TACC-IIa

General Information

TACC-IIa, (Built in 1991)

The Main PCB is different from TACC-IIR.

TACC-IIa, (Built in 1992)

Timing Disk changed to accommodate the absence of the Lower Sensor PCB.

TACC-IIa (Built in 1993)

Serial Number information

Problem Identifi cation By Component

TACC-IIa - Production began 1994

The diameter of the Vend Tubes were increased to accomodate international coins.

The Solenoid mounting bracket moved approximately one inch toward the center

The new Main PCB is backward compatible with older units.

To stop the “tube dump” feature, the Vending Keyswitch must be turned to the

TACC-IIa with rear door.

This unit was equipped with a door on the front and rear of the unit. The solenoid was

TACC-IIa built for overseas applications (Thailand)

TACC-IIa redesign for Sentinel cabinet design. Production began late 2006.

The Control Panel Chassis size increased to be interchangeable with Sentinel, TACC-V

The size of the back wall on the unit was reduced by approximately half. Only (2) 3/4”

Problem Identifi cation By Component

The Control Panel basically is a

Touchpad consisting of 8 vend buttons, the

There a 4 vend motors. Each motor turns a cradle back and forth to dispense tubes from two

This is an indication that the unit “saw” you press the button. The button and

It is important that you verify that a response is given by the Control Panel when

If no response is indicated when the vend button is pressed, (the LED’s do not re-

spond), the unit does not “see” the button.

The “STACKER FULL” LED is not used by the TACC-IIa.

Door timer or Alternate Vend timer will not start

The Alternate Vend delay timer cannot be started if the unit “sees” the door in the un-

The problem may be related to the button or the Manager Keyswitch.

To isolate the problem, perform the following test:

Problem Identifi cation By Component

Drink spills

Worn/stuck buttons

LED’s do not illuminate

Static Discharge

Control Panel

Problem Identifi cation By Component

Sprung Door

The door tends to push outward. Customers usually report they have to push in on the door to

Sagging Door

Worn Hinges

Problem Identifi cation By Component

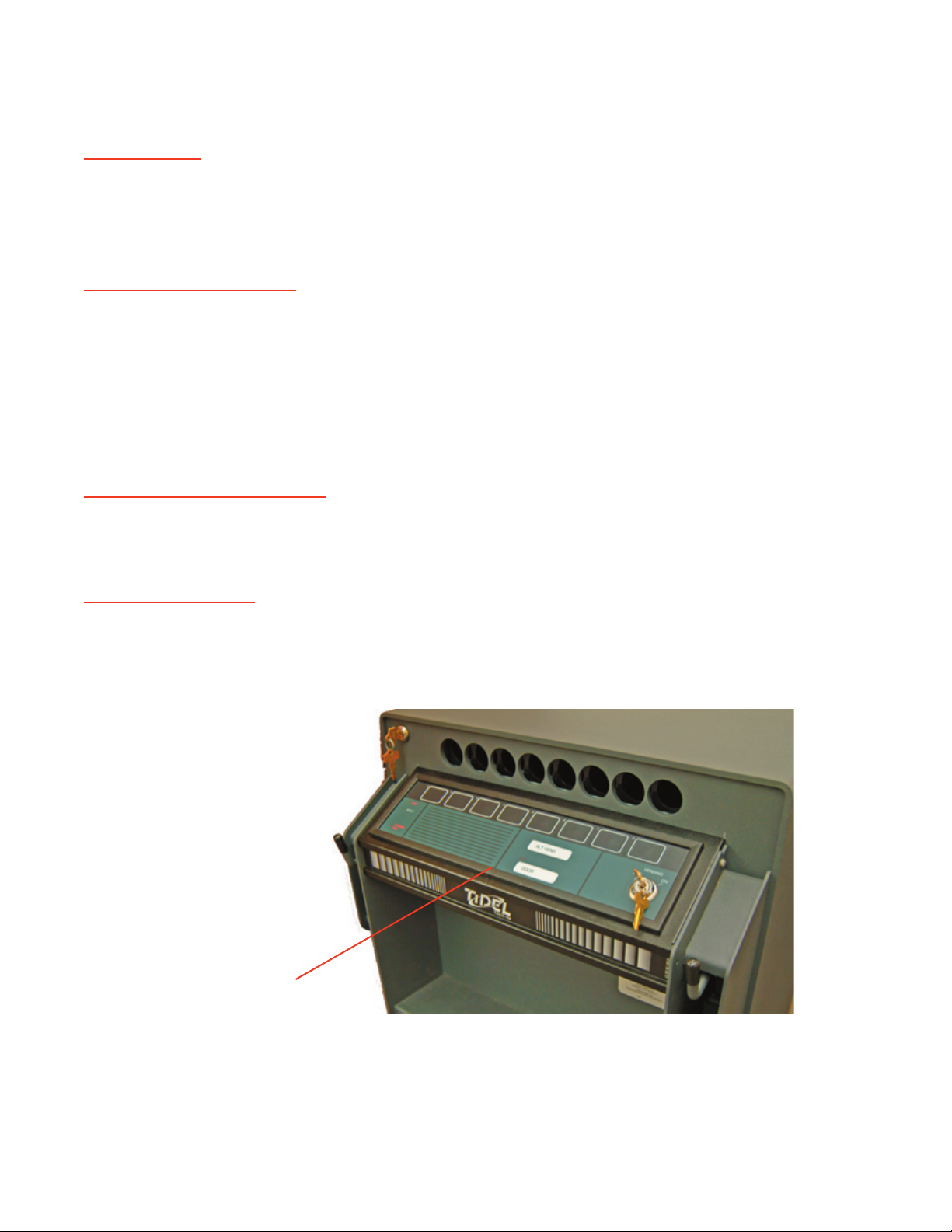

The fuse is located under the Control Panel, next to the serial # sticker.

