Installation and Maintenance

Guide

Cascade installation

of modulating oil-fired

condensing boilers

Biofell 30 BV

Biofell 50 BV

Page 2 of 20 601130040 [Revision 1502.00] [subject to changes with no previous notice] Biofell Cascade

1 Set Measurements .............................................................................................................................................................. 3

2 Power Connections ............................................................................................................................................................ 3

2.1 Basic Hydraulics ................................................................................................................................................................................ 4

2.2 Filling the System .............................................................................................................................................................................. 5

2.2.1 General Notes ........................................................................................................................................................................... 5

2.2.2 Water Features .......................................................................................................................................................................... 5

3 Combustion Waste Disposal ............................................................................................................................................. 6

3.1 Single Exhaust Pipes......................................................................................................................................................................... 6

3.2 Evacuation Manifold .......................................................................................................................................................................... 7

3.3 Drainage of Condensate.................................................................................................................................................................... 8

4 Fuel Installation .................................................................................................................................................................. 9

5 Temperature Control .......................................................................................................................................................... 9

5.1 Heat Demand ...................................................................................................................................................................................... 9

5.1.1 Heating and DHW Controlled by Biofell’s Cascade System ...................................................................................................... 9

5.1.2 Heating and DHW Controlled by an External Device (0-10 v) ................................................................................................... 9

5.2 Module Ignition Sequence ................................................................................................................................................................ 9

6 Electric Wiring .................................................................................................................................................................... 9

6.1 Wiring diagram ................................................................................................................................................................................. 10

7 Settings ............................................................................................................................................................................. 12

7.1 Configuring All Modules ................................................................................................................................................................. 12

7.2 Configuring Module 1 [master] ....................................................................................................................................................... 14

8 Temperature Display ........................................................................................................................................................ 15

9 System Parameters .......................................................................................................................................................... 15

9.1 Operation Levels .............................................................................................................................................................................. 16

9.2 LPB Parameters ............................................................................................................................................................................... 16

9.3 Configuration Parameters ............................................................................................................................................................... 16

9.4 Boiler Parameters ............................................................................................................................................................................ 16

9.5 DHW Parameters .............................................................................................................................................................................. 16

9.6 CCP/CCB Heating Parameters ........................................................................................................................................................ 16

9.7 Maintenance Parameters................................................................................................................................................................. 17

10 Alarm Codes ..................................................................................................................................................................... 17

11 Settings Tab ...................................................................................................................................................................... 18

12 Monitoring and Maintenance Plan .................................................................................................................................. 18

Thank you for choosing a Tifell boiler. Within the Tifell range of products you have chosen one Biofell model. This is a boiler capable of providing the right comfort level for your

home, together with an adequate, diesel-powered hydraulic system delivering a balanced and economical supply of domestic hot water.

This document is an integral and essential part of the product, and shall therefore be delivered with it to the user. Read the warnings and advice contained in this manual, as

they provide important information about the product’s safe installation, use and maintenance.

The installation of this boiler must be carried out by qualified personnel in accordance with current standards and following the manufacturer's instructions.

Both commissi oning and maintenance of these boilers should be performed by Ti fell’s Official Technical Assi stance Service.

Current Spanish regulations on thermal installations in buildings, Royal Decree 1027/2007 of July 20, hold the owner or user responsible for the installation and maintenance of

machinery and equipment, regardless of whether there exists a legal warranty on them by the manufacturer or seller. They also demand a mandatory annual inspection. Breach

of this requirement may hold the owner or user liable for any damage to third parties, without prejudice to any administrative penalties applicable.

Improper installation of these boilers can cause damage to people, animals and objects. The manufacturer disclaims all responsibility in this regard.

Biofell Cascade 601130040 [Revision 1502.00] [subject to changes with no previous notice] Page 3 of 20

