Page 1

TE3000

MPEG-2 DSNG Encoder

Installation and Operation Guide

A Radyne ComStream Company

6340 Sequence Drive San Diego, California 92121

phone: 858.587.0252 fax: 858.587.0257

TPN: 505-010690-0001 Rev. C 07/02/01

Page 2

Notice

This manual and its contents are proprietary to Tiernan Radyne ComStream, Inc. (Tiernan) and are intended solely for the contra ctual use of its

customers for no other purpose than to install and operate the equipment described herein. This manual and its contents shall not be used or

distributed for any other purpose and/or otherwise communicated, disclosed, or reproduced, in any way whatsoever, without prior written

consent of Tiernan.

Only experienced personnel should install and/or operate this equipment. Prior to installing or operating any equipment or parts thereof,

personnel must carefully read and understand all of the contents of this manual. To properly install and operate this equipment and/or all parts

thereof, personnel must strictly and explicitly follow all of the instructions in this manual.

AILURE TO COMPLETELY READ AND FULLY UNDERSTAND AND FOLLOW ALL OF THE CONTENTS OF THIS MANUAL PRIOR TO INSTALLING AND/OR

F

OPERATING THIS EQUIPMENT, OR PARTS THEREOF, MAY RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT, OR PARTS THEREOF

Tiernan does not assume any liability arising out of the application or use of any products, component parts, circuits, software, or firmware

described herein. Tiernan further does not convey any license under its patent, trademark, copyright, or com mon- law rights nor the similar

rights of others. Tiernan further reserves the right to ma ke any changes in any products, or parts thereof, described herein without notice.

©2001 Tiernan Radyne ComStream, Inc. All rights reserved.

Tiernan Radyne ComStream is a registered trademark. Other brand and product names mentioned herein may be trademarks or registered

trademarks of their respective owners.

Contents are provided with R

subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software [OCT. 1988] clause at DFARS 252.227-7013 and

subparagraphs (a) through (d) of the Commercial Comp uter Software-Restricted Rights [JUNE 19 87] clause at FAR 52.227-19, as applicable.

Manufacturer is Tiernan Radyne ComStream, Inc., 6340 Sequence Drive, San Diego, CA 92121 USA.

Contents of this manual are provided as is without warranty of any kind, either expressed or implied, including, but not limited to, the implied

warranties of merchantability, fitness for a particular purpose, and non-infringement.

Content could include technical inaccuracies or typographical errors. Changes are incorporated in new editions of this manual. Tiernan may

make improvements and/or changes in the product(s) and/or the program(s) described in this manual at any time without notice.

In no event will Tiernan be liable for direct, indirect, special, incidental, economic, cover, or consequential damages arising out of the use or

inability to use the contents even if advised of the possibility of such damages. Some jurisdictions do not allow the exclusion or limitation of

implied warranties, or the limitation of liability for incidental or consequential damages, so the above limitation or exclusion may not apply to you.

For further information on legal and intellectual property matters, contact Tiernan Radyne ComStream Corporate Counsel.

This equipment has been tested and found to comply with the limits fo r a Class A digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interfer ence in which case the user will be required to correct the interference at his own expense.

ESTRICTED RIGHTS

. Use, duplication, or disclosure by the government is subject to restrictions as set forth in

WARNING! Electric Shock Hazard

Do Not Open The Equipment!

Service Only by Tiernan Radyne ComStream, Inc.

DANGER!

Electric Shock

Hazard

Gefährliche Spannung!

Öffuen des Gerätes und Service nur dur Tiernan Radyne ComStream, Inc.

The TE3000 contains no user-serviceable parts. Do not attempt to service this product

yourself. Any attempt to do so will invalidate any and all warranties.

.

Page 3

Contents

Preface Using This Manual .......................................................................................... .....iii

Customer Service ..................................................................................................v

Product Shipments .................................................................................................v

Warranty Information ............................................................................................v

Other Tiernan Products .........................................................................................v

Safety Precautions ................................................................................................vi

Chapter 1 TE3000 Overview ....................................................................................1

Features ................................................................................................................. 1

Network Management Software ............................................................................3

Chapter 2 Installing the TE3000 ..............................................................................5

Placement .............................................................................................................. 5

Powering On The TE3000 .....................................................................................5

Rear Panel Connections ........................................................................................7

V ideo Ports ............................................................ ..........................................7

Audio Ports .....................................................................................................8

Aux Data A and B Ports ..................... ............................................................9

Remote Unit Connections .............................................................................12

DTE/DCE Switch .........................................................................................14

Fault Relay ................................................................................................ ....14

Transport Conne ct ion Ports .................................................................................15

Modulator Output to Upconverter Connections ..................................................16

Chapter 3 Using the Fron t Panel ...................................................... .....................17

Chapter 4 Using a Remote Unit ...... .......................... .............................................4 3

Front Panel Components .....................................................................................17

Navigating Through the Menus ...........................................................................19

LCD Display .......................................................................................................19

Front Panel Navigation Buttons ..........................................................................20

Issuing Commands ............................................................... ...............................23

Modulator Control Buttons .................................................................................25

Front Panel Menu Descri pti ons ...........................................................................26

TE3000 Procedures .............................................................................................38

Configuring the Remote Control Software Parameters .......................................43

Ethernet Port ................................................................ ........................................44

Remote Communications Overview ...................................................................45

Issuing Remote Commands .................................................................... .............46

Contents i

Page 4

Error Messages ....................................................................................................48

Remote Command Descriptions ..........................................................................49

Chapter 5 Configuring the TE3000 ....................................................................... 63

TE3000 Configuration Procedure ........................................................................63

Setting a Default Conf iguration ...........................................................................63

Configuration Examples ............................................................................. .........65

Chapter 6 Troubleshooting ...................................................................................73

Fault Reporting and Monitoring ..........................................................................73

Status LED ..........................................................................................................73

Current Faults ......................................................................................................73

Fault History Log ................................................................................................75

Fault Relay Monitoring .......................................................................................76

Initialization Self-Test Function ..........................................................................77

Fault Summary ....................................................................................................78

Operational Problems and Possible Solutions .....................................................81

Chapter 7 Maintenance and Software Upgrades .................................................83

Appendix A Technical Specificatio ns .... .......................... .............. .......................... 85

Appendix B IF Looptest ...... ................ ............... ............... ................ ............... ......... 87

Required Equipment ................................................................................... .........87

Setting Up the TE3000 ............................................................................... .........87

Powering the Equipment .....................................................................................88

TE3000 Looptest Configuration ..........................................................................88

IRD Looptest Configuration ................................................................................90

Performing the IF Looptest .................................................................................90

Testing the TE3000 Operational Features ...........................................................90

Appendix C TE3000 PID Assignments ....................................................................91

Appendix D Table Top and Rack Mount Installation Instructions ........................93

Table Top Instructions .........................................................................................93

Front Rack Mount Instructions ............................................................................93

Rear Rack Mount Instructions .............................................................................94

Safety Precautions ...............................................................................................96

Glossary

Index

ii Contents

Page 5

Preface

Using This Manual Welcome to the Tiernan world of digital TV compression and transmission

products and systems. Our products are used worldwide by broadcasters, cable

operators, common carriers, and Internet service providers.

This manual is your sourcebook for using the Tiernan TE3000 and describes the

installation, operation, and configuration for this product. An overview of system

and product level require ments, techn ical specifications, and troubleshooting

procedures are also provided.

This manual is designed to help you find information quickly and easily. To take

full advantage of this design, please take a moment to review the specific formats.

Locating Information

To help you quickly locate information, this manual includes:

! Table of contents ! Index

! Glossary ! Quick reference cards

Import a n t In forma t io n

Throughout this manual you will find icons designed to help you identify

important information. These icons are:

The hazard icon – identifies the possibility of electric shock when you perform an

DANGER!

Electric Shock

Hazard

operation with the TE3000 or if you do not use the TE3000 according to

instructions

CAUTION!

Please Read

Carefully

NOTE...

The caution icon – i denti f ies in formati on tha t requ ir es car eful atten tion i n order to

prev ent equipment damage and/or in jury to the operator

The note icon – identif ies informa tion for the pro per operati on of your equipment ,

including helpful hints, shortcuts, or important reminders

Illustrations

Some illustrations contained in this manual may differ slightly from those shown

on your front panel display, rear panel, or remote terminal due to variations in

your system components, configuration, or customization.

Figures depicting equipment may differ from those at your site; therefore, refer to

the labeling on your Tiernan equipment to identify the components. An effort has

been made to use illustrations that reflect basic equipment and configurations of

the majority of customers.

Preface iii

Page 6

Issuing Commands

Tasks and examples are presented in a serie s of st ep-by-step instructio ns.

Commands or information that you enter into the system appear in a different

type, as shown in the following example:

To restore the factory default config uration, select

config>default>restore

command

mc load_def

from the fro nt panel, or issue th e remote

.

If the command contains vari able information that is to be type d into the system,

the variab le info rmatio n is found wit hin kar ats < >. In th e following example, you

would type

CPA

then the correct va lue for

<packet address>

.

Type CPA <packet address>

Front Panel Navigation

This manual uses right angle brackets (>) to indicat e a sequence of menus,

submenus, and menu items.

For example, s elect

! From the control menu, select clock.

! From the clock menu, select date.

! At the date option, enter the date, June 03, 2003, in the correct format.

Control>Clock>Date>June 03, 2003

means:

Displays

The system may return values and messages on a front panel LCD, remot e

terminal, or both. In this manual these values and messages appear in a different

type:

date = 06/23/2003

restore = default1

Revision History This manual is pe riodically updated and revised. For docu mentation updates, call

Tiernan Customer S ervice.

Revision Date Type of Revision

A 07/13/00 Initial release of the manual. Compatible with TE3000 firmware

version 1.70.

B 08/18/00 Updated front panel command to reflect new menu structure.

Compatible with TE3000 firmware version 1.81 build 3.

