Page 1

“G5”

Stainless Steel Disc

Brake Owner’s Manual

Page 2

Stainless Steel Disc Brake Instructions

The advantages disc brakes have over drum brakes include:

• Greater fade resistance • Self-cleaning

• Self-adjusting • Less maintenance

• Greater stopping power • Easy visual inspection without removing any parts

Tie Down Engineering G5 Stainless Steel disc brakes with aluminum caliper have

many exclusive features not found on automotive type brakes modified for trailer use.

Please visit our web site www.tiedown.com for further information on features and benefits.

G5 Stainless Steel disc brakes are designed to activate when the vehicle’s brakes

are applied. As the vehicle stops or slows, the momentum of the trailer pushes

forward developing pressure in the actuator (master cylinder), used to apply pressure to

the brakes.

Operating Information

Read and understand the towing instructions for your tow vehicle, trailer and actuator.

Check your trailer frequently for any leaks in the hydraulic system, which includes the

actuator, brake lines and brakes.

If the trailer is used in salt water, it is highly recommended that you rinse off the

brakes with fresh water after each use to reduce the effects of saltwater corrosion and

salt build-up (residue).

Your trailer should tow easily. Disc brakes operate at a higher temperature than

drum brakes. This is normal and is very similar to the way disc brakes operate on your

vehicle. If for any reason your trailer does not tow easily or wants to veer to one side,

stop and investigate immediately and solve the problem.

Towing a trailer (even a trailer with brakes) puts an added load on the tow vehicle’s

handling and braking capabilities. Do not follow to closely; you will need extra distance

to maneuver and to stop.

Towing downhill puts added stress on both the tow vehicle and the trailer. Slow

down before you start on an incline and maintain a controlled downhill speed with

repeated application of brakes followed by a cooling period when brakes are not

applied. It is very important to start off with a slow speed and maintain it rather than

trying to slow down from a higher speed. Should you feel the brakes on the trailer or

tow vehicle are running hot or showing signs of fade, stop immediately on the side of

the road and allow the brakes to cool before resuming your trip.

Page 3

Stainless Steel Disc Brake Instructions

Should you feel that the tow vehicle brakes or trailer brakes are not working

properly; have the tow vehicle and trailer brake system inspected. Make sure your

trailer’s GVWR is within the tow vehicles capacity. If your trailer has multiple axles,

verify that the GVWR of the trailer does not exceed the capacity of the brakes, which

is 3750 lbs on 10-inch (5 lug) brakes and 6000 lbs on 12-inch (6 lug) brakes, per axle.

Some states require brakes on all axles.

Check with your state laws and the state laws of where you will be using your trailer

prior to towing.

After long trips or downhill towing, your brakes could become very hot and it is a

good idea to let them cool down before submerging in cold water. The change in

temperature of very hot brakes submerged in water creates additional stress on the

parts and could cause damage to your brakes.

Pads must be replaced when the friction material is 3/32°± or less. Original Tie

Down Engineering brake pads for the G5 Stainless Steel disc brakes have a ceramic

pad material and a stainless steel backing plate that aids in corrosion resistance.

Disc brakes require the use of flexible brake lines attached to the caliper. The calipers

“float” and should not be used with metal brake lines that will restrict movement and

cause overheating or brake failure. If you are replacing existing brakes and using the

existing metal brake lines, either replace metal brake lines with a Tie Down Engineering

brake line kit or add flexible extensions to the metal lines to connect to the disc brake

calipers.

Disc brakes require the use of an actuator designed for disc brakes. If you are

replacing drum brakes, you must also change the actuator to a disc brake model. Using

a drum brake actuator with disc brakes will cause overheating, loss of braking power

and possible brake failure.

Use DOT 3 brake fluid only. DOT 3 can be labeled as “synthetic”.

DO NOT USE SILICONE BASED BRAKE FLUID.

When backing a trailer with disc brakes, you must have a lockout device on the

actuator or preferably an electrically operated solenoid to stop brake pressure to the

disc brakes. The solenoid is mounted at the rear of the actuator, between the master

cylinder and brake line. The solenoid has a wire that is connected to your back up

lights. When the tow vehicle transmission is put in reverse, the reverse light voltage

activates the solenoid. This will either stop or redirect the brake fluid to keep the brakes

from operating while in reverse.

2

Page 4

Caliper

Mounting

Bracket

Slider Pin

“G5” Installation/Replacement Instructions for

9.6” 5-Lug Stainless Steel Disc Brakes

1. Elevate the trailer on a level surface using the trailer manufacturer’s instructions.

Always use jack stands for support. Do not depend on a jack to support the trailer.

