ll align the gimbal

handle to the FRONT when

powering on later.

See page 11 about power up.

Now let’s get to the gimbal!

Page 17

29 30

Installing the Steadicam® Volt™

The initial steps for ALL gimbals require you to pull the gimbal from

your post, so take particular care if this is the rst time you’ve

disassembled the components of the system. The remaining steps can

be performed with the gimbal ON or OFF the post, though you may

nd installing the belts easier with it removed.

If you’re upgrading a non-Volt-compatible gimbal, exchange the yoke

and balance the gimbal using the notes as shown starting on page

45. Then return to this page to see how the rest goes together.

Take a moment with your blue

whale wrench to make sure

the gimbal top cap is tight and

everything spins smoothly.

Use alcohol to clean the top cap

when you’re done.

NOTE: The pan encoder ring

will cover the wrench holes.

Future gimbal servicing may

require removing the encoder.

Gimbal prep

Peel off the backing from the

four adhesive strips on the pan

encoder ring.

Careful, this stuff is sticky!

Carefully line up the two pins of

the pan encoder ring with either

two of the pin-wrench holes and

press it onto the gimbal.

Orientation is not important.

Make sure the ring sits ush

and is adhered all the way

around.

To install the pan

encoder ring onto the

gimbal of any rig, you

must remove the top

stage from the post

to gain access to the

gimbal.

The modular design

of the M-1 makes this

extremely easy.

Page 18

31 32

Installation

For M-1 gimbals, replace

BOTH covers with the supplied

threaded cap adapters using the

same pins on the blue whale

wrench.

Leave the trunnion screws in

place.

Next, if your gimbal is wearing

trunnion covers, remove BOTH

of them using the smallest pin

set on the blue whale wrench

supplied with your sled or

gimbal upgrade.

Slide the gimbal handle pulley

over the gimbal handle.

Line up the lock screws with the

four holes on the knurled blue

ring.

Use a 0.05” Allen key to tighten

the four lock screws enough to

secure the pulley. Do not over-

tighten.

TIP: If you’re upgrading a PRO

gimbal, it’s easier to install

the handle pulley during the

upgrade process.

For upgraded gimbals, install

one thread adapter ONLY on the

side of the gimbal where you

will mount the motor assembly.

Right side shown here. If

mounting Volt on the left,

thread the adapter to that side.

Leave the trunnion screws in

place.

M-1 gimbals use a 1/8” Allen

wrench to remove the small

button screw and Belleville

washer of the gimbal trunnion

from the PULLEY side.

We will be re-using the washer,

but set aside the screw.

Right side install shown.

Page 19

33 34

Installation

Gimbal upgrades will install the

pulley with bearing OVER the

trunnion screw.

The blue pin wrench is used to

secure the pulley.

For LEFT side motor installs on

any gimbal, remove the encoder

from the horseshoe bracket

with your 1/16” Allen key, and

re-route the cable so it exits

opposite the pulley side and

re-attach.

Install the trunnion pulley in

place of the M-1 trunnion screw,

with the washer behind it. Use

the narrow pins on your blue

whale wrench to tighten.

NOTE: The pulley should be

installed as shown, with the

relief around the lock screw

hole facing outwards.

With a 5/64” Allen wrench,

remove the place-holding set

screws from the two holes

opposite the gimbal handle.

Afx the pan encoder horseshoe

to the top of the gimbal, as

shown, using a 3/32” Allen

wrench to turn the included

1/2” long 8-32 button head

screws.

Use a 1/16” Allen key to attach

the pulley lock bracket to the

pulley side of the gimbal with

the included SHORT 4-40

screws.

Use the same wrench to lock

the pulley in place using the

LONG 4-40 screw (part 817-

7958) through the lower hole in

the lock bracket.

Right side shown.

Page 20

35 36

Installation

Using the 1/8” Allen key

inserted through the hole in

the side of the housing, tighten

the trunnion screw into the

threaded cap adapter.

Take your time to make sure

not to cross the ne threads.

Fully seat the fastener, but do

not over-tighten.

Before mounting the Volt

motors, check that the internal

wiring is properly routed and

the captive trunnion screw is

aligned with the housing.

TIP: Use a 1/8” Allen key to

wiggle and turn the trunnion

screw a few times to ensure it’s

seated in the Volt housing.

Hold the gimbal handle up

slightly to enable proper

clearance while installing the

Volt.

Align the relief on the inside of

the Volt and t it against the

gimbal.

Snug the opposing pair of set

screws on Volt motor assembly

with a 1/16” Allen key.

There’s one above and one

below the yoke. Tighten them

each a little until they both

contact the yoke.

Do not over-tighten.

You’re almost there!

Gimbal Motor Assembly

Thread the encoder cable

through the guide and attach it

to the horseshoe with a 1/16”

Allen key and 4-40 screws.

Plug in the Hirose cable.

Page 21

37 38

Pop out the little plastic plug

from the cover.

Use a non-metallic object to

carefully press and hold the

invert button for 3 seconds. All

LEDs will pulse off to indicate

the mode change.

Power off the unit and you’re

done ipping.

Installation

Important step for RIGHT mounted Volt

Left side mounting is default to the electronics within the Volt, so if

you mount the hockey stick on the right side, you must press the

ip button on the internal PC board. It’s just a button press, but pay

attention here.

