Page 1

)

Concrete Foundation System

Installation Instructions for Wind Zone I, II & III

(Except Florida and California)

By Tie Down Engineering

Updated: 10/11/2013

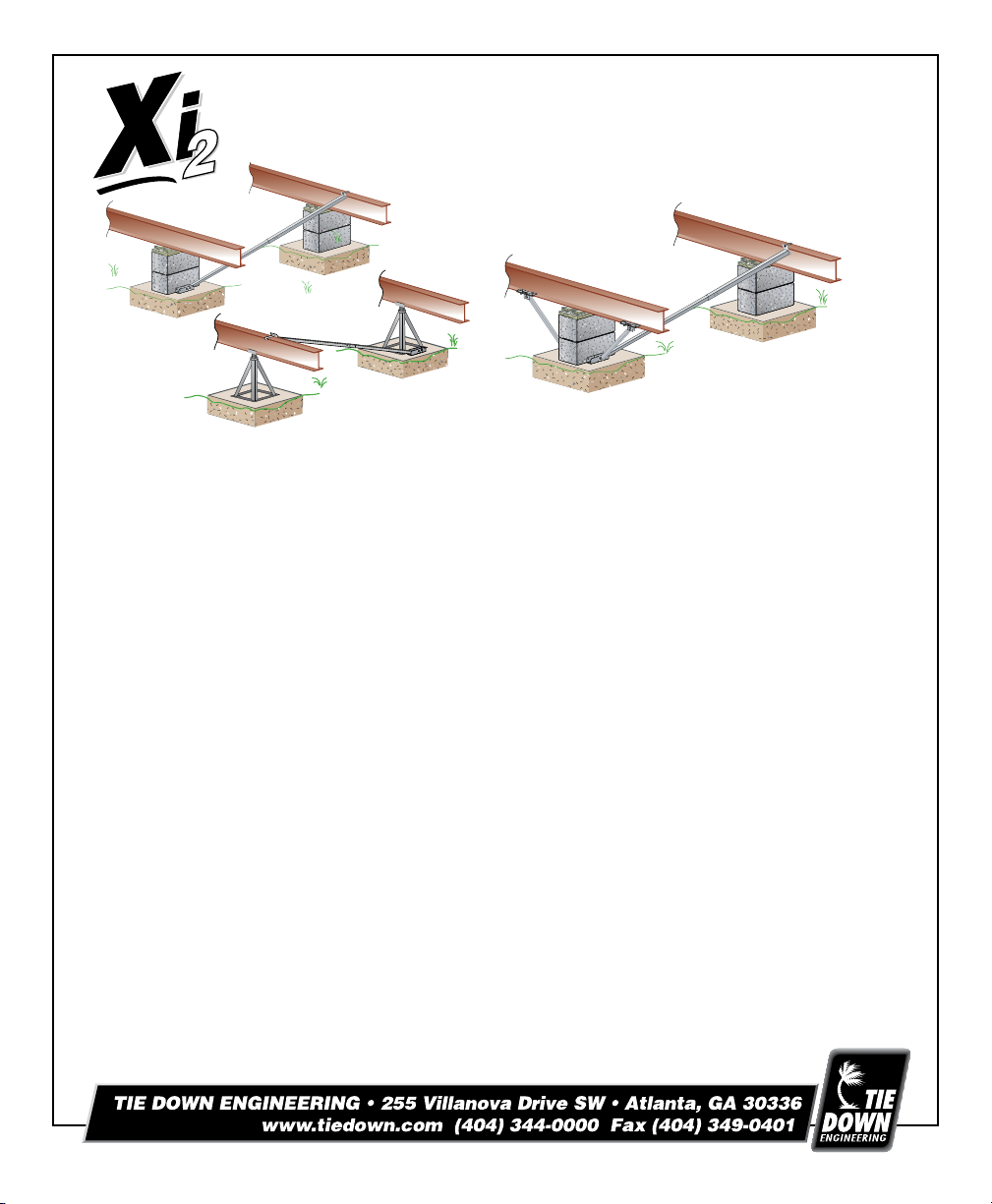

Xi2 Concrete System

Xi2

Concrete System

(For Block or Steel Pier)

REQUIREMENTS

• Install in any type soil, 4B (175 – 275 lbs.) or better.

