Page 1

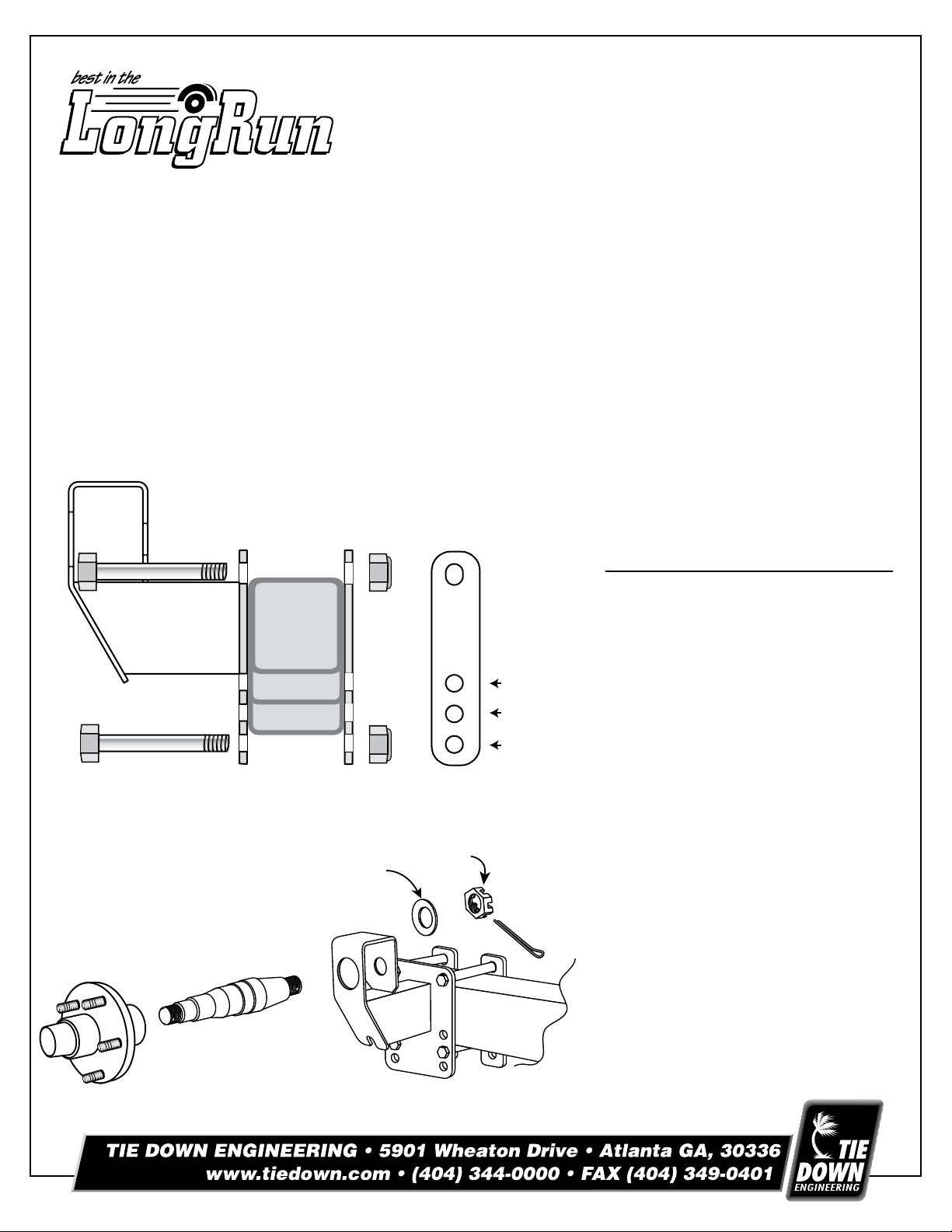

Hub & Tire Carrier

With Eliminator Quick Change Spindle

Assembly Instructions for Part #86068

1. Using the spare tire carrier and spare tire as a guide, determine a suitable mounting location on trailer frame.

2. The mounting plate will accommodate several size frames by using the various hole patterns.

NOTE: see below diagram for 3x3, 3x4 & 3x5 frame tubes.

3. Push two 1/2" bolts through the top of the carrier and position on top of the trailer frame.

4. Place the mounting plate against the outside of the frame with the 1/2" bolt going through the top holes.

5. Hand tighten nyloc nuts. Insert the two remaining bolts through the bottom holes and hand tighten the

nyloc nuts.

6. Mount spare spindle/hub and tire with washer, castle nut and cotter pin provided.

7. Check position of the tire mount for proper clearance with the spare tire before tightening bolts.

3“

Frame

4“ Frame

5“ Frame

Conical

Washer

Rear Mounting

Plate(s)

3“ Frame

4“ Frame

5“ Frame

Castle Nut

Cotter

Pin

This kit contains the

following components:

Description Qty.

