Page 1

Parts list • Instruction guide • Warnings

Please read carefully before assembling and using product.

Jet Rail XL

Part Number 27377

Tools required for assembly

Hammer

9/16” Wrench

3/4” Wrench

Ratchet

9/16” Socket

3/4” Socket

3/8” Socket

Phillips Screwdriver

Instructions #15369, Version: 102308,A514

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

Page 2

Part # Stock # Description Qty.

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

1 26617 Jet Rail Frame Tube (72” long, 3x4) 1

2 26606 Jet Rail Carriage (20” long) 1

3 26615 Jet Rail Rear Deck Mount 1

4 26608 Jet Rail Front Deck Mount 1

4a 26618 Front Brace 1

5 26614 Jet Rail Deck (47” long) 1

6 26610 Winch Mount Extension Tube (42” long, 2x3) 1

7 26611 Winch Mount 1

8 26612 Bow Stop 1

9 26613 Winch Mount Tube 1

10 44816 Carpeted Bunk, 5’ 2

10a 48667 Bunk Slicks 2

11 17057 Keel Pad 6” Long 3

12 50460JR Winch Strap, 15’ 1

13 17135 Brake Winch, 1200 lb. 1

HARDWARE

14 45245 Bushing, 4” 7

15 45246 Bushing, 1” 2

16 45251 Winch Strap Roller 1

17 44610 1/2” x 5-1/2” Rod 5

18 86116 Swivel Bracket 6

19 17085 2” End Cap 4

20 10605 Safety Locking Pin 1

21 BBPELLNUT500 1/2” Pal nut 12

21a BBPELLNUT625 5/8” Pal Nut 2

22 10602 Hair Cotter Pin 1

23 17052 Spool Roller 4” 2

24 10904 Self-Tapping Screw, #10 x 3/4” 6

25 10903 Self-Tapping Screw, #14 x 1-1/2” 12

26 84472z 1/2” U-Bolt 2

27 10538 3/8” x 1” Hex Head Bolt 11

28 BBB3750400 3/8” x 4” Hex Head Bolt 7

Note: Three of the 3/8” x 4” hex head bolts are grade 5 bolts, used on page 4, section 5.