If you mounted Volt on the LEFT side of the gimbal, skip this step!

Flip Button

Make sure the pause switch

is DOWN, indicating the Volt

motors will not run.

Switch the power ON and the

blue LEDs will illuminate.

Only press it once!

Each consecutive 3-second

press will toggle LEFT/RIGHT

side operation.

Replace the plastic cover.

NOTE: If you ip your Volt

to LEFT side mounting in the

future, you’ll have to repeat the

invert button process.

Plug in the 90˚ end of the

gimbal cable to the control box,

wrap a loop or two around the

post and plug in the Volt.

The LEMO connectors rotate

90˚ in the control box to allow

for convenient cable placement.

Page 22

39 40

With the same Allen key, turn

the trunnion motor belt tension

screw counter-clockwise, to

slide that motor toward the

gimbal.

TIP: If you’re installing belts

with the gimbal ON the rig,

stand your sled on a table so

the gimbal handle is free to

move during belt install.

First, move the handle motor as

close as possible to the gimbal

handle by turning the belt

tension screw counter-clockwise

with a 7/64” Allen key.

Adding the belts

The two belts transfer power from the Volt motors to the gimbal yoke

and gimbal handle. The belts will never stretch and should not need

replacement with normal use. Installing them will take nding the right

belt angle and rotation of the pulleys, but they are self-aligning once in

place. Let’s put on our belts!

NOTE: Right side build shown here; left side is a mirror image.

Installation Motor belts

Place the other belt over the

trunnion motor pulley and over

the top of the trunnion pulley.

Use your ngers to walk the

belt over the sidewall of the

trunnion pulley.

TIP: If the belt is stubborn, try

lifting the gimbal handle while

installing the belt to help walk it

onto the pulley

Place one of the belts (they’re

identical) over the handle pulley

and over the top of the motor

pulley.

Rotate the handle and use your

ngers to walk the belt over the

sidewall of the pulley.

Be careful not to get pinched!

Slowly adjust each belt tension,

a little at a time, so the Volt is

loaded evenly.

Adjust BOTH belt tensions by

turning each tension screw

clockwise with the 7/64” Allen

ke y.

Page 23

41 42

The belts should not have any

slack, but not be so tight as to

create friction.

Slowly adjust, test and repeat.

TIP: You may wish to adjust

the tension again with Volt

powered on to check its

behavior.

The nishing touch is to spin

the trunnion weight into the

1/4-20” threads of the trunnion

pulley.

Just make sure it’s on tight,

no need to over-torque it.

Installation

Your Volt equipped sled should now be ready

for action! Flip back to page 7, and get ready to

balance before powering on.

Plug in the 90˚ end of the

gimbal cable to the control box,

wrap a loop or two around the

post and plug in the Volt.

The LEMO connectors rotate

90˚ in the control box to allow

for convenient cable placement.

TIP: Depending on your normal

builds, you may prefer the

optional “long” gimbal cable.

If you haven’t yet, reinstall the

gimbal onto the sled.

With the gimbal lock open, slide

the gimbal back onto the post

and re-assemble the top stage.

