TiEmme GLH110 User Manual

Pag. 1/15

0CAR6IN019124_Manual_GLH110_Rev_0.3

GLH110 Glass Temperature Controller

User Manual

1. MAIN FEATURES

The GLH110 Temperature Controller manages Wood Fireplaces and Boilers, for heating and domestic hot water production, with the

possibility to integrate it to a Gas Boiler.

Safety Rules

Read carefully the following safety regulations, in order to prevent accidents

damage to people and things.

Before working on the hydraulic plant, please be aware of the following:

Accident prevention measures

Environmental protection measures

National Institute for Work accidents measures

Recognized prevention measures

This manual is intended for qualified technical staff only

Electrical wiring and connection must be performed by qualified

technicians only

The first installation of the hydraulic plant must be performed expert

personnel

Declaration of Conformity

Regulations:

EN 60730-1 50081-1

EN 60730-1 A1 50081-2

TiEmme elettronica

06055 Marsciano (PG) Italy Tel.+39.075.874.3905; Fax.

+39.075.874.2239info@tiemmeelettronica.it

Technical data

Supply:230 Vac 50 Hz 10%

Absorption:2,5 VA

Outputs Range:5A 250 Vac

Internal fuse:3,15 A

Mechanical Characteristics

Material: PA

Flush mount Installation:Incasso 3

Modules/ Wall

Dimensions:Flush mount: 132x68x50 mm

Degree of Protection:IP40

Installation conditions and Use

Operating Temperature: 0÷40 °C

Storage Temperature:0 ÷ 60 °C

Umidity: 85% @25°C

2. INSTALLATION

Make sure that the Main Power Supply is OFF prior to installing the device

Install the product in a dry environment with proper climatic conditions

Insert a bipolar main switch compliying to local regulations

Avoid coupling the probe cables with these of power

Use for wiring, cables with conductors of appropriate section and in according the rules

Position the probes to detect correctly the temperature

Make sure the probe wires are placed away from direct/indirect flame

3. ELECTRICAL CONNECTIONS

All the probe inputs and command outputs are controlled

automatically according to the type of hydraulic/plumbing

plant selected.

For electrical connections

you must refer to Chapter 7 and the following paragraphs

concerning the hydraulic/plumbing schematic drawings.

Fig.2 – Electrical connections

Code

Connectors

Device

Characteristics

INPUTS

LINE

1 – 2

Voltage Supply

230 Vac 50 Hz 10%

S1

13 – 14

Fireplace Temperature Probe

Operating Range: -50°C ÷ 125 °C

NTC 10K Measure: -10 ÷ 110 °C 1°C

NTC 100K Measure: -10 ÷ 300 °C 1°C

PT 1000 Measure: -40 ÷ 300 °C 1°C

Flow switch contact ON/OFF

S2

15 – 16

Sanitary Boiler Probe / Buffer

Flow Switch

S3

16 – 17

Ambient Probe/Thermostat

Buffer, Manifold

16 – 17 – 18

Pressure Sensor

Operating Range: 0 ÷3 bar / 0 ÷ 3V

OUTPUTS

P1

3 – 4

Pump 1

230 Vac 5A

P2

5 – 6 – 7

Diverter Valve / Pump 2

230 Vac 5A

P3

8 – 9 – 10

Boiler Integration Consent

Contact in exchange: COM.(9)-N.O.(8) - N.C.(10)

