Page 1

DRUM BRAKE INSTALLATION

Position the trailer on a stable and LEVEL working surface. If possible, leave the tow vehicle hooked to the trailer in

order to limit movement as well as keeping the front end supported and level. If the trailer is not supported on the

tow vehicle, it MUST be blocked directly to the ground at the frame/tongue junction.

UNDER NO CIRCUMSTANCES IS THE TRAILER TO BE SUPPORTED BY THE TONGUE JACK WHILE BEING RAISED AT THE

WHEELS! Block the wheels opposite the side being worked on both front and rear so that the trailer cannot roll.

NOTE: Using an adequate capacity floor or scissors jack, raise the side of the trailer. NOTE: Check under frames for

brake lines BEFORE lifting. DO NOT position jack in areas that may damage brake lines, etc.

NOTE: A. Tandem and tri-axle trailers should be jacked on the frame between the wheels, or directly under the axle

within 8” of the backside of the tire. B. Single axle trailers can be lifted on the frame just behind the axle or directly

under the axle within 8” of the backside of the tire (if lifting at the axle).

CAUTION- always support the trailer with adequate capacity support stands. DO NOT rely on the jack as the only

means of support.

1. Check Brake Mounting Flange

To mount brakes to an axle, the axle must have brake flange welded to the axle. Tie Down’s 10” drum brakes

fit standard 4 hole brake flanges and mount with 7/16” grade 5 or better bolts and lock nuts or lock washers. Our

12” drum brakes fit standard 5 hole brake flanges and mount with 3/8” grade 5 or better bolts and lock nuts or lock

washers. The brake flange connected to the axle must be square and concentric with the axle spindle. If the brake

flange is not properly installed, it will contribute to rapid lining wear and improper brake action. If your axle does

not have flanges pre-welded to the axle, see a qualified technician to weld the plates to your axles. Improper

welding can weaken the axle causing severe problems.

2. Brakes Installation

Brakes are marked as “RIGHT” and “LEFT”. The “LEFT” brake travels on the driver’s side of the trailer. Place

the brake against brake flange with the hydraulic wheel cylinder at the top. Secure with four 7/16” (grade 5) hex

head bolts for the 10” brakes or five 7/16” (grade 5) hex head bolts for the 12” brakes. Use lock washers or lock

nuts w/flat washers on the back side of the flange. Torque to 30 ft. lbs.

