Page 1

REFRIGERANT RECOVERY UNIT

USER’S OPERATING MANUAL

RG5410A

ADVANCED TEST PRODUCTS. INC • Miramar, FL

Telephone: (954) 499-5400 • Fax: (954) 499-5454 • Toll Free: (800) 327-5060

www.PromaxRecovery.com

Page 2

NOTES:

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INFORMATION 4

OPERATING GUIDELINES 5-6

CARE AND MAINTENANCE OF YOUR RG5410A 6

ADDITIONAL RECOVERY TANK INFORMATION 7

PURGING NON-CONDENSABLE GASES 8

HELPFUL HINTS FOR REFRIGERANT RECOVERY 9-10

OPERATING YOUR RG5410A 11

DIAGRAM FOR REFRIGERANT RECOVERY 11

SELF PURGING YOUR RG5410A 12

SELF PURGE/AUTO EVACUATE 12

DIAGRAM FOR “PUSH/PULL” METHOD 13

SET-UP DIAGRAM FOR TANK PRE OR SUB COOLING PROCEDURE 13

OPTIONAL RECOVERY / TANK PRE OR SUB 14

COOLING FOR FIXED HOSE SET-UP

REFRIGERANT FLOW DIAGRAM 15

RG5410A PARTS DIAGRAM/PARTS AND ACCESSORIES LIST 16

RG5410A WIRING DIAGRAM 17

INSTALLATION OF OPTIONAL80% TANK

CAPACITYSENSING COMPONENTS (KIT KT-50001)

RG5410A-KT MODEL 18

TROUBLESHOOTING YOUR RG5410A 19

FULL ONE YEAR WARRANTY 20

ENVIROMENTALPROTECTION AGENCY (EPA) INSTRUCTIONS 21

EPA REGIONAL OFFICES 22

3

Page 4

m IMPORTANT SAFETY INFORMATION m

SAFETY COMES FIRST! Read all safety, operating

guidelines and instructions before operating your

RG5410A.

1. CAUTION: ONLY A QUALIFIED TECHNICIAN

SHOULD OPERATE THIS RECOVERY UNIT.

The operator must be familiar with air conditioning

and refrigeration systems, refrigerants and the

dangers of pressurized components.

2. Always think before acting, familiarity breeds care-

lessness and carelessness can be harmful to your

health or, worse, result in death.

3. m WARNING Always wear safety goggles and

protective gloves when working with refrigerants.

Contact with refrigerant may cause injury.

Disconnect hoses with extreme caution! All hoses

may contain liquid refrigerant under pressure.

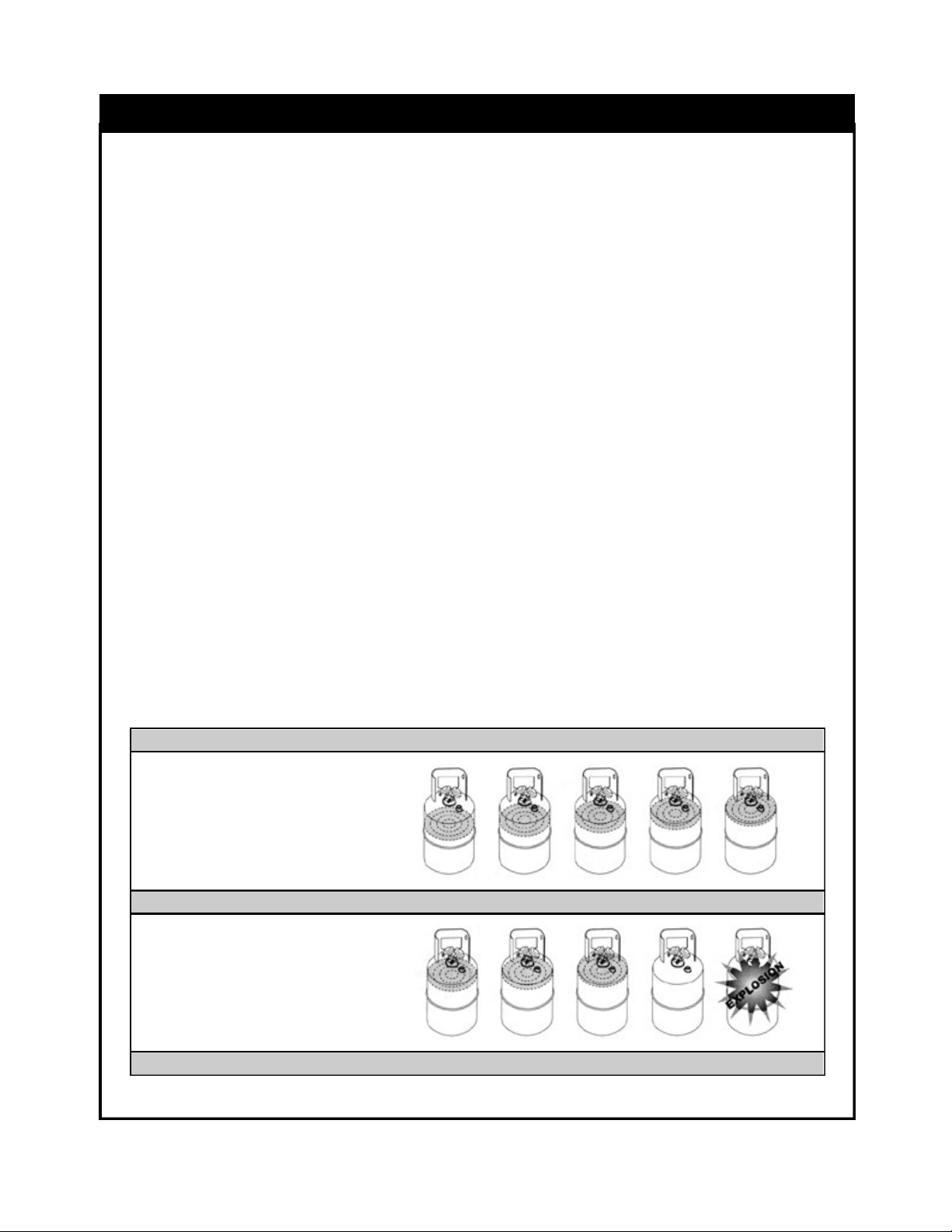

4. m PRESSURIZED TANK CONTAINS LIQUID

REFRIGERANT. NEVER OVERFILLSTORAGE

TANKS. OVERFILLING OF THE TANK MAY

CAUSE AVIOLENTEXPLOSIONANDPOSSIBLE

INJURY OR DEATH.DONOT: Exceedthe working

pressure of Recovery Tank cylinder.