29 10537 3/8” x 3” Winch Bolt 1

30 10938 1/2” x 5-1/2” Hex Head Bolt 2

31 10936 1/2” x 7” Hex Head Bolt 1

32 10937 1/2” x 8-1/2” Hex Head Bolt 2

33 10645 1/2” Nyloc Nut 9

34 10627 3/8” Nyloc Nut 25

35 10504 1/2” Nylon Flat Washer 28

36 B58-15208 Nylon Bushing 17

37 10573 1/2” Washers 4

38 44540 Shackle Plate 1

39 10804 3/8” x 1” Carriage Bolt 3

40 10630 Stainless Steel Screws 8

42 44611 1/2” x 6-1/2” rod 1

43 45247 1/2” ID x 5.5” Bushing 1

Page 3

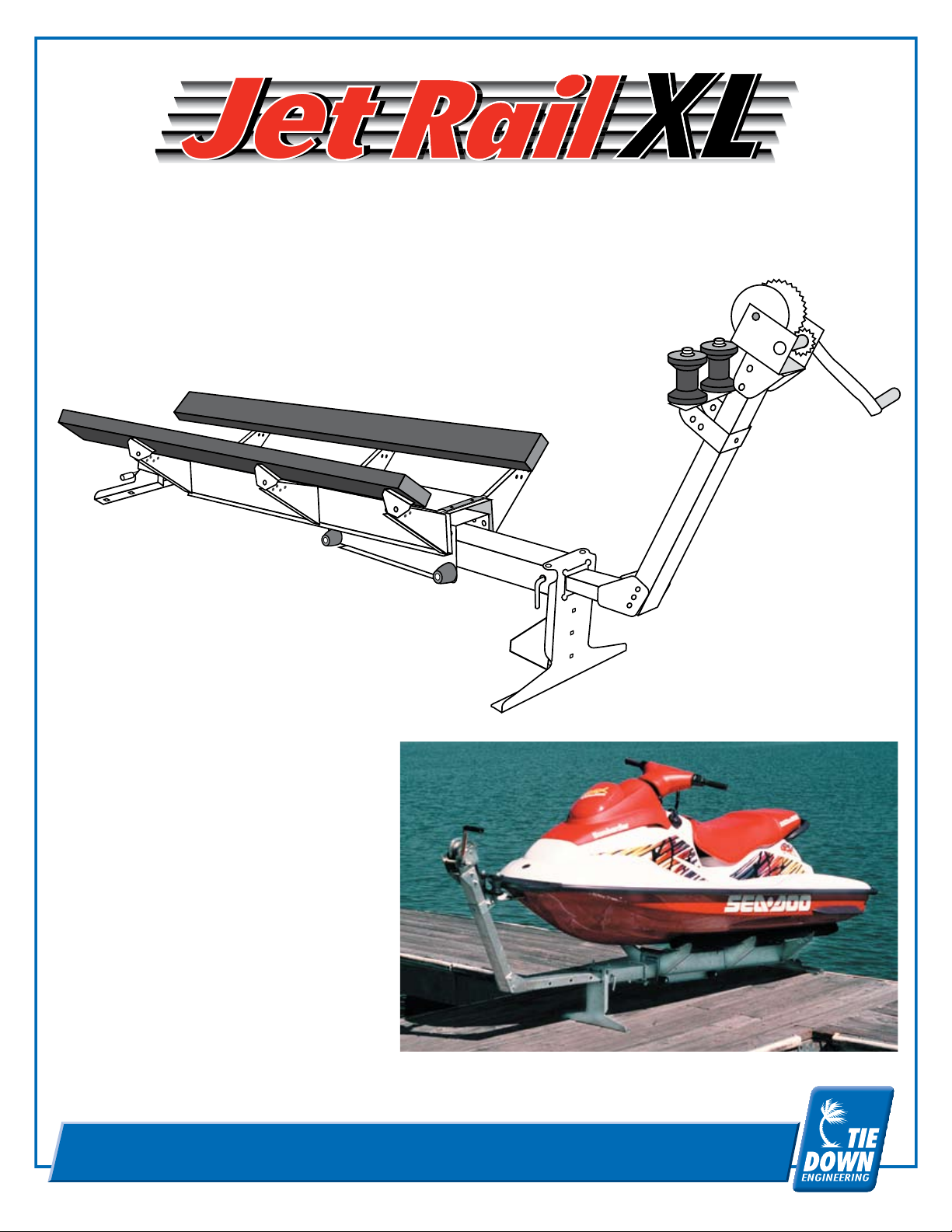

1. Assembly of Carriage

32

33

19

35

36

35

19

14

32

36

35

21

17

33

19

35

36

35

19

14

32

36

35

21

17

3

15

21

27

34

33

19

35

36

35

19

14

Step One

Roller assemblies are installed in the top five holes of the Jet Rail

Carriage. Hammer a pal nut on one end of each of the five rods. Lay

carriage upside down as shown in picture 1. In “bottom” five holes,

slide the rods through one side of the carriage. Install 2 - 1/2” nylon

washers, the 4” nylon bushing, 2 - short nylon bushings over the 4”

bushing, 2 nylon washers, through the other side of the carriage, hammer pal nut on end of rod. Repeat for the remaining four rods. (Picture

2 shows bushing/washer line up)

Parts required for this step.

# Stk. # Description Qty.

2 26606 Jet Rail Carriage 1

17 44610 1/2” x 5-1/2” Rod 5

21 BBBPELNUT500 Pal nut 10

36 B58-15208 Nylon Bushing 10

14 45245 Bushing, 4” 5

35 10504 1/2” Nylon Flat Washer 20

Step Two

Install roller assemblies in two “upper” holes as shown in Picture 1.

Use 8” bolt as shown in picture 2a to assemble the roller assemblies.