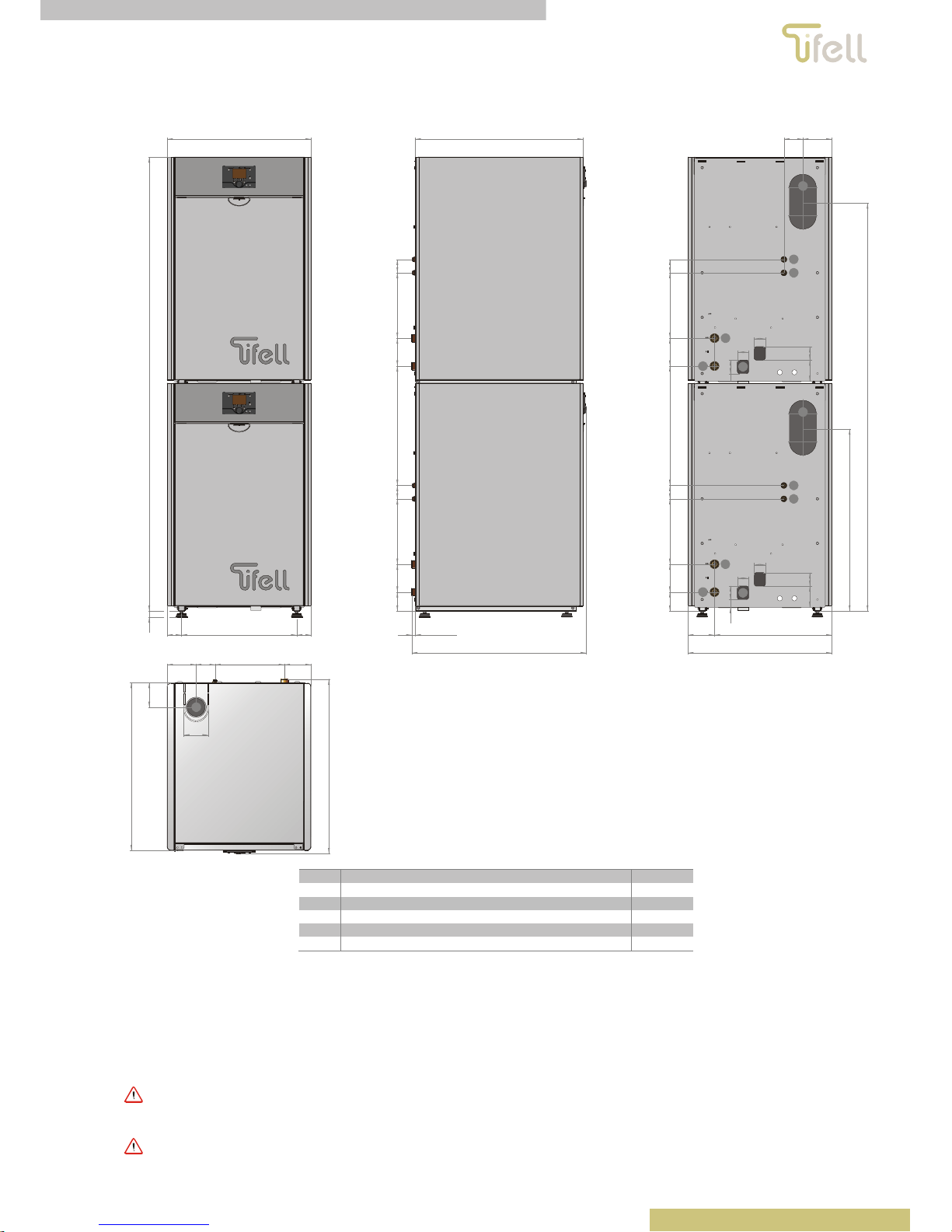

1 Set Measurements

129,50

110

780,2

84,5 310 119

749,5

110

K

2.028,5

643

28

64 515 64

535,5 60 292124,5

749,5

84,5 60 292124,5

15,70

780,2

84,5 129,5

533,5 60 292124,5

95

60

50

50

60

1.823 [Biofell 50] / 1.880 [Biofell 30]

K

84,5 60 292124,5

95

60

50

50

60

643

524119

35

813 [Biofell 50 ] / 870 [Biofell 30]

K

J

D

F

A

B

J

D

F

A

B

A

Fuel inlet 3/8”M

B Fuel return 3/8”M

D Heating return 3/4”M

F Way of heating 3/4”M

J Condensate outlet 20 mm

K Flue 80 mm

Figure 1

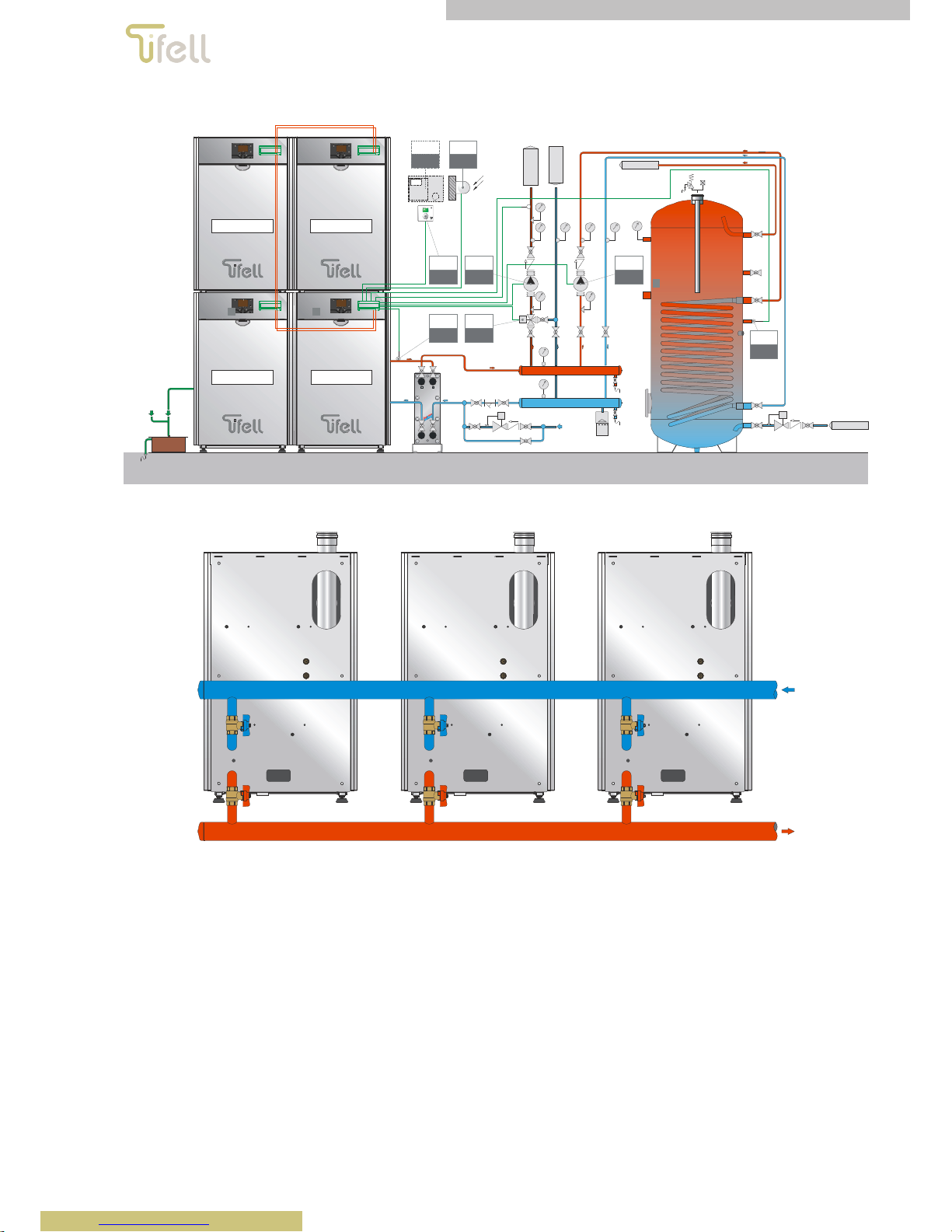

2 Power Connections

Up to 16 sets of Biofell BV [30] [50] thermal units (modules) may be installed.