5. m Warning: DO NOT: Exceed the working pres-

sure of each cylinder. Recovery cylinders are

designed for different pressures.Your RG5410A

is not supplied with a recovery tank, it requires the

use of tanks with a minimum of 350 psi working

pressure and PROMAX strongly recom-

mends the use of 400 psi tanks.

NOTE: The use of a 400 psi tank is

mandatory when recovering R-410A.

See PROMAX Recovery Tanks under Parts and

Accessories section on Page 16.

5. m A scale must be used to avoid overfilling the

storage tank. DO NOT OVERFILL. Tank is full at

80% volume. Tank may explode if filled more than

80% due to liquid expansion.

7. Read all safety information regarding the safe

handling of refrigerant and refrigerant oil, includ-

ing the Material Safety Data Sheet. MSDS

sheets can be obtained from your refrigerant

supplier.

8. If you expect temperatures in excess of 135° F,

contact the refrigerant supplier.

9. Be sure that any room where you are working is

thoroughly ventilated, especially if a leak is suspected. Refrigerant vapor is hazardous to your

health and can cause death.

10. m Avoid breathingA/Crefrigerantand lubrica-

tion vapor or mist. Exposure may irritate eyes,

nose and throat. If accidental system discharge

occurs,ventilateworkareabeforeresuming service.

11. i WARNING:TOREDUCE THE RISKOF FIRE:

• Never operate unit inanexplosiveenvironment!

Do not use this equipment in the vicinity of

spilled or open containers of gasoline or any

other flammable liquid.

• When using an extension cord it should be a

3-wire, 14 AWG minimum and no longer than

25 feet.

• Usethisequipment in locationswithmechanical

ventilation that provides at least four air

changes per hour or locate the equipment at

least 18 inches above the floor.

• Never use oxygen when testing for leaks. Any

oil in contact with oxygen under pressure will

form an explosive mixture.

12. c High voltage electricity inside panels.

Risk of electrical shock. Be sure to disconnect

theunitfrom thepowersource before servicing it.

13. To reduce the risk of injury, care should be

taken when moving this equipment.

6. Use ONLY authorized refillable refrigerant tanks.

NEVER use a standard disposable 30 lb. tank

(the typeofcontainerinwhichvirginrefrigerant

is sold) to recover refrigerant.

4

Page 5

OPERATING GUIDELINES

m Before operating the RG5410A recovery unit,

read the following m

1. RG5410A IS APPROVED FOR USE WITH THE

FOLLOWING CATEGORY III, IV and V REFRIGERANTS (Per ARI 740):

R-12, R-22, R-134A, R-401A, R-401B, R-401C,

R-402A,R-402-B,R-404A,R-406A,R-407A,R-407-B,

R-407C, R-407D, R-408A, R-409A, R-410A,R-411A,

R-411B, R-412A, R-500, R-502, R-507 and R-509

2. A FILTER must always be used and should

replaced frequently. We recommend that a clean

filter be used for every service job.

Failure to use a filter will invalidate your warranty.

The use of a filter will greatly reduce the risk of

damage to your RG5410A, by preventing

foreign material from entering the unit.

3. Each filter should be labeled and used exclusively

for one type of refrigerant only.

4. Always open service and cylinder valves slowly.

This allows rapid control of the flow of gases if

there is any danger. Once it is determined that

there is no danger, the valves can be opened

fully.

5. Always isolate large amounts of refrigerant and

close off valves after use, so if a leak should

develop anywhere in the system, the refrigerant

will not escape.

6. Keep all connections to the refrigeration system

thoroughly dry and clean. If moisture enters the

refrigeration system, it is likely to cause considerable damage.

7. Promax strongly recommends the use of the

optional 80% Capacity Shutoff Kit (p/n KT-5001).

When installed and used with a recovery tank that

has an internal float switch, the RG5410A will

shut down automatically when the tank is 80% full.

Your RG5410A is pre-wired from the factory for

this kit. Note: The RG5410A is also available in

model RG541OA-KT, with the 80% Shutoff Kit

installed direct from the factory.

8. m A CAUTION: Use only authorized refillable

refrigerant recovery tanks. Federal regulations

require refrigerant to be transported only in

containers meeting DOT spec. 4BA or 4BW.

NEVER use a standard disposable 301b. ta, .1% (the

type of container in which virgin refrigerant is sold) to

recover refrigerant.

9. m A scale must be used to avoid overfilling the

storage tank. DO NOT OVERFILL. Tank is full at

80% volume. Tank may explode if filled more than

80% due to liquid expansion. Below is a repre-

sentative sample for R-22 refrigerant:

TANK SIZE MAX NETWEIGHT

30 lb. Tank 24 lbs.

50 lb. Tank 40 lbs.

Note: Promax strongly recommends the use of the

ADS-100 Refrigerant Scale for monitoring tank

capacity.