C 07/02/01 Updated front panel and remote commands to reflect new features;

updated Tiernan Radyne ComStream corporate information.

Compatible with TE3000 firmware version 2.00 build 20.

iv Preface

Page 7

Customer Service We hope this manual provides all the information and instructions you need to

operate the TE3000. However, if you need assistance, contact Tiernan Customer

Service at our corpor ate h ead quarte rs, lo cated in the United State s, thr ough any of

the following methods:

! Phone 85 8-5 87- 0252, Monday – Friday,

7:30 a.m. – 6:00 p.m. pacific standard time

! Fax 858-587-0257

! Email support@tiernan.com

! 24-hour emergency Customer Service P ag ing Center: 858-587-0252 ext. 5 00

Leave a det ailed voice message and your call will be returned.

Product Shipments Please verify that your company name and address are correct on the packing slip

that is included with your equipment. Notify Tiernan Customer Service if any of

the informat ion is incorre c t.

Ensure that you write down the following numbers and include them in any

correspondence with Tiernan concerning your order:

! Purchase order ! Model

! Reference line ! Sales order

Errors

If any part of your shipment is mi ssing or incorrect, call Tiernan Customer

Service.

Cartons and Packing Materials

The factory shipping carton an d packing mate rials are designed to protect the

equipment f rom excessive shock and vibration that can occur during shipping.

Use the original shipping carton and packing materials to repack the unit for

shipment to another location or to return the unit to Tiernan for repair.

For additi onal information on equipment repacking, refer to the Warranty booklet

that accompanied the produ ct shipment.

LCD Display

When you receive your TE3000, the LCD display may be covered with a plastic

protective covering. To remove the protective covering, gently lift one of the

corners and pe el off th e covering.

Warranty Information For warranty or return ma terial authorizat ion information, refer to the Warranty

booklet that accompani ed the product shipment.

Other Tiernan Products The Tiernan Web site also provides information about the entire line of Tiernan

products and systems, including encoders, integrated receivers/decoders (IRD),

switches, ATM products, network interfaces, and network management software.

Preface v

Page 8

Safety Precautions Carefully read and follow all safety, use, and operating instructions before

operating the TE3000. Heed all wa rni ngs and cautions contai ned in this manual.

Retain these instructions for future refer ence.

Follow Startup Procedure

Do not plug in the TE30 00 until you have connected the system and read the chapter on installation.

Provide a Safe Location

Place the TE3000 in a rack or on a stable surface of sufficient size and strength, where it will not be

jarred, hit, or pushed off its surface. Ensure that all cables and cords are out of the way and will not

be tripped over, as this could cause personal injury or serious dam a ge to the equipment.

Avoid Water and Mois ture

If the equipment is exposed to any liquid , contact Tiernan, as serious damage could occur to the

TE3000 or its componen ts.

Avoid Heat , Humidity, and Dust

To avoid internal damage, the TE3000 should be placed away from all heat sources, including

radiators, heater ducts, and so on, out of direct sunlight and away from high humidity, excessive

dust, or mechanical vibrations that can cause damage to internal parts.

Provide Ad eq uate Ventilation

Slots and openings on the TE3000 are provided for ventilation that is needed to ensure reliable

operation. To avoid overheating and ensure that the ventilation slots are not blocked, place the

TE3000 on a smooth, hard surface that has at least two inches of clearance around the unit and

adequate air circulation. If the equipment is placed in a closed area, such as a rack, ensure that

proper ventilation is provided and that the i nternal rack operating tempera ture does not exceed the

maximum rated te mperature at th e position of the TE3000.

Never place the TE3000 on a soft surface that would obstruct the required airflow into the ventilation

slots.

Use Correct Power Source

For units equipped with a North American power cord, the cord has an IEC-compatible female plug

on one end, and a male plug on the other end. This cord is UL and CSA approved up to 1 25VAC at

10 A and is ready to use with no user wiring required.

For units equipped with an Internation al po we r cord, the co rd has a n IEC-compatib le femal e plug on

one end, and three stripped and tinned bare wires on the other end. This cord is approved up to

250 VAC at 6A and complies with the international color codes of green/yellow (ground), blue

(neutral), and brown (line).

If these color codes do not correspond to the colore d mark ings on the terminals i n the plug, use the

following standards:

The green/yellow wire must be connected to the plug terminal marked by the letter E or by the

!

earth symbol ( ) or color-coded green and yellow.

The blue wire must be connected to the plug terminal marked with the letter N or color-coded

!

black.

The brown wire must be connected to the plug terminal marked with the letter L or color-coded

!

red.

An AC plug must be attached to the International power cord in accordance with government

standards and codes in effect at the installation site. If an unterminated power cord is supplied with

the unit, the appropriate certified terminati on plug must be installed. The following is a list of the

required certifying agencies for various countries:

Country Agency Country Agency

Australia SAA Italy IMQ

Austria OVE Japan MITI

Belgium CEBEC Netherlands KEMA

Canada CSA New Zealand SECV, SECQ, SECWA, EANSW, ETSA, HECT, SANZ

Denmark DEMKO Norway NEMKO

Finland FEI Rep. S. Africa SABS

France UTE Spain AEE

Germany VDE Sweden SEMKO

India ISI Switzerland SEV

Ireland IIRS United Kingd om (UK) ASTA, BSI

vi Preface

Page 9

Route Power Cords Safely

Route power cords so they are not walked on or pinched. Pay particular attention to cords and

connections at the plug s , recepta cles (such as power strips), and the point wher e t hey exit from the

TE3000 and attach to other equipment. Do not place any items on or against power cords.

No Stacking

Do not place or stack any objects on top of the TE3000. Other equipment may be placed in a rack or

on a shelf above or below the TE3000, but never stacked directly on top of it.

Protect Against Lightning and Power Surges

When the TE3000 is installed, have the professional installer ground the system to protect against

voltage surges and b uilt-up static charges. For information on grounding standards for electrical and

radio equipment, refer to th e electric a l co de in th e coun try of in stallat i on .

Protect the TE3000 from lightning and power-line surges during a storm by unplugging it from the

wall outlet and disconnecting the coaxial cable.

Turn the TE3000 Off When Changing Circuit Boards

Turn the TE3000 off before i nstalling or removing any circuit boards from chassis slots. Possible

damage may occur to modem, boards, or related equipment if power is left on during this procedure.

Provide Antistatic Protection

Wear a properly grounded antistatic wrist str ap to pr event electrostatic da m ag e t o components when

handling circuit boards or other electronic modules.

Keep Objects Outside

Touching internal TE3000 parts is dangerous to both you and the unit. Never put any object,

including your f in ge r s, thro u gh s lo t s or ope nin gs , as this could result in touc hin g da ng e rous voltage

points, short-circuiting parts, electric shock, or fire.

There are no user-serviceable parts inside the TE3000. If an object falls into the equipment, unplug

the unit and contact Tiernan Customer Service, as serious damage could occur to the TE3000 or its

components.

Use Approved Attachments Only

Use only Tiernan-approved option cards and equipment with the TE3000.

Clean the TE3000

Before cleaning the TE3000, unplu g it fro m the wall outlet. Do not use any type of abrasive pads,

scouring powders, aerosol cleaner s, or solvents such as alcohol or benzene.

Use only a clean, soft cloth lightly moistened with a mild detergent solution. Wipe all equipment

with a clean, soft cloth lightly moistened with water to remove the detergent solution.

Service the TE3000

Do not attempt to service the TE3000 yourself, as there are no user-serviceable parts. Opening or

removing covers may expose you to dangerous voltages or other hazards as well as void your

warranty. Contact Tiernan Customer Service to obtain qualified service personnel.

The following conditions indicate that the equipment needs servicing:

The power cord or plug has been damaged.

!

An object has fallen into the TE3 00 0.

!

Liquid has b een spilled int o the TE3000, or it has been exposed to rain or water.

!

The unit has been dropped or the cover has been damaged.

!

The TE3000 does not operate normally, or it shows a marked change in performance.

!

Perform Safety Checks

Upon completion of any service or repairs to the TE3000, ask the service technician to perform

safety checks to verify that the system is in safe operating condition.

Preface vii

Page 10

viii Preface

Page 11

TE3000 Overview

Tiernan’s TE3000 single channel MPEG-2 encoder i s ideal for high-performance

digital satellite news gathering (DSNG) and fly-away applications. The TE3000

encodes information in the following man n er:

! Accepts video, audio, auxiliary data, and control information as inputs

! Performs analog-to-digital conversion

! Performs MPEG-2 video and audio compression and encoding

! Generates an internal transport stream from program components

! Multiplex es its internal transport stream with any external transport s tr eam

! Provides both an MPEG- 2 transport stream output and a DVB-compliant

QPSK modulated IF carrier

Features The TE3000 consists of the following standard feature set:

! Advanced video compression chip-set which encodes the input video

following the 4:2:0 Main Profile @ Main Level standards

! A high-quality horiz ontal decimation filter for intermediate hor izontal

resolutions

! Supports compressed audio rates of 64 to 384 kbps and four different audio

channel compression methods

! Accepts two high-speed, independently programmable auxiliary data

channels

! Automatic configuration of video and audio rates to match the available

transmission bandwidth for optimum performance

! Dedicated m o dulator contro l buttons are provid e d on the front panel for one

touch control

! Front panel interf ace for local conf iguration, monitoring, and control

! Front panel lock out to pre v ent accidental configuration changes

At-a-glance status monitoring via a tri-colored Status LED indicator

!

! Status hot key enables you to toggle between fault lists and other front panel

menus

! Remote control via Ethernet or EIA-2 32 pro vidin g all configuration, monitor,

and control functions

! Built-in-self-tests and extensive self-diagnostics to assist with system

checkout and pro blem solving

! Non-volatile, field-programmable memory

! User configuration sets that can store and recall commonly used parameters

sets

! Auto-ranging, auto-sensing power supply

! Rugged chassis construction

1

TE3000 Overview 1

Page 12

Video The TE3000 uses an advanced video compression chip-set which

encodes the input video following the 4:2:0 Main Profile @ Main Level,

according to the MPEG-2 standard (ISO/IEC 13818-2). Compressed video rates

are supported from 1 to 1 5Mbps.