P4

11 - 12

Service = Thermostat

230 Vac 5A

Service = Grill

Combustion Air Shutter

Pump 2

PWM1

19 – 16 o 14

Control PWM1

0-5Vdc, Frequency 1Khz, Duty Cycle 0-100%

PWM2

20 – 16 o 14

Control PWM2

Pag. 2/15

0CAR6IN019124_Manual_GLH110_Rev_0.3

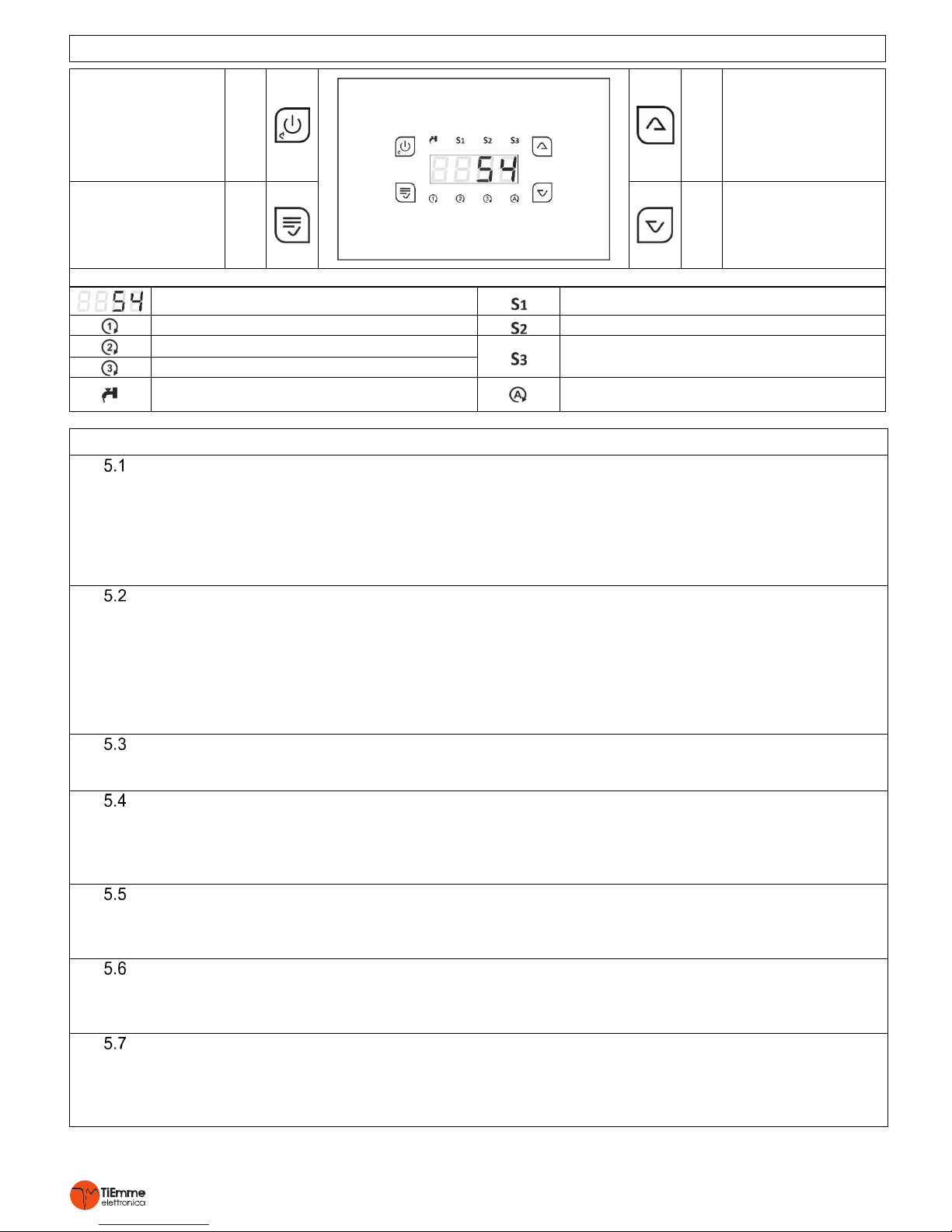

4. Control Panel: USE AND FUNCTIONS

ON/OFF

Exit the Menu

Grill Service

Shutter Manual Start

K1

K3

Scroll/Increase

Pump1 Test

Probes Menu

Enter User Menu

SET

Shower Key

K2

K4

Scroll/Decrease

Pump2 Test

Probes Menu

Fig. 3 Main Screen

S1 Probe Temperature

S1 Probe Displayed

P1 Output Activated

S2 Probe Displayed

P2 Output Activated

S3 Probe Displayed

Fashing: Ambient Thermostat open

P3 Output Activated

ON: Flow Switch Closed

Fashing: Shower Function Activated

P4 Output Activated

5. FUNCTIONALITIES

IGNITION/EXTINGUISHING

Controller Ignition/Extinguishing is perforemd by applying prolongued pressure to K1 key

OFF-mode is displayed by K1 key being turned-on

When the controller is turned on, the following messages will appear

o Product Code t002

o Product Revision r 0.1

o Configuration CF01

PROBE DISPLAY

The display shows the correct temperature sensor value S1 (S1 led is lit up).