10. Your RG5410A has two Internal Pressure

Shut Off switches, a standard 400psi and

a 550psi (when the High Pressure (R410A)

switch is engaged). The shut off switches will

automatically reset after the pressure drops

below 200 psi.

m WARNING: The Internal Pressure Shut Off

Switches do not prevent tank overfill. If your system

shuts off on high pressure and is connected to your

tank, you may have overfilled your tank and created

a very dangerous situation! Take immediate measures to relieve any high pressure and/or tank overfill.

11. When recovering large amounts of liquid, use the

"Push/Pull method (see diagram on page 13).

m CAUTION: When using the "Push/Pull" method,

once the "Push/Pull" siphon is started, it can continue and overfill the storage tank even if the tank is

equipped with a "shut off" float sensor. The siphon

can continue even after the machine is turned off.

You must manually close the valves on the tank and

the unit to prevent overfilling of the recovery tank.

12. Always operate the unit on a flat level surface.

13. To achieve the deepest final vacuum, use the

tank cooling method to lower the head pressure

on the recovery tank. (See Pages 13 & 14).

Repeat as necessary to achieve the desired

vacuum level.

5

Page 6

OPERATING GUIDELINES - cont.

NOTE: If there is no liquid in the recovery tank, then

the cooling method will not work. In this case, use an

empty tank that has been fully evacuated to achieve

the final vacuum level required.

14. If the tank pressure exceeds 300 psi, use the tank

cooling procedure to reduce the tank pressure.

(See Pages 13 & 14)

CARE AND MAINTENANCE OF YOUR RG5410A

1. USE of a filter/dryer at the inlet is mandatory. A fil-

ter/dryer must always be used between the recovery machine and the inlet hose.

2. Special care should be taken when recovering

from a "burned-out" system. Use two high acid

capacity filters, in series. (Alco type EK-162-F or

Sporlan type C-162-F are recommended )When

you have finished recovering from the system,

flush your RG5410A with a small amount of

clean refrigerant and refrigerant oil to purge off

any foreign substances left in the unit.

3. Always empty refrigerant from the RG5410A

into a storage tank; see Self-Purge/Auto Evacuate

15.To maximize recovery rates, use the shortest

possible length of 3/8" or larger hose.

A hose no longer than 3 feet is recom-

mended.

16.For maximum throughput, always remove all

unnecessary hose core depressors and the

Schrader valves from port connections.

17.Deformed rubber seals and core depressors in

hoses and faulty or unnecessary Schrader

valves can restrict flow up to 90%.

procedure on Page 12. Liquid refrigerant left in

theRG5410A’s condenser may expand,causing

damage to components.

4. c Warning! Whenever you perform any type of

maintenance work on your RG5410A, insure

that it is disconnected from the power supply

before you begin.

5. If the unit is to be stored or not used for any

length of time, we recommend that it be complenty evacuated of any residual refrigerant and

purged with dry nitrogen.

6

Page 7

ADDITIONAL RECOVERY TANK INFORMATION

m Warning: Also read the information pertain-

ing to recovery tanks, previously listed under

Safety Information and Operating Guidelines.

1. CAUTION: NEVER use a standard disposable

30 lb. (the type of container in which virgin refrigerant is sold) to recover refrigerant.

Use ONLY authorized refillable refrigerant tanks.

Federal regulations require refrigerant to be trans

ported only in containers meeting DOT specs.

4BW or 4BA.

2.m Warning: DO NOT: Exceed the working pres-

sure of each cylinder. Recovery cylinders are

designed for different pressures. Your RG5410A

is not supplied with a recovery tank, it requires the

use of tanks with a minimum of 350 psi

working pressure and PROMAX strongly recom-mends the use of 400 psi tanks.

NOTE: The use of a 400 psi tank is mandatory

when recovering R-410A.

See PROMAX Recovery Tanks under Parts and

Accessories section on Page 16.

tank, evacuate it and purge the tank using dry

nitrogen, and then re-evacuate it.

3. Always store refrigerant containers in a cool dry

place.

5. Do not mix refrigerants in a system, a tank or any

where else. Each type of refrigerant must have its

own tank, filter, etc.

6. Storage cylinders sometimes have valves that are

not properly seated when manufactured. Keeping

caps on these valves will guard against refrigerant

leakage.

7. Do not exceed 80% of tank capacity. PROMAX

strongly recommends the use of the Promax ADS100 Refrigerant Scale for monitoring tank capacity.

Safety codes recommend that closed tanks not be

filled over 80% of volume with liquid. The remaining 20% is called head pressure room.

8. If you expect temperatures in excess of 135º F

contact the refrigerant supplier.

3. Tanks and filters should be designated for one

refrigerant only. Before using a tank previously

used for another refrigerant, completely empty the

m NEVER TRANSPORT AN OVERFILLED CYLINDER m

Refrigerant expands when it gets warm and may cause a tank to explode if overfilled.

CYLINDER TEMPERATURE 60°F 70°F 100°F 130°F 150°F

STARTING WITH CYLINDER

80% BY VOLUME

SPACE OCCUPIED BY LIQUID 80% 81% 83% 90% 94%

STARTING WITH CYLINDER

90% BY VOLUME

SPACE OCCUPIED BY LIQUID 90% 92% 96% 100%

7

Page 8

PURGING NON-CONDENSABLE GASES

FROM REFRIGERANT TANK

1. Allow the tank to sit undisturbed for 24 hours. This

allows the air to rise to the top.

2. Connect a manifold to the tank and read the

amount of pressure in the tank by looking at the

output pressure gauge.

3. Determine the ambient temperature in the room.

4. Refer to a Refrigerant pressure/temperature chart.

Find the temperature on the chart and look across

to the corresponding pressure for the type of

refrigerant in the tank. Determine how that relates

to the reading on the gauge.