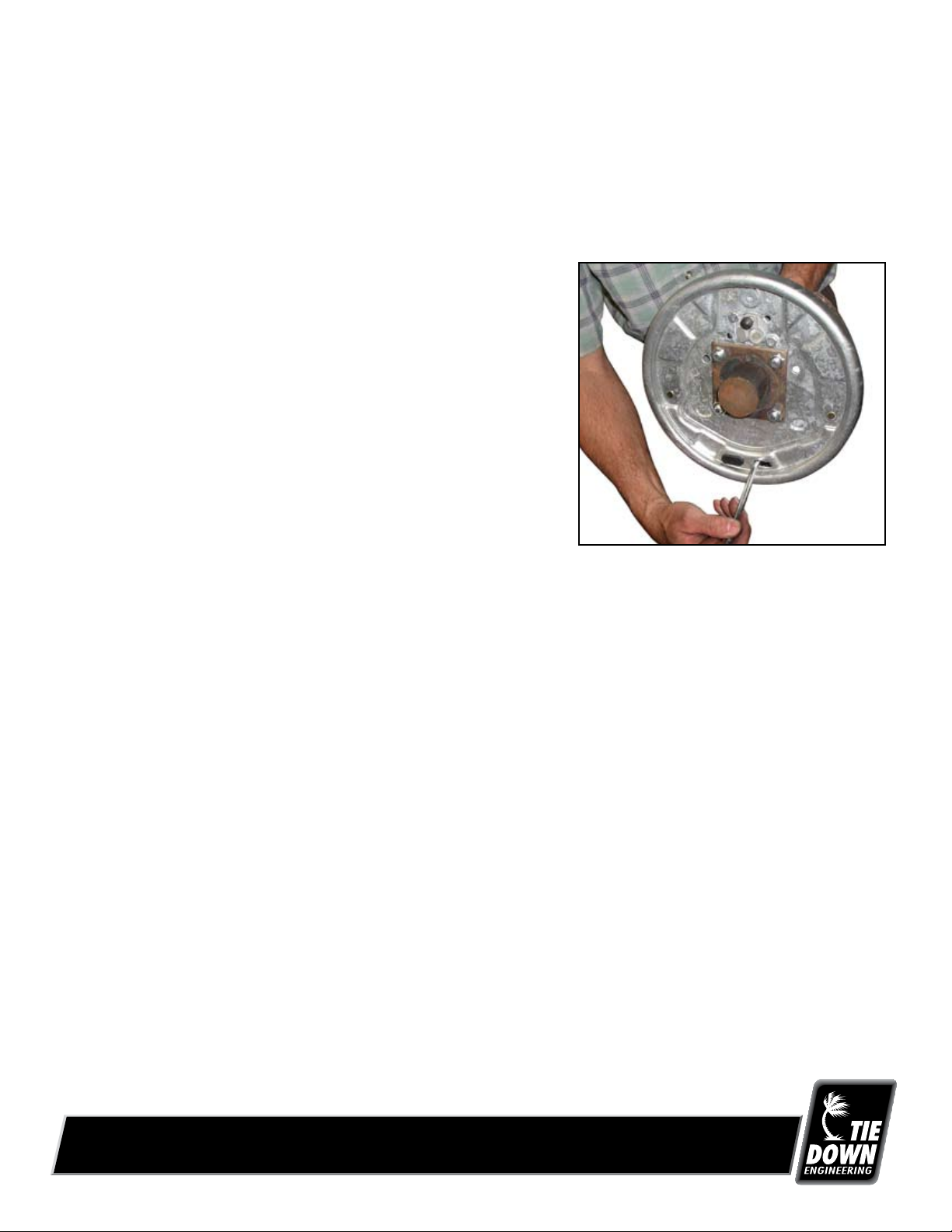

3. Installing Brake Drum

After the brakes have been correctly assembled to the brake flanges, TAKE NOTE which direction the spoon

needs to be moved in order to open the star wheel, mount the brake drum to the spindle. If re-using drum and

bearings, check for wear or pitting in the bearings and cup surfaces. Check drum for surface ware. Replace any

parts that show wear. Pack the inside bearing with suitable wheel bearing grease. Force grease through and

around the rollers. Place the bearing in the hub and install the grease seal flush with the end of the hub using

an arbor press or soft mallet. The bearing seal should be lubricated before putting it on the brake drum. Remove

excess grease.

Instruction #15384

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

071709,c143

Page 2

4 color

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

Lubricate and install the outer bearing on spindle. Place thurst washer and new locking tab washer (if aplicable)

and castle nut on spindle. Turn the brake drum as you the tighten spindle nut. When a pronounced drag is felt in

the bearings, back off the spindle nut one complete slot and install cotter pin or bend tab on locking tooth washer

(if aplicable) and dust cap. Caution: Do not over pack hub with grease. Excessive grease may leak into brake

drums causing brake failure. Install wheels at this time. Tighten wheel nuts to proper torque as recommended by

trailer or wheel manufacturer. Recheck lug torque after first 50 miles. Spin wheel at this time to make sure the

wheel rotates freely without wobble or drag.

4. Initial Adjustment of Brakes

Adjust the brakes before removing the jacks.

A. With trailer wheel off the ground and tire mounted. Remove

the rubber access hole plugs from the rear of the brake

backing plate.

B. Inserting a brake spoon or flat screwdriver through the access

hole(s), tighten the star adjuster while rotating the

wheel in the forward direction. NOTE: Always spin wheel in

the forward direction as if the trailer was traveling forward on

the road. Tighten the star adjuster until the wheel reaches a

point where the brake shoes start to engage.