The video encoder features a Tiernan proprietary, high-quality horizontal

resampling filter for intermediate horizontal resolutions.

Audio Two stereo or four mono audio channels are compressed using MPEG

audio encoding standards.

The TE3000 supports compressed audio output rates of 64 to 384kbps and four

different audio channel compression methods.

Auxiliary Data Two channels of synchronous data up to 4.096 Mbps each

(RS-422 levels) or asynchronous data up to 38.4 kbps each (RS-232 or RS-422

levels) are supported by the TE3000.

Modulator The TE3000 has a built-in DVB

®

-compatible QPSK modulator

with a 70 MHz IF carrier capable of supporting up to 20 MSym/sec.

Modulator Control Buttons The TE3000 provides dedicated modulator

control buttons on the front panel. These are designed to bring carriers up onto

satellites in a fast and efficient manner .

Transport Stream Output The TE3000 supports both

single-channel- per -carrier (SCPC) and multip le-channels-per-car rier (MCPC)

configurations and can operate in point-to-point or point-to-multipoint

transmission applications.

The TE3000 accepts all commo nly used video and audio input formats and out puts

an MPEG-2 DVB compliant transport stream in addition to a DVB-compliant,

QPSK-modulated 70 MHz IF carrier.

If an external trans port stream is prov ide d fro m ano the r encoder, the TE3000 will

multiplex the t wo tr ansport streams t o form a combi ned trans port str eam (MCPC).

This daisy chaining of encoders and multiplexing of transport streams may

continue until the units reach the 70 Mbps limit or the modulator symbol rate

limit.

Within the data rate limitations of the channel, the TE3000 can be reconfigured for

different video resolutions, video optimization, and audio compressed bit rates to

get the best video performance. Higher compressed bit rates result in better

decoded v ideo quality.

For high reliability applications, the TE3000 provid es exceptional MTBF

performance with its extensive digital processing and proprietar y FPGA circui ts.

In addition, the TE3000 can automatically configure the video and audio rates in

order to match the available transmission bandwidth for optimum performance.

Monitor and Control Functions The TE3000 monitor and co ntrol funct ions

include:

! Fault Relay with passive normally-open and normally-closed contacts

! Front panel operator control utilizing an easy-to-use, intuitive menu and

backlit push-buttons

! Remote control using either an Ethernet or RS-232 interface

2 TE3000 Overview

Page 13

Front Panel The TE3000 front panel interface allows you to scroll through a

standard set of menus to easily set your operating parameters. All configuration

and monitoring functions can be efficiently performed using the front panel.

At-a-glance system status can be quickly determined by checking the tri-colored

front panel status LED:

! Green — indicates that the uni t is rec eiving AC power and that there are no

faults

! Yellow — indicates that the uni t has a current fault

! Red — indicates that the unit has a hard fault

If the Status LED indicates that there is a fault, the Status hot key enabl es you to

go directly to the current faults list with the press of a button.

Remote Control A remote unit, such as a computer terminal, is easily

connected to either th e EIA- 232 remote control port or Ethernet port allowing the

TE3000 to be configured, monitored, and co ntr ol le d us ing character -ba sed ASCII

protocol.

Programmable Memory The TE3000 is a field-deployable unit with

non-volatile, field-pro grammable memory that ensu res retention of conf iguration

parameters during power outages, power off, and transportation. The TE3000

maintains the last user configuration in flash memory.

Configuration Sets The TE3000 has a number of default configurations that

can be restored as well as numerous user-defined configuration sets that can be

saved and restored.

Network Management

Software

Construction The TE3000 is a small, 2RU (90mm/3.15”) high, 21-inch rack

mount chassis with an international auto

-sensing AC power supply

.

To simplify and centralize equipment cont rol,

Tiernan offers a variety of Network

Tiernan Encoder

Management Software (NM S) systems which

allow single or multiple network devices to be

configured, monitor ed, and controlled from a

Tiernan Encoder

central workstation.

Tiernan’s NMS systems implement an

Tiernan Decoder

easy-to-use graphical user interface (G U I)

through which an operator or systems

administrator can:

! Configure all network devices to their site

Workstation

Running NMS

Typical NMS System Managing Multiple Devices

Non-Tiernan Equipment

requirements, including conditional

access, security administration, and event logging

! View and fi lt er network system events, including user configuration changes,

failed connec ti ons, and failed de vic es

! Implement and monitor securi t y measure s incl udi ng discretionary access

control, deletion and reuse, identity and authentication, and auditing

! Customize the NMS software to support non-Tiernan equipment in the

network, providing single point control and monitoring

For information a bout Tiernan’s NMS systems, please contact the T iernan Sales

Department.

TE3000 Overview 3

Page 14

4 TE3000 Overview

Page 15

Installing the TE3000

This chapter provides step-by-step procedures for installing and cabling the

TE3000.

Do not remove the TE3000 top cover! The TE3000 is powered by an exposed,

switching AC power supply which presents an electric shock hazard when the top

DANGER!

Electric Shock

Hazard

CAUTION!

Please Read

Carefully

Placement The TE3000 can be installed on a table top or in a rack. Use the following

cover is removed. Personal injury or damage to the equipment can occur when the

top cover is removed. None of the procedures in this manual require the removal

of the TE3000 top cover.

Before beginning your installation, read the Safety Precautions as the y contain

important safety informa tion and ot her instruc tions required to in stall the TE3000.

guidelines to determine the appropriate installation for your needs:

! If the equipment must be moved frequently, install the TE3000 on a table top

or other flat surface.

! If the equipm ent is going t o be installed permanently, install the TE3000 in a

rack using rack mount brackets.

Whichev er install ation is used, always pos ition the equ ipment to allo w easy ac cess

to the rear panel and provide adequate ve ntilation.

To properly install the TE3000, follow the instructions provided in the appendix

on table top and rack mount installation instructions.

2

Powering On The

TE3000

Ventilation

The TE3000 must be positioned to receive adequate ventilation at all times. The

cooling fan p ulls ai r in th rough the side vent s, circ ulates the air, and exhausts it out

the side vents. The minimum air flow clearance required on both sides of the

chassis is three (3) inches.

The rear panel AC power supply interface includes a fuse holder, and an IEC 320

power cord receptacle. The On/Off (—/0) power switch is located on the front

panel. The typical TE3000 configuration requires 125 amps.

The TE3000 uni t is powered by an aut o-sensing, auto-ranging AC switchin g

power supply. The supply accepts 100 to 240 VAC nominal input voltage levels

cycling at 50 to 60 Hz. A 3.15 amp fuse on the rear panel protects the power

supply from excessive current.

AC Power Cords

The TE3000 shipping kit includes two AC power cords, one for North American

applications, specifically the United States and Canada, and the other for

international applications.

Installing the TE3000 5

Page 16

CAUTION!

Please Read

Carefully

CAUTION!

Please Read

Carefully

AC wiring must be done in accordance with governmental sta ndards and codes in

effect at the TE3000 installation site. Refer to the Safety Precautions for

additional information.

North American Applications One cord has an IEC-compatible female

plug on one end and a North American male plug on the other. This cord is UL

and CSA approved up to 125VAC at 10A. This cord is ready to use with no user

wiring required.

International Applications The international cord has an IEC-compatible

female plug on one end and three stripped and tinned ba re wires on the other end.

This cord is approved by many international safety agencies, including VDE, up

to 250VAC at 6A.

Connecting to a Power Source

To connect to an AC power sourc e , follow these st eps:

1. Select an AC power cord. If an international po wer cord is selected, attach a

connector in accordance with local regulations and laws.

2. Ensure th e TE3000 power switc h is in the Off, or 0, posit io n.

3. Connect the female plug of the AC power cord to the AC power receptacle on

the TE3000 rear panel.

4. Connect the male plug of the AC power cord to an external A Cpower

conditioning surge suppressor.

5. Connect the AC power conditioning surge suppressor to an A Coutlet.

Corrupted AC input power can interrupt TE3000 operations and cause permanent

damage to the unit. You should purchase and install a commercially available,

external AC power conditioning surge suppressor to protect the TE3000 against

power spikes and line transients.

Power-up Sequence

Once the cabling and interconnections for the TE3000 are completed, you may

power-up the unit. The TE3000 power switch is a rocker switch located on the

front panel.

The power switch is lab elled with a

position, while the

0

represents th e Off position.

To power up the TE3000, press the po wer switch to the ON, or

—

and an 0. The — represents the On

—, position. The

power -on cycle takes approximately three to four minutes to comp lete, as the unit

performs exte nsive self-diagnostics in this time period. During the powered-up

cycle, the TE3000 displays

Initializing

, and the tri-colored Status LED

illuminates and may flash. After the unit is initialized, the LCD displays the SD

Encoder main menu.