Picture 1 shows finished assembly.

Picture 1

Picture 2

Parts required for this step.

# Stk. # Description Qty.

36 B58-15208 Nylon Bushing 4

14 45245 Bushing, 4” 2

35 10504 1/2” Nylon Flat Washer 8

19 17085 2” End Cap 4

32 10937 1/2” x 8-1/2” Hex Head Bolt 2

33 10645 1/2” Nyloc Nut 2

2. Attach carriage to frame tube

Place carriage onto 72” frame tube, so that the swivel tube on carriage

points to the rear. Rear of frame tube has two holes together on bottom

to attach rear deck mount as shown in Picture 4. (Front of tube has a

single hole on each side of the tube as shown in Picture 6).

Picture 2a

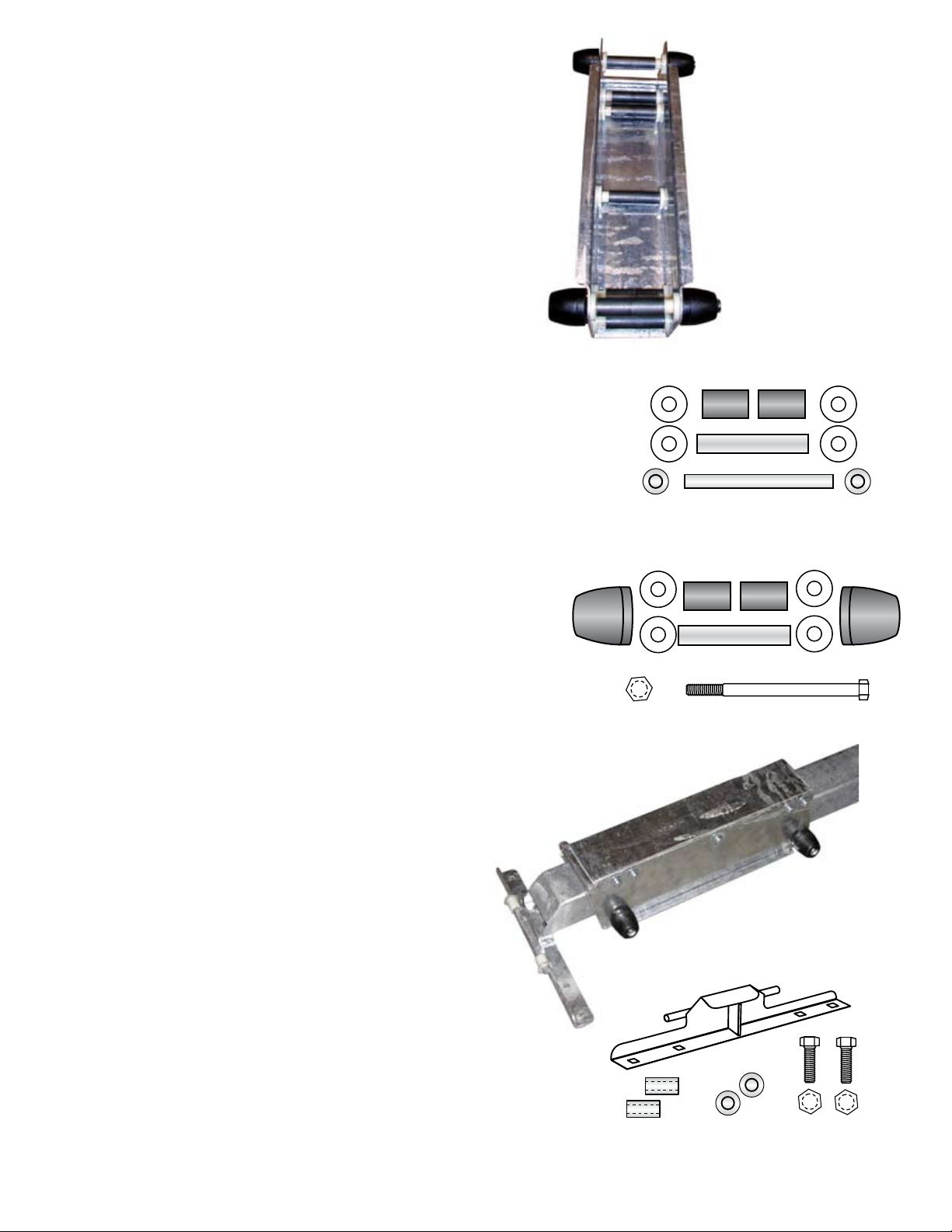

3. Assemble & Attach Rear Deck Mount

Slide 1” bushings over rods on rear deck mount (Picture 4).

Secure with 5/8” pal nuts. Use a hammer to attach pal nuts to rods.

Using the two 3/8” x 1” hex head bolts and nyloc nuts, attach the rear

deck mount to the Jet Rail Frame Tube as shown in Picture 3.

Picture 3

Parts required for this step.

Picture 4

# Stk. # Description Qty.

3 26615 Rear Deck Mount 1

1 26617 Frame Tube 1

15 45246 1” Bushings 2

21A BBPELNUT625 5/8” Pal nuts 2

27 10538 3/8”x1” Hex Head Bolts 2

34 10627 3/8” Nyloc Nuts 2

TIE DOWN ENGINEERING 3 www.tiedown.com

Page 4

1

33/nut

26

37/washer

4

4a

36

35

21

17

21

27

34

4. Attach Front Deck Mount to Frame Tube

Attach front deck mount to front of frame tube (front of tube has a

single hole on each side of the tube,Picture 6). Front deck mount is

mounted flush against end of the frame tube using the U-bolt, metal

washers and nyloc nuts as shown in Picture 5.

Parts required for this step.

# Stk. # Description Qty.

4 26608 Front Deck Mount 1

1 26617 Jet Rail Frame Tube 1