If the heating circuit is old, or likely to contain or generate sludge or impurities that can clog the modules’ heating bodies, a plate heat exchanger must be

installed to separate the heating circuit from the modules.

In case of not using a plate heat exchanger, it is imperative to install a balanced needle, and a sludge filter and/or decanter, on return

modules. This obligation is doubly justified when the gage height at installation exceeds a 2-bar pressure.

Before hydraulically connecting the modules to the insta llation, a sweep of the entire hydraulic circuit should be performed.

Page 4 of 20 601130040 [Revision 1502.00] [subject to changes with no previous notice] Biofell Cascade

2.1 Basic Hydraulics

15

1616

DHW OUTPUT

GENERATOR CONDENSA TION

FLUE CONDENSATI ON

FILLING

THE

SYSTEM

MIXED CIRC UIT´ S

FLOW

MIXED

CIRCUIT´S

RETURN

COLD WATER INLET

Module 1Module 2

Module nModule 3

S

ACS

M B3

S

CAL

M B 1X

TA

CAL

M H3

0-10v

M H3

S

E

M B9

B

CAL

QX1 N

B

ACS

Q3 N

VM

CAL

Y2 Y1

Figure 2

Figure 3

Biofell Cascade 601130040 [Revision 1502.00] [subject to changes with no previous notice] Page 5 of 20

Figure 4

2.2 Filling the System

2.2.1 General Notes

To prevent lime scale damage to the DHW exchanger, the feed water hardness should not exceed 15°fH. In any case it is advisable to

check the water used, and install the appropriate device for its treatment.

To fill up the system, clean tap water must be used only. If adding antifreeze chemicals, a hydraulic breaker must be installed in the filling

system, to allow separation between the heating circuit and the water circuit.

After making the hydraulic connections, complete the installation as follows:

Check that the pump is not blocked.

Check that the automatic air vent is loose to allow gas evacuation.

Open the DHW’s main circuit input.

Unscrew the pump cap to remove any air bubbles, and close it when water comes out of it.

Open the traps on any devices connected to the circuit, and control the process of removing any air. When water comes out, close radiator straps.

Check the gauge so that installation pressure reaches a value of about 1.5 bar.

If after performing the operations indicated, a decrease in pressure is detected, open the fill again until the gauge pressure reaches 1.5 bar.

Ensure that the fill is securely closed.

2.2.2 Water Features

To ensure that the device should work properly, take into account the following basic rules:

Make sure there are no leaks, and closing any large or evident ones.

If there is an automatic filling system, a counter should be available to determine the size of any leaks.

To fill the system soft water should be used to reduce the total hardness. Furthermore, water must be treated to keep the pH value within corrosion-

preventing limits.

For new installations or boiler replacements, installations must be effectively filtered or screened to protect the boiler from impurities and air.

Ensure that no water come out of the system during maintenance operations, even though the amount seem insignificant: for example, it is

recommended that the system incorporate cutting keys allowing filter cleaning.

Before connecting the boiler, the system’s water should always be tested to check if the values shown advice emptying the system, using existing

waters or performing a chemical cleaning (if the system is particularly dirty or clogged) before filling it with treated water.

Water treatment

Page 6 of 20 601130040 [Revision 1502.00] [subject to changes with no previous notice] Biofell Cascade

To preserve the primary circuit heat exchanger and ensure optimum heat transfer, the features of the water flowing through the boiler’s primary condensate

exchanger must remain constant over time. Preparatory work such as the system’s cleaning and maintenance, checking water features, and installing

filtration systems are essential to achieve this goal.

The choice of water treatment should be made according to the water features, the system type, and the limits of purity required.

Oxygen

Inevitably a certain amount of oxygen will infiltrate the system, both in the filling phase and during operation (system refills, or using materials without

oxygen barrier). Oxygen reacts with steel, causing corrosion and sludge formation. The heat exchanger is made of stainless steel to avoid corrosion, but

sludge may accumulate on hot parts, including the exchanger. As a consequence, the boiler’s power is reduced, and the primary exchanger’s active parts

may obstruct, which in turn may damage the boiler.

To limit this consequence one can resort to:

Mechanical systems: a suitable combination of traps and water softener reduces the amount of oxygen present in the system.

Chemical systems: additives that allow oxygen to remain dissolved in water.

Hardness

Depending on the mains water hardness, its calcium content varies. Calcium sticks to hot parts, including the primary heat exchanger. This may reduce the

boiler’s capacity, and obstruct the primary exchanger’s active parts, which can seriously damage the boiler.

If the mains water does not comply with the values shown in the following table, then it must be treated to soften it. Additives can be used to keep the lime

dissolved. Water hardness should be controlled regularly, and the following values recorded:

A

cidit

y

6,6 < pH < 8,5

Conductivity 400 ÷ 600 μS/cm (a 25°C)

Chlorides < 125 mg/l

Iron < 0,5 mg/l

Coppe

r

< 0,1 mg/l

When the above values are exceeded, applying a chemical treatment is necessary.

Remember that the choice of a water treatment should be made according to the water features, the system type, and the limits of purity

required.

3 Combustion Waste Disposal

3.1 Single Exhaust Pipes

The installation of exhaust ducts for combustion products must be performed by qualified personnel, and must comply with the requirements of the national

and local laws and regulations. The Biofell boilers are pressurized, so the evacuation of combustion products is via a sealed 80 mm-diameter outlet duct,

while the air is taken in from the room where the boiler is installed.

All accessories used in the evacuation of combustion products must be supplied by Tifell.