5. If the pressure reading is higher than the pressure

shown on the chart, very slowly (so as not to

cause turbulence inside the tank) crack open the

vapor port valve. Watch the pressure on the

gauge decrease. To prevent venting, add 4-5 psi

to the pressure shown on the chart.

when the gauge corresponds to that pressure,

close the vapor port valve.

6. Allow the tank to sit for 10 minutes and check the

pressure again.

7. Repeat the process again if necessary.

8

Page 9

HELPFUL HINTS FOR

REFRIGERANT RECOVERY

Refrigerant recovery has come a long way in a few short years. On the surface it's simply the process of taking refrigerant out of a system and putting it into a tank. However, this simple process can quickly become problematic if a few

items are overlooked. The following are some tips and pointers we've accumulated over the last few years that can save

you time and make the process go smoother.

First you need to identify the refrigerant type and quantity in the system you are servicing. If you determine it’s a

burnout, you need a special tank (a tank that's identified as containing burnout or other unidentified gases), and you

need to use extra filtration prior to recovery. (See item #2 on page 6)

If, on the other hand, you know the gas in the system is relatively clean or new, then a new tank should be used. If

you're planning on putting the refrigerant back into the same system after you have finished the service or if the refrigerant is going to be reclaimed, then use a tank that has the same refrigerant in it. A word of caution about the

Environmental Protection Agency (EPA): If you use a variety of refrigerant gasses in your service work - as evidenced by

your refrigerant purchases - and you only own one tank, you are asking for trouble. You would be well advised to own at

least one tank for every refrigerant type serviced, plus an extra for burnouts and other unknowns.

Results of Liquid Refrigerant

PLANNING AHEAD

Knowing the quantity of refrigerant is important for planning storage requirements, as well as planning for the

actual recovery. For instance, any system with more than

5lbs. of refrigerant is likely to have areas where the liquid

can get trapped.

The key to a quick recovery procedure is to get the liquid

out first, and then get the remaining vapor out. However

most systems are not "recovery friendly." That is they

don't have access ports at their lowest points. If some

units you're servicing are on maintenance contracts, you

would save significant time by installing access ports at all

of the lowest points in the system, where liquid is likely to

accumulate.

Since most systems don't have these ports you need to

be prepared to boil off the trapped liquid with a heat gun,

when ever it's found. An indicator of trapped liquid in a

system is frost or condensation forming on the plumbing

or components where the liquid is trapped. The trapped

liquid may be in an area that is not visible. In all cases

trapped liquid in a system during recovery causes the

recovery process to slow down, regardless of the size or

type of machine (see diagram).

If you are unable to locate the trapped liquid, but you

know it's there, because the recovery job is taking "forev -

er". Turn on the system compressor (if it's operable) for a

few seconds, this will get the refrigerant moving to another part of the system and in the process pick up enough

heat to boil off.

Pstart

Pe

10” Hg

HOSES AND VALVES

Hoses and Schraeder valves have a large impact on recovery speed. In general, the larger the hose, the less friction

on the flow of refrigerant, the quicker the recovery time.

Many contractors are now using 3/8' lines for the input to

the recovery machine, even those lines originating out of

1/4" fittings.

Schraeder valves must be removed from the connection

prior to an expedient recovery. Most wholesalers sell a

tool for removing these cores, while keeping the connection sealed. The core depressor, in the end of the hose,

should also be removed. These two items can turn a 20

minute job into one that goes on for hours. So, be sure to

remove the Schraeder valves and core depressors before

every recovery job.

Another hose consideration is the little rubber grommet at

the end of the hose that makes a seal with the flare fitting.

We've seen these seals so worn and deformed that when

the hose is connected to the flare fitting the grommet virtually seals off the connection.

Trapped in a System

Forever

0

Tstart Time Tfinish

9

Page 10

HELPFUL HINTS FOR

REFRIGERANT RECOVERY - cont.

This is probably never noticed in charging, because the

pressure opens the grommet, but during recovery (or with

suction) the deformed grommet severely restricts the flow

of refrigerant.

REFRIGERANT RECYCLING

Current regulations state that used refrigerant shall not be

sold, or used in a different owner's equipment, unless the

refrigerant has been laboratory analyzed and found to meet

the requirements of ARI 700 (latest edition). As a result,

recycling and verifying ARI 700 conformance isn't economically justified in most cases. It's still a great idea to do as

much cleaning of refrigerant going back into the same system (or owners system) as possible. We recommend using

the largest, high-acid capacity filter, that are economically

feasible. Put these filters on the suction or inlet side of the

recovery unit. Change filters often.

The recovery of large amounts of liquid refrigerant can

sometimes carry with it large quantities of oil, if the system

being serviced doesn't have an adequate oil separator

installed. If this recovered refrigerant isn't going to be liquid

charged back into the same system, you might want to separate the refrigerant from the oil in order to measure the oil

(to know how much oil to charge back into the system).

Refrigerant sent back for reclaim does not need to have the

oil removed. One of the simplest and most cost effective

ways to achieve this is to use a (30 or 50 lb.) tank in line

with your recovery machine. Connect the system to the liquid port of the tank, then from the vapor port of the tank

connect to the input of your recovery machine. A second

tank, for storing refrigerant, should then be connected to

the output of the recovery machine. If you encounter large

amounts of liquid you will need to put a band heater around

the first tank. When the recovery job is complete the oil can

be removed, from the first tank, by applying a small amount

of pressure, using nitrogen, to one of the ports and extracting the oil from the other. If you are going to remove the oil

from the vapor port you will need to turn the tank upside

down. Always wear safety glasses when performing this

operation as the oil may be acidic and could cause severe

burning.

KEEPING THE DIRT OUT

During the recovery process your recovery machine can be

exposed to debris that can, potentially, damage it. This

includes brazing spatter and copper/ brass slithers. Further

contamination can be introduced from the refrigerant storage tanks. To prolong the life of your recovery machine,

always use an inline filter at the inlet Port.