C. Loosen the star adjustor one click at a time while turning the

wheel in a forward rotation. Continue adjusting one click at a

time until the wheel rotates with little effort.

D. Replace the rubber access hole plugs.

E. Repeat this procedure for all braking wheels.

5. Connect Hydraulic Lines

The use of double flare steel tubing will assure tight leak proof connections. Anchor all hydraulic lines at two foot

intervals to prevent chafing and vibration.

6. Bleeding the Brake System

Use only DOT-3 heavy duty fluid. Do not re-use brake fluid. Do not use any other type of brake fluid other than DOT-3.

If pressure bleeding equipment is available, follow the manufacturer’s instruction in bleeding the system.

(6a) Use only DOT-3 heavy-duty hydraulic fluid in the actuator. If using a pressure type brake bleeder to bleed

brakes. (This type of brake bleeder is available at your local automotive jobber.) Follow manufacturer’s directions.

If manually bleeding the brakes using a heavy-duty flat blade screwdriver inserted in the hole provided on top of

the actuator near the front. Insert the screwdriver and use a pumping action to activate the master cylinder in

order to bleed the brakes.

To bleed master cylinder and brakes, install bleeder hose on first wheel cylinder to be bled; bleed closest axle

first, and the closest brake on that axle first. Use a loose end of hose from the bleeder valve submerged in a glass

container of brake fluid to observe bubbling (hose must be submerged into clean brake fluid to keep air from

traveling back into the brake cylinder).

Loosen the bleeder screw located in the wheel cylinder one turn, the system is now open to the atmosphere. The

bleeding operation for that brake is complete when bubbling stops. Be sure to tighten bleeder screw securely.

Page 3

Each wheel cylinder must be bleed until all air is out of the lines. Replenish the brake fluid during the

4 color

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

bleeding process so the level does not fall below half full level in the master cylinder reservoir. When bleeding

and testing is completed, make sure master cylinder is filled the reservoir and filler cap is securely in place.

(6b) When using drum or disc brakes on tandem axle trailers, both axles must be installed with brakes, Failure

to install brakes on both axles will result in loss of braking performance, overheating of brakes & wheel hub,

and significantly reduce brake pad life.

WARNING

Brakes should always be flushed with fresh water after using trailer in corrosive conditions. This

includes salt water, fertilizers and other corrosive materials. Before storing trailer remove brakes and

clean thoroughly. It is also wise to repack the bearings at the same time.

WARNING

DO NOT REUSE BRAKE FLUID. Always use fresh DOT 3 fluid from a fresh container. Failure to maintain

proper levels of fluid will cause brake failure.

Page 4

Brake Trouble Shooting

Symptoms Possible Cause

Noise or brake chatter Improper brake adjustment.

Brake fluid or grease on lining.

Improperly adjusted or worn wheel bearing.

Drum out of round.

Dirt on drum or lining surface.

Dust in rivet holes.

Lining glazed or worn.

Scored drum.

Loose backing plate.

Weak or broken return springs.

One brake is activating and the other

is not activating. Improper brake adjustment. (see brake adjustment)

Brake line is restricted.

Improperly adjusted or worn wheel bearing.

Drum out of round.

Loose backing plate.

Faulty wheel cylinder.

Weak or broken shoe return spring.

Glazed or worn lining.

Loose lining.

Air in hydraulic system.

Dirty brake fluid.

All brakes drag. Faulty actuator.

Mechanical resistance at actuator or shoes.

Brake lines restricted.

Dirty brake fluid.

Faulty back up solenoid (if used).

Brakes do not apply. Leaks or insufficient brake fluid.

Air in hydraulic system.

Improper brake adjustment.

Faulty actuator.

Lining glazed or worn.

Brake fluid or grease on lining.

Dirty brake fluid.

Leaking wheel cylinder. Check and replace wheel cylinder and bleed brakes.

Seized wheel cylinder piston. Check and replace wheel cylinder and bleed brakes.

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

071709,c143

Loading...

Loading...