Page 1

Sleeve/Swage Instructions

Danger

READ ALL INSTRUCTIONS BEFORE USING THIS PRODUCT. Sleeves for forming loops and laps on cable are specially

made from high grade aluminum alloy, and must be applied only with a special tool, designed for this special purpose,

properly adjusted, used in strict accordance with the tool instructions. Use of any other tool or method, such as a vise or

hammer blow, will result in an unsafe and inferior loop or laps on the cable, highly probable to pull loose and fail, causing

severe property damage and serious injury or death.

WARNING

• Failure to use cable sleeves correctly may cause loads to slip or fail.

• Failure to read, understand, and follow these instruction may cause death or serious injury.

• Read and understand these instructions before using cable sleeves.

• Prepare cable and sleeves only as instructed.

• Do not use with vinyl jacked cable. Vinyl must be removed from cable surfaces where sleeves are applied.

• Use with Champ Cable. Be certain to match with corresponding cable size and dash number.

WARNING: Vinyl must be removed from cable surfaces where sleeves are applied.

INSTRUCTIONS

1. To form a loop, insert enough cable through one side of the sleeve to form a large loop, turning back

the cut end and inserting into opposite side of sleeve. Use two sleeves if desired.

2. Pull back on cable until desired loop size is obtained. It is recommended to use thimble in loop.

3. Allow 1/8" of cable cut end to extend beyond end of sleeve. Make sure this does not slip back into

sleeve while swaging.

4. Referencing the dash number to determine correct groove, insert the sleeve into the swaging tool jaws

at a right angle, making sure the sleeve is aligned in the jaw grooves.

5. With one end of the sleeve projecting slightly beyond the tool jaws, now apply pressure, completely

closing the swaging tool, compressing the sleeve, performing the required number of tool

compression, rotate the sleeve 180 degrees, each time slightly re-positioning the jaws along the sleeve,

performing the required number of tool compressions.

6. Gauge each compressed area making certain the gauge slips freely onto the sleeve. If this does not

occur, cut the cable and discard the improperly compressed sleeve.

7. Adjust swaging tool inaccordance with the swaging tool instructions, and begin again.

8. Two cables of the same size only may be joined together as shown below, referred to as a lap,

following steps 3 through 7. TWO SLEEVES ARE REQUIRED.

Cable Dash No of tool SAFE

Size No. Compressions WORKING LOAD

1/16" 2 2 100 lbs.

3/16" 3 2 184 lbs.

1/8" 4 3 340 lbs.

5/32" 5 3 600 lbs.

3/16" 6 4 840 lbs.

The "Safe Working Load Limit" (rated capacity) is the

maximum load in pounds which should ever be

applied to the product in service, even when the

product is new, and when the load is uniformly

applied in direct tension to the product.

RATING

WARNING: DO NOT EXCEED SAFE WORKING LOAD LIMITS.

TIE DOWN ENGINEERING, Inc. cannot be responsible for failure as a result of careless or ignorant use.

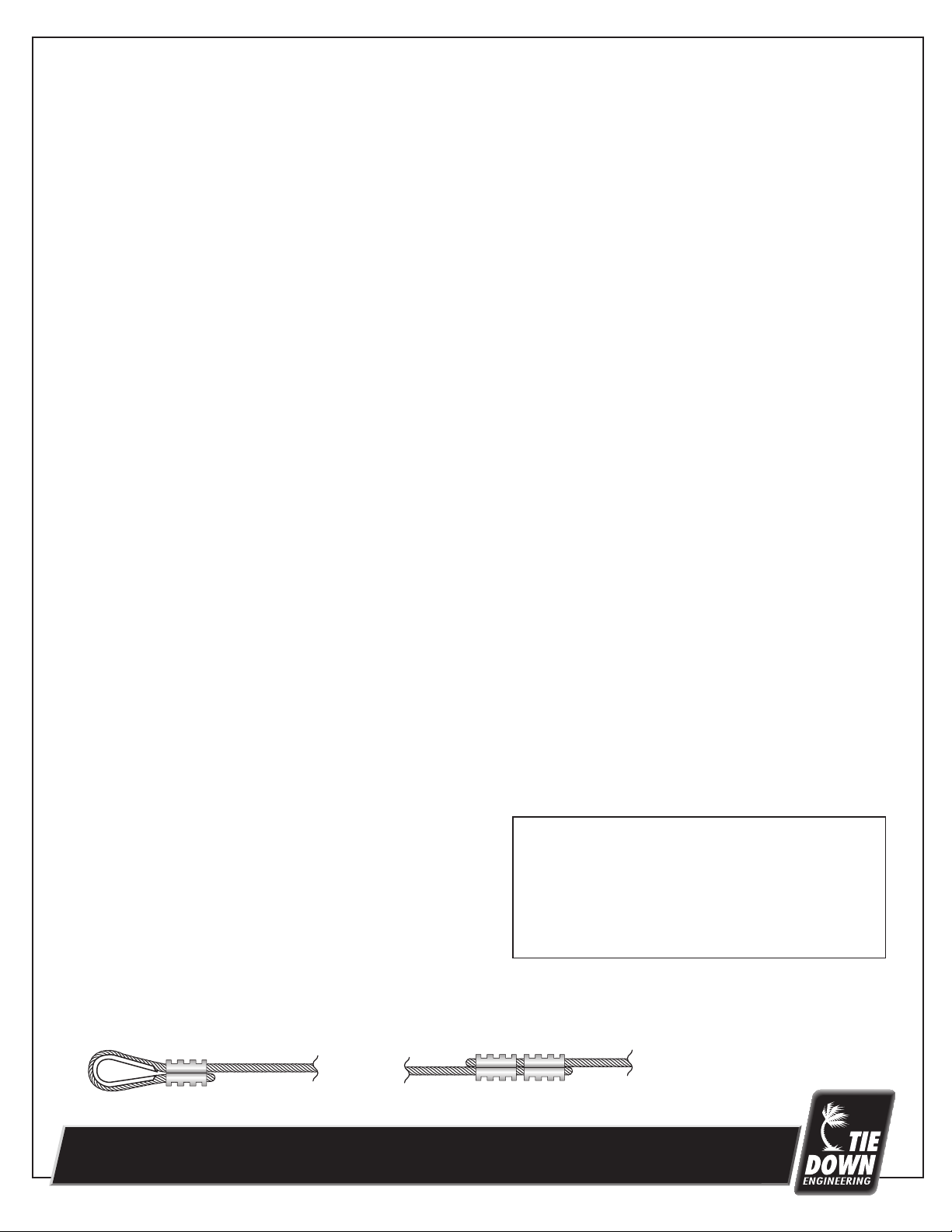

Proper Lap Swage

Proper Loop Swage

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

061312,F574

Loading...

Loading...