Whenever you are charging a system from a recovery cylinder it is a good idea to use an in-line filter to protect the system from contamination. Again, change your in-line filters

often.

GETTING THE LIQUID OUT

See diagram on page 13 of this manual

Push/pull is a method of removing bulk liquid from a sys-

tem using the pressure differential created by the recovery

machine. Push-pull will generally not work on smaller systems because there is no bulk liquid reservoir to create a

siphon from.

Push-pull is mostly used on systems with a receiver tank or

those with greater than 20 lbs. of refrigerant, or when transferring from one tank to another. The rate of liquid transfer

is very much dependent on hose size, with larger hoses providing much better throughput.

Another trick is to cool the tank, if it's partially filled, prior

to or during recovery. This operation will lower the pressure

in the storage tank and therefore speed up recovery. There

must be a minimum of 5 lbs of liquid refrigerant in the tank

you wish to chill. This operation can be performed prior to

or during the recovery. See the two set updiagramsand procedures on page 13-14 of this manual.

There is nothing magic here, you are simply using your

recovery machine to make a refrigerator where the tank is

the evaporator. By throttling the output valve, you're effectively creating a capillary tube or an expansion device, but

you need to adjust the back pressure to suit the conditions

and the refrigerant. Five to ten minutes of chilling can produce some very dramatic tank cooling, depending on the

conditions. If there are any non condensables in the tank

this process will not work. The greater the quantity of refrigerant in the tank the longer the process will take.

10

Page 11

OPERATING YOUR RG5410A

PROCEDURE FOR NORMAL SYSTEM RECOVERY

1. Inspect the RG5410A thoroughly to insure that

it is in good operating condition.

2. Make sure all connections are correct and tight

(see set-up diagram below).

3. Open the liquid port of the recovery cylinder

(always open valves slowly to check hoses and

connections for leaks).

4. Make sure the Recover/Purge valve is set on

Recover.

5. Open the output port of the RG5410A.

6. Open the liquid port on your manifold gauge set;

opening the liquid port will remove the liquid from

the system first, greatly reducing the recovery

time. (after the liquid has been removed, open

the manifold vapor port to finish evacuating the

system).

7. Connect your RG5410A to a 115V outlet.

a. Switch the main power switch to the ON position.

You should hear the fan running.

b. Press the compressor start switch. This “momen-

tary” switch will start the compressor. It may be

necessary, under certain circumstances, to press

thisswitchmore than once tostart thecompressor.

8. Slowly open the input port on the RG5410A.

a. If the compressor starts to knock, slowly

throttle back the input valve until the knock-

ing stops.

b. If the input valve was throttled back, it should

be fully opened once the liquid has been

removed from the system (the manifold gauge

set vapor port should also be opened at this

time).

9. Run until desired vacuum is achieved.

a. Close the manifold gauge sets vapor and

liquid ports.

b. Close the RG5410A-E input port.

c. Shut off and proceed with the Self Purge

procedure on the next page.

Note: Always purge the RG5410A after each

use (see Self Purge procedure on page 12).

Failure to purge the remaining refrigerant from

theRG5410A could result in the acidic degradation

of internal components, ultimately causing

premature failure of the unit.

10. High Pressure Select (R410A) Switch:

When the High Pressure Select (R410A) Switch

is in the on position, the unit will shut off at 550

PSI. In the off position it will shut of at 400 PSI.

DIAGRAM FOR REFRIGERATION RECOVER Y

THIS IS THE FASTEST METHOD FOR RECOVERING VAPOR REFRIGERANT

RECOVER

PURGE

OUT

SYSTEM BEING

SERVICED

A SCALE MUST BE USED TO AVOID

OVER FILLING THE STORAGE TANK

m

OPTIONALMOISTURE

SIGHTGLASS

MANIFOLD

GAUGE

SET

VAPOR

LIQUID

INPUT

OUTPUT

LIQUID

11

First turn knob to liquid

port. When liquid is

removed, move to full

open for vapor

IN

CLOSED

Page 12

SELF PURGING YOUR RG5410A

PROCEDURE FOR PURGING REMAINING REFRIGERANT FROM THE RG5410A

1. Close the ports of the system being serviced that

are connected to the input port of the RG5410A.

2. Close the input port on the RG5410A.

3. Turn off the RG5410A.

4. Turn the Recover/Purge valve to the Purge position.

5. Restart the RG5410A.

6. Run until desired vacuum is achieved.

SELF PURGE / AUTO EVACUATE

To change from Recovery mode to Purge follow the steps below:

1. Close the Input port

7. Close the ports on the recovery tank and the

RG5410A.

8. Turn the RG5410A off.

9. Return the Recover/Purge valve to the Recover

position.

10.Disconnect and store all hoses.

11.Replace the in-line filter on your RG5410A

after every job.

2. Turn the unit off (to prevent high pressure shutoff).

3. Switch to Purge position.

4. Restart the unit.

RECOVER

IN

CLOSED

PURGE

OUT

12

Page 13

DIAGRAM FOR “PUSH/PULL” METHOD

Push/pull method only works with large systems where the liquid is readily accessible. Do not use this

method on systems that contain less than 15 lbs. as it may not work.

The sight glass is used to provide a method of determining the moisture content and quality of a system’s

refrigerant.

m CAUTION: When using the “Push/Pull” method, once the siphon is started, it can continue and overfill

the storage tank even if the tank is equipped with a float level sensor. The siphon can continue even when

the machine is turned off. You must manually close the valves on the tank and the unit to prevent overfilling of the recovery tank.

