Tie Down Manufactured Housing Anchor User Manual

Manufactured Housing

Anchor Installation

Information

(Updated: January 2009)

Provided by

TIE DOWN ENGINEERING

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

010809,d12

INSTALLATION INFORMATION

Anchor Installation

1. Position anchor at a slight back angle (10˚) so that when

fully installed, the anchor head will be inside any skirting or

side wall.

2. Install anchor to +/- 2/3 depth, then install stabilizer

vertically, within 3”-4” of anchor shaft, parallel to

wall of home.

3. Fully drive anchor, attach strap (see proper strap

tensioning), and pretension strap to pull anchor

rod against the stabilizer plate.

Manual Anchor Installation

1. Dig holes to a depth of 2/3 of the anchor length. Install

anchor with rod or length of pipe for leverage.

2. Replace earth in hole after anchor/plate is installed at

full depth. Pack dirt with a tamping rod every 6 inches of fill.

3. Testing may be required in loose soil conditions to check that

anchor has proper holding power.

1a

1b

Important:

Anchor must be installed to full depth. Anchor head must

be at ground level or at the top of the stabilizer plate

which is fully installed to ground level.

2a

2b 2c

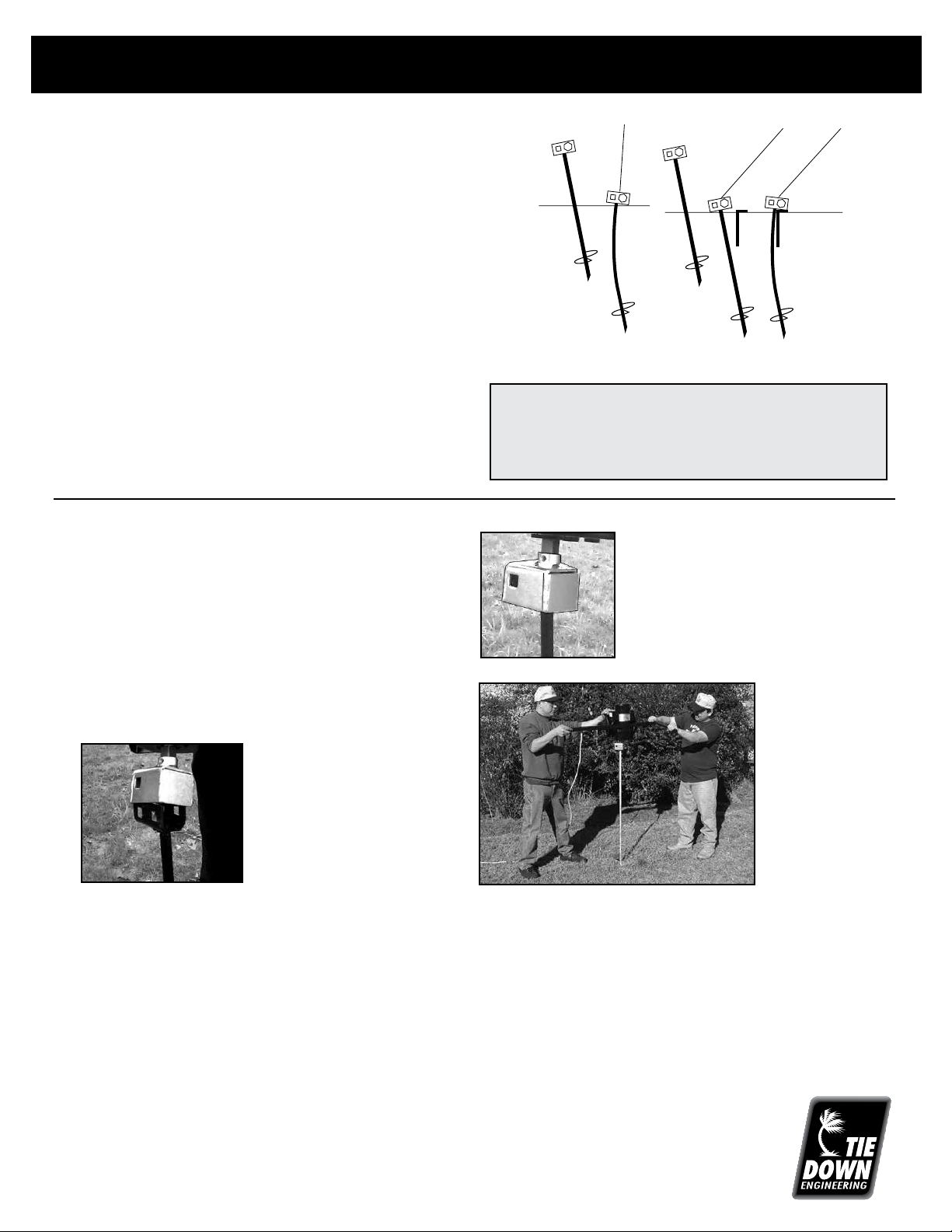

Electric Drive Machine Installation

Operating Instructions:

1. Attach adapter head to shaft of the EDM motor,

tighten set screw.

2. Place extension handle in the end of the EDM if needed.

3. Place anchor head into adapter, line up anchor

shaft with EDM shaft, for easier installation.

4. Flip forward/reverse switch to forward.

5. Place anchor tip in location where anchor is to be buried.

Hold on/off switch to install.

EDM Adapter Head.

Electric Drive Machine Cautions and Warnings:

• Before installation of any ground anchor, determine that the ground anchors to be installed will not be near any underground

electrical cables, phone lines, water lines, sewer pipes, or gas lines. Failure to do so may result in serious injury or death

• The EDM is designed for operation by two people.

• Do not allow the EDM to be wedged against the home or other solid objects, when operating the EDM.

• Electrical cord must be a minimum of 14-2 wire size w/ground up to 25 ft. of cord. Longer cords must be 12-2 wire size w/ground or lower.

• Never operate the EDM in wet or rainy conditions.

• Frayed or patched electrical cords should never be used with the EDM.

• Care should be taken to keep electrical cords away from anchors.

• Never operate drive machine without the GFI power cord. Damage to motor and injury to operator can r esult from

by passing the GFI.

• The GFI will shut off power when a ground fault is detected. The GFI will also shut off power when

it detects low voltage improper amps required to drive the motor. Many times the problem will be

the use of an extension cord that is too long or is too light in gage.