Motor belts

Page 24

43 44

Page 25

2

1

1

1

2

.222ETITCOLYLPPA

222ETITCOLYLPPADNALABMIGECNALABER

.GNICNALABFOEMITTA

0121C410B-ICSX3

0321F8004-ICSX5

3217-503

1217-503

2217-503

1117-518X2

8

5

1

7

-

5

0

3

7317-5

13

878431-GRO

8317-513

0321B210B-ICS

108-RHW

3117-503

0121N4004-ICS

0121C2004-ICS

4217-503

108-RHW

0321B210B-ICS

6217-503

4117-503

)FER(071310-GRB

7217-503

)FER(071310-GRB

5367-008

812401-CSM

)FER(1017-503

)FER(9017-408X2

)FER(024501-GRB

)FER(724501-GRB

1

2

R

E

H

C

R

A

,

E

D

A

R

G

P

U

L

A

B

MI

G

ELBITAPMOCTLOV

9291-548-818:xaF0064-348-818:enohP

EMAN

ETAD

:STNEMMOC

REENIGNE

DEKCEHC

NWARD

SNOISIVER

L

A

I

T

N

E

D

I

F

N

O

C

D

N

A

Y

R

A

T

E

I

R

P

O

R

P

81/11/5

81-11-70

81/11/5

FRO.R

FRO.R

WM

D

C

B

8 7 65

4

3

2

1

E

F

A

VER

.ON.GWD

EZIS

:ELTIT

®

SIHTNIDENIATNOCNOITAMROFNIEHT

.ONMETIREBMUNTRAPNOITPIRCSED.YTQ

13117-503POTSLABMIG,REHSAW1

24117-503LOOTLABMIG,YSSA1

31217-503,EBUTECARRENNI1

42217-5032REHCRA,LABMIG,GNIRRETUO1

53217-503LABMIG,EGNALF1

64217-503,LABMIG,EGNALF1

76217-503LABMIG,TFAHSTOVIP1

87217-503LABMIG,REHSAW1

98517-503TLOV,EKOY1

017317-513

ESAELER

KCIUQ,ELDNAH1

118317-513LABMIG,ELDNAH1

215367-008KT"065.,LLAW"550.,EKARB1

311117-518LA

BMIG,EKOY,PAC2

41

571821

-TNIGL461.X23-8TRESNILACILEH3

51812401-CSM6#,TIBRENNAPSLLIRD1

61878431-GRO4/3X8/5X61/1,GNIR-O1

710121C2004-ICS

XEH

C_TES,61/1X04-4,WCS1

810121N4004-ICSXEHC_TES8/1X04-41

910321F8004-ICSXEHº28F4/1X04-4,WCS5

020321B210B-ICS

KLBSS8-81XEHTUB8/3x23-8,WCS

NOLFET

2

120121C410B-ICSSSPUCTES61/7X23-8,WCS3

22108-RHWSS,REHSAW8#2

DNASEHCNINIERASNOISNEMID

HSINIFSSECORPRETFAYLPPA

:SECNARELOT

LANOITCARF46/1

HCAM:RALUGNA 1 DNEB 1

X."1.

XX."10.

XXX."500.

XXXX."5000.

.R.I.T300.:YTICIRTNECNOC

010.-500.:SEGDEPRAHSKAERB

R500.-R300.:STELLIFDENIHCAM

SMR36HSINIFENIHCAM

40519AC,knabruB,.evAanoniW5182

ELGNADRIHT

NOITCEJORP

:DEIFICEPSESIWREHTOSSELNU

YB.VEROCENOITPIRCSEDETADDEVORPPA

WMA 830081ESAELERNOITCUDORP81/11/50

P

CB 560081SETONNOITCURTSNIDDA 8102/12/6

45 46

Archer/Archer2

Gimbal upgrade

It’s recommended you have an experienced Steadicam technician do

the service for you, but upgrading an Archer or Archer2 gimbal is a

fairly straightforward procedure. Here are the assembly notes used

by the factory for reference.

Visit tiffen.com/steadicam/voltsystem/ for more information.

ASSEMBLY PROCEDURE

1. REMOVE GIMBAL FROM SLED AND DIS-ASSEMBLE ALL PARTS FROM

TOP BEARING PORTION OF GIMBAL. BE CAREFUL TO NOT DAMAGE

ANY PARTS AS SOME WILL BE RE-USED UPON RE-ASSEMBLY.

2. PERFORM BEARING CLEANING OR RE-LUBRICATION IF REQUIRED.

3. PRESS BRG-105420 INTO 305-7122 OUTER RING, CAREFULLY AND

EVENLY ONLY ON THE OUTER RACE OF THE BEARING UNTIL IT IS

FULLY SEATED.

4. PRESS BOTH BRG-105427 BEARINGS INTO 305-7122 OUTER RING

CAREFULLY AND EVENLY ONLY ON THE OUTER RACE OF THE BEARING

UNTIL THEY ARE FULLY SEATED.

5. INSTALL 305-7124 ONTO 305-7101, AND ALIGN SCREW CLEARANCE SLOT WITH SCREW HOLES IN 305-7101.

6. INSTALL AND TIGHTEN SCI-4004N1210 INTO 305-7124 AND THEN

INSTALL AND TIGHTEN SCI-4002C1210 INTO SAME HOLE AND TIGHT-

EN.

7. THREAD 305-7121 INTO 305-7101 AND FULLY TIGHTEN WITH 305-

7114 WRENCH.

8. INSTALL 800-7635 INTO 305-7121.

9. INSTALL 305-7123 ONTO 305-7122 USING 3X SCI-4008F1230

SCREWS AND LOCTITE 222. NOTE ORIENTATION OF RING WITH RESPECT TO 305-7122.

10. IF GIMBAL IS NOT BEING OUTFITTED WITH A VOLT SYSTEM AT

THIS TIME, INSTALL 3X SCI-B014C1210 INTO THE THREADED HOLES

IN 305-7122. OMIT IF A VOLT SYSTEM IS TO BE INSTALLED.

11. NOTE SOME NEWER ARCHER 2 ASSEMBLIES ALREADY FITTED

WITH 315-7137 AND ASSOCIATED PARTS. IN THIS CASE, ASSEMBLY

OF 305-7158 YOKE AND ASSOCIATED PARTS ARE ONLY REQUIRED.

12. IF AN OLDER ARCHER GIMBAL IS TO BE MODIFIED, ASSEMBLE

ALL HANDLE COMPONENTS TOGETHER AS SHOWN NOTING THE USE

OF LOCTITE 222 WHERE REQUIRED.

13. INSTALL COMPLETED YOKE ASSEMBLY ONTO 305-7122 USING

2X 804-7109 ADJUSTMENT C SCREWS AND BALANCE GIMBAL AS

REQUIRED USING BALANCE PROCEDURE AND MSC-104218 SPANNER

SCREWDRIVER BIT.

14. COMPLETE ASSEMBLY BY INSTALLING 2X 815-7111 CAPS. OMIT IF

A VOLT SYSTEM IS TO BE INSTALLED.

Perform the balancing procedure found on the

next page prior to Volt installation.

Page 26

SNOISIVER

D

C

B

2

1

E

F

.ONMETIREBMUNTRA

PN

OITPIRCSE

D.