The maximum flue length (L) that can be installed is:

Flue’s maximal length D=80

Models Maximum length

Biofell 30

15.00 m

Biofell 50

7.00 m

When setting up the flue, one must consider the equivalent lengths of the fittings listed in the following table in any case maximum length be exceeded.

Equivalent lengths of accessories

Accessory

V

ertical Horizontal

1,000 mm linear section 1.00 m 1.50 m

90º bend 1.50 m 2.50 m

45º bend 1.75 m 1.00 m

It is recommended to place the vent pipe slightly inclined (2 to 3 %) upwards, thus preventing its blowing out condensate produced in the duct. Do not turn

the flue more than four times in the whole length of the discharge.

If the flue is completely vertical, and its length grea ter than 3 m, a condensation-collecti ng siphon should be connec ted to a drain on the

duct’s base.

Biofell Cascade 601130040 [Revision 1502.00] [subject to changes with no previous notice] Page 7 of 20

1,00 m

2,50 m

L > 3,00 mminimum 300 mm

1,0

0

m

2,50 m

L < 3,00 m

Figure 5

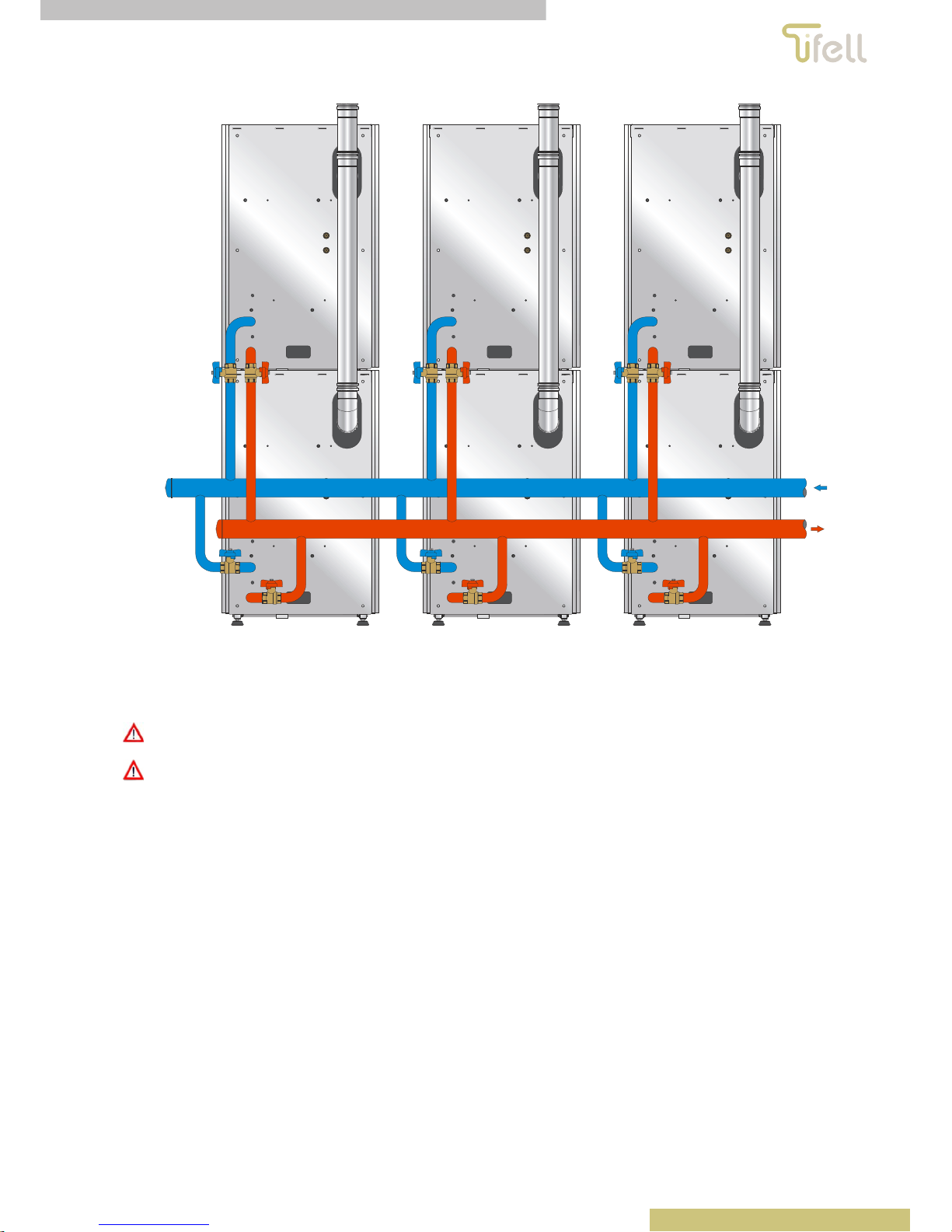

3.2 Evacuation Manifold

For cascade installations with a common exhaust manifold, it is necessary to install smoke check valves in each of the modules that make

up the whole.

All accessories used in the fume exhaust duct shall be suitable for condensing boilers, and resistant to the corrosive action of the acid condensation

generated by the combustion of liquid fuels.

In any case, flue condensate must be prevented from infiltrating the main exchanger.

Prevent the ducts that empty into the manifold from:

facing one another, to avoid smoke from one device revoking another.

Being connected to the manifold’s bottom, so that the flue condensate is collected in the main exchanger.

Figure 6 Figure 7

Page 8 of 20 601130040 [Revision 1502.00] [subject to changes with no previous notice] Biofell Cascade

182 mm 182 mm

M

i

n

i

m

u

m

s

l

o

p

e

:

3

%

Figure 8

M

i

n

i

m

u

m

s

l

o

p

e

:

3

%

M

i

n

i

m

u

m

s

l

o

p

e

:

3

%

Figure 9

3.3 Drainage of Condensate

The condensation generated by the combustion of liquid fuels can have a pH below 5, so to neutralize the acidity neutralizationgranulate must be installed in

the drain (Figure 10).