SD Encoder

[ Config ] Status

→

6 Installing the TE3000

Page 17

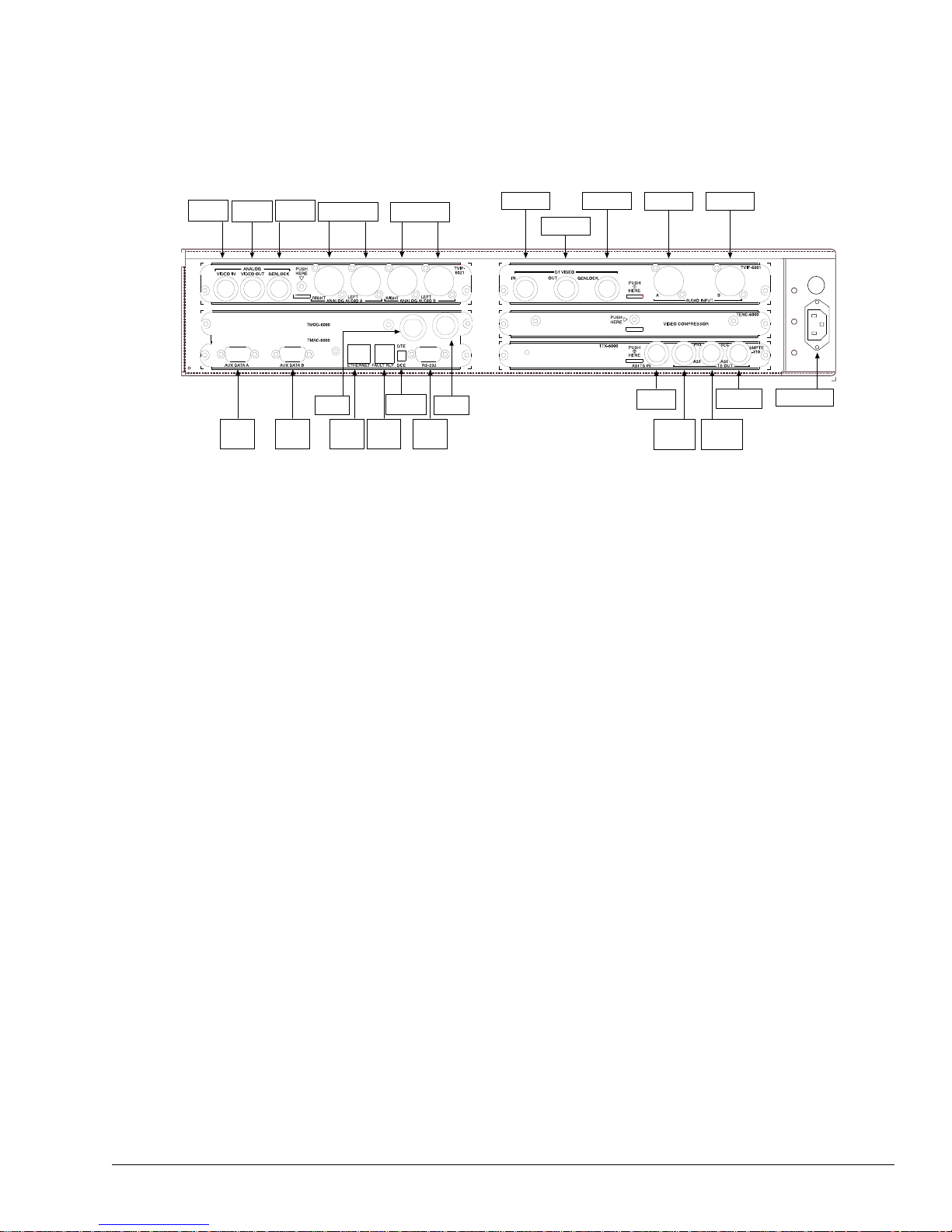

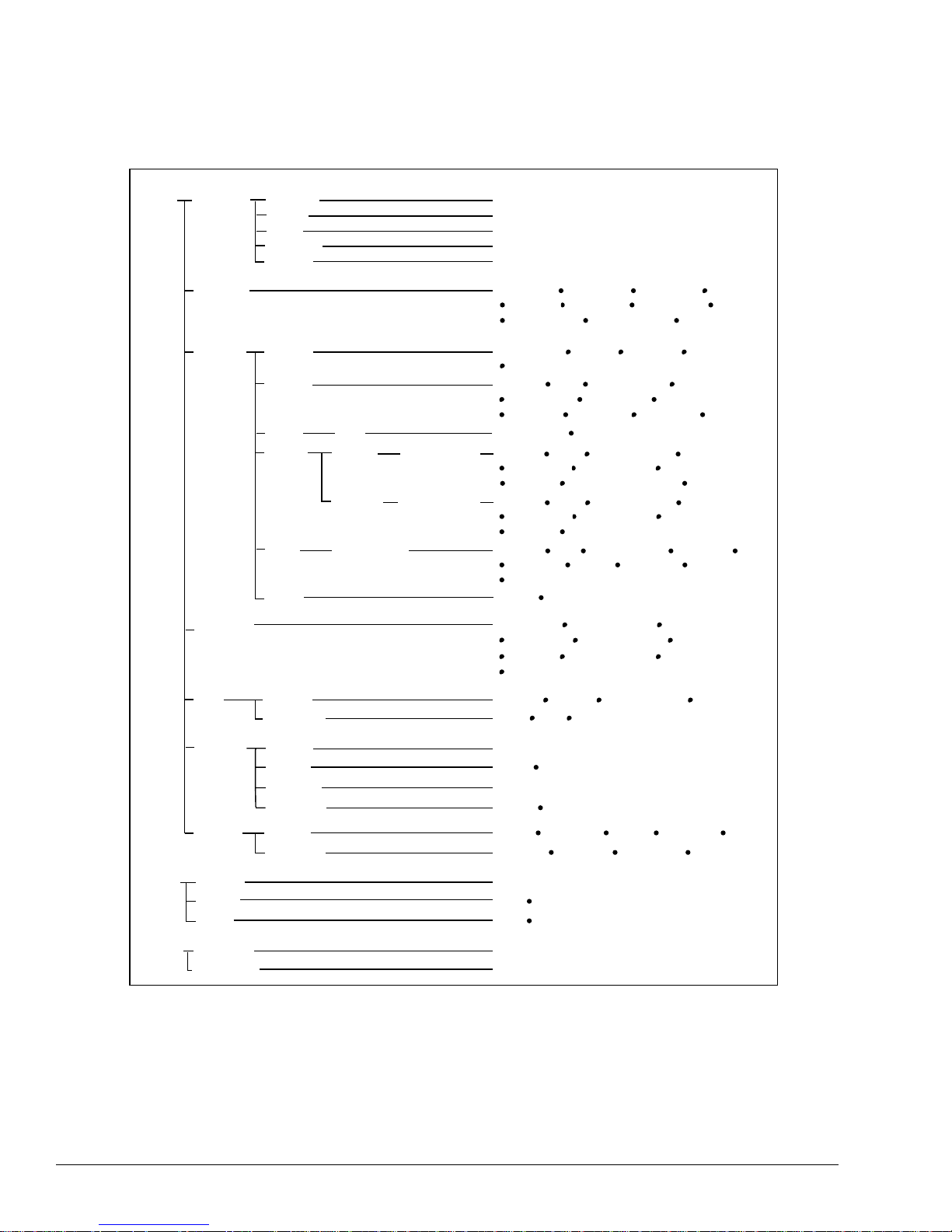

Rear Panel Connections All TE3000 external conne ctions are located on the rear panel, as shown in the

following illustration.

Analog

Video In

Aux

Data A

Analog

Video Out

Analog

Genlock

Aux

Data B

Analog Audio A

Right Left

Tx IF

Out

Ethernet

Control

Analog Audio B

Right Left

TX IF Out

DTE DCE

Fault

Relay

Switch

Mod ASI In

RS-232

Control

Mod

ASI In

D1 Video In

D1 Video

Out

D1 Video

Genlock

Audio Input

A

ASI

TS In

TS Out

Primary

ASI

Audio Input

SMPTE-310

TS Out

Secondary

ASI

B

TS Out

Video Ports The TE3000 provides connections for both analog and digital video.

Analog Video Ports (TVIP6021)

The TE3000 analog video ports, found on the TVIP-6021, are as follows:

! Analog Video In

! Analog Video Out

! Analog GenLock

Fuse

IEC Power Cord

Receptacle

Analog Video In Analog Video In is a female BNC connector with 75Ω

impedance, accepting a NTSC or PAL composite analog video input that is

1.0Vpp nominal level. The analog composite video input must be compliant with

SMPTE 170M NTC, ITU-R BT.470, and PAL-I/B/D. The connector shell is

connected to signal ground.

Connect the video input cable to the Analog Video In connector on the rear panel.

Analog Video Out Analog Video Out is a loop through of the composite

video in signal on a female BNC connector. This connector should be terminated

with a 75Ω load to maintain proper video levels through the system.

Analog GenLock The Analo g GenLock is a femal e BNC conn ector with 75Ω

impedance. The 27 MHz source clock is derived from one of the following

sources:

! Incoming video

! External analog genlock input, SMPTE RP154 (NTCS), EB UD23, and EBU

D25 (PAL)

The external genlock input permits the user to hot switch the video input during

the vertical blanking interval without losing synchronization. Typically GenLock

is connected to a black burst house sync signal in a video plant.

Installing the TE3000 7

Page 18

Digital Video Ports (TVIP 6001)

The TE3000 digital video ports, found on the TVIP-6001, are as follows:

! D1 Video In

! D1 Video Out

! D1 Video GenLock

D1 Video In D1 Video In is a female BNC connector, with 75Ω impedance.

The port accepts a 525 line or 625 line D1 serial digital video input that is format

compliant with SMPTE-259M. The video input is expect ed to be 270 Mbps, with

10bit ITU-R Rec. BT.601 sampled video in 4:2:2 (YCbCr) component format.

Connect the digital video input cable to the D1 Video In connector on the rear

panel.

D1 Video Out D1 V i deo Out is a loop through of the digital video in signal on

a female BNC connector. When the TE3000 is powered off, D1 Video Out is a

passive loop through. When the TE3000 is powered on, the D1 Video Out is an

active loop through driven by a 75Ω driver.

D1 Video GenLock The D1 Video GenLock is a female BNC connector with

75Ω impedance. The port accepts external SMPTE 259M input. When activated,

the D1 Video GenLock is used as the timing reference for the 27 MHz MPEG

system clock of the TE3000.

The external genlock input permits the user to hot switch the video input during

the vertical blanking interval without losing synchronization. Typically GenLock

is connected to a black burst house sync signal in a video plant.