Eliminator Spindle/Tire Carrier 1

Eliminator Spindle Assembly 1

1750# GalvX Hub Assembly 1

Back Mounting Plates 2

1/2” x 4-1/2” Hex Head Cap Bolts 4

1/2” Nyloc Nuts 4

Tools required:

9/16" socket & 9/16” wrench

NOTE: Hub & Tire Carrier can

be used with any trailer using

a 5 lug 1750# UHI Hub, Quick

change spindle can only be

used with a 3500/3750#

Eliminator Torsion Axle.

Eliminator

Quick Change Spindle

Instruction Sheet #08086

121207,A843

Page 2

Spare Tire/Hub Carrier

With Eliminator Quick Change Spindle

Instructions

Road Side Repairs

When required, you have several options when confronted

with a flat tire, bearing failure or spindle damage. Flat tires

should be handled like any other trailer tire change. Make

sure trailer is on level or near level ground. Loosen lug nuts

on wheel. Use jack on trailer frame to elevate tire in order to

place spare tire on the hub. Make sure all lug nuts are

securely tightened before moving trailer. Re-check lug

nuts after several miles to make sure they are tight. Bearing

failure is usually discovered by a loud grinding noise or

wheel wobble. If there is obvious bearing damage, jack up

the trailer to remove the tire. Remove the dust cap with a

hammer by striking at the edge, rotating the hub to strike

different sides until the dust cap is removed. The castle nut

that holds the hub on has a “tang” washer to keep it from

coming off. Bend or straighten the tab so that the nut will

come off. Remove the hub and inspect the spindle for

damage. If none is detected, wipe the spindle clean and

replace the damaged hub with a pre-greased spare. The

washer and castle nut are replaced. Tighten the nut until it is

tight with obvious friction on the bearings. Back off nut 1/4

turn to allow fluid bearing movement Re-lock the castle nut

with the unused tang on the washer. Replace tire and secure

with lug nuts.

Spindle failure is usually defined as damage to the spindle

causing excessive worn spots in the bearing surfaces or

damage due to an accident. Follow the instructions for hub

removal or replace the entire spindle and hub combination by

removing the cotter key and castle nut on the backside of the

spindle. Hit the backside of the spindle with a heavy hammer

to dislodge the spindle. Place the replacement spindle in the

torsion arm. Place washer and nut on spindle and tighten

with 100 ft. lbs of torque. Replace hub and or wheel as

discussed above.

Always re-check all work performed when you return to a

safe area.

Part #86068

Wheel Hub/Spindle Instructions

Your Spare Tire Carrier is equipped with a Super Lube Spindle. The hubs are

pre-greased and assembled at the factory and should not require any initial

adjustments. The UHI hub uses tapered roller bearing cones and cups. This

configuration requires a minimal amount of end play that is provided at the

time of assembly.

SuperLube Lubrication

The bearings can be periodically lubricated without removing the hubs from

the axle. The advantage to this system is that new grease saturates the inner

bearing and outer bearing while pushing out the old grease, unlike systems

that just push new grease on top of old grease.

1. Remove the rubber plug from the grease (hub) cap.

2. Use a standard grease gun onto the grease fitting located at the

end of the spindle, or behind the hub, making sure the grease gun

nozzle is engaged on the fitting tightly.

3. Pump grease into the fitting, while slowly turning the wheel. Grease

will flow out of the hub around the spindle.

4. When the grease appears to be the new clean grease, remove the

grease gun and wipe off any excess grease.

5. Replace the rubber plug in the cap.

Removal/Remounting for the SuperLube Hub

Removing the hub for inspection or maintenance should be done in a safe

location away from moving vehicles.

1. Elevate the trailer using the manufacturers instructions. Always use

jack stands or other solid supports. Do not depend on a jack to

support the trailer. Block wheels to keep trailer from rolling.

2. Remove the tire/wheel assembly.

3. Remove the grease cap from the hub by prying around the edge of the cap.

4. Bend the locking tang washer to the “free” position.

5. Remove the spindle nut in a counterclockwise direction and

remove the spindle washer.

6. Remove the hub from the spindle. Be careful not to allow bearings

to fall out of the hub.

7. Clean bearing and cup surfaces, repack with lithium marine

grade grease.

8. Place hub on spindle in reverse order as listed above. Rotate the hub

while tightening the spindle nut to approximately 50 ft lbs. This

translates into full hand pressure with a 12” long set of pliers or 12”

long wrench.

9. Loosen the spindle nut to remove the torque, do not rotate hub.

10. Finger tighten the spindle nut until snug, backing out only to line

up the locking tang washer.

11. Bend the locking tang tab in place.

12. Replace grease/hub cap.

13. Test hub with wheel mounted for excessive play or tightness,

readjust if required.

121207,A843

Loading...

Loading...