• Main Rail spacing must be 75.5” – 99.5”, 112” exception with proper strut.

• Maximum pier height at system is 48”.

• Wind Zones II & III require sidewall anchors for up lift, check manufacturers requirements.

• Poured concrete must be must be 2.500 PSI minimum at 28 days. Bottom of footers must be below the frost line or a

minimum of 4” below finished grade, check with authorities for local requirements (LAHJ).

• Footer Requirement: Must to be large enough for the pier load at that location and be a minimum of 22” wide

by 6” deep with anchor wedge bolts a minimum of 4” from any edge or 18” wide by 12” deep with anchor wedge

bolts a minimum of 1 ½” from edge. Strip footings minimum of 18” wide by 14’ long by 6” deep or 27” wide by 14’

long by 4” deep.

• Maximum vertical projection at sidewall is 9’ (wall and eave). Higher walls may be used when design loads are

adjusted accordingly.

• Longitudinal strut angles need to be no more than 50 degrees and no less than 25 degrees. See page 4.

• Longitudinal stabilization is easily added with Tie Down’s unique multi sided bracket. The longitudinal component of the

Xi2 System replaces end frame ties. Check manufacturer’s set-up requirements.

• The Xi2 System is installed on one of the pier footers required by the home manufacturer set up instructions.

• Two systems designed to work in conjunction with each other must be placed as evenly as possible. Measuring from

the center of the block/pier, systems are to be placed no less than 2’ and no more than 10’ from each end of home.

Additional systems per instructions, see page 3. Components of the Xi2 System such as the longitudinal strut and

connecting hardware, may extend beyond the pier location.

• For roof slopes greater than 20 degrees, (4.37” in 12” Pitch) see page 3.

• This System only replaces normal lateral frame tie and or longitudinal end tie anchorage. The home manufacturer may require

additional vertical anchor ties that are unique to a home’s design. These locations may include shear walls, marriage line ridge

beam supports, and rim plates. Check the manufacturer’s installation instructions for set-up requirements.

with Longitudinal Stabilization

(One Strut for Wind Zone I

Two Struts for Wind Zones II & III

Xi2 components exceed HUD code 3280.306 g “Anchoring equipment exposed to weathering shall have a resistance to

weather deterioration at least equivalent to that provided by a coating of zinc on steel of not less than 0.30 ounces per

square foot of surface coated.