Audio Ports The TE3000 provides the following audio input connections:

! Analog audio on the TVIP-6021

! Digital audio on the TVIP-6001

Analog Audio (TVIP6021)

The TE3000 has two sets of analog audio input ports located on the TVIP-6021:

! Analog Audio A Right and Left

! Analog Audio B Right and Left

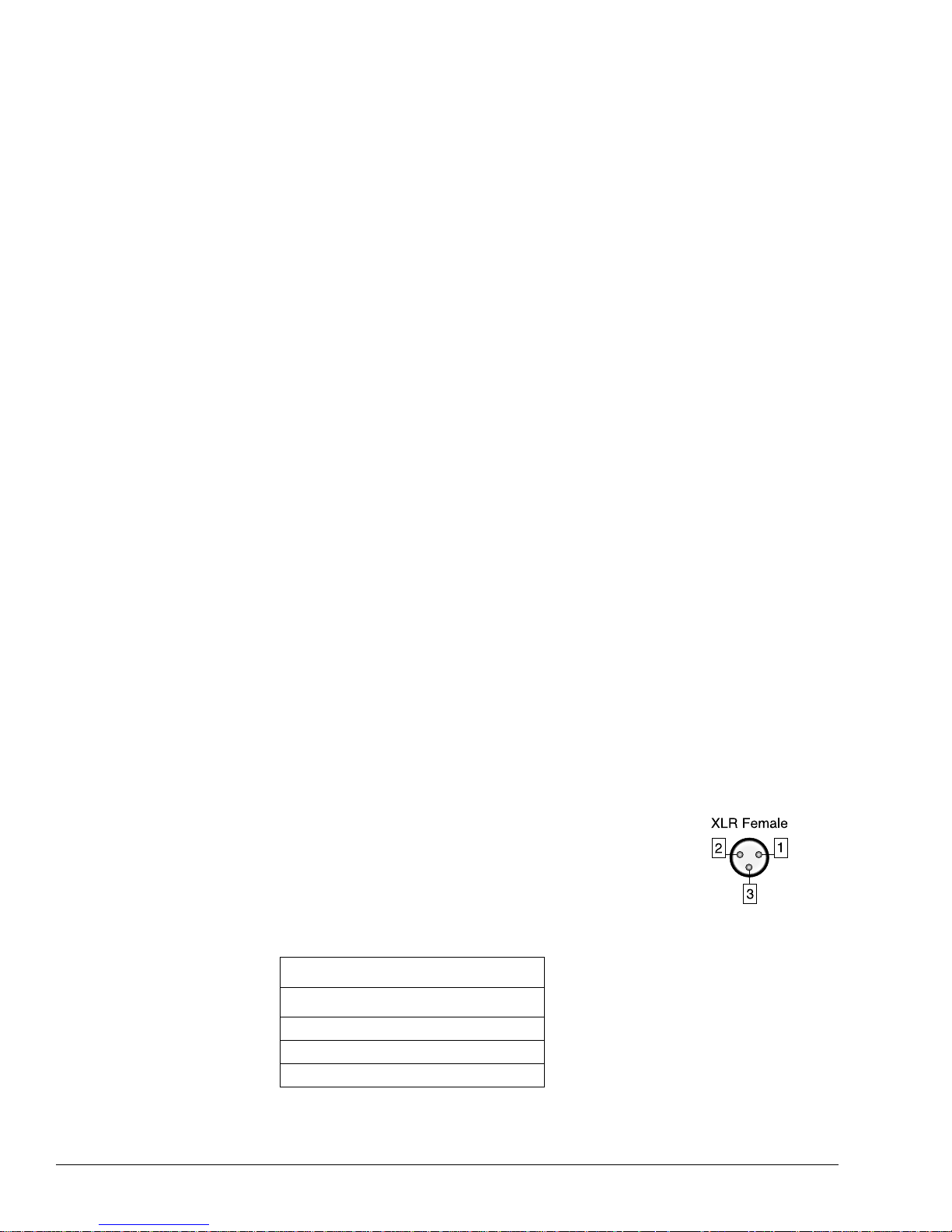

The ports can be co nfigured for two stereo or four

independent analog mono channels.

Each port has a female XLR connector with high

impedance (>10k Ω) termination.

The pin assignments for all the analog audio ports are

listed in the following table.

Audio Port Pin Assignments

Pins Signal

1Gnd

2+

3–

8 Installing the TE3000

Page 19

Digital Audio Ports (TVIP6001)

The TE3000 has two digital audio input ports locat ed on the TVIP-6001:

! Audio Input A

! Audio Input B

Each port has a female XLR co nnector wi th 110Ω. nominal termination. The ports

accept AES/EBU serial di git al input that is complian t wit h ANSIAES3-1992

(ANSI S4.40-1992) recommendations. The ports are typically configured for two

stereo channels.

Aux Data A and B Ports Aux Data A and Aux Data B ports are located on the TMAC-6000. These ports

are female DB-9 connectors. Each channel can be independently configured as

synchronous or asynchronous.

Synchronous Configuration

In synchronous configuration, the ports accept RS-422 input at 1 kbps to 4 Mbps.

The auxiliary Data A and Data B synchronous port pin assignments are list ed in

the following table.

Aux Data Port Pin Assignments: Synchronous – RS-4 2 2

Pins Signal Direction Definition

1Unused — —

2 ST+ Out Send Timing

3 SD+ In Transmit Data

4 TT– In Term Timing

5 GND — Ground

6 ST– Out Send Timing B

7Unused — —

8 SD– In Transmit Data

9 TT+ In Terminal Timing

Shell GND — Ground

Configuring the DTE and TE3000 Clock Interfaces

After you have cabled the data termination equipment (DTE) to the TE3000, you

must deter m in e the most effective TE3000 and DTE clock source arrangements.

There are three different ways to configure the clock interface for the TE3000 and

the DTE:

! Clock Interface Configu ration 1 is the most rel iable cloc k source arrange ment.

This configuration requires the DTE to provi de a clock (TT) synchronous

with the data (SD) to the TE3000.

! Clock Interface Configuration 2 is the second most reliable clock source

arrangement. This conf igur ation is u sed when the DTE ca nnot turn a round the

ST, but has an internal clock source tha t can be pro vid ed as TT to the TE3000.

! Clock Interface Configuratio n 3 is the least rel i abl e clock source arrang ement

— it should only be used if the first two clock configurations cannot be used.

In this configuration the TE3000 is configured to use ST to latch the data.

Installing the TE3000 9

Page 20

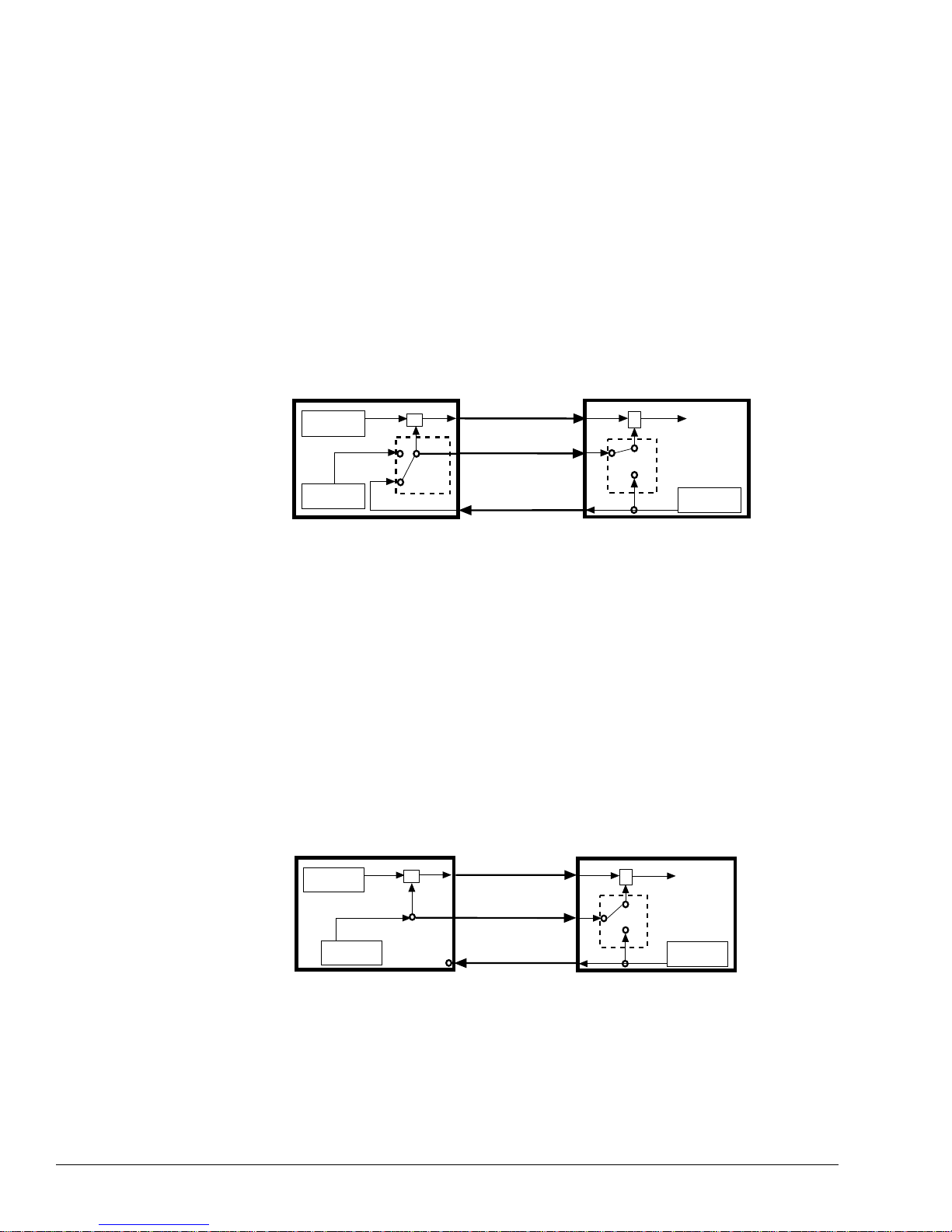

Clock Interface Configuration 1 The most reliable auxiliar y data channel

clock source configuration requi re s t h e DTE t o p rovide a clock (TT) synchronous

with the data (SD) to the TE3000. This scenario allows the TE3000 to latch the

data using a clock th at has tr aveled the same path as the data, which ensures that

both the clock and the data are received in phase at the TE3000.