The pH of condensate outlet to the drainage network must be controlled periodically so that its value does not drop below 7.

Biofell Cascade 601130040 [Revision 1502.00] [subject to changes with no previous notice] Page 9 of 20

1 2

3

4

6

5

978

1 Drain

2 Condensate collection

3 Water

4 Neutralization granulate

5 Filter

6 Grating

7 Siphon

8 Charcoal bag

9 Condensate

Figure 10

4 Fuel Installation

Biofell boilers incorporate a modulating oil burner. For proper fuel installation, proceed according to each boiler’s instructions. Fuel installation and burner

start-up must be carried out by qualified, authorised personnel.

In order to ensure a correct fuel supply, a deaerator filter should be installed in the burner’s fuel vacuum cleaner for each of the modules.

5 Temperature Control

The accumulate temperature is controlled through a DHW sensor connected to the M B3 input; and heating or primary temperature is controlled through a

probe placed in the balanced needle or exchanger plates primary connected to the input M BX1.

5.1 Heat Demand

5.1.1 Heating and DHW Controlled by Biofell’s Cascade System

Heating demand is managed via a voltage-free contact connected to M H3. The drive temperature can be adjusted manually at fixed temperature, or it can

be made to depend on the outside temperature by means of an external probe connected to M B9. To that effect the external probe mode must be enabled

on module 1 [parameter 1326], and the heating curve should be adjusted [parameter 1320].

The DHW storage tank temperature and the heat demand are managed through DHW probe connected between M B3. The DHW temperature is set with

parameter 1610.

5.1.2 Heating and DHW Controlled by an External Device (0-10 v)

The heat demand in the Biofell cascade system can be controlled and/or effected by a 0-10 VDC voltage obtained from an external upper control.

This properly polarized signal is connected to the module 1 through connection M H3, which must be configured as a "heat request" in the 5960 parameter.

The Biofell cascade system stops operation if the signal’s voltage falls below 1 V DC signal; or varies the setpoint temperature according to a curve

defined by the parameter 5964 (temperature set to 10 V).

5.2 Module Ignition Sequence

The ignition module will rotate depending on the number of operation hours set by the parameter 3540.

6 Electric Wiring

For communication, modules should be connected in parallel and comply with the polarity of the MD BD connection on all modules.

Page 10 of 20 601130040 [Revision 1502.00] [subject to changes with no previous notice] Biofell Cascade

nnn np nnpnkh f bbb

a

M UX M BX4 M BX3 M MH3 B12 M BX2 M MBX1 B1 M MH1 M B3B9 M B2 G+ CL- CL- CL+CL- CL+ MB DB

X50

X60

X30

BSB

LPB

ZUU TS U TSRQ NLP

CL+

QX4QX4

FX4EX2

QX3NQX2NY6 Y5 Q6

NY2

QX1

NN NY1Q2N

Q3 SK1SK24S3

T2NT1NL1S3L1 N L

nnn np nnpnkh f bbb

a

M UX M BX4 M BX3 M MH3 B1 2 M BX2 M MBX1 B1 M MH1 M B3B9 M B2 G+ CL- CL- CL+ CL- CL + MB D B

X50

X60

X30

BSB

LPB

ZUU TS U TSRQ NLP

CL+

QX4QX4

FX4EX2

QX3NQX2NY6 Y5 Q6

NY2

QX1

NN NY1Q2N

Q3 SK1SK24S3

T2NT1NL1S3L1 N L

nnn np nnpnkh f

bbb

a

M UX M BX4 M BX3 M MH3 B1 2 M BX2 M MBX1 B1 M MH1 M B3B9 M B2 G+ CL- CL- CL+ CL- CL + MB D B

X50

X60

X30

BSB

LPB

ZUU TS U TSRQ NLP

CL+

QX4QX4

FX4

EX2 QX3NQX2NY6 Y5 Q6

N

Y2QX1

NN N

Y1 Q2NQ3 SK1SK24S3 T2NT1NL1 S3 L1

NL

Module 2 Module 3

Module n

nnn np nnpnkh f

bbb

a

M UX M BX4 M BX3 M MH3 B12 M BX2 M MBX1 B1 M MH1 M B3B9 M B2 G+ CL- CL- CL+CL- CL+ MB D B

X50

X60

X30

BSB

LPB

ZUU TS U TSRQ NLP

CL+

QX4QX4

FX4

EX2 QX3NQX2NY6 Y5 Q6

N

Y2QX1

NN N

Y1 Q 2NQ3 SK1SK24S3 T2NT1NL1 S3 L1

NL

Verde -Am ari llo

Azul

Marrón

Verde -Am ari llo

Marrón

Module 1

Abrir

Cerrar

S

ACS

M B3

S

CAL

M B 1X

TA

CAL

M H3

S

E

M B9

B

CAL

QX1 N

B

ACS

Q3 N

VM

CAL

Y2 Y1

Figure 11

Module 1 will be the main or master, and is where all electrical connections and system configurations are made according to the following table and Figure

11.

Cascade system comp o nent conne ct io n

Component Ref. RVS connector

Heating pump installation B

CAL

QX1 N

A

ccumulation pump B

ACS

Q3 N

DHW sensor/thermostat S

ACS

M B3

Primary flow sensor S

CAL

M BX1

Room thermostat

0-10 V heat demand

TA

CAL

0-10v

M H3 *

Mixing valve VM

CAL

Y2 Y1

* M H3connections in other modules should be open, without bridge

To complete module connection, one must purchase the necessary connectors according to the following tables:

Cascade connection kit, MASTER [BIOFE LL]

Connector Ref. No. Description Items

MB DB 601111490

3-POLE RVS a CONNECTOR

Cascade communication 1

M BX1 CKTETR20

2000 EUROFELL BATTERY PROBE

Collector probe 1

M BX1 601116520

2-POLE RVS n CONNECTOR

Collector probe connector 1

QX1 601116070

3-POLE RVS U CONNECTOR

General pump connector 1

Cascade connection kit, SLAVE [BIOF EL L]

Connector Ref. No. Description Items

MB DB 601111490

3-POLE RVS a CONNECTOR

Cascade communication 1

6.1 Wiring diagram

The module cable connection for cascade operation varies from the standard connection. Unless modules have not been specifically ordered for cascade

operation, make sure the wiring is in accordance with the following scheme.