1. Close INPUT and OUTPUT valves

2. Put RECOVER/PURGE knob on RECOVER

3. Start machine

4. Open INPUT and OUPUT valves

5. When the scale stops rising close all ports

CAUTION: Do not overfill tank

6. Switch off the machine

SET-UP DIAGRAM FOR TANK

PRE OR SUB COOLING PROCEDURE

INPUT

OUTPUT

VAPOR

INPUT

SYSTEM BEING

S E RV I C E D

m A scale must be used to avoid over filling

the storage tank.

See page 10 of this manual for more information.

1. To start you must have a minimum of

5 lbs.of liquid refrigerant in the tank

2. Close INPUT and OUTPUT valves

3. Put RECOVER/PURGE knob on RECOVER

4. Start machine

5. Open INPUT valve to liquid

6. Throttle the output valve so that the output pres-

sure is 100 psi greater than the input pressure,

but never more than 300psi

7. Run until tank is cold

VAPOR

LIQUID

OPTIONAL MOISTURE

SIGHT GLASS

OUTPUT

LIQUID

LIQUID

13

Page 14

OPTIONAL RECOVERY/TANK PRE OR SUB

COOLING FOR FIXED HOSE SET-UP

MANIFOLD

GAUGE

SET

SYSTEM BEING

SERVICED

INPUT

OUTPUT

LIQUID

VAPOR

LIQUID

m A scale must be used to avoid over filling the storage tank.

NORMAL RECOVERY:

Tank Vapor valve is closed

TANK PRE OR SUB COOLING:

Tank Vapor valve is open and both manifold gauge set valves are closed.

14

Page 15

REFRIGERANT FLOW DIAGRAM

15

Page 16

23

RG5410A DIAGRAM

1

2

3

4

ITEM DESCRIPTION PA RT #

1 PLASTIC CASE 100134 (L&R)

2 FAN GRILL 100505

3 AXIAL FAN EL1817

4 CONDENSER CD1201

5 MOTOR EL1821

6 COUPLER CP1315

7 BELL HOUSING CP1001

8 COMPRESSOR CP1320

9 PRESSURE SW EL2800

24

5

6

7

25

11

10

22

18

9

26

27

8

19

20

RG5410A PARTS LIST

ITEM DESCRIPTION PA RT #

10 INPUT GAUGE GA1500

11 OUTPUT GAUGE GA0800

12 GAUGE LENS GA1000

13 ON/OFF SWITCH EL1310

14 START SWITCH EL1309

15 BLUE KNOB 100123

16 RED KNOB 100124

17 BLACK KNOB 100122

1 8 FRONT PANEL 100137

IITEM DESCRIPTION PA RT#

19 FILTER 100343

20 FLARE CAP NB6501

21 CORD SET 100162

22 HIGH PRESSURE SW EL2802

23 BACK PLATE 100318

24 CAPACITOR EL1412

25 COMPRESSOR BRACKET 100351

26 MANIFOLD 700133

27 HOSE 4” 100345

21

15

16

12

14

13

17

REPLACEMENT KITS & ACCESSORIES

PART# DESCRIPTION

KT3302 PISTON SEAL REPLACEMENT (middle section of compressor)

KT3303 VALVE REPLACEMENT KIT (top section of compressor)

KT3307 COMPRESSOR REPAIR KIT (all three sections of compressor)

KT3308 SHAFT REPLACEMENT KIT (bottom section of compressor)

KT5001 80% CAPACITY TANK SENSING KIT

RGT30 30 LB RECOVERY TANK (350 psi working pressure) with capacity sensor

RGT30NS SAME AS RGT30, WITHOUT SENSOR

RGT50 50 LB RECOVERY TANK (350 psi working pressure) with capacity sensor

RGT50NS SAME AS RGT50, WITHOUT SENSOR

RGT50HP 50 LB RECOVERY TANK, HIGH PRESSURE(400 psi working pressure) with capacity sensor

ADS-100 REFRIGERANT SCALE, 200LB CAPACITY, WITH REMOVABLE PLATFORM

16

Page 17

RG5410A WIRING DIAGRAM

17

Page 18

INSTALLATION OF OPTIONAL 80% TANK

CAPACITY SENSING COMPONENTS (KIT:KT5001)

Note: PROMAX also offers the model, RG5410A-KT,

with the 80% Capacity Shut Off Kit installed at the

factory.

c Warning: Prior to performing any type of mainte-

nance work on your RG5410A, insure that it is disconnected from the power supply before you begin.

NOTE: Refer to the wiring diagram on page 17

during installation of your kit.

1. Disconnect your RG5410A from the power source

2. Remove the fasteners from each side of the

RG5410A and separate both halves of the plastic

case.

3. Place the metal frame of the RG5410A in the

upright position

4. Remove the "pry out plug" from the hole located

at the lower right of the front panel, and pass the

tank sensor cord (p/n EL1420) through it.

5. Visually identify the two studs located on the

base, directly behind the lower front panel. (this

will be the location for the relay, p/n EL1500,

all your electrical connections are made.)

6. Disconnect a red wire from the high-pressure

switch (located under the start switch) Note:

There are two red wires on the high-pressure

switch, disconnect the one that originates from the

Power Switch.

7. Ensure that the terminal multiplier (p/n EL1221) is

placed on terminal #4 of the relay and then place

the red wire removed from the high pressure

switch on that terminal.

8. Place the black wire from the sensor cord on the

other side of the terminal multiplier, on the same

terminal #4 of the relay.

after

Note: Ensure that the green wire from the sensor

cord is connected to the center of the 3-pin connector. (Note: only two wires are used in this connector).

11. Connect the 3-pin connector to its female counterpart, already pre wired on your RG5410A.

Note: make sure the two wires, (1) green and (1)

white, are in the proper position (directly across)

from their mating wires.

12. Connect one end of the red wire (p/n WR1403),

supplied with your kit, to terminal #2 of the relay

and the other end to the high pressure switch.

13. Secure the relay onto the two studs mentioned in

Step 5, using the hardware already installed on

the studs.