The following bl ock dia gram shows the clock configuration for a DTE conf i gured

to turn around the ST clock source, and a TE3000 auxiliary data channel

configured for an external clo ck source.

Notice in the illustration that the switch for the TE3000 auxiliary data channel

clock source is conf igured f or ext ernal e v en tho ugh the TE3000 is provi ding ST to

the DTE.

Data

Internal Clock

DTE

Int

Source

Ext

Source

Timing Data

ST

Switch

ST

Data SD

Clock TT

Clock ST

TT

SD

ST

TE3000

Latching Data

Switch

Ext

Source

Int

Source

To TTM

Internal Clock

ST

In this configur ation, the TE3000 provide s cloc k (ST) to the DTE. The switch for

the DTE clock source is configured to accept the external clock (ST) provided by

the TE3000. The DTE uses the ST to time the data, sends the data to the TE3000

on SD, and returns the ST to the TE3000 on TT. The TE3000 uses TT to latch the

data.

The TE3000 auxiliary dat a channel must be configured for an external clock

source to accept TT from the DTE.

Clock Interface Configuration 2 If the DTE cannot tur n around th e ST, but

has an internal clock source that can be provided as TT to the TE3000, use this

option to configure the auxiliary data channel.

The follo wing block diagram shows the clock configuration for a DTE providing

an internal clock source as TT to the TE3000.

In this configuration, the DTE clock is set to internal and the TE3000 auxiliary

data channel clock sourc e is set to externa l. The DTE uses its interna l clock source

to time the data, sends the data to the TE3000 on SD, and sends its internal clock

to the TE3000 as TT. The TE3000 uses TT to lat ch the d ata. The TE3000 au xiliary

data channel must be configured for an external clock source.

10 Installing the TE3000

Data

Internal Clock

Int

Source

Timing Data

Data SD

Clock TT

Clock ST

TT

SD

Source

Source

ST

TE3000DTE

Latching Data

Switch

Ext

Int

To TTM

Internal Clock

ST

Page 21

Clock Interface Configuration 3 If the DTE cannot turn ar ound the ST, and

does not have an internal clock source that can be provided as TT to the TE3000,

configure the TE300 0 to us e the ST to la tch t he data . However, this scenar io is not

recommended and should be considered only if neither of the other two clock

source configurat i ons can be used.

The following bl ock dia gra m sho ws t he cloc k conf i gurati on for a DTE conf i gured

for an external clock and a TE3000 auxiliary data channel configured for an

internal clock.

CAUTION!

Please Read

Carefully

Data

DTE

Timing Data

ST

Data SD

Clock ST

TT

SD

Source

Source

ST

TE3000

Latching Data

Ext

Switch

Int

To TTM

Internal Clock

ST

In this scenario, both the DTE and the TE3000 use ST, but the ST is provided to

the DTE on one path and to the TE3000 on a different path. Depending upon the

length of cable between the DTE and the TE3000, the clock may be received out

of phase at the TE3000. The longer the cable, the further out of phase the clock

will be.

If the internal clock i s used to latch the data, the lengt h of cable between the DTE

and the TE3000 must be limited to one meter (3 feet). Additionally, the auxiliary

data rate must be l imited to not more th an 64 kbps. If the cable length exc eeds one

meter, or if you attempt to process data at rates above 64 kbps, the auxiliary data

may be corrupted.

Asynchronous Configuration

In asynchronous configurations, ports can be configured to accept RS-232 or

RS-422 input at rates of 1200 bps to 38400 bps.

RS-232 The DB-9 connector allows a standard RS-232 DCE connection. The

auxiliary Data A and Data B asynchronous port pin assignments for RS-232 are

listed in the following table.

Aux Data Port Pin Assignments: Asynchronous – RS-232

Pins Signal Direction Definition

1Unused — —

2Unused — —

3 TD In Transmit Data

4Unused — —

5 GND — Ground

6Unused — —

7 RTS In Ready to Send

8 CTS Out Clear to Send

9Unused — —

Installing the TE3000 11

Page 22

RS-422 The auxiliary Data A and Data B asynchronous port pin assignments

for RS-422 are listed in the following table.

Aux Data Port Pin Assignments: Asynchronous – RS-422

Pins Signal Direction Definition

1Unused In —

2 CTS+ Out Clear to Send

3 RD+ In Transmit Data

4 RTS– In Request to Send

5 GND — Ground

6 CTS– Out Clear to Send

7Unused — —

8 RD– Receive Data In

9 RTS+ In Request to Send

Remote Unit

Connections

A remote unit can be connected through either of two ports located on the

TMAC-6000:

! RS-232

! Ethernet Control

RS-232 Control Por t

The RS-232 port is a DB-9 female connector. The port can be configured as a

DTE or DCE. The default configuration is as a DCE.

DCE Configuration The pinouts for the RS-232 port configured as DCE are

listed in the following table.

RS-232 Port Pin Assignments: DCE

Pin # Signal Direction Signal Definitions

1 DCD In Carrier Detect

2 RXD In Receive Data

3 TXD Out Transmit Data

4 DTR Out Data Term inal Ready

5 GND — Ground

6 DSR In Data Set Ready

7 RTS Out Request to Send

8 CTS In Clear to Send

9 RI In Ring indicator

Shell GND — Ground

12 Installing the TE3000

Page 23

DTE Configuration The pinouts for the RS-232 port configured as DTE are

listed in the following table.

RS-232 Port Pin Assignments: DTE

Pin # Signal Direction Signal Definitions

1Unused— —

2 TXD Out Transmit Data

3 RXD In Receive Data

4 DSR In Data Set Ready

5 GND — Ground

6 DTR Out Data Terminal Ready

7 CTS In Clear to Send

8 RTS Out Request to Send

9 RI In Ring indicator

Connecting to the RS-232 Control Port To connect a remote unit to the

TE3000 through the RS-232 control port, you need a cable that is the appropriate

length for the application. The cable must be made to the following specifica tions:

! RS-232 electrical

! DB-9 female connector on one end

! An appropriate connector for the remote unit on the other end

A 6-foot lo ng direct connect DB-9 male to DB-9 female cable is included in the

TE3000 shipping kit.

Using the direct connect cable provided with the TE3000, attach one end to a

remote unit and the other end to the RS-232 control port.

NOTE...

Ethernet Control Port

The Ethernet control port is an RJ-45 connector. Remote control using this port

requires the fo llowing:

! Tiernan Network Management Software (NMS) program

! Category 5 UTP patch cable (not supplied)

Connecting to a Network Using the Ethernet Port You can connect the

TE3000 to a LAN using the Ethernet port, which enables you to monitor and

control the TE3000 through a remote unit not directly connected to the TE3000.

When connecting the TE3000 to a LAN using Ethernet, contact your Information

System department to coordinate installation and setup.

Perform the following steps to connect to the network using the Ethernet port:

1. Connect a Category 5 cable with RJ-45 connectors (standard ethernet cable)

between the TE3000 Ethernet port and a LAN hub.

2. Assign the device a unique IP address, if necessary.

The TE3000 default IP address is 0.0.0.0. Contact your Information Systems

department for a valid IP address .

Installing the TE3000 13

Page 24

To change the IP address using the front panel:

a. Select Config>Comm>Network>IP Addr

b. Using the keypad, enter the IP address in the format xxx.xxx.xxx.xxx

where xxx is a decimal number between 0 and 999.

c. Press the Enter button

To change the IP address using a remote unit, issue the

MC IP XXX.XXX.XXX.XXX command where XXX is a decimal number

between 0 and 999.

3. Assign additional network information, if necessary. Depending on the

configurati on of the LAN, you may need to enter additional parameters

including:

"

Ethernet IP address mask (IP subnet mask)

"

Ethernet IP gateway

4. From a personal computer connected to the LAN, try to ping the TE3000. At

the command prompt of the personal computer, typ e ping <TE3000 IP

address> where <TE3000 IP address> is the address assigned in step 2.

If a reply is received, the TE3000 is correctly configured .

For information on establishing remote communications or on Ethernet

commands, refer to the chapter on using a remote unit.

DTE/DCE Switch The DTE/DCE switch is used to change the configuration of the RS-232 port.

When the port is conf igured as DCE, use a standar d cable for th e computer Comm

port. In this configuration, the port suppo rt s all of the signals required for ba sic

modem support:

! Rdata ! Tdata

! DTR ! DCR

! CTS ! RTS

! DCD

When the port is configur ed as DTE, use a null modem cable to connec t the PC to

the TE3000.

Fault Relay The Fault Relay is an RJ-11 connector. The fault relay is used in a redundant

configurat io n. In this configurati on inp ut is fed from distribution amplifiers into

each of two TE3000s. A Tiernan redundancy switch monitors the output through

the Fault Relay. If the primary TE3000 faults, the secondary TE3000

automatically takes over operation.

A relay fault condition is defined as:

! A unit power failure

! Unit power switch turned off

! Unit is unplugged

! A unit hardwa re failure

The fault condition is indi cate d by contac t closur e be tween pins one (1) and three

(3) and open contacts between pins one (1) and si x(6).

The non-fault condition is indicated by contact closure between pins one(1) and

six (6) and open contacts between pins one (1) and three (3).

14 Installing the TE3000

Page 25

The illustration indicates the physical locations of pins 1

and 6 within the fault relay port, as viewed from the rear

panel.

When the fault relay detects a fault cond ition, the f au lt

relay trips , an d the Status LE D located on the TE3000

front panel illuminates red.