To enter the probe menu press either K4 or K3, the temperature of Probe S2 is displayed (S2 Led flashes) or S3 (S3 Led

flashes)

By pressing K3 or K4 it is possible to scroll and check other connected probes

To exit the Menu press K1 or wait 10 seconds

If the probe reading is below the minimum range of the sensor the message Lo appears

If the probe reading is above the maximum range of the sensor the message Hi appears

SAFETY FEATURE

When this function is activated; P11=1, it starts a heat disposing process to remove excess heat buildup of the fireplace

The management of the safety feature is expalined in the plumbing/hydraulic schematic drawing parapraphs

ALARM FUNCTION

If the temperature measured by Sensor S1 exceeds the value of the thermostat alarm A08

An audible and visual signal is activated (the temperature flashes on the Display)

SILENCE Function: The audible signal can be turned off for 5 minutes by pressing any key. If the controller remains in

the alarm condition the audible signal will start again.

ANTIFREEZE FUNCTION

If the temperature measured by Probe S1 falls below the value of the Antifreeze Thermostat A06

The output for Pump P1 is turned on for t01 time at intervals of t02 time

The display will show the writing ICE

PUMP P1 ANTISEIZE FUNCTION

If Pump P1 remains inactive, also while OFF, for a time greater than Timer t05

The output for Pump P1 is turned-on for t04 seconds

The display will show the writing bLP

STANDBY FUNCTION

If the controller is OFF, and in ALARM, ANTIFREEZE or ANTISEIZE FUNCTION of Pump P1

The controller automatically turns itself ON

At the end of ANTIFREEZE or ANTISEIZE of Pump P1 functions, the controller will turn itself OFF.

Al the end of ALARM function the controller will remain ON

Pag. 3/15

0CAR6IN019124_Manual_GLH110_Rev_0.3

PUMP P1 FUNCTIONING TEST

When the controller is OFF, prolongued pressure of K3 key:

P1 output is activated for as long as the key is pressed and the display will show tSt1

PUMP P2 FUNCTIONING TEST

When the controller is OFF, prolongued pressure of K4 key:

P2/P4 output is activated for as long as the key is pressed and the display will show tSt2

SERVICE OUTPUT

P4 SERVICE output is programable from the Installer MENU by using parameter P06:

P06 = 0 DISABLED: the output does not work.

P06 = 1 THERMOSTAT: the output is activated if the temperature of S1 probe is above Thermostat A09.

P06 = 2 GRILL: press K1 key to turn on/off the output.

P06 = 3 AIR DAMPER: this output is used to manage an Air Damper to adjust for Combustion Air Flow.

AIR DAMPER

To make use of the Air Damper function set parameter P06 = 3

If the output is ON the Air Damper will be Open, if the output OFF the Air Damper will be closed.

The Air Damper will stay Open as long as the temperature of S1 probe is below A05 Thermostat. The Air Damper will close

when the temperature is above this Thermostat.

If P12 = 1 the Start Manual function is enabled:

If S1 Temperature is below A01, the Air Damper will Close. During the Ignition phase of the Fireplace, by pressing K1 key

the Air Damper will Open manually (the output corresponding Led will flash). When the Temperature falls below A01,

Thermostat after t06 time the Air Damper will close automatically.

PROBE TYPE

The controller can manage NTC10K, NTC100K and PT1000 type of probes, which can be configured by using parameters

P01, P02, P03 and P17 of the Installer MENU.