YTQ

13117-50

3P

OTSLABMIG,REHSA

W1

24117-50

3L

OOTLABMIG,YSS

A1

31217-50

3,

EBUTECARRENN

I1

42217-50

32

REHCRA,LABMIG,GNIRRETU

O1

53217-50

3L

ABMIG,EGNAL

F1

64217-50

3,

LABMIG,EGNAL

F1

76217-50

3L

ABMIG,TFAHSTOVI

P1

87217-50

3L

ABMIG,REHSA

W1

98517-50

3T

LOV,EKO

Y1

017317-513

ESAELER

KCIUQ,ELDNA

H1

118317-51

3L

ABMIG,ELDNA

H1

215367-00

8K

T"065.,LLAW"550.,EKAR

B1

311117-51

8L

ABMIG,EKOY,PA

C2

41

571821

-TN

IG

L461.X23-8TRESNILACILE

H3

51812401-CS

M6

#,TIBRENNAPSLLIR

D1

61878431-GR

O4

/3X8/5X61/1,GNIR-

O1

710121C2004-ICS

XEH

C_TES,61/1X04-4,WC

S1

810121N4004-IC

SX

EHC_TES8/1X04-

41

910321F8004-IC

SX

EHº28F4/1X04-4,WC

S5

020321B210B-ICS

KLBSS8-81XEHTUB8/3x23-8,WCS

NOLFET

2

120121C410B-IC

SS

SPUCTES61/7X23-8,WC

S3

22108-RH

WS

S,REHSAW8

#2

/12/6

47 48

Archer/Archer2

Gimbal Balancing Procedures for:

Archer 2 Series 305-7120-XX

1. Mount simulated camera weight (maximum payload capacity of sled

recommended) onto sled and place onto appropriate balance spud.

2. Fine tune fore-aft and left-right balance by adjusting fore/aft and

side/side adjustment knobs on stage. Verify balance using a bubble

level attached atop the stage on a at surface.

3. Balance sled with an approximate 3 second drop time by ne tuning

vertical position of gimbal.

4. With the front of the sled facing left, and the stage perpendicular

to the curved gimbal handle, raise the sled to the right to a horizontal

position and release until it swings back to a vertical position.

5. Unit should always return to the established vertical position. If it

does not, ne-tune the adjustment pin screws (part# 804-7109) using

included #6, 0.125” spacing spanner screwdriver and repeat the previ-

ous step.

6. To adjust pin screws remove bearing caps (815-7111) to access pin

screws

7. Gimbal ring (305-7122) to yoke (305-7158) clearance should have

zero end play but swing free, this is adjusted by turning pin screws.

8. The adjustment pin screws should have some resistance when turn-

ing.

9. If the unit is leaning to the left of vertical: turn the right adjustment

screw counter-clockwise and the left adjustment screw clockwise in

equal increments. If leaning right of vertical, reverse this procedure.

Warning: turn these screws in small increments (1/16 of turn) as

it will have a magnied affect when drop time is set at 3 seconds or

more.

10. Repeat drop test again. If unit does not repeat check to make sure

all clamps, plates, camera and whatever else might shift or become

loose is stable and not shifting the balance point.