Instruction #08107

101113,D974

Page 2

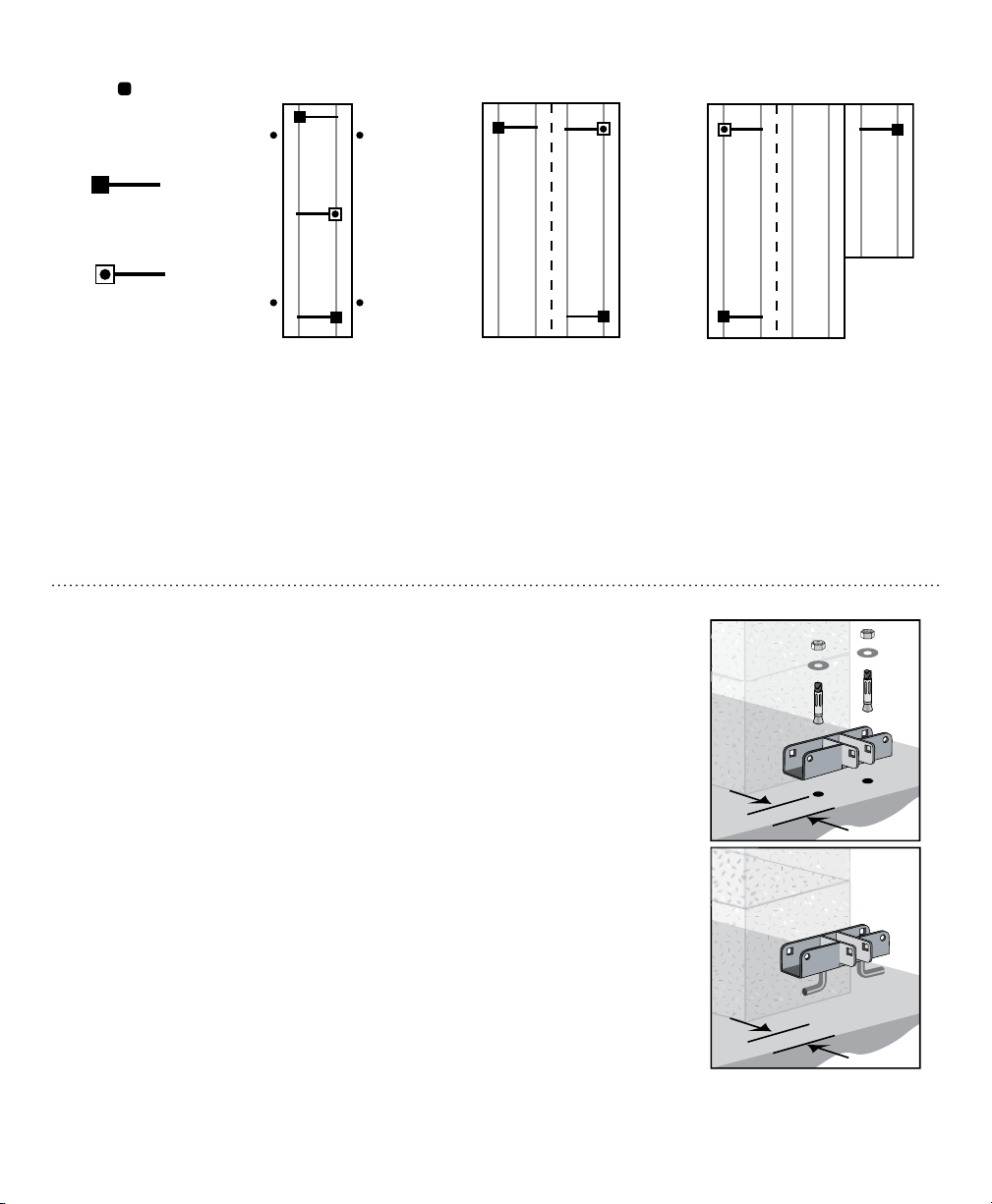

Approved Anchor*

with strap from

45 to 90 degrees

Xi2 Pier

Placement

3rd System

for Placement

Xi2 Lateral Stabilization with Concrete Footers

Wind Zones

I & II

Wind Zones

III

* For Wind Zone I - Approved anchor w/strap from 45 to 90 degrees, within 10’ of end of home on single sections.

NOTE: Diagram represents single section up to 16’ width, double section up to 32’ width, and triple section homes up to 48’ width.

Single Section Home

0 - 76’ Box 2 Xi2 Systems

Over 76’ Box 3 Xi2 Systems

Single Section Home

0 - 64’ Box 2 Xi2 Systems

Over 64’ Box 3 Xi2 Systems

Double Section Home

0 - 76’ Box 2 Xi2 Systems

Over 76’ Box 3 Xi2 Systems

Double Section Home

0 - 64’ Box 2 Xi2 Systems

Over 64’ Box 3 Xi2 Systems

Triple Section Home

0 - 76’ Box 2 Xi2 Systems

Over 76’ Box 3 Xi2 Systems

Triple Section Home

0 - 64’ Box 2 Xi2 Systems

Over 64’ Box 3 Xi2 Systems

Installation of Concrete Bracket: Dry Set/Wet Set

1. Identify the number of systems to be used on the home using the

chart provided.

2. Identify the location where the lateral systems will be installed. If installing

lateral and longitudinal together, check page 4 for alignment of bracket.

3. Build pier according to State, Local or Home Manufacturers guidelines.

4a. For dry set: drill two 3/8”x 3” deep holes in the concrete using holes in

galvanized bracket as a guide. Attach bracket to concrete pad using

3/8”x 3-1/2” wedge anchors provided. Place nut & washer on anchor, leave

enough room for 1 to 2 threads showing on top of bolt. Using a hammer,

tap the wedge bolts into hole through bracket, leaving nut & washer flush

with bracket. Using a 9/16” socket wrench, tighten wedge/anchor bolt,

securing bracket to the concrete.

4b. For wet set: align bracket and submerge legs completely in concrete.

Bottom of bracket should rest on surface.

5. Attach the end of the smaller tube to the bracket mounted on the pad, using the

grade 5, 1/2” x 2-1/2” bolt/nut provided.