Pin 1 Pin 6

Transport Connection

Ports

The TE3000 multiple xer outputs an ASI transport stream with a variab le rate of 1

to 7 0Mbps. This transport stream is the combination of the video, audio, and

auxiliary data streams in an MPEG-2 compliant transport stream. Depending on

the operating mode, the transport stream is either:

! Input to the modulator or the multiplexer of another TE3000 where it is

multiplexed with another transport stream before being output

! Output to an exte rnal satellite modulator

Operating Modes

The two TE3000 operat o r modes are:

! Single channel per carrier (SCPC)

! Multiple channel per carrier (MC P C )

SCPC Mode In SCPC mode, the ASI transport stream is connected from the

TE3000 multiplexer to the internal modulator of the same TE3000. In this mode,

the modulator supports tran sport st ream data rates fr om 1 up to 18 Mbps in SCPC

mode, depending on the FEC rate selected. Output symbol rates range from 1 to

20 MSps.

MCPC Mode In MCPC mode, the ASI output of one TE3000 is fed into the

multiplexer of another TE3000 so that the output of the two encoders are

multiplexed in a single transport stream. The signal from a series of TE3000s can

be combined in this way. The combined transport stream is then output to the

modulator of the f inal TE3000 in the chain.

In MCPC mode, the modulator supports transport stream data rates from 1 to

32 Mbps, de pending on the FEC rate selecte d. Output symbol rates range from 1

to 20 MSps. For applicat io ns requiring higher data rates, an external modulator

can be used instead of the TE3000 integrated modulator.

Connections

The TE3000 ports used to connect the transport stream to the modulator and the

MCPC chain are:

! ASI TS In

! ASI Out Pri (primary ASI out)

! ASI Out Sec (secondary ASI out)

! SMPTE -310

! Mod ASI In

ASI TS In ASI TS In is a female BNC connector with 75Ω impedance. When

the encoder is configured for MCPC operation, this port accepts the transport

stream from either ASI Out port of another encoder.

Installing the TE3000 15

Page 26

ASI Out Primary ASI Out Primary is a female BNC connector with 75Ω

impedance. The port outpu ts a DVB- compliant ASI transport stream at rates

between 1 and 70Mbps.

ASI Out Primary is used for normal operation and is typically cabled to the Mod

ASI In connector with a short (14”) coaxial cable.

The transport stream output on ASI Output Primary is a spare and is not bypassed

in case of failure.

ASI Out Secondary ASI Out Secondary is a female BNC connector with

75Ω impedance. The port outputs a DVB-com pliant ASI transport stream at rates

between 1 and 70Mbps.

ASI Out Secondary port can be us ed to output the t ransp ort s tream of one TE3000

to the multiplexer of another TE3000 for MCPC operation. In this configuration,

this port is cabled to the Mux ASI In port of the next TE3000 in the MCPC chain.

If a fault conditio n or power failure exists, the input tran sport stream, w h ich is

connected to ASI TS In, is bypassed directly to ASI Out Secondary through a

passiv e by pass r elay. This ensures th at onl y the progr am assoc iate d with the f ai led

TE3000 in an MCPC chain of encoders or in a redundant configuration is

interrupted by the failure.

ASI Out Secondary can also be used to monitor the transport stream.

SMPTE -310 This port is used to output a SMPTE-310 compat ible transport

stream.

Modulator Output to

Upconverter

Connections

Mod ASI In Mod ASI In, located on the TMOD-6000, is a female BNC

connector with 75Ω impedance. The po rt accepts the transport stream from either

ASI Out port.

The Mod ASI In transport data is processed according to DVB standards and

output from the integrated TE3000 QPSK modulator on the port labeled Tx IF

Out.

The internal modulator outputs a modulated IF signal, which is connected to an

upconverter.

Connections are made through the Tx If Out port. This port is a female BNC

connector that outputs a 70 Mhz, DVB-compliant, QPSK modulated, FEC

encoded IF signal at symbol rates from 1 to 20 MSps.

Before you cable the modulator output to the upconverter, turn the modulator off

until you are ready to begin satellite transmissions.

T o cable th e modulator out put to an upconverter , connect the output of the i nternal

modulator from Tx IF Out to an IF-to-RF upc onverter.

16 Installing the TE3000

Page 27

Using the Front Panel

This chapter describes the following TE3000 front panel information:

! Components

! Navigating through menu s

! Description of menus, parameters, and options

3

Front Panel

Components

The front panel enables you to easily and efficiently configure and monitor the

TE3000.

Tri-color

Status

Button

STATUS

CARRIER

MOD

Modulator

and LEDs

Status

LED

TE3000

MPEG2 ENCODER

|

0

On / Off

Switch

LCD

Display

Enter

Button

ENTER

EXIT

Exit

Button

Button

Left

Button

Down

Button

Up

Right

Button

GHI JKL MNO

PQRS TUV WXYZ

Alpha-numeric

ABC DEF

Keypad

Control Buttons

The front panel consists of:

! LCD – displays menus, parameters, informat io n, and message s

! Enter button – used to select a menu item, issue a command, or set a

parameter

! Exit button – used to scroll up to a previous menu level or leave a parameter

without changing it’s option

! Left and Right buttons – used to scroll within the current menu level, or to

scroll through a list of parameters

! Up and Down b utt ons – used to s croll thro ugh par ameter options and increase

and decrease parameter values

! Alpha-numeric keypad – used to enter alphabetic and numeric parameter

values

! Status button – hot key which toggles between the current front panel menu

and the current faults list

! Status LED – tri-color LED alerts you to status and fault conditions

! Modulator control but tons and LEDs – thes e two bu tt ons affect the power and

form of the output IF transmit carrier from the encoder:

"

Carrier – enables carrier wav e at nominal power

"

Mod – enables modulated carrier at nominal power

Using the Front Panel 17

Page 28

TE3000 Menu Structure

SD Menu Submenu Submenu Submenu Parameters

Config

Presets

Output

Service

Tx Strm

Restore

Save

New

Rename

Delete

Setup Service ID Name

Video

VBI CC Tiernan CC ATSC CC

Audio

Data Data A to B Enable Comm Mode Interface Baud

PCR

Digital Slot 4A to 4B

Analog

Submenu

Slot 1A to 1B

<list of configuration sets>

<list of configuration sets>

<enter new configuration name>

<list of configuration sets>

<list of configuration sets>

Out Mode

Tx Freq

Mod Source Tx Power-up Mod Status

Minor Channel

Enable

Format Ctrl Data Rate

Chroma

Enable Compression

Data Rate

Format Delay

Enable Compression

Data Rate

Format Delay

Data Bits Parity Stop Bits Data Rate

Clock Source

Delay Transmit Rate

Rate Calc Redund StateChannel Mode

Table Type

ExtRate

LocRate

Mod State Code RateData Rate

Spect InvertTx Power SymRate

Provider Major Channel

Input Source

PID

Resolution

Optimize

PID Source

Sample Rate

D1 Audio Chnl Pair

PID Source

Sample Rate

PID

Ext TS Enable Ext TS Status

Loc TS Enable Loc TS Status

Format

Timebase

Data Resolution

Data Resolution

Delay

CA

Control

Comm

Status

Version Firmware <firmware version label>

Current

History

Relay

Hardware <version label of installed modules>

Setup

IRD Cfg

Reset

Clock

FP Lock

Serial

Network

"Press ENTER to Reset"

Date Time

ScreenSaverDisplay

State Password

Baud Data Bits Parity Stop Bits Flow

IP Addr

<list of current faults>

List

List

Enable

List

IP Mask IP Router TMA

Clear

Clear

Scramble Key Message PIDFormat

DeleteNew

18 Using the Front Panel

Page 29

Navigating Through the

Menus

LCD Display LCD Symbols

The front panel LCD display and buttons were designed to help you navigate

through the TE3000 menu structure quickly and efficiently.

There are six important symbols that appear on the LCD:

! Brackets [ ] ! Asterisk (

! Arrows ! Colon (:)

! Equal sign (=)

)

*

Brackets As you are moving through menu items, brackets indicate which

menu item is currently selected.

Arrows As you are navigating through the TE3000 menus, a left and right

arrow will often display on the LCD. Depending upon where you are in the menu

structure, this arrow denotes the following information:

! At a menu level the arrow indicates that there are additional items availab le at

that current menu level

! In a list of param eters the arrow indicates that there are additional items

available in that parameter list

Asterisk While the TE3000 is executing a command or setting a parameter

option, an asterisk (*) appears on the LCD, indicating that the TE3000 is

processing information. When the asterisk disappears, the process is complete.

Equal Sign Most parameters, though not all, can be modified in order to

configure the TE3000. Configurable par ameters are followe d by an equal sign,

denoting that the parameter can be modified.

Colon There are some paramete rs that are automatically se t for your system o r

that are query-only paramet ers. These type of parameters are followed by a colon.

When a parameter is followed by a colon, that parameter can be viewed but not

changed.

LCD Text Formats

All menus, parameter options, and system information are displayed on the front

panel LCD.

Menus All menus are displayed in the following format.

Service Menu

[ Setup ] Video

! The first li ne identifies the current menu level. This example shows the

→

Service menu.

! The second line displa ys two of the avail ab le me nu ite ms.

! The brackets indicate which menu item is selected. In this example, the vi deo

menu item is selected.

! The arrow, when displayed, signifies that there ar e additional menu items

available at that level.

Using the Front Panel 19

Page 30

Parameter Options All parameter options are displayed in the following

format.

Auxillary Data A Menu

Data Bits = 8

! The first line identifies the current menu level, in this example, the Auxiliary

→

Data A menu.

! The second line displays the parameter, Data Bits, and its current setting of 8.

! The equal sign (=) denotes that this parameter can be modified. If this

parameter was followed by a colon (:) the parameter would be view-only.

! The arrow indi cates that there are additio nal Data A parameters.

Information Information, such as current faults, faults in the history log, and

system me ssages are displayed as ASCII text strings as shown in the following

example.

Current Faults

VI.A Loss of Input

! The first line identifies the type of information displayed, in this example,

current faults.