11. Re-install bearing cap covers, if not installing Volt.

Page 27

1717-008

4717-008

0611B230D-ICS

363741-RHW

5317-518

1117-518X2

7717-008X2

573091-RHWX2

).FER(124501-GRBX2

DERIUQERSA30-/20-/10-9717-008X2

8717-008

10-8717-008

300731-NIP

30-97

17-008X2

20-9717-008X2

10-4117-503

5717-008

1

.222

ETITCOLYLPPA

2 .GNICNALABFOEMITTA222ETITCOLYLPPADNALABMIGECNALAB-ER

1

2

1

).FER(0121S0207-ICSX8

).FER(7017-008

).FER(7017-008

).FER(0121C800A-ICS

).FER(1217-008

).FER(2217-008

C

C

0121C400A-ICS

X3

0121C800A-IC

S

.ONMETIREBMUNTRAPNOITPIRCSED

60-0017-008

.YTQ

110-4117-503LOOTLABMIG,YSSA1

21717-008PMALCGNIRAEB1

34717-008PACPMALCGNIRAEB1

45717-008TLOV,EKOY1

57717-008WERCSKCOL2

68717-008PIRGELDNAH1

710-8717-008PIRGELDNAH1

810-9717-0080000.,LABMIG,NOINURT2

920-9717-008"0100.-,LABMIG,NOINURT2

0130-9717-008"0100.+,LABMIG,NOINURT2

111117-518LABMIG,EKOY,PAC2

215317-518POTSLABMIG,REHSAW1

31300731-NIP"61/3,ESAELERKCIUQ,NIP1

510121C400A-ICSXEHC_TES8/1x23-6,WCS3

610121C800A-ICSXEH

C_TES4/1x23-6,WCS1

710611B230D-ICSXEHTUB1x23-01,WCS1

81363741-RHWSS.KHT70.-40.DO44.DI91.,8#,REHSAW1

91573091-RHWELLIVELLEB"720.X"573.X"091.,REHSAW2

60-0017-008

2U/WODAHS,EDARGPULABMIG

ELBITAPMOCTLOV

C

DEIFICEPSESIWREHTOSSELNU:SETON

9291-548-818:xaF0064-348-818:enohP

EMAN

ETAD

:STNEMMOC

REENIGNE

DEKCEHC

NWARD

:EMANELIF

SNOISIVER

LAITNEDIFNOCDNAYRATEIRPORP

81/91/40

81-11-70

81/91/40

FRO.R

FRO.R

WM

D

C

B

8 7 65

4

3

2

1

E

F

A

VER

.ON.GWD

EZIS

:ELTIT

C

®

:REPGNIWARDTERPRETNI

90025.41YISNA

SIHTNIDENIATNOCNOITAMROFNIEHT

FOYTREPORPELOSEHTSIGNIWARD

YNA.YNAPMOCNEFFITEHT

ELOHWASAROTRAPNINOITCUDORPER

FONOISSIMREPNETTIRWEHTTUOHTIW

.DETIBIHORP

SIYNAPMOCNEFFITEHT

DNASEHCNINIERASNOISNEMID

HSINIFSSECORPRETFAYLPPA

:SECNARELOT

LANOITCARF46/1

HCAM:RALUGNA 1 DNEB 1

X."1.

XX."10.

XXX."500.

XXXX."5000.

.R.I.T300.:YTICIRTNECNOC

010.-500.:SEGDEPRAHSKAERB

R500.-R300.:STELLIFDENIHCAM

SMR36HSINIFENIHCAM

40519AC,knabruB,.evAanoniW5182

ELGNADRIHT

NOITCEJORP

60-0017-008

:DEIFICEPSESIWREHTOSSELNU

YB.VEROCENOITPIRCSEDETADDEVORPPA

WMA 830081ESAELERNOITCUDORP81/02/40

PCB 560081SETONN

OITCURTSNIDDA 8102/12/6

FRO.RC 0121C400A-ICS&0121C800A-ICSDDA 8102/21/7

49 50

Ultra2/Shadow/Clipper

ASSEMBLY PROCEDURE

1. REMOVE GIMBAL FROM SLED AND DIS-ASSEMBLE MAIN BEARING

HOUSING FROM GIMBAL HANDLE. BE CAREFUL TO NOT DAMAGE ANY

PARTS AS SOME WILL BE RE-USED UPON RE-ASSEMBLY.

2. PERFORM BEARING CLEANING OR RE-LUBRICATION IF REQUIRED.

3. INSTALL 800-7174 USING 8X SCI-7020S1210 SCREWS AND 222

LOCTITE. NOTE ORIENTATION OF BEARING CLAMP.

4. THREAD 800-7171 INTO 811-7107 AND FULLY TIGHTEN WITH 3057114-01 WRENCH.

5. DISASSEMBLE YOKE COMPONENTS AND THEN RE-ASSEMBLE USING NEW 800-7175 YOKE AS SHOWN NOTING THE USE OF LOCTITE

222 WHERE REQUIRED.

6. REMOVE 800-7121 SUB ASSEMBLY FROM 800-7122 BY FIRST

LOOSENING SCREW SCI-A008C1210.

7. INSTALL 800-7178 OR 800-7178-01 AS REQUIRED AND RE-ASSEMBLE 800-7121. NOTE THAT 800-7178-01 WILL BE USED FOR SLEDS

WITH A GIMBAL STAGE REMOTE AND 800-7178 FOR THOSE

SLEDS WITHOUT.

8. INSTALL COMPLETED YOKE ASSEMBLY ONTO 800-7107 USING INITIALLY 2 X 800-7179-01 PARTS ON EITHER SIDE OF YOKE.

9. BALANCE GIMBAL AS REQUIRED USING BALANCE PROCEDURE.

NOTE THAT PIN- 137003 IS USED TO INSTALL AND REMOVE 8007179-XX PARTS.

10. COMPLETE ASSEMBLY BY INSTALLING 2X 815-7111 CAPS. OMIT IF

A VOLT SYSTEM IS TO BE INSTALLED.

Gimbal upgrade

It’s recommended you have an experienced Steadicam technician do

the service for you, but upgrading an Ultra2 or Shadow gimbal is a

fairly straightforward procedure.. Here are the assembly notes used

by the factory for your reference.

Visit tiffen.com/steadicam/voltsystem/ for more information.

Perform the balancing procedure found on

page 57 prior to Volt installation.

Page 28

.ONMETIREBMUNTRA

PN

OITPIRCSED

60-0017-008

.YTQ

110-4117-503LOOTLABMIG,YSS

A1

21717-008PMALCGNIRAE

B1

34717-00

8P

ACPMALCGNIRAE

B1

45717-008TLOV,EKO

Y1

57717-008WERCSKCO

L2

68717-008PIRGELDNA

H1

710-8717-008PIRGELDNA

H1

810-9717-00

80

000.,LABMIG,NOINUR

T2

920-9717-00

8"

0100.-,LABMIG,NOINUR

T2

0130-9717-00

8"

0100.+,LABMIG,NOINUR

T2

111117-518LABMIG,EKOY,PA

C2

215317-51

8P

OTSLABMIG,REHSA

W1

31300731-NI

P"