26 84472Z 1/2” U-Bolt 1

33 10645 1/2” Nyloc Nut 2

37 10573 1/2” Flat Washers 2

4A. Attach Brace to Front Mount

Mount using 3 - 3/8”x1” carriage bolts or 3/8”x1” hex head bolts.

Brace must be positioned so that it is level with the bottom of the front

brace. As shown in picture 5

Parts required for this step.

# Stk. # Description Qty.

4a 26618 Front brace 1

39 10804 Carriage bolt 3

34 10627 3/8” Nyloc nut 3

6-Winch Mount Ext. Tube

Picture 6

Picture 5

9- Winch Mount Tube

NOTE: At this time, place frame tube/carriage with deck mounts

attached, in the general area where you are planning to attach the Jet

Rail to your dock. Make sure there is room for the watercraft to be

winched onto the Jet Rail without obstructions.

5. Attach Winch Mount Extension Tube to Winch Mount Tube.

Slide Extension Tube into front of Jet Rail Frame Tube. Cut-out in front

deck mount matches the end that slides into the tube. Bolt winch

mount tube to extension tube using the 3- 3/8” x 4” Grade 5 hex head

bolts and nyloc nuts (Picture 7a).

Parts required for this step.

# Stk. # Description Qty.

1 26617 Jet Rail Frame Tube 1

6 26610 Winch Mount Ext. Tube 1

9 26613 Winch Mount Tube 1

28 BBB3750400 3/8” x 4” Hex Head Bolts 3

34 10627 3/8” Nyloc Nut 3

5a. Assemble Rollers to Jet Rail Deck

Insert a 6-3/4” x 1/2” roller shaft, and two 1/2” pal nuts, place the

5-1/2” long plastic bushings with three nylon bushings (Picture 7b).

(NOTE: some hardware kits substitute a 1/2”x6-1/2” hex head bolt

& nut for the roller shaft.)

6. Attach Jet Rail Deck To Carriage Assembly

Lift Jet Rail deck assembly over carriage. Align carriage tube hole with

pivot hole in deck. (Picture 8) Install 1/2” x 7” bolt with 1/2” nyloc nut.