Block wheels to keep trailer from rolling.

2. If installation is on a completed trailer, remove tire/wheel.

3. Disc Brakes require the use of flexible brake lines attached to the caliper. The

calipers “float” and should not be used with metal brake lines that will restrict

movement and cause overheating or brake failure. If you are replacing existing

brakes and have metal brake lines, either replace the metal brake lines with a Tie

Down Engineering flexible brake line kit or add flexible extensions to the metal lines

to connect to the disc brake calipers.

4. Remove existing brakes or hubs. Clean spindles with a soft cloth to remove old

grease and containments. Coat the spindle with a light coat of clean oil or grease to

allow a smooth installation of the hub/rotor.

5. Place the G5 hub/rotor on the spindle. Install the washer and castle nut supplied

with your axle, Rotate the hub while tightening the spindle nut to approximately

50 ft lbs. This translates into full hand pressure with a 12” long set of pliers or

12” long wrench.

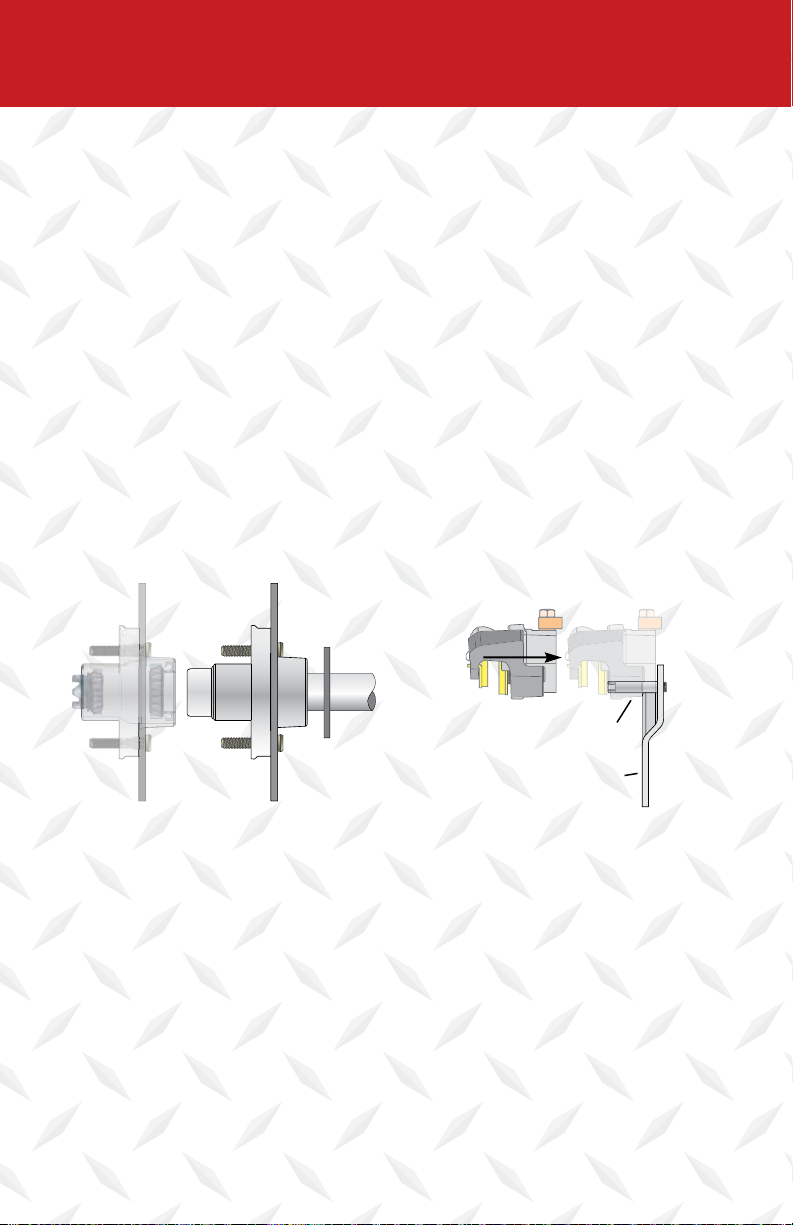

Rotor/Hub

Install rotor/hub on spindle Slide caliper onto the slider pins

6. Loosen the spindle nut to remove the torque, do not rotate hub.

7. Tighten the spindle nut until snug, backing out only to line up the locking tang

washer or cotter pin to the first available position.