! The second line lists one line of information, in this example, the most recent

current fault.

! There is no arrow displa yed, signifying that there are no additional current

faults.

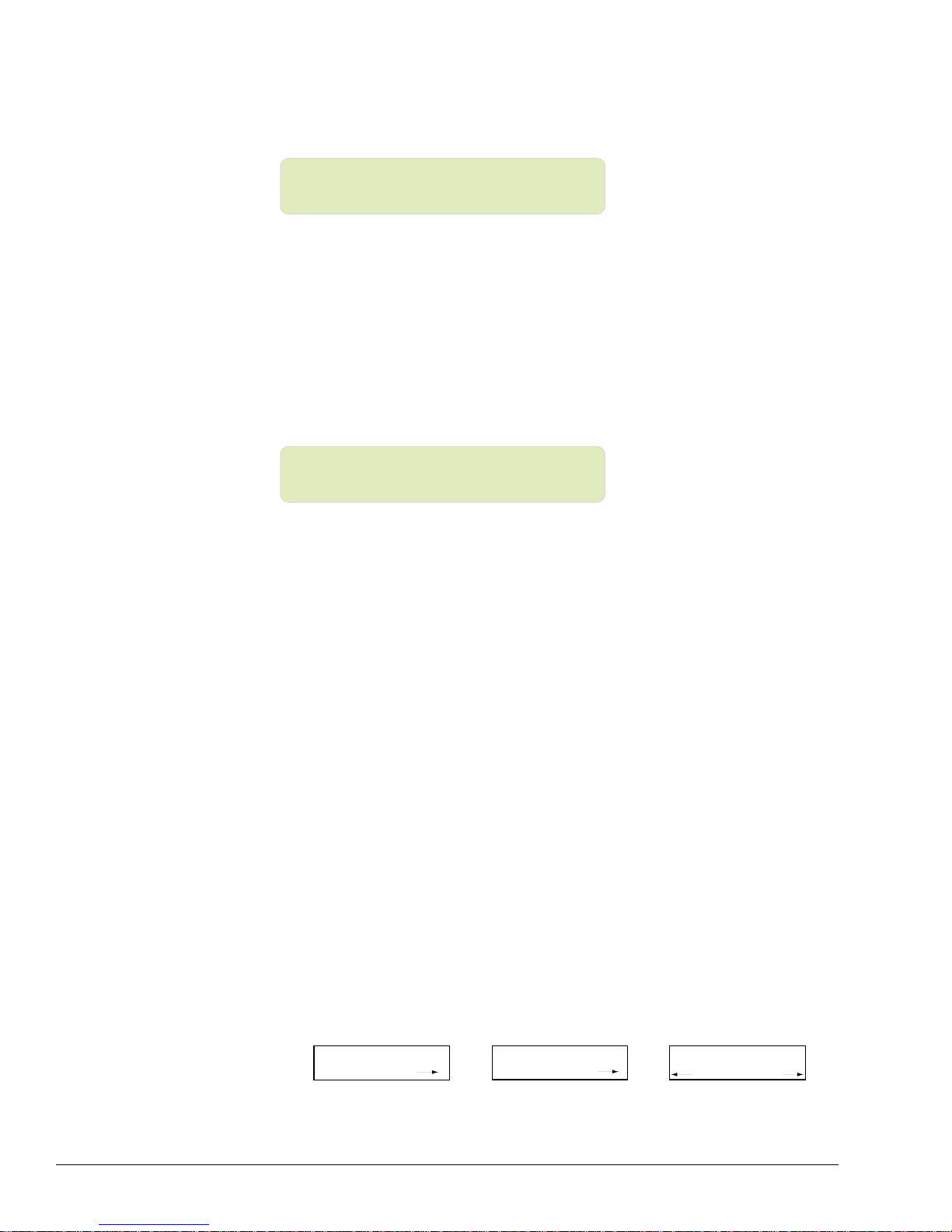

Front Panel Navigation

Buttons

The follo wing front panel buttons ar e used to move through menus in order to

issue commands and view status and fault information:

! Right and Left buttons ! Enter button

! Exit button ! Up and Down buttons

! Numeric keypad ! Status button

Right and Left Buttons The Right and Left buttons are used when either a

right or left arrow is displayed on the LCD. These buttons move you through the

menu structure in the following manner:

! At a menu lev el these buttons move the selection brackets [ ] and scroll right

and left, (forward and backwards), respectively, through all available menu

items at that current level. When the last menu item is displayed, the TE3000

continues scrolling through the list again. The following graphic illustrates

how the right button functions at a men u level.

Press Right Arrow

Brackets Move to

Next Menu Item

SD Encoder Menu

[ Version ]

SD Encoder Menu

[ Config ] Status

Press Right Arrow

Brackets Move to

Next Menu Item

SD Encoder Menu

Config [ Status ]

20 Using the Front Panel

Page 31

In a parameter list, the right and left buttons scroll through the parameter list.

!

When the last parameter is reached, the TE3000 scrolls through the list again.

LCD Display

Video Encoder Menu

Enable On

Input Source Digital

Press right button; the next parameter displays

Press right button; the next parameter displays

Delay 0

Press right button; system returns to

first parameter in list

Using both the right and left b uttons en ables you to sc roll thr ough a paramete r

list in eithe r a fo rw ard or backward m otion.

LCD Display

From Enable, press left button;

system returns to last parameter

Video Encoder Menu

Enable On

Input Source Digital

Timebase Video Input

Delay 0

Press left button;

the previous parameter displays

Press left button;

the previous parameter displays

If you accidentally scroll past the required parame ter, you simply use the

appropriate left or right button to go back to the required parameter.

Enter Button The Enter button is used to :

! Select the menu item displayed in brackets [ ] on the LCD

! Issue a command

! Set a new parameter option

To select a menu item, you use the Left/Right buttons until the brackets

encompass the menu item, then press the Enter button. The Enter button moves

you to the selected submenu.

To issue a command, such as the clear history log command , press the Enter

button to execute the command.

To set a parameter option, such as a new vid eo fra me rate, press the Enter button.

The TE3000 is configured with the new parameter value. The new values are then

stored in nonvolatile memory .

Exit Button The Exit but ton moves you through the menu structure in the

following manner:

! At a menu level, the Exit button moves you up one menu level. If you are at

the very top of the menu structure, at the SD Encoder main menu, you are

moved to the beginning of this menu when you press the Exit button.

Using the Front Panel 21

Page 32

! In a parameter list, the Exit button moves you up to the previous menu leve l.

SD Encoder Menu

[ Service ] Tx Strm

Press Exit From any Menu;

Service Menu

[ Setup] Video

Press Exit From any Parameter;

System Returns to the Previous Menu Level

Video Encoder Menu

Enable On

Input Source Digital

Delay 0

System Returns to the

Previous Menu Level

Up and Down Buttons Once a parame te r is di spl ay ed, use t h e Up a nd Down

buttons to scr ol l thr ough its avail abl e options.

The Up and Down buttons cause the option to flash, indicating that you can

modify that option. Once the option is flashing, you can continue to press the Up

and Down buttons to scroll through the list of avai l able options.

The Up and Down buttons will also increase and decrease the numeric value, if

they are pressed before any keys on the keypad are pressed.

Alpha-numeric Keypad The alpha-numeric keypad is used to enter both

alphabetic and numeric parameter values.

Alphabetic Entries — when entering values in an alpha-numeric field, the

following alphabetic and numeric characters are displayed when a key is pressed:

Key Character Displayed

1 . , ? ! - 1

2A B C 2

3D E F 3

4G H I 4

5J K L 5

6M N O 6

7 P Q R S 7

8T U V 8

9W X Y Z 9

0 space 0 ‘ +

The first pre ss of a numbe r key displays the first character in the set; sequential

presses of the same key advance through the set, in a circular fashion. The cursor

is advanced by either pressing another number key, or by pressing the right arrow

key.

For example to enter the word

ALL

which has two charac ters in the same

characters set, the following keys would be pressed:

2

!

!

! → advances the cur sor so the next lett er can be selected

!

555

555

selects L

selects A

selects L

22 Using the Front Panel

Page 33

A space can be entered by either a single press of the “0” key, or by two or more

presses of the ri ght cursor key.

For example, to enter the words

LA Default

the following keys would be

pressed:

! 555 selects L

! 2 selects A

! 0 selects space

! 3 selects D

! → advances the cur sor so the next lett er can be selected

! 33 selects E

! → advances the cur sor so the next lett er can be selected

! 333 selects F

! 2 selects A

! 88 selects U

! 555 selects L

! 8 selects T

! Enter to issue the command

Numeric Entries — When entering values in numeric field, you simply type the

required numeric value using the keypad and press Enter.

The default value that is initially displayed disappears upon the first numeric key

press. Once a numeri c ke y is pr essed, th e Up and Down but tons are nonfuncti onal;

they resume their normal functions once the Enter or Exit buttons are pressed.

To enter a negative value, press the minus key (-) on the keypad; this toggles the

value between negative and positive.

Status Button The Status button is a hot key which enables you to

immediately view any faults currently occurring on the TE3000 and then toggle

back to the front panel menu on which you were working.

Issuing Commands To issue a command from the front panel, perform the following steps:

1. Navigate to th e required command or parameter using the Left, Right, a n d

Enter buttons.

2. Change the parameter option as required:

"

Scroll through the options usi ng the Up or Down buttons.

"

If the option requires a numeric value to be entered, enter the value using

either the Up and Down buttons to increment the value or the numeric

keypad to type in the value.

3. Issue the command by pressing the Enter key. An asterisk will briefly display

and then disappear when the system is finished processing the request. The

parameter, with its updated value, is then displayed and does not flash.

"

If the Enter button is not pressed, the option is not changed.

"

While the TE3000 is reconfiguring the parameter to the new value, the

front panel is temporarily disabled.

Using the Front Panel 23

Page 34

Correcting

Mistakes