14. Secure the tank sensor into the hole in the front

panel with the strain relief grommet provided.

15. Secure any loose wiring with the wire ties provided.

16. Replace the plastic case halves and fasteners.

17. Test the installation by momentarily attempting

to start the RG5410A without thesensor cord

connectedtoatank sensor.The unit’s compressor

should not start up. Turn the RG5410Aoff and

reattempt to start the unit with the sensor cord

connected to a tank with a tank capacity sensor.

The unit should function normally. Disconnecting

the sensor cord while the unit is running should

cause the unit to shut down.

18. If your unit does not function per above,

DISCONNECT the RG5410A from the Power

Supply, and re-check your connections per the

above steps and the wiring diagram on page 17.

9. Place the white wire from the sensor cord on

terminal #0 of the relay.

10. Connect the white wire from the male side of the

3 pin connector (p/n EL1215) to terminal #1 of

the relay.

18

Page 19

TROUBLESHOOTING YOUR RG5410A

CONNECT UNIT

TO 115V

SAFETY FIRST

Read and understand all safety information contained

in this manual before servicing the unit.

FAN IS RUNNING

WHEN POWER SWITCH

IS IN “ON” POSITION

YES

COMPRESSOR STARTS

WHEN START SWITCH

IS PRESSED

YES

UNIT PUMPS INTO

HIGH PRESSURE SHUT

OFF

YES YES YES

NO NO

NO NO

NO NO NO

CHECK POWER

SUPPLY

YES

IS UNIT IN HIGH

PRESSURE

SHUT OFF?

YES

ARE VALVES OPEN?

CHECK

FOR SCHRADER

VALVES

DO YOU

HAVE 115V

YES

IS THE TANK

CORD ATTACHED

TO THE TANK

YES

DOES TANK FLOAT

SWITCH WORK

PROPERLY?

UNIT PULLS

INTO A VACUUM

YES

ARE YOUR

HOSES TIGHT?

DOES UNIT PULL A

VACUUM WHEN INPUT

VALVE IS CLOSED?

YES

TROUBLESHOOTING ENDS

19

NONONO

YES

Page 20

FULL ONE YEAR WARRANTY

Note: First 2 digits represent the

MFG #

Promax products are warranted to be free from defects in workmanship and materials for a period of one

year from date of purchase.

THE FOLLOWING RESTRICTIONS APPLY:

1. The warranty applies to products in normal use only, as described in the operating manual. The product

must also be serviced and maintained as described therein.

2. If the product fails, it will be replaced at the option of Advanced Test Products, Inc. (ATP)

3. Warranty service claims are subject to factory inspection for product defect(s). If during the warranty evaluation it is determined that a filter has not been used or that the filter was not properly maintained or that

the machine has been used in any way other than the purpose for which it was designed, ATP, reserves

the right to void the warranty.

4. All warranty claims must be made within the warranty period. Proof of purchase must be supplied .

This warranty is non-transferable.

5. Please note that the warranty does not apply if the product or product part is damaged by accident, misuse, tampered with or modified in any way.

year and the 3

rd

digit the quarter

6. Normal wear items (seals, filters, etc.) are specifically excluded from warranty, unless found by Promax

to be defective.

WARRANTY SERVICE

This warranty is given by ADVANCED TEST PRODUCTS, INC.

Service under this warranty must be obtained by the following steps:

1. Outside the U.S.A. contact your local Promax Distributor.

2. Inside the U.S.A. call 1.800.327.5060 or 954-499-5400

for a return material authorization (RMA) number.

20

Page 21

THE UNITED STATES ENVIRONMENTAL PROTECTION

AGENCY (EPA) REFRIGERANT RECOVERY AND RECYCLING DEVICE

ACQUISITION CERTIFICATION FORM

EPA regulations have required establishments that service or dispose of refrigerant or air conditioning

equipment to certify that they have acquired recovery and recycling devices that meet the EPA standards

for such devices since August 12. 1993. To certify that you have acquired equipment, please complete this

form according to the instructions and mail it to the appropriate EPA Regional Office. BOTH THE

INSTRUCTIONS AND MAILING ADDRESS CAN BE FOUND ON THE NEXT PAGE OF THIS MANUAL.

Part 1: ESTABLISHMENT INFORMATION

Name of Establishment

Street

City

Zip Code

State County

(Area Code)

Telephone Number

Name of Establishment

Street

City

Zip Code

UNIT STORAGE ADDRESS

NUMBER OF SERVICE VEHICLES BASED AT ESTABLISHMENT

Part 2: REGULATORY CLASSIFICATION

Identify the type of work performed at your establishment. Check all boxes that apply.

Type A - Service small appliances.

Type B - Service refrigeration or air conditioning equipment other than small appliances.

Type C - Dispose of small appliances

Type D - Dispose of refrigeration or air conditioning equipment other than small appliances.

Part 3: DEVICE IDENTIFICATION

Name of Device Manufacturer

Model #

Month/Year

Mfg# (if any)

State County

(Area Code)

Telephone Number

Self Contained

Part 4: SIGNATURE

I certify that the establishment named in part 1. has acquired the refrigerant recovery or recycling

devices listed in part 3. and that this equipment will be properly used in service (and/or) disposing

of appliances. I also certify that the information supplied herein is correct and true.

Signature of owner / Responsible Officer

Public reporting burden for this collection of information is estimated to vary from 20-60 minutes per response with an average of 40

minutes per response including time for reviewing instructions, searching existing data sources, gathering and maintaining the data

needed and completing the collection of information. Send comments regarding the burden estimate or any other aspect of this collection of information, including suggestions for reducing the burden to: Chief information Policy Branch EPA, 401 M St. S.W. (PM223Y),

Washington, DC 20460 and to the Office of information and Regulatory A ffairs, Office of Management and Budget, Washington, DC

20503 marked Attention, Desk Officer for EPA .

