Tier1 RO5 Installation Instructions Manual

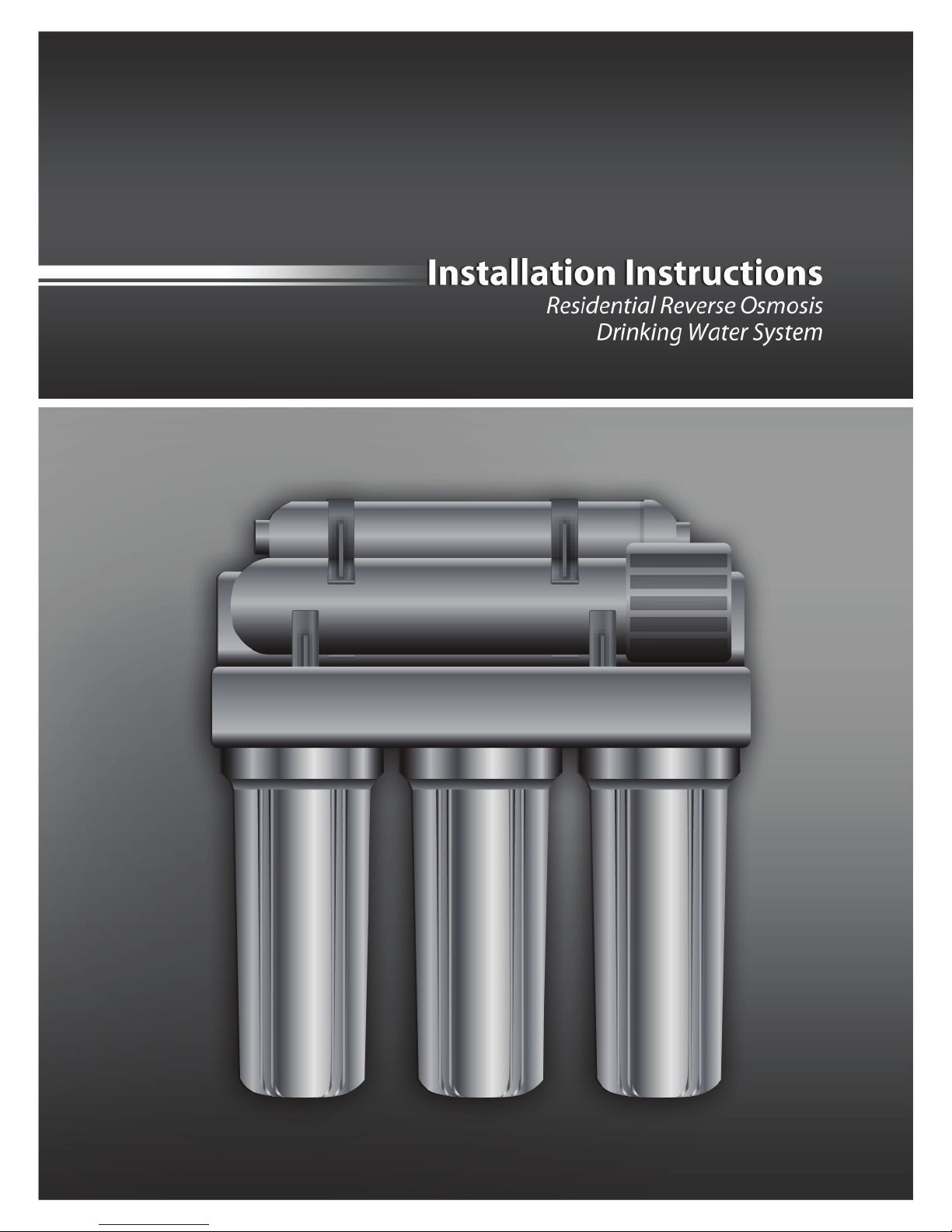

Installation Instructions

Residential Reverse Osmosis Drinking Water System

Installation Instructions

Residential Reverse Osmosis Drinking Water System

Your Reverse Osmosis System has been tested to

ensure it will operate correctly. The following periodic

maintenance is recommended so your system will

provide years of trouble-free service:

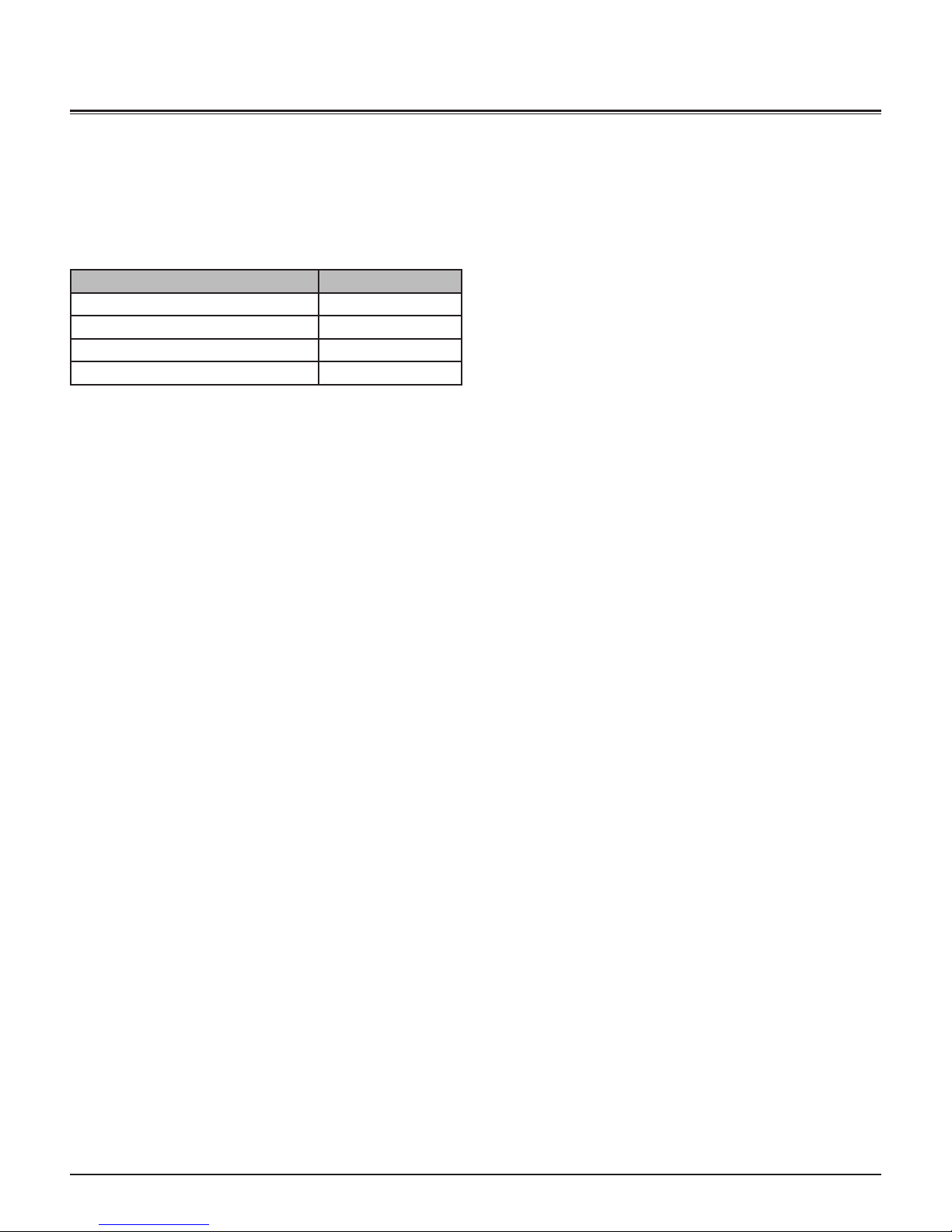

Replacement part Frequency

Pre- lter (sediment) Every 6 mos.

Pre- lters (activated carbon) Every 6 mos.

R/O membrane Every 2-3 years

Post lter (carbon) Every 6 mos.

Components

The following components make up your Reverse Osmosis

Drinking Water System:

PREFILTER (sediment) removes larger particles such as

sand, silt, rust and scale.

PREFILTERS (activated carbon) remove chlorine in the

feed water to protect the reverse osmosis membrane.

REVERSE OSMOSIS MEMBRANE reduces dissolved

minerals, metals and salts. During the process, harmful

compounds are separated by the membrane and the

reject water goes to waste (drain).

An activated carbon POSTFILTER is provided for a nal

“polish” and to remove foul tastes, odors and to provide

great tasting drinking water.

TUBING supplies feed and reject water.

FITTINGS are used for necessary hose connections.

Tools

The following tools may be necessary, depending on each

particular installation:

• 3/8” variable speed electric drill, 1/8” & 1/2” bits

• 1-1/4” porcelain hole cutter (if hole for second

• faucet is not provided

• Center punch and hammer

• 1-1/4” wood bit

• Concrete drill bits

• Phillips head and at blade screwdrivers

• Adjustable wrench

• Crescent wrench

• Te on tape

• Plastic tube cutter

• Air pressure gauge (low pressure)

• Air pump (hand)

System location

Your R/O system may be installed under a sink, in a

basement or other location, depending on available

space. Do not install unit where temperatures fall below

freezing; otherwise, damage will result. Connection to

an icemaker should also be considered for optimum

performance.

