Ticonium Premium 100 Technique Manual

TM

TM

premium 100

TECHNIQUE MANUAL

TICONIUM COMPANY

DIVISION OF CMP INDUSTRIES LLC

Albany, New York

USA

TTAABBLLEEOOFFCCOONNTTEENNTTS

S

P

remium 100

Ticonium Technique Manual

ith pictures and clear, concise instructions, you will find this Technique Manual

W

For best results, follow these instructions carefully. Thank you for your support of

Ticonium Company.

DUPLICATION ..............................................................................................2-8

MODEL PREPARATION...............................................................................9-10

SPRUING .................................................................................................11-16

METAL MIZER & INGOT ALLOY .............................................................17-19

PAINTING & FLASKING...........................................................................20-23

easy to understand. Please keep it in a handy place for quick reference.

BURNOUT.....................................................................................................24

CASTING .................................................................................................25-26

FINISHING ..............................................................................................27-30

REPAIR ....................................................................................................31-34

TECHNIQUE AT A GLANCE...........................................................................35

PROCEDURES & PRECAUTIONS....................................................................35

INDEX...........................................................................................................36

PREPARED BY: Ticonium Company • Division of CMP Industries LLC • P.O. Box 350 • Albany, NY 12201

Copyright 2003

• All Rights Reserved

1

DUPL I CAT ION

DDUUPPLLIICCAATTIIOON

N

Ticonium Premium 100

Ticonium duplicating material normally does not

require dilution, however, you should be familiar

with the strength of the duplicating material. The

duplicating material cannot be too stiff, this will

decrease the setting expansion of the investment

when poured into the duplicating material.

After removing the master model from the

colloid, you should check the strength of the

walls of the duplicating material. If they are

more rigid than usual, distilled water should

be added to the material and remelted.

(see figure 1)

Figure 1:

DIONIZER WATER

DISTILLER #61750

Ticonium Dionizer

Cartridges produce

water equivalent to

single distilled water,

removing all ionized

particles except free

carbon dioxide and

silica. They deliver

water hat is ideal for

duplicators, mixing

investments and many

other uses within the

laboratory. Resin color

change shows when to replace cartridges. Comes

complete with cartridge, mounting bracket and

accessories.

refractory model.

The Ticonium Technique provides three methods

to achieve this:

1. Hygroscopic Expansion – is directly

related to the percentage of water existing

in the duplicating material. The hygroscopic

expansion should be approximately 0.3%.

2. Setting Expansion – is achieved when the

Ticonium Investment is mixed according to ratios

indicated later in this chapter, and vibrated into

the duplicating material. During the setting of

the investment in contact with the duplicating

material, the setting expansion should be

approximately 0.4%. It is easy to understand

that if the duplicating material is too strong

the investment cannot expand properly.

3. Thermal Expansion – the average

thermal expansion is 1% and is achieved

when the flasks are placed in the oven and

burned out at 1350° F (732° C).

AUTO-DUPLICATOR INSTRUCTIONS

The use of a Ticonium 2 or 3 1/2 gallon

Auto-Duplicator will simplify the melting of the

duplicating material. Ticonium Auto-Duplicators

will perform melting and cooling operations

automatically and maintain correct pouring

temperature at all times. (see figure 2)

Because of weather conditions and shipping

distances, it is possible that the same material

will present different characteristics. The quantity

of distilled water added to the material will

vary for each specific situation. It could be

rated from100 cc’s per each four pounds of

material to 300 cc’s per each four pounds.

We believe this information is important due

to the shrinkage of Ticonium alloy after casting,

which on an average represents 1.7%, and

will be compensated for by oversizing the

Figure 2:

2 Gallon #405811 & 3-1/2 Gallon

2

AUTO-DUPLICATORS

#405711 Auto Digitals

DDUUPPLLIICCAATTIIOON

N

Ticonium Premium 100

Place small chunks of material inside the

Auto-Duplicator and follow the detailed

information provided in the Auto-Duplicator

Operating Instructions

Periodic maintenance of the Auto-Duplicators

is necessary. The inside tank should be cleaned

once a week. The inside cover and blades of

the Auto-Duplicators should also be cleaned

and all the stainless steel parts should be

sprayed with a silicone lubricant periodically.