8. Bend the locking tang tab or cotter pin in place.

9. Your G5 brakes come with pre-assembled mounting brackets and stainless steel

slider pins. DO NOT REMOVE SLIDER PINS. If the slider pins are removed for any

reason the threads must be cleaned and a new coat of “permanent” Loctite®

must be applied. Clean and apply Loctite® to threads on the mounting plate. Be

careful not to get Loctite® on slider pins or bushings. Torque slider pins

to 40 ft. lbs

3

Caliper

Slider Pin

Mounting

Bracket

Page 5

Bolt & Nyloc Nut

Bolt &

Nyloc Nut

Brake

Flange

Rotor/Hub

Caliper

Caliper

Mounting

Bracket

Slider Pin

Brake Lin

e

Caliper

Mounting

Bracket

Slider Pin

e

Brake Lin

Mounting

Bracket

Brake

Flange

Slide caliper/mounting bracket

10. Slide the assembled caliper onto the slider pins. Attach the assembled mounting

plate to the brake flanges on the axle, after sliding the caliper over the stainless

steel rotor. Preferred positions are 12:00, 9:00 and 3:00 “o-clock” or to the

backside. The brake flange will determine the exact positioning. Use 7/16”x 1-1/4”

zinc hex bolts, lock nuts/washers and torque to 40 ft. lbs.

11. Replace grease cap.

12. Caliper has a swivel inlet connector for the brake hose and a stainless steel bleeder

valve. The bleeder valve should have the top or highest position on the caliper.

Position the swivel brake connector so that the brake line easily connects to the

caliper. Tighten the bolt on the swivel connector to 20 ft. lbs.

13. Connect the flexible brake line to the swivel connector.

14. Repeat this assembly for the other wheels.

15. Install tire/wheel assembly(s), tighten wheel nuts to Trailer manufacturer or wheel

manufacture’s specifications. Test wheel for excessive tightness or excessive play.

Re-tension spindle nut if necessary.

16. Bleed brakes according to the trailer actuator’s instructions.

17. Road test vehicle in a safe place before traveling on main roads in traffic.

over rotor

Bolt mounting bracket to the

brake flange

Bolt &

Nyloc Nut

Brake

Flange

Bolt & Nyloc Nut

VERY IMPORTANT,

RE-CHECK LUG NUTS FOR PROPER TORQUE AFTER 25 MILES OF USE.

4

Page 6

Rotor/Hub

Rotor/Hub

“G5” Installation/Replacement Instructions for

12” 6-Lug Stainless Steel Disc Brakes

1. Elevate the trailer on a level surface using the trailer manufacturer’s instructions.

Always use jack stands for support. Do not depend on a jack to support the trailer.

Block wheels to keep trailer from rolling.

2. If installation is on a completed trailer, remove tire/wheel.

3. Disc Brakes require the use of flexible brake lines attached to the caliper. The

calipers “float” and should not be used with metal brake lines that will restrict

movement and cause overheating or brake failure. If you are replacing existing

brakes and have metal brake lines, either replace the metal brake lines with a Tie

Down Engineering flexible brake line kit or add flexible extensions to the metal lines

to connect to the disc brake calipers.

4. Remove existing brakes or hubs. Clean spindles with a soft cloth to remove old

grease and containments. Coat the spindle with a light coat of clean oil or grease to

allow a smooth installation of the hub/rotor.

Mounting

Bracket

Brake

Flange

Bolts & Nyloc Nuts

Install rotor/hub on spindleBolt the mounting bracket to the

front of the brake flange

5. Attach the mounting bracket to the front of the brake flanges on the axle.

Preferred positions are 12:00, 9:00 and 3:00 “o-clock” or to the backside. The

brake flange will determine the exact positioning. Use 7/16”x 1-1/4”

zinc hex bolts, lock nuts/washers and torque to 40 ft. lbs.

6. Place the G5 hub/rotor on the spindle. Install the washer and castle nut supplied

with your axle, Rotate the hub while tightening the spindle nut to approximately

50 ft lbs. This translates into full hand pressure with a 12” long set of pliers or

12” long wrench.

7. Loosen the spindle nut to remove the torque, do not rotate hub.

8. Tighten the spindle nut until snug, backing out only to line up the locking tang

washer or cotter pin to the first available position.