(Front of deck has two holes on each side) End with rollers goes to the

rear/water side.

# Stk. # Description Qty.

5 26614 Jet Rail Deck Assembly 1

2 26606 Jet Rail Carriage Assembly 1

31 10936 1/2” x 7 “ Hex Bolt 1

33 10645 1/2” Nyloc Nut 1

Parts required for this step.

Picture 7b

Picture 7a

31

Markings on Grade 5

Hex Head Bolts

5

Picture 8

TIE DOWN ENGINEERING 4 www.tiedown.com

Page 5

7. Attach Bunks to Jet Rail Deck

Bunk

Bunk Slick

Attach one swivel bracket on each “corner” of the Jet Rail Deck as

shown in Picture 9. There are several holes in which to adjust the width

of your bunk boards to fit your watercraft. We recommend that you

start with the outer most hole and adjust inward if necessary. Tighten

bolts enough to allow adjustment of the bunks on your watercraft.

Attach bunk boards to the swivel brackets on each side of the deck,

with two 1-1/4” screws at each bracket. For easier installation predrill holes with a 1/8” bit. Bunks should be mounted with one inch of

overhang on the front swivel brackets. After deciding on the permanent

placement of the bunks (picture 10), tighten all four bolts holding the

swivel brackets to the deck.

Parts required for this step.

# Stk. # Description Qty.

5 26614 Jet Rail Deck 1

18 86116 Swivel Bracket 6

27 10538 3/8” x 1” Hex Bolt 6

34 10627 3/8” Nyloc Nut 6

10 44816 5’ Carpeted Bunk 2

25 10903 1-1/2 0” Screw 12

7a. Attach Keel Pads

Attach a keel pad in the center of each end of the Jet Rail Deck, with

the 3/4” long screws (picture 11).

18

Picture 9

Parts required for this step.

# Stk. # Description Qty.

11 17057 Keel Pad, 6” long 3

24 10904 Self Tapping Screw, 3/4” 6

8. Optional Bunk Slick Installation

Bunk slicks provide a slippery surface that makes loading your water

craft easier. Due to the slippery nature of the bunks slicks, Do Not add

additional bunk slicks to the bunk boards, use only the bunk slicks

provided.

Place the bunk slick so that it’s flush with the rear end of the bunk

board. Secure with the stainless screws provided (pict 11a). Make sure

the screws arre completly set and below the bunk slick upper surface.

If the screws are left higher, damage to the water craft hull could hap-

pen.

Parts required for this step.

# Stk. # Description Qty.

10a 48667 Bunk Slicks 2

40 10630 Stainless Screws 8

Picture 10

Position bunk boards evenly spaced to fit on

smooth surface of the hull.

Picture 11a

TIE DOWN ENGINEERING 5 www.tiedown.com

Picture 11

Page 6

9. Assemble Bow Stop

9

8

33

23

3

0

37

Attach 4 inch spool rollers to the bow stop using two hex head bolts,

5” x 1/2”, two flat steel washers and two 1/2” nyloc nuts. The washers

are used on top of the rollers. (Picture 12)

Slide the bow stop over the upright winch mount tube, rubber rollers

in the “up” position. Using the holes in the bow stop plate next to the

winch mount tube,place a 4 inch x 3/8” bolt and nyloc nut. Tighten bolt

so that the bow stop is about 12 inches below the top of the tube. You

will adjust this later to fit your watercraft.

Parts required for this step.

# Stk. # Description Qty.

8 26612 Bow Stop 1

23 17052 Spool Rollers, 4” 2

30 10938 1/2” x 5-1/2” Hex Head Bolt 2

33 10645 1/2” Nyloc Nut 2

37 10573 1/2” Flat Washers 2

28 BBB3750400 3/8” x 4” Hex Head Bolt 1

34 10627 3/8” Nyloc Nut 1

10. Attach Winch & Winch Mount to Winch Mount Tube

Attach winch mount to winch using three - 3/8” x 1” hex bolts and

nyloc nuts (picture 13). Attach winch mount & winch, to tube as shown

in picture 14, using two - 3/8” x 4” hex head bolts. (Picture 14)

Parts required for this step.