Fireplace Probe: P01 = 0 → NTC10K; P01 = 1 → NTC100K; P01 = 2 → PT1000

DHW Boiler Probe/ Tall Buffer : P02 = 0 → NTC10K; P02 = 1 → NTC100K; P02 = 2 → PT1000

Short Buffer Probe: P03 = 0 → NTC10K; P03 = 1 → NTC100K; P03 = 2 → PT1000

Ambient Probe: P04 = 0 → NTC10K; P04 = 1 → NTC100K; P04 = 2 → PT1000

Manifold Probe: P17 = 0 → NTC10K; P17 = 1 → NTC100K; P17 = 2 → PT1000

S3 INPUT CONFIGURATION

Parameter P05 can be enabled to mange the following:

P05 = 0, S3 input = DISABLED

P05 = 1, S3 input = PRESSURE SENSOR

P05 = 2, S3 input = AMBIENT SENSOR

P05 = 3, S3 input = AMBIENT SENSOR

PRESSURE SENSOR

If P05=1 pressure sensor management is enabled on probe S3.

If P07=1 pressure sensor errors are enabled:

If Water Pressure < Pr1 dispaly shows PrLo + audible signal.

If Water Pressure > Pr2 dispaly shows PrHi + audible signal.

PROBE SENSOR/AMBIENT THERMOSTAT

Parameter P05 can be setup to enable the management of the Probe Sensor/Ambient Thermostat

If the Ambient Temperature S3>b01 or the Ambient Thermostat is Open ( Led flashing) and there is NO DHW request

The Shutter is closed

The hydraulic/plumbing plants with a Buffer tank; if the Ambient Temperature is S3>b01 or the Ambient Thermostat is

Open the Heating Pump will be turned off (deactivated)

SHOWER

(P13=1) if used in specific hydraulic/plumbing plants where it is required, it can be enabled by pressing K2 key for 3 sec:

The display shows T03 time (minutes) giving (DHW) Domestic Hot Water priority;

K3 and K4 keys increase /decrease the duration

Wait 5 seconds to save and exit from this setup.

To exit without saving press K1 key.

T03 time is signaled by led flashing, giving priority to DHW production based on the type of hydraulic/plumbing plant

in use.

This function is over when

T03 time has expired.

By pressing again K2 key

If the temperature of S1 Probe is greater than A07 Safety Thermostat:

And T03=0, the shower function can be disabled by pressing K2 key.

Pag. 4/15

0CAR6IN019124_Manual_GLH110_Rev_0.3

SOLAR CIRCUIT

Buffer Tank Loading:

The Solar Manifold Pump is activated:

If the Temperature of (S3) >A33 and Δ (S3-S2) > d02

The Buffer Loading is disabled once the Buffer Comfort Thermostat has been reached on S2 (A20).

Manifold and Buffer Safety:

If the Temperature of the Manaifold (S3) > A35 (Manifold Safety Thermostat) the Manifold Pump is turned on again and

fills the Buffer Tank until A23 high temp. Thermostat has been reached.

Manifold Protection:

If the manifold Temperature (S3) > A36 (Manifold Safety Thermostat) the manifold pump is turned off

Antifreeze:

When this function is enabled (P09=1) if the temperature detected by S3 probe (even while the controller is OFF) falls

below the Antifreeze Thermostat A34 the manifold pump is turned on for t04 time at intervals of t05 time

WOOD INTEGRATION PRIORITY (Hydraulic/Plumbing plants including Buffer Tank)

This feature gives priority to the integration of the fireplace instead of the Gas boiler.

Se P10=1 priority is given to the wood fireplace in managing the integration of the Buffer Tank instead if the Gas Boiler.

PUMPS MANAGEMENT WITH PWM CONTROL

P18 and P19 parameters are used to enable and select the operating mode of the PWM1 and PWM2 signals, to manage the

pumps provided in the hydraulic/plumbing schemes:

PWM1: P18 = 0 → Disabled; P18 = 1 → Manual; P18 = 2 → Automatic

PWM2: P19 = 0 → Disabled; P19 = 1 → Manual; P19 = 2 → Automatic

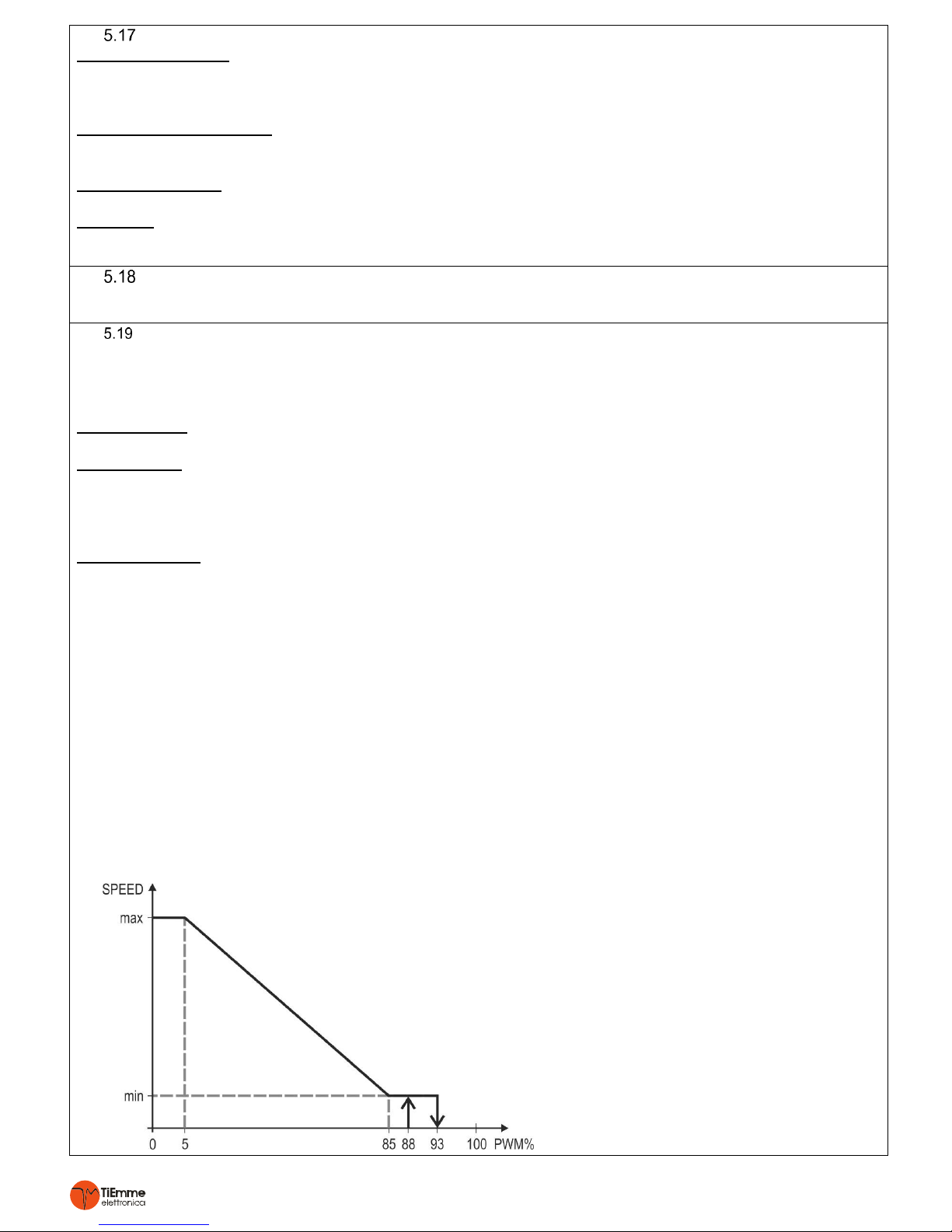

PWM Disabled:

The pumps are controlled exclusively via 230V outputs

PWM Manual:

The PWM duty cycle which determines the speed of the pumps is set with the following parameters:

U06 if PWM1 with Heating profile (Fireplace Pump)

U16 if PWM2 with Heating profile (Heating Pump)

U26 if PWM2 with Solar profile (Solar manifold Pump)

Automatic PWM:

In relation to the type of pump, the PWM duty cycle is calculated on the basis of the temperature of the fireplace probe,

high Buffer Tank probe or solar manifold probe and can vary within the following ranges:

Between U01 and U02 if PWM1 with Heating profile (es. 85 ÷ 5 %)

Between U11 and U12 if PWM2 with Heating profile (es. 85÷ 5 %)

Between U21 and U22 if PWM2 with Solar profile (es. 15 ÷ 95 %)

Fireplace Pump speed change is enabled within the following temperature range:

Between A01 and A01+A80 in heating management (ex. if A01=35°C, A80=20°C then range: 35 ÷ 55 °C)

Between A01 and A01+A81 in DHW management (ex. if A01=35°C, A81=15°C then range: 35 ÷ 50 °C)

Heating Pump Speed change is enabled within the following temperature range:

Between A04 and A04+A82 (ex. if A04=45°C, A82=20°C then range: 45 ÷ 65 °C)

Or if the Buffer Tank is present

Between A17 and A17+A82 (ex. if A17=45°C, A82=20°C then range: 45 ÷ 65 °C)

Solar manifold Pump speed change is enabled within the following temperature range:

Between A33 and A33+A82 (ex. if A33=45°C, A82=20°C then range: 45 ÷ 65 °C)

The profile of the PWM signal, Heating or Solar, is selected automatically on the basis of the pump that needs to be

managed and the following are the profiles of the pumps that can be found on the market:

HEATING Profile

On the basis of this profile it is advisable to set

the PWM duty cycle parameters as shown

below:

PWM1

Vmin: U01 <= 85%

Vmax: U02 >= 5%

PWM2

Vmin: U11 <= 85%

Vmax: U12 >= 5%

Pag. 5/15

0CAR6IN019124_Manual_GLH110_Rev_0.3

SOLAR Profile

On the basis of this profile it is advisable to set

the PWM duty cycle parameters as shown

below:

PWM2

Vmin: U01 >= 15%

Vmax: U02 <= 95%

In the following conditions the PWM can be setup with the following parameters:

ANTIFREEZE: U03, U13 e U23

SAFETY: U04, U14 e U24

ANTISEIZE: U05, U15 e U25

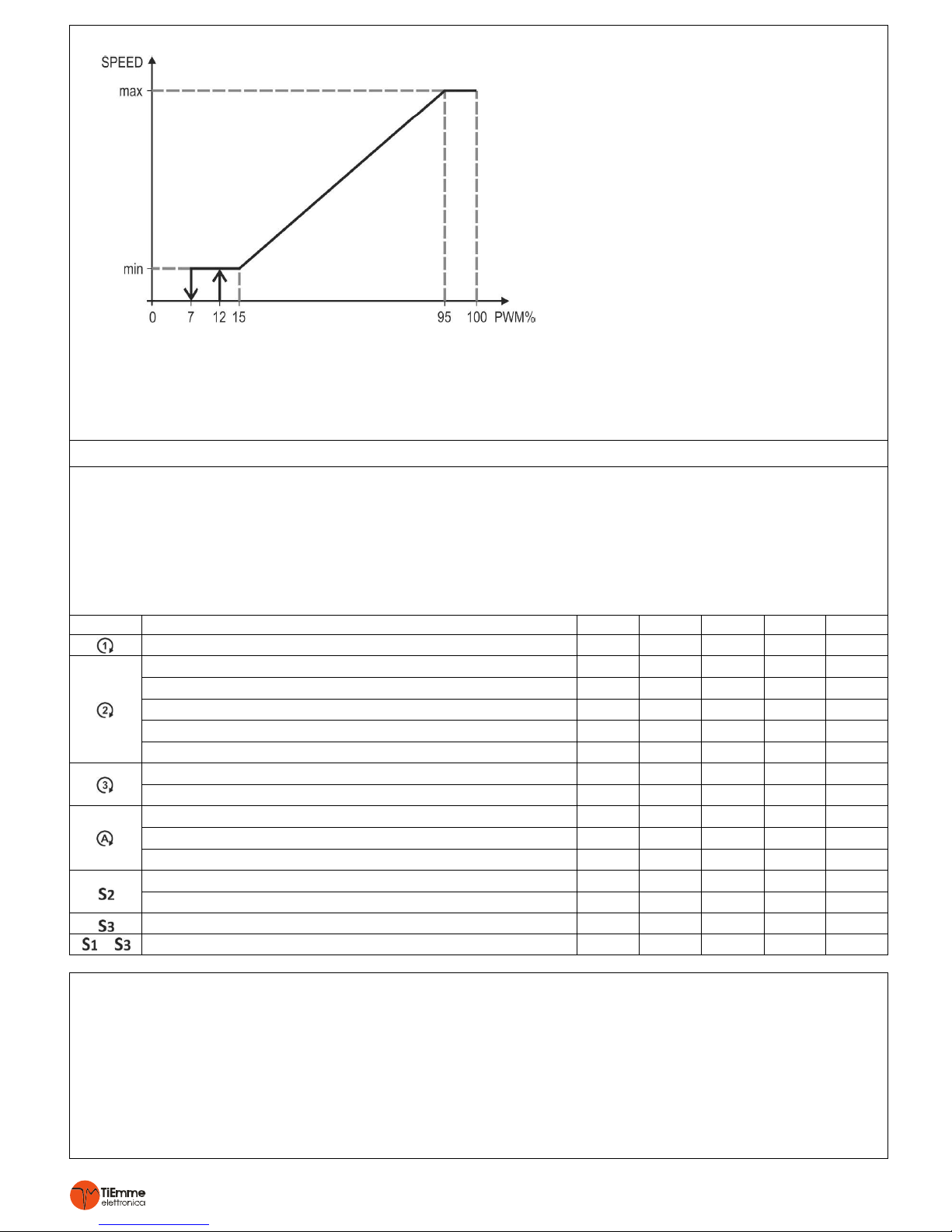

6. MENU’

6.1 MAIN MENU

To enter into the main menu simply click on K2 key:

Keys K3 and K4 are used to scroll through various parameters signaled by the corresponding flashing led.

Press K2 key to modify (the led remains solid while value flashes).

Keys K3 and K4 are used to change the parameter value.

Press K2 to save the new value.

Press K1 to exit without saving.

Press K1 again to exit the Menu or wait 30 seconds.

Led

Description

Code

Min

Set

Max

U.M.

Low Temp. Thermostat for Fireplace Pump

A01

20

35

90

[°C]

Diverting Valve Thermostat on Fireplace probe

A02

20

45

90

[°C]

Heating Pump Thermostat on Fireplace probe

A04

20

45

90

[°C]

Heating Pump Thermostat on high Buffer Tank probe

A17

20

45

90

[°C]

Service Thermostat on Fireplace probe

A09

20

50

90

[°C]

Valve Thermostat for DHW priority

A24

20

70

90

[°C]

Thermostat to activate Integration on Fireplace probe

A03

20

45

90

[°C]

Thermostat Integration Buffer Tank on High Buffer Tank Probe

A19

20

45

90

[°C]

Heating Pump Thermostat on Fireplace probe

A04

20

45

90

[°C]

Service Thermostat on Fireplace probe

A09

20

50

90

[°C]

Heating Pump Thermostat on High Buffer Tank probe

A17

20

45

90

[°C]

DHW Boiler Thermostat on S2

A18

20

50

90

[°C]

Buffer Comfort Thermostat on High Buffer Tank probe

A20

20

60

90

[°C]

Ambient Probe Thermostat on S3

b01 5 20

50

[°C]

+

Differential Thermostat Fireplace-Boiler DHW/Buffer

d01 5 20

2

[°C]

6.2 INSTALLER MENU

Only QUALIFIED PERSONEL must access this MENU , because if the set parameters are changed this could make the

product completely unsuitable for the application.

To enter into the INSTALLER MENU press at the same time K2 and K4 keys for 3 seconds.

To scroll through the parameter codes use K3 and K4 keys.

To view the value of a parameter and to enter modification mode press K2 key.

To modify the value press K3 and K4 keys.

To save the new value press K2 key.

To exit without saving press K1 key.

Press K1 again to exit the Menu or wait 60 seconds.

Loading...

Loading...