9. Bend the locking tang tab or set cotter pin in place.

10. Replace dust/grease cap.

5

Page 7

Brake

Flange

Rotor/Hub

Mounting

Bracket

Caliper

Slider Pin

Bolts & Nyloc Nuts

Swivel Brake

Line Connector

Brake Lin

e

Rotor/Hub

e

Swivel Brake

Line Connector

Brake Lin

Slider Pin

Slide the caliper over the

mounting bracket and rotor

11. Slide the G5 caliper over the rotor and between both brake pads

12. Install slider pins. Clean and apply Loctite® to threads on the mounting plate. Be

careful not to get Loctite® on slider pins or bushings. Torque slider pins to 40 ft.

lbs. NOTE: The slider pins come pre-coated with Loctite®. If the slider pins are

installed then REMOVED for any reason the threads must be cleaned and a new coat

of “permanent” Loctite® must be applied.

13. Caliper has a swivel inlet connector for the brake hose and a stainless steel bleeder

valve. The bleeder valve should have the top or highest position on the caliper.

Position the swivel brake connector so that the brake line easily connects to the

caliper. Tighten the bolt on the swivel connector to 20 ft. lbs.

14. Connect the flexible brake line to the swivel connector.

15. Repeat this assembly for the other wheels.

16. Install tire/wheel assembly(s), tighten wheel nuts to Trailer manufacturer or wheel

manufacture’s specifications. Test wheel for excessive tightness or excessive play.

Re-tension spindle nut if necessary.

17. Bleed brakes according to the trailer actuator’s instructions.

18. Road test vehicle in a safe place before traveling on main roads in traffic.

Install and tighten the slider pins

to 40 ft. lbs. Attach brake lines

VERY IMPORTANT,

RE-CHECK LUG NUTS FOR PROPER TORQUE AFTER 25 MILES OF USE.

6

Page 8

Caliper

t

Swivel Brake Line Connector

Slider Pin

Intergal Style Rotor

11.5” & 12”

G5 Stainless

Steel Disc

Brake

Assembly

Stainless

Steel

Rotor

Caliper

Intergal Style Rotor

Mounting

Bracket

Spindle

Nut/Bolt

Brake

Flange

9.6”

G5 Stainless

Steel Disc

Brake

Assembly

Swivel Brake

Line Connector

Slider Pin

Mounting

Bracket

Nut/Bol

Brake

Stainless

Steel

Rotor

7

Flange

Page 9

Replacing Brake Pads

1. Elevate the trailer on a level surface using the trailer manufacturer’s instructions.

Always use jack stands for support. Do not depend on a jack to support the trailer.

Block wheels to keep trailer from rolling.

2. Remove the tire/wheel assembly. Inspect the rotor surface. Check for excessive

wear or grooves that may affect braking. Original rotor thickness is .313 in.;

minimum thickness is .25 in.

3. Inspect brake pads. Minimum thickness is 3/32°±. Pads should be replaced if less

then minimum thickness.

9.6” G5 Brake Pad Replacement

4. Remove the caliper by first removing the four mounting bolts from the mounting

bracket and brake flange. Lift the mounting bracket and caliper assembly off of the

rotor. Be careful to hold the caliper in place so that it does not fall and pull on the

brake hose The inside pad is spring loaded in the caliper piston. Pry this pad out

gently with a flat blade screwdriver. The outside pad is held in place with a center

mounted spring tab. After removing the inside pad, the outside pad can be pulled

from the caliper.

5. Clean the rotor with a brake cleaning spray. Replace brake pads in the reverse

order. For ease of assembly, make sure the piston in the caliper is fully depressed

into the caliper.

6. Re-attach the mounting bracket to the axle brake flange, sliding the caliper over

the rotor. Tighten the four mounting bracket bolts. Torque bolts to 40 lbs.

7. Should you remove the slider pins for any reason, clean the threads on the slider

bolt and mounting plate and apply a coating of Loctite or similar brand of thread

lock. Tighten slider pins to 40 ft lbs. DO NOT REASSEMBLE WITHOUT APPLYING

LOCTITE® TO THE SLIDER PIN THREADS AND THE BACKING PLATE. SLIDER

PINS WITH OUT LOCKTITE® APPLIED COULD BACK OUT AND CAUSE

PERMANENT DAMAGE TO YOUR BRAKES AND TRAILER.

12” G5 Brake Pad Replacement

4. Remove the caliper by first removing the two slider pins from the mounting

bracket. Be careful to hold the caliper in place so that it does not fall and pull

on the brake hose. The inside pad is spring loaded in the caliper piston. Pry this

pad out gently with a flat blade screwdriver. The outside pad is held in place with

a center mounted spring tab. After removing the inside pad, the outside pad can be

pulled from the caliper.