# Stk. # Description Qty.

13 17135 Winch 1

28 BBB3750400 3/8” x 4” Hex Head Bolt 2

34 10627 3/8” Nyloc Nut 2

7 26611 Winch Mount 1

27 10538 3/8” x 1” Hex Head Bolt 3

34 10627 3/8” Nyloc Nut 3

Picture 12

12

13

34

7

27

11. Assemble Winch Handle

See “NOTE” on page 8 for this step

Parts required for this step.

# Stk. # Description Qty.

26 84472Z 1/2” U-bolt 1

33 10645 1/2” Nyloc Nut 2

38 44540 Shackle Plate 1

Picture 13

Picture 14

TIE DOWN ENGINEERING 6 www.tiedown.com

Page 7

Attach the winch handle to the winch. Turn clockwise until handle turns

gears. Place spring in handle shaft, followed by the nyloc nut supplied

with the winch. Tighten nut.

12. Attach Winch Strap to Winch

Using a three inch x 1/4” hex head bolt, washer & nyloc nut, attach the

winch strap to the winch as shown in pictures 15 & 16. Wind the winch

strap onto the winch using the winch handle.

Pull length of strap down side of tube, through the bow stop. Use a

3/8” x 4” bolt and the 3” x 3/4” strap roller in the remaining holes in

the bow stop. Winch strap should be between the mounting bolt closest to the winch mount tube and the 3” x 3/4” roller. Picture 17

Parts required for this step.

# Stk. # Description Qty.

12 50460JR 15” Winch Strap 1

16 45251 3” x 3/4” Strap Roller 1

28 BBB37500400 3/8” x 4” Hex Head Bolt 1

34 10627 3/8” Nyloc Nut 1

13 17135 Winch 1

Included above (13) 1/4” x 3” Hex Head Bolt 1

Included above (13) 1/4” Nyloc Nut 1

Included above (13) 1/4” washer 1

Picture 15

NOTE: If your PWC does not have a bow eye and uses a hole in the

front deck, do not thread the winch strap through the bow stop. Use

the strap direct from winch to PWC using the “soft hook” provided. Also

see page 8 of these instructions.

Mount Jet Rail with lag bolts or bolts through the dock floor. Check

for obstructions under the dock before drilling any holes. Rear mount

should be close to edge of dock where you will be hoisting the

Watercraft.

Picture 16

Picture 17

TIE DOWN ENGINEERING 7 www.tiedown.com

Page 8

Instructions For Use

To load watercraft onto Jet Rail, slide deck back to rear of

Jet Rail. Tilt deck into water. Jet Rail extends to the length

of the watercraft. Use pin provided to lock winch tube in

place before using lift. Also make sure the bow stop is

tightened approximately at bow level. This may need to

be adjusted to fit your watercraft. Pull enough strap out to

reach watercraft. Hook to watercraft and turn winch handle

to pull watercraft out of water. Winch until watercraft

meets bow stop.

To unload watercraft, slowly release strap by turning winch

handle counter clockwise. Push watercraft backwards

allowing Jet Rail deck to roll and tilt into the water. Jet Rail

may be shortened by pulling pin and sliding extension tube

into frame tube when not used to store watercraft.

NOTE: TO BALANCE WATERCRAFT ON JET RAIL, an extra

U-bolt and plate is included to use as a stop for the

rolling carriage on the frame tube. Some watercraft will not

slide on the bunk rails as it is being winched up,

causing an unbalanced mount. The U-bolt can be mounted

on the frame tube to stop the carriage from moving

forward, if your watercraft experiences this imbalance. A

starting point would be 22 inches from the front

mounting plate. Adjust accordingly after using your Jet

Rail. SEE PICTURE ON PAGE 6.

