Page 1

Hubs and Spindles

Owner’s Manual

Page 2

Super Lube Wheel Hub/Spindle Operating Instructions

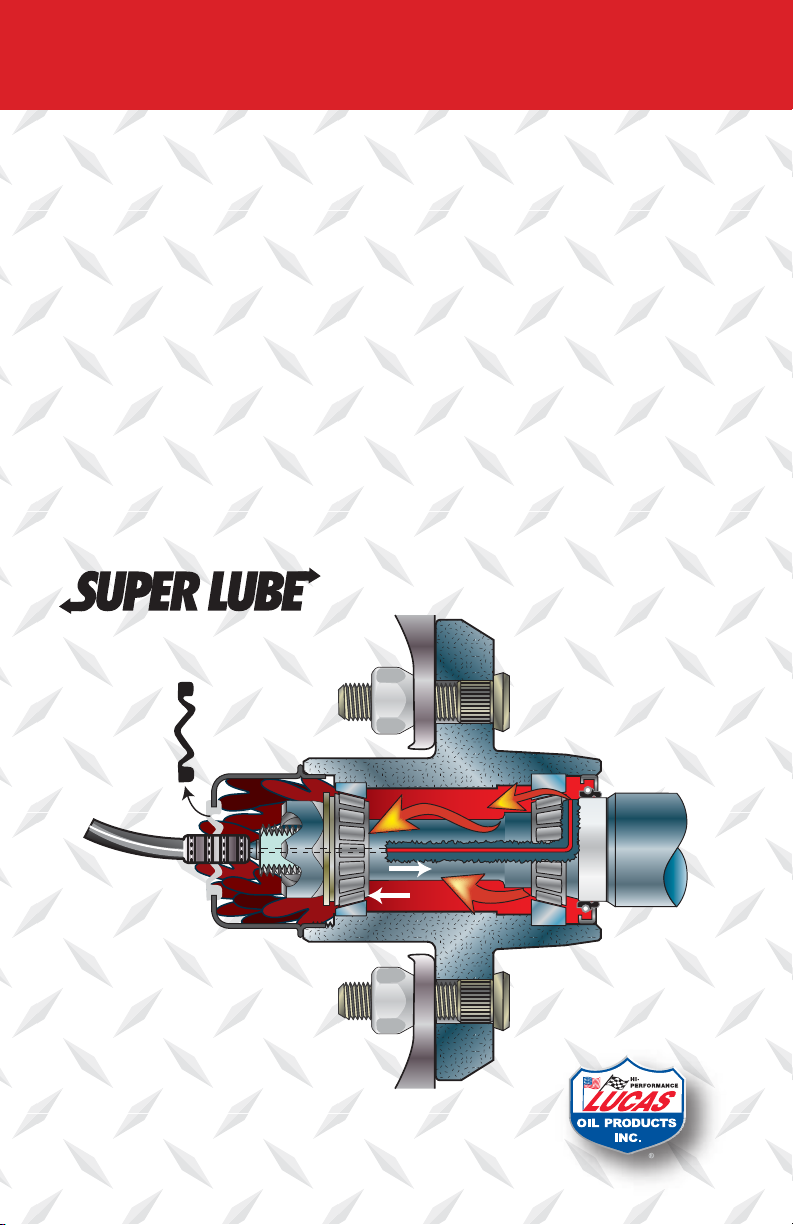

Simple is best. Especially when it comes to wheel bearing maintenance. That’s why

Tie Down introduced Super Lube, the hub bearing lubrication system that provides

continuous protection with a fast and easy maintenance program.

Attach a conventional grease gun to the grease fitting. As new grease is pumped into

the system, the old grease is forced out of the bearings and into the dust cap

reservoir. Remove all excess grease from the dust cap reservoir, replace the

rubber expansion access cap and repacking is completed, with out the expense

of a service center.

Your trailer is equipped with Tie Down Engineerings wheel hubs/spindles. The hubs

are pre-greased with Lucas “Red n‘ Tacky” grease and assembled at the factory. The

hubs should not require any initial adjustments. The hub uses tapered roller bearing

cones and cups. This configuration requires a minimal amount of end play that is

provided at the time of assembly. Use Lucas “Red n’ Tacky” grease or a quality

lithium based marine grease.

“Spindle”

Rubber

Plug

New

Grease In

Old

Grease

Out

In

Out

Hub Grease

Manufactured

by:

Page 3

Super Lube “Spindle” Lubrication

1. Remove the rubber plug from the grease (hub) cap.

2. Use a standard grease gun onto the grease fitting located at the end of the

spindle, making sure the grease gun nozzle is engaged on the fitting tightly.

3. Pump grease into the fitting, while slowly turning the wheel. Grease will flow out

of the hub around the spindle.

4. When the grease appears to be the new clean grease, remove the grease gun

and wipe off any excess grease.

5. Replace the rubber plug in the cap.

Rubber

Plug

New

Grease In

Old

Grease

Out

Out

Hub Grease

Manufactured

by:

“Hub”

Super Lube “Hub” Lubrication

1. Remove the rubber plug from the grease (hub) cap.

2. Use a standard grease gun pressed onto the grease fitting located behind

wheel/hub, making sure the grease gun nozzle is engaged on the fitting tightly.

3. Pump grease into the fitting, while slowly turning the wheel. Grease will flow out

of the hub around the spindle.

4. When the grease appears to be the new clean grease, remove the grease gun

and wipe off any excess grease.

5. Replace the rubber plug in the cap.

Page 4

Removal/Remounting for the Super Lube Hub

Removing the hub for inspection or maintenance should be done in a safe location

away from moving vehicles.

1. Elevate the trailer using the manufacturers instructions. Always use jack stands

or other solid supports. Do not depend on a jack to support the trailer. Block

wheels to keep trailer from rolling.

2. Remove the tire/wheel assembly.

3. Remove the grease cap from the hub by prying around the edge of the cap.

4. Remove the cotter pin if equipped or bend the locking tang washer to the

“free” position.

5. Remove the spindle nut in a counterclockwise direction and remove the

spindle washer.

6. Remove the hub from the spindle. Be careful not to allow bearings to fall out

of the hub.

7. Clean bearing and cup surfaces

8. To re-install, coat bearings with Lucas Oil grease before re-installing.

9. Install bearings and place hub on spindle in reverse order as listed above.

Rotate the hub while applying approximately 50 ft. lbs. of torque to the

spindle nut. This translates into a full hand pressure load with a 12” long

wrench. This “seats” the bearings.

10. Loosen the spindle nut to remove the torque applied. DO NOT ROTATE THE HUB.

11. Tighten the spindle nut until snug, backing off only enough to line up the

cotter pin with the hole in the spindle.

12. Bend the cotter pin into place

13. Replace grease/hub cap. Remove the Super Lube rubber plug.

14. LOAD HUB WITH LUCAS OIL GREASE USING THE INSTRUCTIONS

FOR ADDING OR CHANGING GREASE.

VERY IMPORTANT: RE-CHECK LUG NUTS AFTER 25 MILES OF USE.

Super Lube Hubs Are

Pre-greased With

Lucas “Red n’ Tacky” Grease

TIE DOWN ENGINEERING

255 Villanova Drive SW, Atlanta, GA 30336

(404) 344-0000 • Fax (404) 349-0401

www.tiedown.com

© 2013 TIE DOWN ENGINEERING, ALL RIGHTS RESERVED

Instruction Manual #08077

081814,C718

Loading...

Loading...