Guidelines for component placement are as follows:

FILTER HOUSINGS and R/O MODULE hold pre- lters

and membranes. A BRACKET is provided so they may

be mounted, typically below sink.

STORAGE TANK holds ltered water, ready for use.

AUTOMATIC SHUTOFF VALVE senses when the

storage tank is full and closes the water supply to

conserve water.

The dedicated FAUCET is used to dispense RO produced

water when needed.

Feed water saddle valve is connected to the cold water

line to supply water to the R/O system.

WASTE WATER SADDLE VALVE is connected to the

drain to remove reject water from the R/O system.

Page 1 of 8

FAUCET should be placed near the sink where drinking/

cooking water is normally required. A 2” at surface is

required to mount the faucet if an existing hole for

a second faucet is not available. The thickness of the

mounting thickness should not exceed 1-1/4”.

STORAGE TANK may be placed where it is convenient,

within ten feet of the faucet. Under the sink or in a

nearby cabinet are excellent choices. If tank is located

further than 10 feet from the faucet, use 1/2” tubing to

reduce pressure drop. Full tanks may weigh more than

thirty pounds, so a sturdy shelf is required.

R/O UNIT may be mounted on either side of the sink, in

a cabinet or heated basement, with nearby access to a

potable, cold water line.

Installation Instructions

Residential Reverse Osmosis Drinking Water System

FEED WATER CONNECTION is accomplished with

a self-piercing feed water saddle valve. Locate this

assembly as close to the R/O unit as possible. Connect

to a potable, cold water supply line only.

NOTE: Softened water is preferred since it will extend the

life of your R/O membrane.

DRAIN CONNECTION is accomplished using a waste

water saddle valve which is designed to t around a

standard 1-1/2” OD drain pipe. The drain saddle valve

should always be installed above (before) the tap and

on the vertical or horizontal tailpiece.

Do not install the drain saddle valve near a garbage

disposal; otherwise, plugging of the waste water line

may occur. If discharging into a utility sink or standpipe,

an air gap must be provided. (Air gaps must be 1” or

greater above the oor rim.)

NOTE: Plumbing codes may require the use air gaps. Please

check with your local municipality.

may require installation by a licensed plumber. Check

local authority prior to installation.

A. Faucet installation

If the sink has a sprayer it may be disconnected for

faucet installation. (Installing dealers should discuss this

with customers.) A pipe cap or plug will be necessary to

seal the sprayer connection.

To make the faucet mounting hole (if sprayer or second

hole is not used), check below to make sure the drill does

not interfere with anything below. Center punch a small

indent at the desired faucet location. (2” at surface is

required, not exceeding the chassis punch and tighten

nut to cut the desired hole size. Clean up sharp edges.

The faucet should be positioned so it empties into the

sink and the spout swivels freely for convenience. If sink

has a hole that can accommodate the RO faucet, no

drilling is required.

Proceed with mounting the faucet.

Do not connect the R/O system drain line to the

dishwasher drain line due to the fact back pressures my

cause the air gap to over ow.

Site preparation

Installing dealers may want to speak with customers in

advance and ask them to clean under the sink to save

time. If a basement installation is advisable, check area

to determine if extra ttings or hosing are required.

Upon arrival, it is a good idea to check the condition of

all plumbing for potential leaks and advise customer so

there will be no misunderstandings in the event leaks

occur.

Unit preparation

Open shipping carton, remove components and check

that all parts are present. Check empty storage tank

to be sure air pressure is approximately 7 PSI. Adjust if

necessary.

Installation steps

NOTE: All plumbing must be completed in accordance

with state and local plumbing codes. Some municipalities

Porcelain, Enamel, Ceramic on Metal or Cast Iron

Precautions must be taken to penetrate the porcelain

through to the metal base and prevent it from chipping

or scratching.

Tools required:

• Variable speed drill

• Relton porcelain cutter tool set

(7/8” or alternative size, 9/16”)

• Plumber’s putty

Procedures

1. Mark the center for the 7/8” hole.

2. Form shallow putty around hole area and ll with

enough water to lubricate carbide drill bit.

3. Carefully drill pilot hole through all layers. (Use light

pressure and slow speed.)

4. Insert pilot tip of spring-loaded porcelain cutter into

pilot hole.

5. Drill porcelain/enamel using spring loaded porcelain

cutter, making certain a complete ring has been cut

through the porcelain / enamel to the metal base.

Page 2 of 8

Loading...

Loading...