61/3,ESAELERKCIUQ,NI

P1

510121C400A-IC

SX

EHC_TES8/1x23-6,WC

S3

610121C800A-IC

SX

EHC_TES4/1x23-6,WC

S1

710611B230D-IC

SX

EHTUB1x23-01,WC

S1

81363741-RH

WS

S.KHT70.-40.DO44.DI91.,8#,REHSA

W1

91573091-RH

WE

LLIVELLEB"720.X"573.X"091.,REHSA

W2

SNOISIVER

D

C

B

3

2

1

E

F

51 52

Ultra2/Shadow/ClipperUpgrade kit

Page 29

53 54

PRO CineLive, PRO CineHD

Gimbal upgrade

It’s recommended you have an experienced Steadicam technician

do the service for you, but upgrading a PRO gimbal is a fairly

straightforward procedure. Here are the assembly notes used by the

factory for your reference.

Visit tiffen.com/steadicam/voltsystem/ for more information.

ELXAELBMI

GECALPER

HCTAMOTDERIUQERSA

TRAPORP-IPGTSETAL

B.VERX11-MIGN/P

2

4

1.222ETITCOLYLPPA

2 .GNICNALABFOEMITTA222ETITCOLYLPPADNALABMIGECNALAB

3.XX-9717-008FOLAVOMERROFDESU300731-NIP

1

3

PIRGLABMIGORP

ELDNAHLABMIGORP

7617-718

6617-718

0121N600B-ICSX2

4617-718

1117-518X2

3211B420D-ICSX2

573091-RHWX2

124501-GRBX2

DERIUQERSA30-/20-/10-9717-008X2

5617-718

0611B040D-ICS

5317-518

30-

9717-008X2

20-9717-008X2

300731-NIP

10-0197-518

4

.YSSAFOTRAPTON,ORP-IPGMORFYLETAREPESDEREDROEBNACTRAP

O

R

P

,

E

D

A

R

G

P

U

L

A

B

MI

G

ELBITAPMOCTLOV

9291-548-818:xaF0064-348-818:enohP

EMAN

ETAD

:STNEMMOC

REENIGNE

DEKCEHC

NWARD

SNOISIVER

LAITNEDIFNOCDNAYRATEIRPORP

81/02/40

81-21-70

81/91/40

FRO.R

FRO.R

WM

D

C

B

8 7 65

4

3

2

1

E

F

A

VER

.ON.GWD

EZIS

:ELTIT

®

SIHTNIDENIATNOCNOITAMROFNIEHT

FOYTREPORPELOSEHTSIGNIWARD

DNASEHCNINIERASNOISNEMID

HSINIFSSECORPRETFAYLPPA

:SECNARELOT

LANOITCARF46/1

HCAM:RALUGNA 1 DNEB 1

X."1.

XX."10.

XXX."500.

XXXX."5000.

.R.I.T300.:YTICIRTNECNOC

010.-500.:SEGDEPRAHSKAERB

R500.-R300.:STELLIFDENIHCAM

SMR36HSINIFENIHCAM

40519AC,knabruB,.evAanoniW5182

ELGNADRIHT

NOITCEJORP

:DEIFICEPSESIWREHTOSSELNU

METI

.ON

REBMUNTRAPNOITPIRCSED.YTQ

110-9717-0080000.,LABMIG,NOINURT2

220-9717-008

"0100.-,LABMI

G,NOINURT2

330-9717-008"0100.+,LABMIG,NOINURT2

41117-518LABMIG,EKOY,PAC2

55317-518POTSLABMIG,REHSAW1

610-0197-518ORP,RENNAPS1

74617-718GNIRLABMIG1

85617-718TLOV,EKOY1

96617-718LABMIG,GNIRRETUO,PAC1

017617-718REDOCNE,YSSA1

11124501-GRB.KHTmm4xmm8,GNIRAEB2

21300731-NIP"61/3,ESAELERKCIUQ,NIP1

310121N600B-ICSXEHC_TES61/3x23-8,WCS2

413211B420D-ICS

X

E

H

T

U

B

4

/

3

x

2

3

-

0

1

,

W

C

S

2

5

10611B040D-ICS

X

E

H

T

U

B

4

/

1

-

1

x

2

3

-

0

1

,

W

C

S

1

61573091-RHWELLIVELLEB"720.X"573.X"091.,REHSAW2

YB.VEROCENOITPIRCSEDETADDEVORPPA

WMA 830081ESAELERNOITCUDORP81/02/40

PCB 560081SETONNOITCURTSNIDDA 8102/12/6

ASSEMBLY PROCEDURE

1. REMOVE PRO GIMBAL FROM SLED AND DIS-ASSEMBLE ALL PARTS

FROM TOP BEARING PORTION OF GIMBAL. BE CAREFUL TO NOT DAMAGE ANY PARTS AS SOME WILL BE RE-USED UPON RE-ASSEMBLY.

2. PRESS PRO BEARING INTO 817-7164 GIMBAL RING CAREFULLY

AND EVENLY ONLY ON THE OUTER RACE OF THE BEARING UNTIL IT

IS FULLY SEATED. IF ANY CLEANING OR RE-LUBRICATION OF A USED

BEARING IS REQUIRED, DO IT BEFORE INSTALLATION.