DO NOT SEND THIS FORM TO THE ABOVE ADDRESSES. ONLY SEND COMMENTS TO THESE ADDRESSES

Date Name (please print) Title

21

Page 22

INSTRUCTIONS EPA REGIONAL OFFICES

Part 1. Please provide the name, address and telephone

number of the establishment where the refrigerant recovery or recycling device(s) is (are) located. Please complete one form for each location. State the number of

vehicles based at this location that are used to transport

technicians and equipment to and from service sites.

Part 2. Check the appropriate box for the type of work

performed by technicians who are employees of the

establishment. The term "small appliance" refers to any of

the following products that are fully manufactured,

charged and hermetically sealed in a factory with five or

less pounds of refrigerant:

Refrigerators or freezers designed for home use, room air

conditioners (including window air conditioners and packaged thermal air conditioners), packaged thermal heat

pumps, dehumidifiers, under-the-counter ice makers,

vending machines and drinking water coolers.

Part 3. For each recovery or recycling device acquired,

please list the name of the manufacturer of the device

and (if applicable) its model number and manufacturer

number. If more than 8 devices have been acquired

please fill out an additional form and attach it to the first

one.

Recovery devices that are self-contained should be listed

first and should be identified by checking the box in the

last column on the right. Aself-contained device is one

that uses it's own pump or compressor to remove refrigerant from refrigeration or air conditioning equipment. On

the other hand, system dependent recovery devices rely

solely upon the compressor in the refrigeration or air conditioning equipment and/or upon the pressure of the

refrigerant inside the equipment to remove the refrigerant.

If the establishment has been listed as Type B and/or

Type D in Part 2, then the first device listed in Part 3 must

be a self-contained device and identified as such by

checking the box in the last column on the right.

If any of the devices are homemade, they should be identified by writing "homemade" in the column provided for

listing the name of the device manufacturer. Homemade

devices can be certified for establishments that are listed

as Type A or Type B in Part 2 until (six months after promulgation of the rule). If a Type C or Type D establishment

is certifying equipment after (six months after promulgation of the rule), then it must not use these devices for

service jobs classified as Type A or Type B.

Part 4. This form must be signed by either the owner of

the establishment or another responsible officer. The person who signs is certifying that the establishment has

acquired the equipment, that the establishment is complying with Section 608 regulations and that the information

provided is true and correct.

Send your form to the EPA office listed under the state or

territory in which your establishment is located.

CONNECTICUT, MAINE, MASSACHUSETTS, NEW

HAMPSHIRE, RHODE ISLAND, VERMONT

CAA 608 Enforcement Contact: EPA Region 1.

Mail Code APC, One Congress Street, John F. Kennedy

Federal Building, Boston, MA 02203-0001

Phone: (617) 565-3420

NEW YORK,NEW JERSEY, PUERTO RICO,VIRGIN

ISLANDS CAA 608 Enforcement Contact: EPA Region 2.

290 Broadway, New York, NY 10007-1866

Phone: (212) 637-3000

DELAWARE, DISTRICT OF COLOMBIA, MARYLAND,

PENNSYLVANIA,VIRGINIA,WEST VIRGINIA

CAA 608Enforcement Contact: EPA Region 3. Mail Code

3AT21, 1650 Arch Street, Philadelphia, PA 19103-2029

Phone: (215) 566-5000

ALABAMA, FLORIDA, GEORGIA, KENTUCKY, MISSISSIPPI, NORTH CAROLINA, SOUTH CAROLINA,TENNESSEE

CAA 608 Enforcement Contact: EPA Region 4. Mail Code

APT-AE, 100 Alabama Street, SW, Atlanta, GA 30303

Phone: (404) 562-8357

ILLINOIS, INDIANA, MICHIGAN, MINNESOTA, OHIO,

WISCONSIN

CAA 608 Enforcement Contact: EPA Region 5. Mail Code

AT18J, 77 West Jackson Blvd., Chicago, IL60604-3507

Phone: (312) 353-2000

ARKANSAS, LOUISIANA, NEW MEXICO, OKLAHOMA,

TEXAS

CAA 608 Enforcement Contact: EPA Region 6. Mail Code

6T-EC, Fountain Place, 12th Floor, Suite 1200

1445 Ross Avenue, Dallas, TX 75202-2733

Phone: (214) 665-6444

IOWA, KANSAS, MISSOURI, NEBRASKA

CAA 608 Enforcement Contact: EPA Region 7. Mail Code

ARTX/ARBR, 901 N. 5th Street, Kansas City, KS 66101

Phone: (800) 223-0425

COLORADO, MONTANA,NORTH DAKOTA, SOUTH

DAKOTA, UTAH,WYOMING

CAA 608Enforcement Contact: EPA Region 8. Mail Code

8AT-AP, 999 18th Street, Suite 500

Denver, CO 80202-2466

Phone: (303) 312-6312

AMERICA SAMOA, ARIZONA, CALIFORNIA, GUAM,

HAWAII, NEVADA

CAA 608 Enforcement Contact: EPA Region 9. Mail Code

A-3, 75 Hawthorne Street, San Francisco, CA 94105

Phone: (415) 744-1305

ALASKA, IDAHO, OREGON, WASHINGTON

CAA 608Enforcement contact: EPA Region 10.

Mail Code AT-082, 1200 Sixth Ave.

Seattle, WA 98101

Phone: (206) 553-1200

22

Page 23

ADVANCEDTESTPRODUCTS

Telephone: (954) 499-5400 • Fax: (954) 499-5454

Miramar, FL

Toll Free: (800) 327-5060

www.PromaxRecovery.com

Designed & Engineered in the USA

Manufactured in China

100132revB

Loading...

Loading...