Adapter fits anchors

and Soil Test Probe

Two man operation

makes easy work of

anchor installation

~ 2 ~

010809,d12

INSTALLATION INFORMATION

Tamp Soil

In 6" increment

s

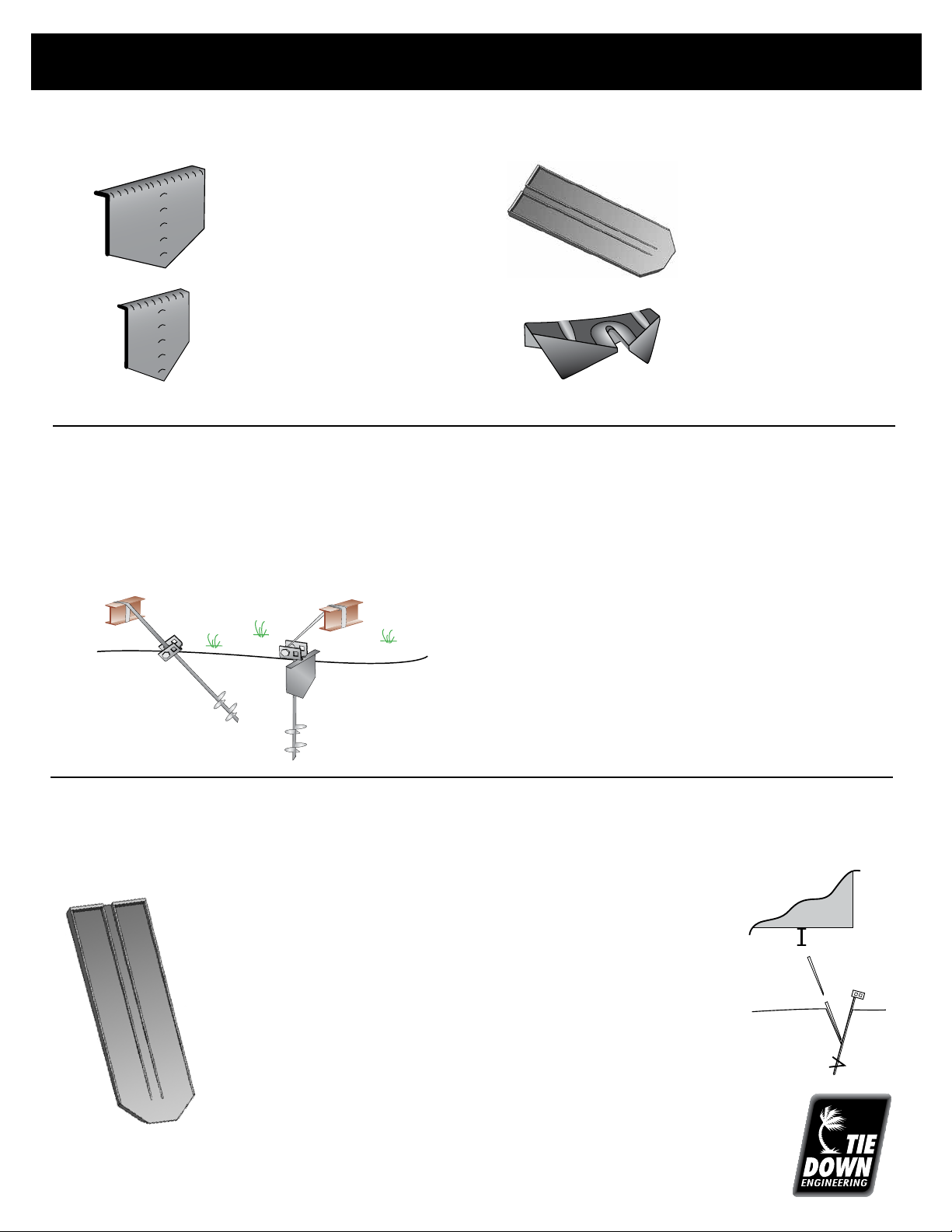

Stabilization Plates

Class 4B Stabilizer Plate

17-1/2” x 13-1/2”

Galvanized: Part # 59286

12” wide Stabilizer Plate

Black Paint: Part #59292

Galvanized: Part #59292G

Anchor Stabilizer

In order to prevent lateral movement of manufactured homes

subjected to high wind loads and to comply with HUD’s Wind

Zone I, II, & III requirements, all lateral frame ties must be

attached to a properly stabilized ground anchor. (Two approved

methods illustrated below.)

Ground Level

"In Line" Installed:

Minimum anchor

length of 36"

ABS Stabilizer Plate

10” x 24”

Part # 59293

Quik-Set Stabilizer Plate

Black Paint: Part #59291

Galvanized: #59291G

Stabilizer Plate Installation

1. Refer to any and all local, state and federal regulations.

2. Use the Soil Test Probe at the anchor location in order to

match soil class with the anchor/stabilizer.. (See Page 11)

3. Partially install anchor to allow 14” to 16” remaining above

ground level.

4. Utilizing oversized hammer, vertically install stabilizer plate,

nesting anchor rod in between formed channels on outside

of stabilizer plate (between anchor and frame).

5. Fully install anchor so that head is at the surface of the soil

(1” tolerance, if necessary) and pretension anchor until

touching stabilizer plate.

ABS Stabilizer Plate

Part # 59293

1. Determine correct anchor to be used with the home installation and

use the manufacturer instruction for installation, following all

safety precautions.

2. Using an electric drive machine, install anchor to a depth of

approximately 28 inches at a slight back angle.