3. INSTALL 817-7166 BEARING CAP AND THREAD ON 817-7167 ENCODER ASSY SECURELY USING 815-7910-01 SPANNER TOOL.

4. IF GIMBAL IS NOT BE OUTFITTED WITH A VOLT SYSTEM AT THIS

TIME, INSTALL E 2X SCI-B006N1210 INTO THE THREADED HOLES IN

817-7164. OMIT IF A VOLT SYSTEM IS TO BE INSTALLED.

5. DISASSEMBLE PRO YOKE COMPONENTS AND THEN RE-ASSEMBLE

USING NEW 817-7165 YOKE AS SHOWN NOTING THE USE OF LOCTITE

222 WHERE REQUIRED. NOTE THAT THE USE OF LATEST PRO GIMBAL

AXEL (P/N GIM-11X) IS REQUIRED AND IS NOT INCLUDED WITH THE

GIMBAL UPGRADE KIT. IMAGE OF THE CORRECT AXEL IS SHOWN BE-

LOW FOR COMPARISON.

6. IF VOLT IS TO BE INSTALLED AT THIS POINT, FIRST INSTALL 3057175 PULLEY (NOT SHOWN) ONTO THE PRO GIMBAL HANDLE BEFORE

INSTALLING THE HANDLE ONTO THE YOKE.

7. INSTALL COMPLETED YOKE ASSEMBLY ONTO 817-7164 USING INITIALLY 2 X 800- D 7179-01 PARTS ON EITHER SIDE OF YOKE.

8. BALANCE GIMBAL AS REQUIRED USING BALANCE PROCEDURE.

NOTE THAT PIN-137003 IS USED TO INSTALL AND REMOVE 800-7179XX PARTS.

9. COMPLETE ASSEMBLY BY INSTALLING 2X 815-7111 CAPS. OMIT IF

A VOLT SYSTEM IS TO BE INSTALLED.

Perform the balancing procedure found on

page 57 prior to Volt installation.

Page 30

SNOISIVER

D

C

B

3

2

1

E

F

METI

.ON

REBMUNTRA

PN

OITPIRCSE

D.

YTQ

110-9717-00

80

000.,LABMIG,NOINUR

T2

220-9717-008

"0100.-,LABMI

G,NOINUR

T2

330-9717-00

8"

0100.+,LABMIG,NOINUR

T2

41117-518LABMIG,EKOY,PA

C2

55317-51

8P

OTSLABMIG,REHSA

W1

610-0197-518ORP,RENNAP

S1

74617-718GNIRLABMI

G1

85617-718TLOV,EKO

Y1

96617-71

8L

ABMIG,GNIRRETUO,PA

C1

017617-718REDOCNE,YSS

A1

11124501-GR

B.

KHTmm4xmm8,GNIRAE

B2

21300731-NI

P"

61/3,ESAELERKCIUQ,NI

P1

310121N600B-IC

SX

EHC_TES61/3x23-8,WC

S2

413211B420D-ICS

X

E

H

T

U

B

4

/

3

x

2

3

-

0

1

,

W

C

S

2

510611B040D-ICS

X

E

H

T

U

B

4

/

1

-

1

x

2

3

-

0

1

,

W

C

S

1

61573091-RH

WE

LLIVELLEB"720.X"573.X"091.,REHSA

W2

55 56

Upgrade kit PRO CineLive, PRO CineHD

Page 31

57 58

Gimbal balancing U2, Shadow, Clipper, PRO

BALANCE PROCEDURE

1. Mount simulated camera weight (maximum payload capacity of sled

recommended) onto sled and place onto appropriate balance spud.

2. Fine tune fore-aft and left-right balance by adjusting fore/aft and

side/side adjustment knobs on stage. Verify balance using a bubble

level attached atop the stage on a at surface.

3. Balance sled with an approximate 3-4 second drop time by ne tuning vertical position of gimbal.

4. With the front of the sled facing left, and the stage perpendicular

to the curved gimbal handle, raise the sled to the right to a horizontal

position and release until it swings back to a vertical position.

5. The sled should always return to the established vertical position

as noted by the bubble level. If it does not, ne-tuning of the gimbal

spacers 800-7179-XX or 815-7110-XX on either side of the yoke will

be required as noted in the next steps to shift the gimbal center with

respect to the yoke to help achieve balance.

a) If after the swing test in step 4 the sled has the right side

of the sled is slightly raised, this will indicate that the gimbal bearing

housing will need to be shifted to the left with respect to the positioning in the yoke. (See image below with respect to gimbal orientation.)

b) If after the swing test in step 4 the sled has the left side

of the sled is slightly raised, this will indicate that the gimbal bearing

housing will need to be shifted to the right with respect to the positioning in the yoke. (See image below with respect to gimbal orientation.)

c) Note that the 800-7179-xx and 815-7110-xx spacers come

in three different sizes (.000”, +.001” and -.001”) as indicated by the

grooves cut into the parts (Refer to image below). The type of spacer

used will depend on the gimbal that is being balanced.

6. Dock the sled such there is no weight applied to the gimbal.

7. Remove the 815-7111 cap from using the supplied blue gimbal tool.

8. Remove the SCI-D020B1123 (10-32 screw) using a 1/8” hex key,

along with washer WHR-190375.

