Tier1 WS-165-150 Series Owner's Manual

Owner's Manual

Water Softener

WS-165-150 Series

2

Table of Contents

3

4

5

13

15

WHAT'S INCLUDED

OPERATING CONDITIONS

ASSEMBLY INSTRUCTIONS

STARTUP INSTRUCTIONS

MASTER PROGRAMMING

3

What

is included in the box?

For

Model

WS-165-150,

you

will

expect

the

following:

1. Control Valve

2. Resin Tank

3. Parts Bags

4. Owners Manual Zip Bag

5. Brine Tank and brine valve Assembly

What is included with the WS-165-150

Check the entire unit for any shipping related damage, missing parts, or damage to shipping cartons. Contact the transportation company for all

damage and loss claims. Tier1 is not responsible for damages in transit.

Small parts, needed to assemble the Softener, are contained in parts bags A and B, the control valve box, or in the instruction(s) zip lock bag. To

avoid loss of the small parts, keep them in the parts bag until you are ready to use them.

1. Control Valve

2. Resin Tank

Distributor

Tube Inside

the Tank

5. Brine Tank Assembly

3. Parts Bags

Upper

Distributor

4

. Owner's Manual Zip bag

1. Manual(s)

2. Hose clamps

3. Lubricant

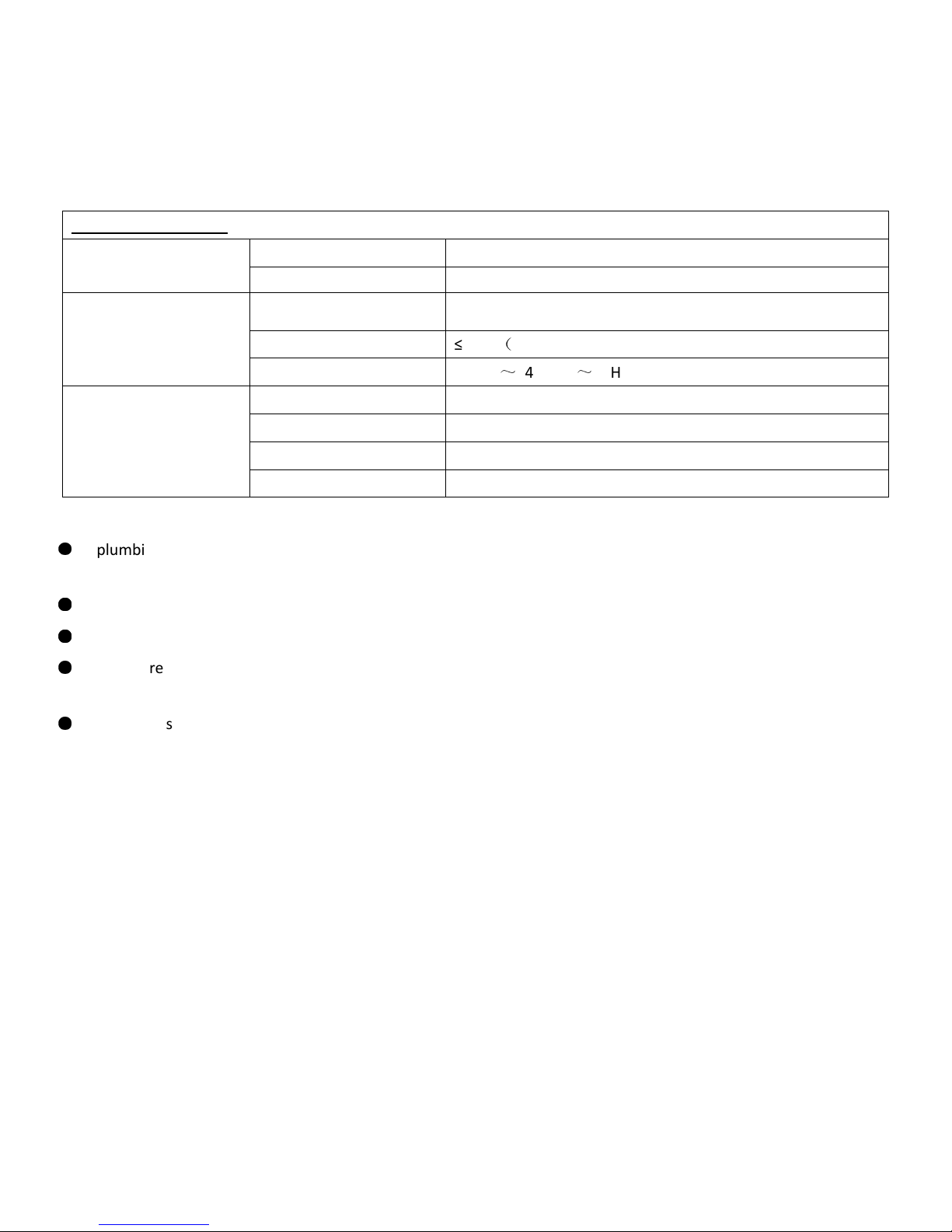

This softening system will operate at maximum efficiency when the following conditions are considered:

Operating Conditions:

Working Conditions

Working pressure 21psi to 120psi

Water temperature

40 °F - 120 °F (5°C - 50°C)

Working Environment

Environment

temperature

40 °F - 120 °F (5°C - 50°C)

Relative humidity

(

≤ 95% When temperature is 25°C/77°F

Power source AC100~240V/50~60Hz

Inlet Water Quality

Water turbidity Down-flow Regeneration < 5FTU

Water hardness 1 grain per gallon (gpg) = 17.1 parts per million (ppm)

Chlorine

< 0.1ppm

Iron2+ < 0.3ppm

●

●

●

●

●

All plumbing and electrical work should be performed by an accredited professional to ensure all local, state,

and municipal guidelines are met.

Do not use the control valve with water that is unsafe or of unknown quality.

Do not use the brine tube, injector body, or other connectors on the valve as a handle to carry the system.

●

Ensure there is salt in the brine tank at all times when this valve is used for softening. The brine tank should contain clean

water softening salt only, at least 99.5% pure. Do not use small grain salt.

●

When there is moderate to high turbidity, a filter should be installed before the water softening system on the inlet side.

If the water pressure exceeds 80 psi, installing a pressure reducing valve

recommended. If the water pressure is under 21psi, a booster pump must be installed before the water inlet.