6. Attach the flag end of the larger tube to the opposite I-beam using the

“J” bolt over the top of the I-beam with the nut & washer provided.

(Figure 1 on last page)

7. Install a minimum of four (#14 x 1” Tek screws) self-tapping screws into

the holes provided in the lateral strut so that the two tubes are connected

together with a minimum overlap of 4” to 6” (Figure 2 on last page).

See “Footer Requirement”

on page 1 for edge

placement

Page 3

Xi2 Longitudinal Stabilization for Wind Zone I, II & III

When using longitudinal

stabilization only, systems

must be as evenly spaced

as possible, no more than

10’ from the end of the

home. Longitudinal struts

do not replace anchors on

single section homes.

Sample Placement for Wind Zone I Shown

Single Section

Up to 16’ Nominal

Double Section

Up to 32’ Nominal

Triple Section

up to 48’ Nominal

NOTE: On triple section homes in

WZII & III an additional longitudinal

system is required. It should be

Use One Strut (per end)

For WZ I

Use Two Struts (per end)

For WZ II & III

installed on the center section.

3285.402(c)(3) All new manufactured homes must have longitudinal stabilization in all wind zones.

Xi2 System Requirements for Roof Pitches Higher than 20 degrees

Module

Wind Zone I Wind Zone II Wind Zone III

Length

5:12 6:12 7:12 9:12 5:12 6:12 7:12 9:12 5:12 6:12 7:12 9:12

(Feet)

34 2 2 2 2 2 2 2 2 2 2 3 3

36 2 2 2 2 2 2 2 3 2 2 3 3

38 2 2 2 3 2 2 2 3 2 3 3 3

40 2 2 2 3 2 2 2 3 3 3 3 3

42 2 2 3 3 2 2 3 3 3 3 3 3

44 2 2 3 3 2 2 3 3 3 3 3 3

46 2 3 3 3 2 3 3 3 3 3 3 4

48 2 3 3 3 3 3 3 3 3 3 3 4

50 3 3 3 3 3 3 3 3 3 3 3 4

52 3 3 3 3 3 3 3 3 3 3 4 4

54 3 3 3 3 3 3 3 3 3 3 4 4

56 3 3 3 3 3 3 3 3 3 3 4 4

58 3 3 3 3 3 3 3 3 3 3 4 4

60 3 3 3 3 3 3 3 3 3 3 4 5

62 3 3 3 3 3 3 3 3 4 4 4 5

64 3 3 4 4 3 3 4 4 4 4 4 5

66 3 3 4 4 3 3 4 4 4 4 4 5

68 3 4 4 4 3 4 4 4 4 4 5 5

70 3 4 4 4 3 4 4 4 4 4 5 5

72 3 4 4 4 4 4 4 5 4 4 5 5

74 4 4 4 5 4 4 4 5 4 5 5 5

76 4 4 4 5 4 4 4 5 4 5 5 6

78 4 4 4 5 4 4 4 5 4 5 5 6

80 4 4 4 5 4 4 4 5 4 5 5 6

Additional Systems:

On a single section home

the 3rd system is placed

in the middle of the

home. When using 3 or

4 systems (double and

triple sections) install

on opposite corners, if

needed, a 5th system

would be in the center of

the unit on either side.

101113,D974

Page 4

Xi2 Lateral Foundation System

Figure 1

J-Bolt

Nut & Washer

Beam Clamp

Bracket

1-3/4" Tube

Lateral Struts

1-1/2" Tube

4 - #14 x 1”

Tek Screws

2 per side

Figure 2

Lateral Stabilization

Po sition B

Figure 3

Xi2 Longitudinal Installations

Po sition A

(either side)

I-Beam

Wind Zone I

Lateral &

One Longitudinal

System

Lateral

Stabilization

(either side)

Xi2 Concrete System

Part #59307

Includes: Strut #48609 &

Hardware kit #59327.

Longer struts are available

Strut Angles:

Need to be no more than

50 degrees and not less than

25 degrees. If needed, tube

can be cut to proper length

and a new hole drilled

according to chart on below.

Strut

17/32"

3/4"

from end

Figure 4

Wind Zone II & III

One additional

Longitudinal

System

www.tiedown.com

(404) 344-0000

©2013 Tie Down, Inc.

All Rights Reserved

I-Beam

Loading...

Loading...