Page 1

Technical Service Bulletin

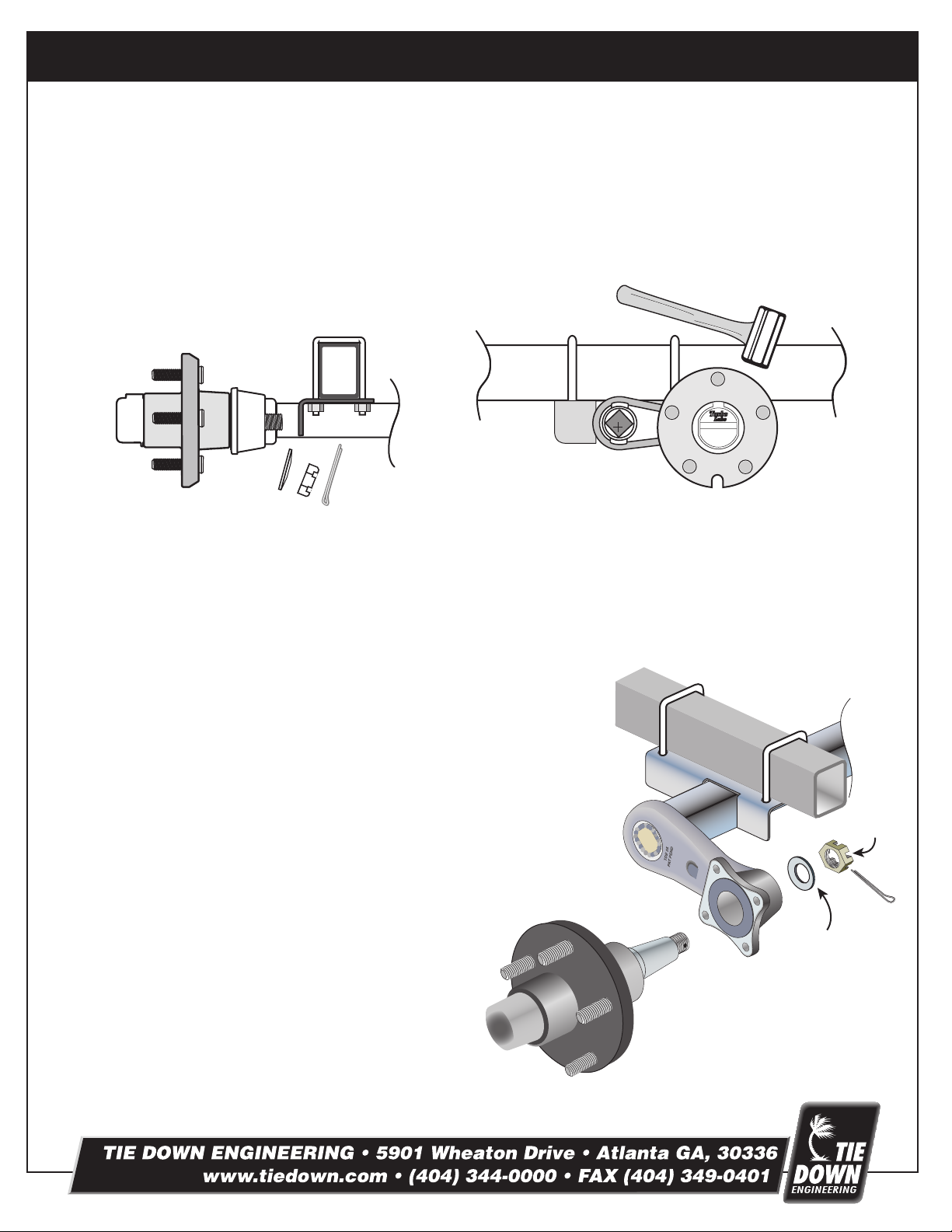

Replacing End Units on Eliminator Torsion axles.

The purpose of this dealer bulletin is the proper way to replace a spindle/hub assembly from an Eliminator torsion axle. In

many cases, repairs created by axle damage or warranty repair for leaking seals can be accomplished much easier and

faster by replacing the entire assembly rather than replacing a seal or hub.

1. Remove tire/rim for hub

TDE 35

PAT PEND

2 & 3, Remove cotter pin,

castel nut and washer

1. Remove tire/rim from the hub. Place all hardware removed onto a clean area for reuse.

4. Loosen torsion arm by tapping

the hub with a rubber hammer

2. Using a pair of pliers, remove the SS cotter pin from the rear of the spindle, on the back side of

the torsion arm.

3. Remove the castle nut and washer from the spindle.

4. The hub/spindle assembly can be loosened from the torsion

arm by using a malleable or hard rubber hammer by

tapping around the edge of the hub. If the torsion arm

is exposed on the backside, you can place the castle

nut back on the spindle so that it is even with the

end of the spindle, and then hitting the rear of

the spindle to force the spindle loose.

5. Remove the hub/spindle assemble.

6. Coat the conical portion of the spindle with an

“anti-seize” compound before inserting into the

torsion arm. Place the washer and castle nut on

the spindle. Tighten castle nut to 100 ft. lbs.

Insert SS cotter pin and bend in place.

7. Replace tire/wheel assembly and tighten lug

nuts to manufacturers specifications.

Conical

Washer

Castle Nut

Cotter

Pin

052605,B806

Loading...

Loading...