This “click” indicates AC power is being applied to the Power Supply. This indicates

Fuse Cap

Fuse Holder Assy

Problem Identifi cation By Component

Keyswitch (Courier/Instant Access)

The Instant Access Keyswitch is mounted below the Manager Keyswitch on the door.

The Keyswitch is spring loaded and should return to the off position when released.

The Keyswitch is supplied with 4 keys and an aluminum tag which has a

The Keyswitch is a restricted keyway. Replacement keys cannot be made locally. The key

The

To open the door using the Instant Access Keyswitch, turn the Instant Access Keyswitch ON and

The

The

The Vend Delay timer will continue to advance.

Instant Access Key Operation Options:

Single Key:

Dual Function:

Keyswitch (Dispensing/Vending)

Problem Identifi cation By Component

Keyswitch (Manager/Time Delay)

The Keyswitch is spring loaded and should return to the off position when released.

The Keyswitch is supplied with 4 keys and an aluminum tag which has a

The Keyswitch is a restricted keyway. Replacement keys cannot be made locally. The key

To start the Door opening delay timer, turn the Manager Keyswitch and release it, then press

A91 series units did not require

The

To isolate the problem, perform the following test:

The Manager

The 30-second Alternate Vend feature cannot be activated if no keyswitch is connected to to the

Current Production Door with

hinges on the left

Manager/Time Delay

Keyswitch

Instant Access/Courier

Keyswitch

Old Style Door with hinges

on the right

Manager/Time Delay

Problem Identifi cation By Component

Keyswitch

Lock (Door Bolt)

The

The Door Bolt Lock is supplied with 2 keys and an aluminum tag, which has a key code,

The Door Bolt Lock is a restricted keyway. Replacement keys cannot be made locally.

The key code must be supplied to Tidel and only then can Tidel supply replacement keys.

The Door Bolt Lock operates the door locking bar by means of a cam.

The Tube Loading Gate Lock lock is located in the top right corner of the unit.

Lock (Tube Loading Gate Lock Bar)

Door Bolt Lock

Tube Loading Gate Lock

Problem Identifi cation By Component

Tubes or rolls of

Problem Identifi cation By Component

The Main PCB controls all functions of the TACC-IIa.

The Main PCB houses the Service Diagnostic Switch and the

The

The

Door Opening Delay Options:

Instant Access Key Operation Options:

Single Key:

Dual Function:

Problem Identifi cation By Component

The Motr Controller PCB controls the motor and vending functions.

The vending function of a TACC is performed by the following:

A Vend Motor runs continuously

Typically a defective drive transistor, replace Motor Controller PCB.

To diagnose Motor Controller PCB problems, perform a power reset and LISTEN for the follow-

The unit makes a loud popping noise or binds. Probable jam in the cradle area

The unit vends a tube, works properly afterward. Tube or coins were jammed.

Wait light fl ashes when a button is pressed

A Vend Motor does not run.

Problem Identifi cation By Component

TACC-IIa units with serial #’s beginning with A91, had Power Supplies mounted on the maga-

The Power Supplies are auto ranging and can be connected to 120vac or 240vac circuit without

The Power Supply converts incoming AC voltage to +12 and +5vdc.

No LED’s illuminate on the display

The

No vend motors will operate and the door solenoid will not activate

Erratic LED behavior

Problem Identifi cation By Component

Read the following completely BEFORE attempting to adjust the

Turn the R31 Potentiometer VERY SLOWLY to raise or lower the output

voltage of the Power Supply.

Do not perform a voltage adjustment if the +5vdc output is correct!

Do Not adjust the voltage above +5.10vdc.

Do Not attempt to adjust the +12vdc, -12vdc or +24vdc if the +5vdc is

correct before making the adjustment.

Do Not apply pressure to the R31 potentiometer when adjusting. Damage will occur.

Problem Identifi cation By Component

Door Sensor

The Door Sensor is located inside the unit, on the left side of the door frame.

justment.

To adjust the Door Sensor, loosen the 2 screws at rear of bracket to and lower the

The Door Sensor may be broken or out of the bracket.

Do not attempt to “splice” a replacement Door Sensor into the existing wiring har-

Problem Identifi cation By Component

The Door

Typically, when the solenoid energizes, a faint mechanical noise can be heard (the plunger be-

Problem Identifi cation By Component

The gear on the Vend Motor shaft engages the gear on the Cradle to rotate the Cradles for

To isolate the defective component, perform the following:

To isolate the defective component, perform the following:

Problem Identifi cation By Component

Loading...

Loading...