5. Clean the rotor with a brake cleaning spray. Replace brake pads in the reverse

order. For ease of assembly, make sure the piston in the caliper is fully depressed

into the caliper.

6. Re-attach the caliper to the mounting bracket, sliding the caliper over the rotor.

Before installing the slider pins, the threads must be cleaned and a new coat

of “permanent” Loctite® must be applied. Clean and apply Loctite® to threads

on the mounting plate. Be careful not to get Loctite® on slider pins or bushings.

Torque slider pins to 40 ft. lbs.

8

Page 10

17

2D

16

2D

15

14

4A

4B

5

4C

4D

2

2A

2B

2C

3

1

11

13

12

10

9

8

6

3,500# Axle,

9.6” Rotor

Mounting Bracket

9

6

6

6

7

7

6,000# Axle,

11.5” Rotor

Mounting Brackets

6,000# Axle,

12” Rotor

Mounting Brackets

7

Page 11

G5 - Stainless Steel Disc Brake Kits 9.6” 11.5” 12”

# Description 3,500# 6,000# 6,000#

1 Stainless Steel Rotor w/GalvXL Hub 46911X 46914XA 46912X

2 Caliper Assembly 46910A 46910A 46910A

2A Piston 42080AZ 42080AZ 42080AZ

2B Piston Rubber Boot 17472 17472 17472

2C Piston Seal 17447 17447 17447

2D Bronze Busings 10010 10010 10010

3 Ceramic/Stainless Steel Brake Pads 11350/51 11350/51 11350/51

4 Adjustable Banjo Assembly 11341 11341 11341

4A Stainless Steel Banjo Bolt 11338 11338 11338

4B Copper Crush Washer 11339 11339 11339

4C Brass Banjo Fitting 11348 11348 11348

4D O-Ring 17473 17473 17473

5 Stainless Steel Bleed Valve(1) 11246SS 11246SS 11246SS

6 Stainless Steel Slider Pins (2) 12114 12114 12114

7 Mounting Bracket

8 Dust Cap 17094 46494 46494

Super Lube Dust Cap 17093 46495 46495

Super Lube Rubber Grommet 46963 46963 46963

9 Cotter Pin 1/8” x 1-3/4” Zinc 10551 10551 10551

10 Castle Nut - 6 position 10665 10665 10665

10 Castle Nut - 12 position 10634 10634 10634

11 Washer - Flat Spindle 1” 10520 10520 10520

12 Bearing Outer (Cone) 1-1/16” (L44649) 11054 ---- --- Bearing Outer (Cone) 1-1/4” (15123) ---- 11056 11056

13 Cup Outer (Race) 1-1/16” (L44610) 11055 ---- --- Cup Outer (Race) 2-1/2” (15245) ---- 11066 11066

14 Studs 1/2”- 20 x 2.0” OAL 11123 11133 11133

15 Cup Inner (Race) 1-3/8” (L68111) 11061 ---- --- Cup Inner (Race) 3.27” (25520) ---- 11067 11067

16 Bearing Inner (Cone) 1-3/8” (L68149) 11060 ---- --- Bearing Inner (Cone) 1-3/4” (25580) ---- 11064 11064

17 Seal - Triple Lip 1.72” (171255UC) 11088 ---- --- Seal - Triple Lip 2.25 (225255UC) ---- 11086 11086

with slider pins installed

44687GA 70518X 44688GA

Replacement Kits:

Ceramic Brake Pad Kit (Consumer Aftermarket) 81252

Ceramic Brake Pad Kit (OEM) 81114

Caliper Rebuild Kit 46304RB

1 - Piston (#2A)

1 - Piston Rubber Boot (#2B)

1 - Piston Seal (#2C)

2 - Bronze Busings (#2D)

10

Page 12

G5 Stainless Steel Disc

Brake Owners Manual

For up to date instructions visit

www.tiedown.com

TIE DOWN ENGINEERING

255 Villanova Drive S.W. • Atlanta Georgia 30336

(800) 241-1806 • (404) 344-0000 • Fax (404) 349-0401

ISO 9001:2008 Registered Firm

Trade, brand, names and drawings are the intellectual property of

TIE DOWN ENGINEERING. ©2014 TIE DOWN, Inc.

Manual #08134 (Rev. 11-25-14)

112514,c1154

Loading...

Loading...