9. In order to remove the BRG-105421 and spacer, insert 3/16” ball

lock plunger (PIN-137003) into the spacer and pull out the spacer and

bearing.

RIGHTLEFT

Page 32

59 60

U2, Shadow, Clipper, PRO

10. Note the type of spacer installed

11. If the gimbal housing bearing needs to be shifted to the left as

noted in step 5a, this means that the spacer on the left side of yoke

will need to be decreased (i.e. go from .000 to -.001) and the spacer

on the right will need to be increased (i.e. go from .000 to +.001).

12. Replace spacers as required, re-assemble gimbal, verify that there

is no Left – Right play in the gimbal, and repeat steps 4-11 as required

until the gimbal is balanced.

13. Note that if the gimbal cannot be balanced within approximately

1-deg of accuracy, make sure all clamps, plates, camera and whatever

else might shift or become loose is stable and not shifting the balance

point, and re-test.

You can now y with the upgraded

yoke OR install the Steadicam™ Volt®

starting on page 25.

Page 33

61 62

Troubleshooting

If you’re experiencing undesirable behaviors,

check the following:

• Is the control box receiving power? The control box will not power

on without the gimbal cable attached to the motor unit.

• Is the Volt motor unit receiving power? Power LEDs should

illuminate on both the control box and gimbal handle.

• Is the Volt paused? It’s okay, we’ve all done that.

• Did you remember to align the gimbal handle before powering on?

Control box knobs on the right, align with the rear of the post;

knobs on the left, align with the front of the post.

• Did you tilt the top stage? Remember to re-balance and

electronically set a new tilt trim to keep the post vertical.

• If you mounted the Volt on the RIGHT side of the gimbal, did you

remember to press the “ip” switch once? See page 37.

• Does the gimbal cable have enough slack or is a cable catching?

• Is the control box mounted rigidly? It shouldn’t move at all.

• Did the rig balance change? Precise, neutral balance is key to

getting the most out of the Volt system.

• Did you trim for headroom with the stage knobs? That’s not how

we do it with Volt. Instead, leave the rig neutrally balanced and

trim for headroom electronically OR by using an integrated tilt

head and a new trim setting.

• Did the control box have time to warm up? Wait 3-4 minutes after

powering up from cold before you store a new trim.

• The Volt allows such light control on the post that you may need to

re-learn how to hold lock-offs. Less is truly more.

• Did you remember to eat breakfast? Some say it’s the most

important meal of the day.

• Visit tiffen.com/steadicam/voltsystem/ for more info.

Notes

A few additional notes on the Volt™ kit:

• Units are delivered with the latest available rmware. Stickers on

the printed circuit boards indicate the rmware version.

• The current software revisions this manual reect are:

Control box, M1VC-1_2

Motor drive, M1VG-1_0

Motor drive, M1VX-1_0

• The die cut foam in the cardboard shipping box is sized for a

Pelican™ iM2200 case.

• New M-1™ sled cases are shipped with Volt™ compatible foam

cutouts. Legacy cases may be modied by users.

• Refer to the M-1™ user guide for additional electronic info and

mechanical adjustments for the gimbal and top stage.

Page 34

63 64

Electronics

12V IN

LEMO ECG.0B.303.CLL

1- PWR GND

2- 11-17Vdc

3- n/c

DISPLAY

HIROSE HR10-7R-6S73

1- VCC 5V

2- LED DATA

3- LED CLK

4- GP6

5- SIG GND

6- SIG GND

GIMBAL

LEMO ECG.1B.308.CLL

1- PWR GND

2- 11-17VDC

3- SIG GND

4- GP3

5- SIG GND

6- GP4

7- SIG GND

8- GP5

GIMBAL

LEMO ECG.1B.308.CLL

1- PWR GND

2- 11-17VDC

3- SIG GND

4- GP3

5- SIG GND

6- GP4

7- SIG GND

8- GP5

PAN ENCODER:

HIROSE HR10-7R-4S(73)

1 - PHASE A

2 - PHASE B

3 - VCC 5V

4 - GND

Page 35

The Tiffen Company

90 Oser Avenue

Hauppauge, NY 11788

Phone: (631) 273-2500 or 1(800) 645-2522

Fax: (631) 273-2557

Tiffen-Steadicam

2815 Winona Avenue

Burbank, CA 91504

Phone: (818) 843-4600 or 1(800) 593-3331

Fax: (818) 843-8321

Tiffen International Ltd.

Pinewood Studios

Pinewood Road

Iver Heath SL0 0NH

United Kingdom

Phone: +44 (0) 1753 783 960

Email:

techsupport@tiffen.com

Web:

tiffen.com/steadicam

65

Designed and manufactured in the United States of America.

Patents pending. Tiffen reserves the right to change specications, accessories,

etc. without prior notice.

There is no implied or expressed warranty regarding this material.

STEADICAM®, M-1™ and Steadicam® Volt™ are trademarks of the Tiffen

Company, LLC.

All other trademarks and product names appearing herein are the property of

their respective owners.

LIT-817001, RevA © 2018 Tiffen Company, LLC. Created by E. Barthelman

Loading...

Loading...