A “soft hook” (1” x 18” nylon strap stitched in a loop) is

provided for watercraft that do not have a bow eye . Place

the “soft hook” through the front “deck hole” and place

the hook from the winch strap through the end of the loop

to winch watercraft on and off of the Jet Rail. If you use

this method, you may use the winch strap straight from the

winch to the PWC and not go through the bow stop

WARNING

JET RAIL WILL FALL INTO WATER IF NOT BOLTED TO

THE DOCK WHEN WINCHING ON OR OFF A WATERCRAFT.

THE LIFT IS NOT DESIGNED FOR LIFTING HUMANS.

DO NOT ALLOW ANYONE TO SIT OR STAND ON

WATERCRAFT WHEN IT IS BEING PUT ON OR OFF THE

LIFT OR IS BEING STORED ON THE JET RAIL.

TIE DOWN ENGINEERING 8 www.tiedown.com

Page 9

The Jet Rail is an all galvanized steel PWC lift

Closed = 7'-1"

Extended = 10'-8"

6'

22"

5'

36"

designed for easy one person “launch and load”.

The small foot print under the ski allows easy walk

around while the watercraft is stored on the dock

or seawall. The 1200 lb. brake winch and mount

adjusts to any size watercraft and slides inside the

lift when not in use, saving even more precious

dock space. Carpeted bunk boards and all hardware

are included. All you add is your PWC!

Model: Jet Rail XL Part Number: 27377

Capacities

Weight of PWC: 950 lb (or capacity of

dock, whichever is less)

Length of PWC: 10 ‘-2”

• One person launch n’ load

• Easy assembly

• Nothing else to buy

• Small “footprint”, takes up

less room on dock

NOTE: Gas and oil capacities must be added to

the “Factory Dry Weight” to get a true weight of

your PWC. Example dry wt. 600 lbs, 15 gallons

gas + 1.6 gallons of oil = 16.6 x 8 lbs= 132.8 bls.

600 lbs + 132.8 lbs. = 732.8 lbs.

Specifications

(3/21/2003)

Weight without PWC 175 lbs

Length with extension in 7’ 1”

Length with full extension 10’ 8”

Width without PWC 22”

Width of dock mounting hdw. 18”

Length between dock mounting hdw 6’

Winch capacity 1200 lbs

Winch strap length 15’

Height without PWC at winch 36”

Height without PWC at bunk rail 19”

Maximum space between edge

of dock and rear dock mount 2.5”

Bunk Length 5’

Max. ht. from water to dock mount 22”

061103,514

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

Assembly Time: Approximately 90 minutes

Tools required: Hammer, 9/16” Wrench,

3/4” Wrench, Ratchet, 9/16” Socket, 3/4”

Socket, 3/8” Socket, Phillips Screw Driver

The Jet Rail was not designed for alterations

such as electric winches, roller bunks or

modifications to the existing parts

Shipping Boxes:

Box 1: Dimensions 43” x 50” x 7-1/4”,

wt. 73 lbs.

Box 2: Dimensions 8-1/2” x 4-1/2” x 74”

wt. 50 lbs.

Box 3: Dimensions 22-1/4” x 8” x 48-1/4”,

wt. 58 lbs.

Page 10

13

102308,516

7

6

23

# Part # Description Qty.

1 26617 Jet Rail Frame Tube 1

2 26606 Jet Rail Carriage 1

3 26615 Jet Rail Rear Deck Mount 1

4 26608 Jet Rail Front Deck Mount 1

4a 26618 Front Brace 1

5 26614 Jet Rail Deck (47" long) 1

6 26613 Winch Mount Extension Tube 1

7 26611 Winch Mount 1

8

9

18

1

4

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

11

4a

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

2

10

10

18

5

3

# Part # Description Qty.

8 26612 Bow Stop 1

9 26610 Winch Mount Tube 1

10 44816 Carpeted Bunk, 5' 2

10a 48667 Bunk Slicks 2

11 17057 Keel Pad 6" Long 3

13 17135 Brake Winch, 1200 lb. 1

18 86116 Swivel Bracket 6

23 27052 Spool Roller 4" 2

Loading...

Loading...