.

Biofell Cascade 601130040 [Revision 1502.00] [subject to changes with no previous notice] Page 11 of 20

nnn np n npnkh f bbb

a

MUXMBX4MBX3 M MH3 B12 M B X2 M MBX1 B1 M MH1 M B3B9 M B2 G+ CL- CL- CL+ C L- CL+ MB DB

X50

X60

X30

BSB

LPB

Z

UU

T

SU

T

S

RQ NLP

CL+

QX4 QX4

FX4

EX2 QX3

N

QX2

N

Y6 Y5

Q6

N

Y2QX1

NN N

Y1 Q2

N

Q3

SK1SK2

4

S3

T2

N

T1

N

L1

S3

L1

NL

1

1

1

1

J4 J6 J7J5

J8

K1

C18

R22

L16

L18

L4

L5

L2

L3

L17

L15

J13 J14

11

D4

R27

D9

R28

R29

C7

D8

R26

C34

C5

C6

C35

C4C33

L20

D3

R18

R20

R19

C36

R21

R58

R13

R15

R59

R38

R40

R41

R43

D14

R42

R44

R45

D17

D18

R5

D16

R39

U15

U16

1

C9

R2

Q4

Q3

D11

R1

D13

D15

C21

U8

C19

C22

Q5Q6

C12

C11

C20

D12

R51

U1

J9

1

L12

L10

J2 J3

11

C2

C13

D5

L1

D7

R54

R24

C3

C14

R25

R17

L14

R32

D6

C1

R23

C8

L9

L11

R31

R61

R56

R60

U17

R4

1

R30

R8

C10

C16

R3

R9

D1

R33

C17

X1

U12

R47

R37

S1

R46

R64

R16

R14

R57

Q1

C30

D2

TP1

R10

R12

D23

Q8

R11

Q2

R36

U6

1

R6

Q7

R7

U7

R34

TP2

J10

C15

C32

R35

U14

J1

1

R53

L7

L8

R52

D21

L19

R48

L21

C29

R49

R50

C28

C26

R62

C23

D20

U13

C25C2 4

D22

D19

C31 C27

R55

T1

R63

U9

D24

1 12234567891011

N 31 32

F

N

CC

Q

B

CCP

P

CAL

R

S

CAL

FA

P

Q

TE

Q

F

Q

V

Q

M

Q

B

Q

UC

C

CR

C

CM

Q

CRE

Negro

Marrón

Rojo

Gris

Marrón

Azul

Marrón

Azul

Amarillo

Negro

Verde

Negro

Rojo

Gris

Negro

Verde

Verde

Azul

Marrón

Azul

Marrón

Azul

Negro

Negro

Marrón

Negro

Negro

Azul

Marrón

Rojo

Verde

Verde

Azul

Gris

Marrón

Negro

Verde

Verde

Marrón

Azul

Azul

Marrón

Rojo

Gris

Negro

Azul

Rojo

Negro

Azul

Marrón

Azul

Marrón

Verde

Rojo

Verde- Amari llo

Azul

Marrón

Verde

Negro

Marrón

Marrón

Azul

A

z

u

l

Negro

Rojo

Gris

Gris

Azul

Azul

Verde

Verde

TS

CAL

Power supply + 15

TACO (Hall sensor OUT)NCPWM input

Power supply - (GND)

Marrón

Ro

j

o

Negro

Azul

V

Q

figura 12

Element BV / S

B

CCP

Heat pump (main circuit)

BQ Fuel pump

CC

Q

LMO switchboard

CER Electrical network connection

CM

Q

Burner modulation circuit

CRC RVS regulating switchboard

F

A

Transient filter

Page 12 of 20 601130040 [Revision 1502.00] [subject to changes with no previous notice] Biofell Cascade

Element BV / S

FQ Photocell

MQ Motor

P

CAL

Heating pressure

PQ Fuel preheater

R Resistance

SA

CCP

Room sensor (main circuit)

S

CAL

Boiler probe

SE External probe (optional)

TA

CCP

Room thermostat (optional)

TEQ Power transformer

TS

CAL

Bolier’s safety thermostat

UCC

A

VS control unit

VQ Fan

7 Settings

Before setting the boilers, all slave modules must be switched to stand-by position by pressing the heating mode selection button on each of them until the

signal is under the symbol.

7.1 Configuring All Modules

The module addresses should be set by accessing parameter 6600 as follows:

Operation Display Description

Boiler temp

Default display. If not shown, press the ESC button to return to it.

Press OK.

Time of day and date

Operator section

Hold the INFO button for 5 seconds.

Enduser

Commissioning

Commissioning

OEM

Engineer

Turn the setting knob to access the “Engineer” menu.

Press OK.

Time of day and date

Operator section

Biofell Cascade 601130040 [Revision 1502.00] [subject to changes with no previous notice] Page 13 of 20

Operation Display Description

Configuration

Fault

LPB system

Turn the setting knob to access the “LPB system” menu.

Press OK.

LPB system

Device address

Press OK to enable value modification.

Turn the setting knob to modify the set value.

Press OK to confirm the new value.

Press ESC to return to the default display.

Each module’s address correspond to the number selected in this parameter:

Parameter

value

Module

Parameter

value

Module

Parameter

value

Module

Parameter

value

Module

1 Module 1 5 Module 5 9 Module 9 13 Module 13

2 Module 2 6 Module 6 10 Module 10 15 Module 14

3 Module 3 7 Module 7 11 Module 11 15 Module 15

4 Module 4

8 Module 8 12 Module 12

16 Module 16

Repeat this procedure for all modules, sketching their place in the cascade.