Operating Conditions

4

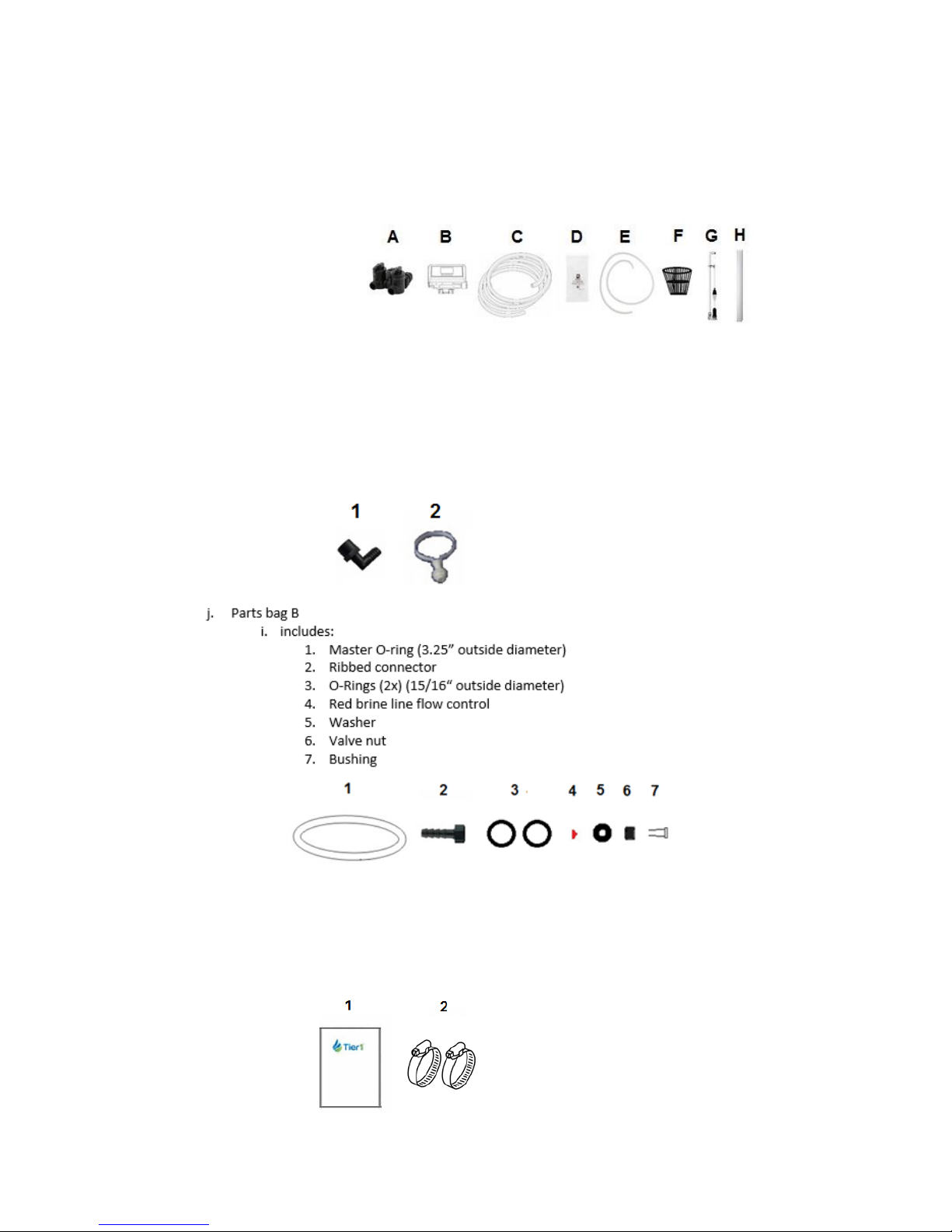

a. Bypass valve

b. Control Valve

c. Clear tubing

d. Lubricant

e. PVC tubing

f. Upper distributor

g. Brine valve

h. Brine well

i. Parts bag A

i. Includes:

1. Brine well overflow elbow

2. Brine well mount

k. Instruction manual(s) zip lock packet

i. Includes

1. 165 Series owner’s manual

2. Hose clamp (2x)

ASSEMBLY INSTRUCTIONS

Locate the following parts:

1. Brine Tank – inside the brine tank you will find:

5

ASSEMBLY INSTRUCTIONS

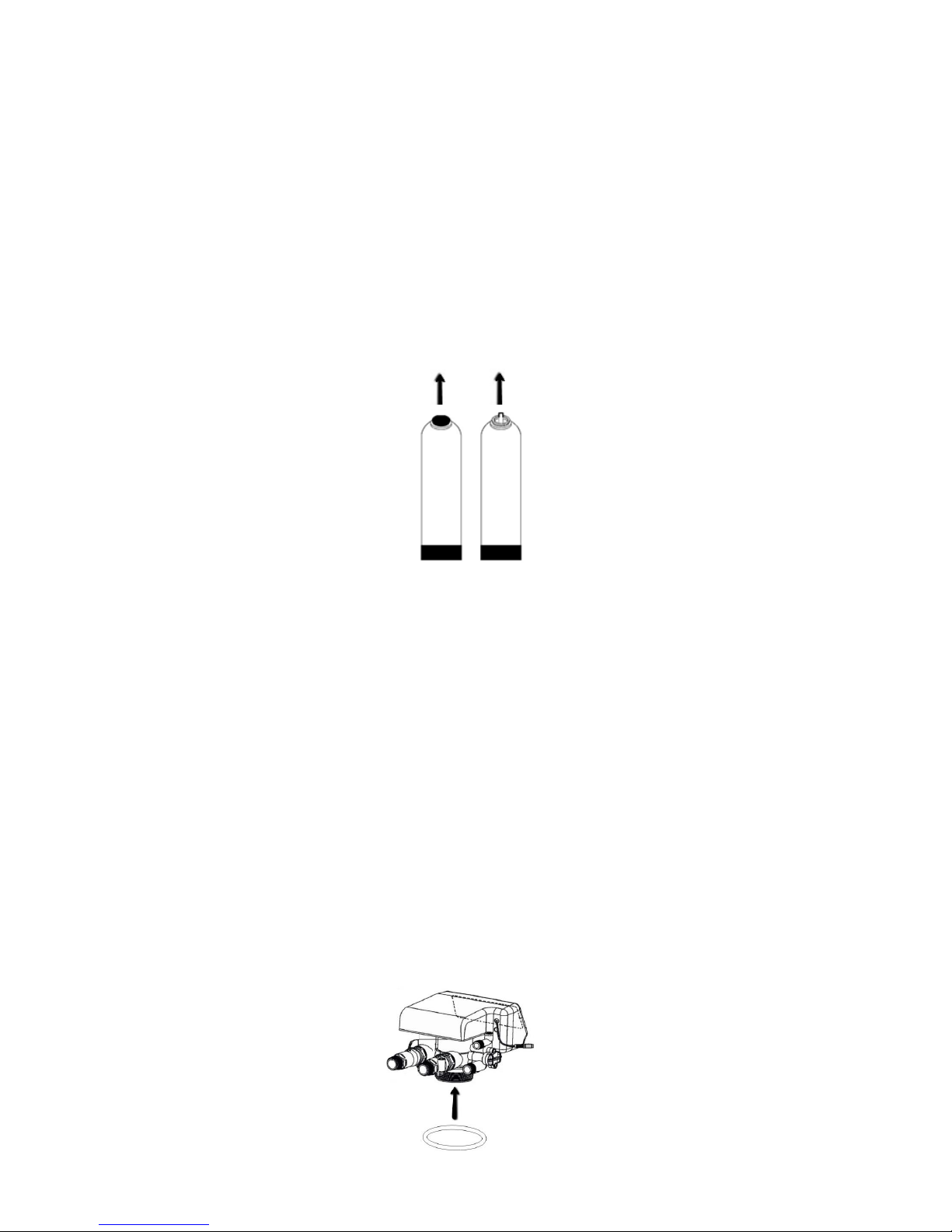

1. Resin Tank - the tank will have a temporary shipping cap, a master O-Ring, and a piece

of tape covering the riser tube. The cap, master O-Ring (another is supplied) and the tape

must be removed and discarded prior to attaching control valve and the upper distributor.

This water softener includes regular control valve connections and a bypass valve connection;

therefore, a set of installation components has been included for each method of installation.

As such, following installation, the installer will be left with an “extra set” of installation

components (animated connectors, brine line flow control, master O-Ring, washers).

2. Read the complete installation guide

3. Unpack the Tier1 WS-165-150 and ensure all parts pictured and listed above are present. such

as tubing, are necessary Rotate the shutoff valve at the main water line to the OFF position

4. Shut off power supply to water heater – only if you will be draining the tank

5. Open the highest and lowest water faucets in your home (drainage and pressure allowance)

6. Ensure you are aware of local laws and codes regarding the installation, use, and maintenance

of water softeners

7. Begin assembly

Assembling the shipped components:

STEP 1: Attaching the Control Valve to the Resin Tank

A. Lightly coat the master O-ring, from Parts bag B, with silicone grease – insert into bottom of

control valve, as shown below

6

Loading...

Loading...