3. Dig out an 8” wide area so that the ABS stabilizer will be placed on

undisturbed soil at a 10 to 15 degree angle toward the home. The

bottom center of the plate should be touching the anchor rod.

4. Complete the installation of the ground anchor until the bottom of the

anchor head is flush with the ground.

5. Attach proper strap and tension strap until anchor head is flush against

the ABS plate and strap is tight. At this point, soil should be tamped

into the vacant area behind the anchor rod, tamping approximately 6”

and repeating until the vacant area is flush with the surface of the

surrounding ground.

Place ABS

Plate Here

~ 3 ~

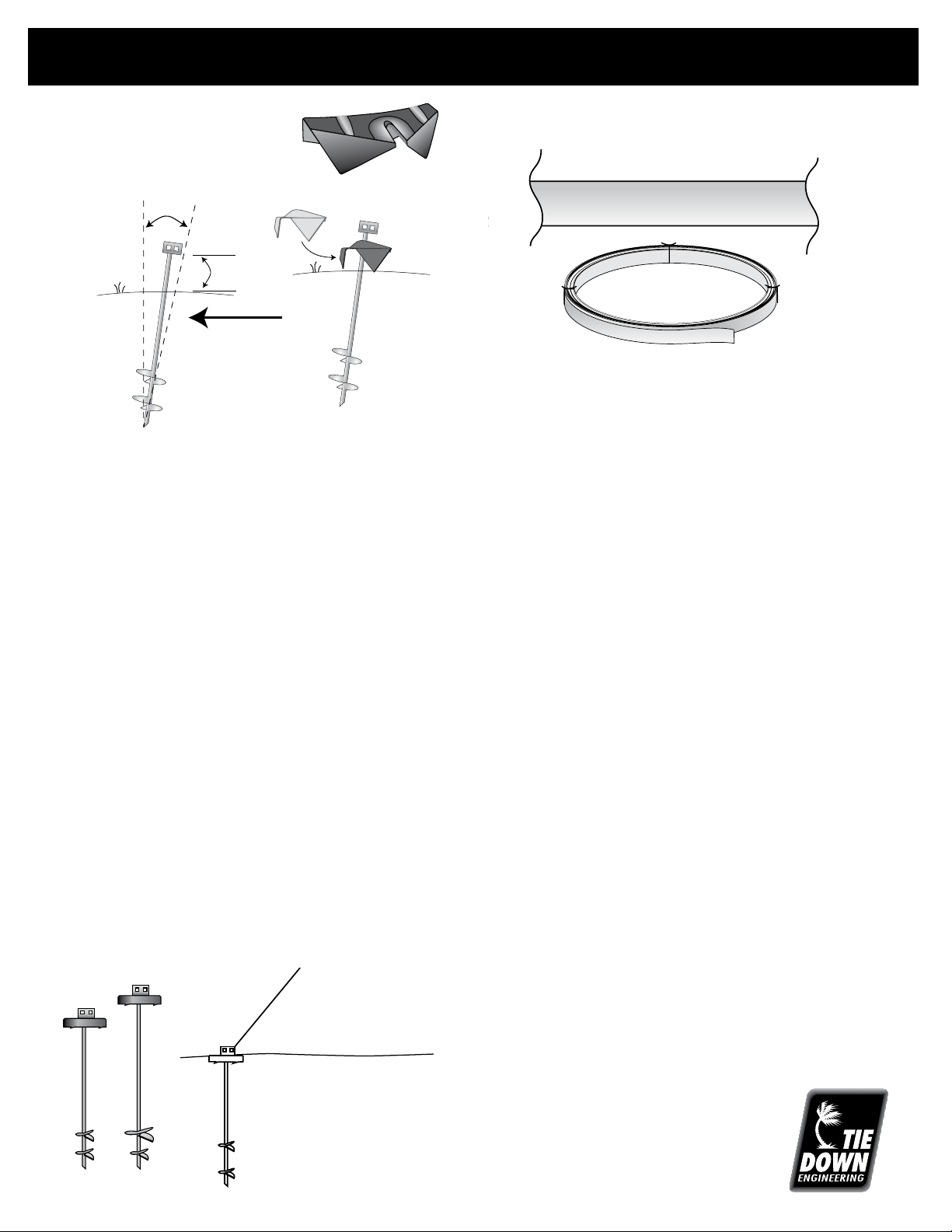

INSTALLATION INFORMATION

NOTE:

Quik-Set Stabilizer

Installation

Black Paint Part: #59291

Galvanized Part: #59291G

10˚-15˚

5" to 6"

Home

Direction

1. Install ground anchor inside skirting line at a slight back

angle of 10˚ - 15˚.

2. While anchor head is still 5” to 6” above ground level: install

Quik Set stabilization plate around anchor shaft, referring to

the direction imprinted on the top of the plate.

3. Install ground anchor until Quik-Set plate is fully set.

Hammering may be required at the corners to insure plate

being fully driven.

4. Install strap(s) to anchor head and pretension according to

approved methods. Maximum anchor load in conjunction

with the “Quik-Set” device is 4725 lbs. (ultimate).

Deep Set Anchor/Stabilizer Instructions

1. Confirm soil classification using standard torque probe at

36” below ground surface, make certain readings meet or

exceed 350 in lbs. (Class 2 and 3 soils) at the depths of

12” & 36”.

2. Clear loose vegetation where anchor will be installed.

Install anchor vertically to its’ full depth. Stabilizer plate at

the top of anchor must be fully embedded into soil.

3. Pull strap past anchor head and cut strap so that there is

12” to 15” of strap to wrap onto anchor bolt insuring 4 to 5

wraps minimum.

4. Insert strap into anchor bolt flush with opposite side of bolt.

Tighten bolt/strap until tight. Secure anchor bolt with nut.

45˚ maximum (if angle

exceeds 45˚ attach

additional strap tie to

opposite frame)

Certified Galvanized Strapping*

DOUBLE THICK G-60

GALVANIZED PROTECTION

The steel strapping by Tie Down Engineering for the

manufactured housing industry has been tested to, and

conforms to, the HUD Code as referenced in Part 3280 of the

Manufactured Home Construction and Safety Standards and

Part 3285 of the installation standards; Final Rule.

3280.306(f), 3285.402(b2) Anchoring Equipment – Load

Resistance. Anchoring equipment shall be capable of resisting an

allowable working load equal to or exceeding 3,150 pounds and

shall be capable of withstanding a 50 percent overload (4,725

pounds total) without failure of either the anchoring

equipment or the attachment point on the manufactured home.

3280.306(g), 3285.402(b2) Anchoring Equipment –

Weatherization. Anchoring equipment exposed to weather-

ing shall have a resistance to weather deterioration at least

equivalent to that provided by a coating of zinc on steel of not

less than 0.30 ounces per square foot of surface coated, and in

accordance with the following:

(1) Slit or cut edges of zinc-coated steel strapping do not

need to be zinc coated.

(2) Type 1, Finish B, Grade 1 steel strapping, 1-1/4 inches

wide and 0.035 inches in thickness, certified by a

registered professional engineer or architect as

conforming with ASTM Standard Specification

D3953-91, Standard Specification for Strapping,

Flat Steel, and Seals.

The above specification of a minimum coating of 0.30 ounces

per square foot equates to a designation of “G30.” Tie Down

strapping exceeds this minimum requirement with a coating of

0.60 (G60) or 1.20 (G120) ounces as per above. Similarly, Tie

Down strapping exceeds, in testing, the minimum load requirements of 3,150 pounds design (working) load and 4,725

pounds (ultimate) overload.

* Available with G60 or G20 galvanized coatings.

TIE DOWN ENGINEERING

CERTIFIED TO

ANSI A225.1 ASTM D3953-97

Wrap strap onto tension

bolt (minimum 4-5 turns)

010809,d12

~ 4 ~

Loading...

Loading...