The segment address in the 6601 parameter should be set to 0 for all modules. To this effect:

Operation Display Description

Boiler temp

Default display. If not shown, press the ESC button to return to it.

Press OK.

Time of day and date

Operator section

Hold the INFO button for 5 seconds.

Enduser

Commissioning

Commissioning

OEM

Engineer

Turn the setting knob to access the “Engineer” menu.

Press OK.

Page 14 of 20 601130040 [Revision 1502.00] [subject to changes with no previous notice] Biofell Cascade

Operation Display Description

Time of day and date

Operator section

Configuration

Fault

LPB system

Turn the setting knob to access the “LPB system” menu.

Press OK.

LPB system

Device address

LPB system

Segment ad dress

Turn the setting knob to reach segment-address parameter 6601.

Press OK to enable value modification.

Turn the setting knob to modify the set value.

Press OK to confirm the new value.

Press ESC to return to the default display.

After these operations remove and restore power on all modules.

7.2 Configuring Module 1 [master]

In Module 1 [master] one must configure a number of parameters accessed through the "Settings" menu. To do this, proceed as follows:

Operation Display Description

Boiler temp

Default display. If not shown, press the ESC button to return to it.

Press OK.

Time of day and date

Operator section

Hold the INFO button for 5 seconds.

Enduser

Commissioning

Biofell Cascade 601130040 [Revision 1502.00] [subject to changes with no previous notice] Page 15 of 20

Operation Display Description

Commissioning

OEM

Engineer

Turn the setting knob to access the “Engineer” menu.

Press OK.

Time of day and date

Operator section

DHW storage tank

LPB system

Configuration

Turn the setting knob to access the “Configuration” menu.

Press OK.

At this point we can access the configuration parameters by turning the setting knob. The parameters to be configured in module 1 are:

Parameter 5730: DHW probe or thermostat (thermostat incompatible with the Anti-Legionella feature)

Parameter 5731: Q3 DHW actuator - Charge pump/diverter valve

Parameter 5930: BX1 probe input - B10 common drive probe

Furthermore, if the cascade system comprises Biofell SUN, it must be set as follows:

Parameter 5932: BX3 probe input - B10 common drive probe

8 Temperature Display

The flow sensor/collector temperature is displayed in the control panel of the boiler set as module 1. The temperature displayed in other modules viewports

will be specific to each module.

9 System Parameters

To configure the system, one must access the "Engineering (F)" level, and proceed as follows:

Operation Exam pl e di spl ay Description

Boiler temp

Default display. If not shown, press the ESC button to return to it.

Press OK.

Time of day and date

Operator section

Hold the INFO button for 5 seconds.

Enduser

Commissioning

Turn the setting knob to access the “Engineer” menu.

Page 16 of 20 601130040 [Revision 1502.00] [subject to changes with no previous notice] Biofell Cascade

Operation Exam pl e di spl ay Description

Press OK.

Time of day and date

Operator section

Configuration

Fault

LPB system

Turn the setting knob to access the “LPB system” menu.

Press OK.

At this point we can access the system parameters by turning the setting knob.

9.1 Operation Levels

User: E

Start-up: I

Engineering: F

OEM: Not accessible without a code

9.2 LPB Parameters

Operation line

Operation

level

Feature Value to adjust Min Max Unit

6600 F Device address 1 1 16 1

6601 F Segment address

A

lways 0 0 0 0

9.3 Configuration Parameters

Operation line

Operation

level

Feature Value to adjust Min Max Unit

5730 F DHW B3 probe Probe Thermostat Probe 5731 F DHW B3 actuator Pump Pump V3

V

-

5930 F BX1 probe input B10 common drive probe - - -

5932 (Biofell Sun only) F BX3 probe input B10 common drive probe - - -

5960 F H3 feature input 0-10V heat demand

5964 F H3 10V temperature 50/80 8 85 ºC

9.4 Boiler Parameters

Operation line

Operation

level

Feature Default value Min Max Unit

2210 F Primary’s min. temperature 8 8 Manual set ºC

2212 F Primary’s max. temperature 80 Manual set 85 ºC

9.5 DHW Parameters

Operation line

Operation

level

Feature Value to adjust Min Max Unit

1610 E-F DHW B3 probe Probe Thermostat Probe -

1640 F

A

nti-Legionella feature

Off, Periodically, Fixed day

Periodically - - -

1641 F

A

nti-Legionella feature period 7 1 7 Days

1642 F

A

nti-Legionella feature fixed-day activation Saturday Monday Sunda

y

-

1644 F

A

nti-Legionella feature activation time 03:00 00:00 23:50 hh:mm

1645 F

A

nti-Legionella feature max. temperature setting 70 55 95 ºC

1646 F

A

nti-Legionella feature max. activation interval 30 10 360 min

5020 F

Primary’s temperature increase on DHW

temperature set

12 (SUN/M models)

20 (T/BV/AS models)

0 30 ºC

9.6 CCP/CCB Heating Parameters

Operation line

Operation

level

Feature Default value Min Max Unit

Biofell Cascade 601130040 [Revision 1502.00] [subject to changes with no previous notice] Page 17 of 20

1320 E-F Heating curve slope 1.5 0.10 4.00 0.10

1321 F Heating curve shift 0.0 -4.5 +4.5 ºC

1326 F Heating curve adaptation Of

fOff

On

1330 F Winter/summer heating limit 18 ---/8 30 ºC

1340 F Min. drive limit 8 8 P 1.314 ºC

1341 F Max. drive limit 80 P 1.340 80 ºC

9.7 Maintenance Parameters

Operation line

Operation

level

Feature Default value Min Max Unit

7044 F Range of months for maintenance 12 --- 12 Months

7170 F SAT phone 0000xxxxxxxxx - - Tel.

10 Alarm Codes

Biofell boilers are equipped with an electronic circuit capable of detecting any malfunction through a continuous self-test. When the control panel detects a

malfunction, it signals it with the icon

. If this happens, press the "Info" button to find out what triggered the alarm. The following list breaks down the main

alarm codes and their meanings:

Code Description Effect

0 No error

10 Error in external probe Disables affected part

20 Error in boiler 1’s temperature probe 1 (one-way probe) / Water pressure switch failure Stops the entire system

30 Error in flow temperature probe 1 (CC1 probe) Disables affected part

50 Error in DHW temperature sensor 1 (DHW thermostat/ probe) Stops the entire system

60 Error in room temperature sensor 1 (CC1) Disables affected part

68 Error in room temperature sensor 3 (CCP) Disables affected part

81 LPB short circuit (RVS63 switchboard) Disables affected part

83 BSB cable short circuit (room temperature sensor) Disables affected part

84 BSB address collision (room temperature sensor) Ignores affected part

85 BSB radio communications failure (room temperature sensor) Disables affected part

105 Maintenance message View maintenance code table

126 DHW load monitoring Disables affected part

131 Burner failure. Error in safety thermostat Stops the entire system

146 Common configuration error message Ignores affected part

217 Common sensor error message Disables affected part

326 BX/mixing valve group, same sensors Ignores affected part

Page 18 of 20 601130040 [Revision 1502.00] [subject to changes with no previous notice] Biofell Cascade

11 Settings Tab

In order to facilitate subsequent interventions, the values set at commissioning should be recorded on the following table:

Manufacturing No. Module No. Manufactur ing No. Module No.

1

9

2

10

3

11

4

12

5

13

6

14

7

15

8

16

Configuration

Operation line

Operation

level

Feature Value to set Adjusted value

5730 F DHW B3 probe Probe

5731 F DHW B3 actuator Pump

5930 F BX1 probe input B10 common drive probe

5932 (Biofell

SUN only)

F BX3 probe input B10 common drive probe

5960 F H3 feature input 0-10V heat demand

5964 F H3 10V temperature 50/80

Boiler

Operation line

Operation

level

Feature Default value Adjusted value

2212 F Max. primary’s temperature 40/80

Domestic hot water

Operation line

Operation

level

Feature Value to set

1610 E-F DHW B3 probe Probe/Thermostat

1640 F

A

nti-Legionella feature

Off, Periodically, Fixed day

Off/Periodically/Fixed day

1641 F Anti-Legionella feature period 7

1642 F Anti-Legionella feature fixed-day activation Saturday

1644 F Anti-Legionella feature activation time 03:00

1645 F Anti-Legionella feature max. temperature setting 70

1646 F Anti-Legionella feature max. activation interval 30

5020 F

Primary’s temperature increase on DHW

temperature set

20

CCP/CCB heating

Operation line

Operation

level

Feature Default value

1320 E-F Heating curve slope 1.5

1321 F Heating curve shift -4,5ºC ÷ +4,5ºC

1326 F Heating curve adaptation Off/On

1330 F Winter/summer heating limit 8ºC ÷ 30ºC

1340 F Min. drive limit 8

1341 F Max. drive limit 80

Maintenance

Operation line

Operation

level

Feature Default value

7044 F

Range of months for maintenance

12

12 Monitoring and Maintenance Plan

Preventive maintenance requires performing the tasks listed below for their record keeping. Omission thereof may void the warranty.

Biofell Cascade 601130040 [Revision 1502.00] [subject to changes with no previous notice] Page 19 of 20

Maintenance tab

Model: Biofell [cascade]

Monthly checks

Proper DHW temperature control

Cleaning the condensate collection siphon and its connection to the vault

Checking the tightness of the burner holder cap

Combustion analysis

Smoke temperature [ºC]

Min. power

______________

Max. power

______________

CO2 [%]

______________ ______________

CO [ppm]

______________ ______________

Air excess []

______________ ______________

Performance [%]

______________ ______________

Operation of security systems

Operation of the anti-smoke check valve [cascade systems]

Measuring the condensate’s pH at the neutralizer’s outlet

Measured

value:

____________ pH

Cleaning the heating circuit return filter [if applicable] and dirt separator [if applicable]

Exercising the water pressure switch

Operation of the DHW pump [if controlled by RVS63]

Operation of the heat pump [if controlled by RVS63]

Proper heating temperature control

Correct temperature control on the primary circuit

Measurement of the temperature difference between heating flow and return

Measured

value:

____________ ºC

Inspect and adjust the fuel pump pressure at maximum power [parameter 7710 = 10] Adjusted value: ____________ bar

Inspect and adjust the fuel pump pressure at minimum power [parameter 7710 = 0] Adjusted value: ____________ bar

Check air loadin primary circuit’s expansion vessel Adjusted value: ____________ bar

Check primary circuit’s water acidity [pHmust be between 6.5 and 8.5]

Measured

value:

____________ pH

Check primary circuit’s water hardness [max: 15°fH]

Measured

value:

____________ ºF

Reading the fill meter [max: 20 l / kW]

Measured

value:

____________ l

Yearly checks

Inspect and clean the combustion chamber

Checking the correct state of the air suction and smoke evacuation ducts

Cleaning the outer fuel filter

Cleaning the infrared cell glass

Cleaning the infrared cell

Inspect fuel injector, and replace if necessary

Inspect and clean ignition electrodes

Adjust the distance between ignition electrodes

Cleaning the fuel pump filter

Checking for leaks in the boiler’s hydraulic circuit

601130040 [Revision 1502.00] [subject to changes with no previous notice] Biofell Cascade

Tifell electro solar s.a.

Vitoriabidea, 10

E-01010 VITORIA

Tfno.: (+34) 945 249 300

Fax: (+34) 945 246 181

www.tifell.com

Loading...

Loading...