PREPARING MASTER MODEL FOR

DUPLICATION

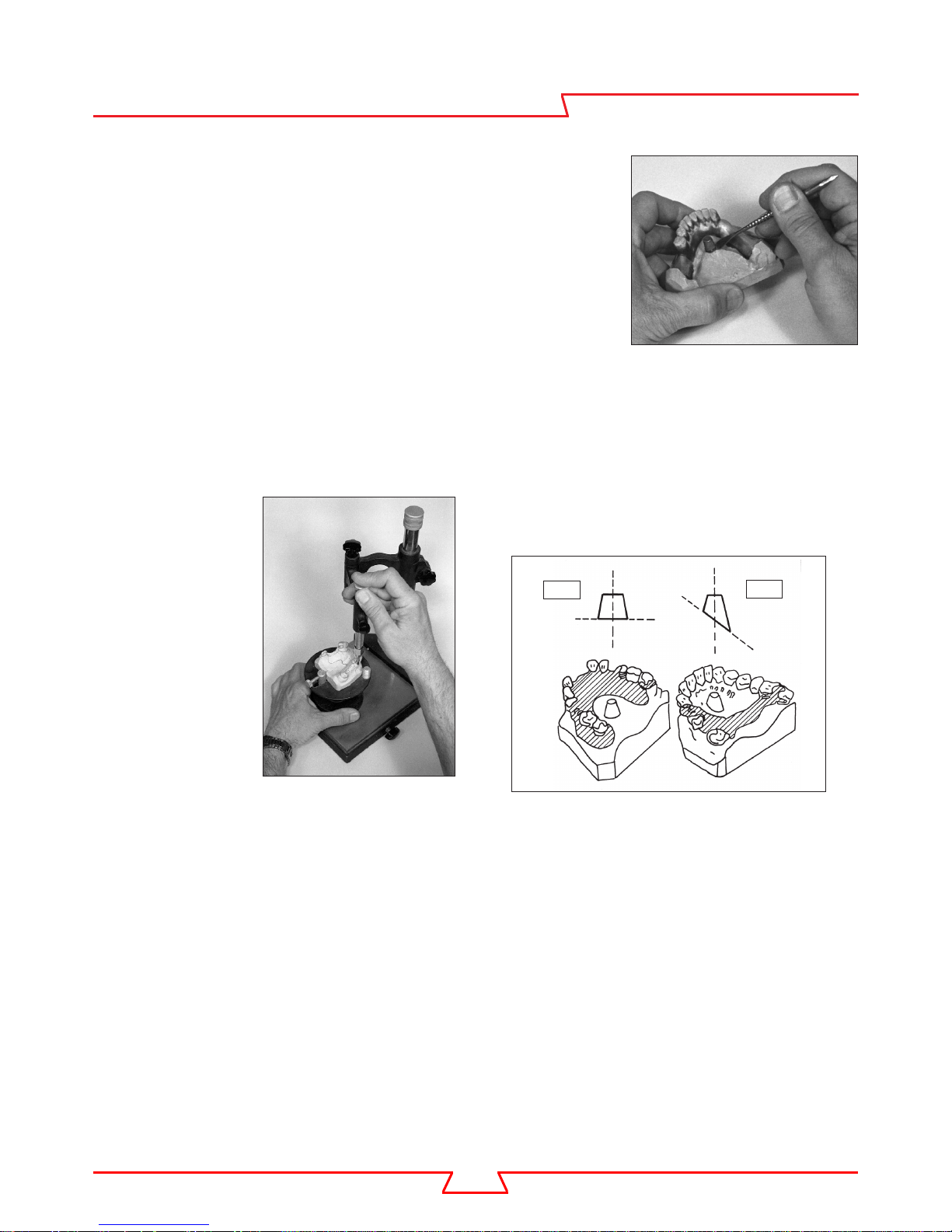

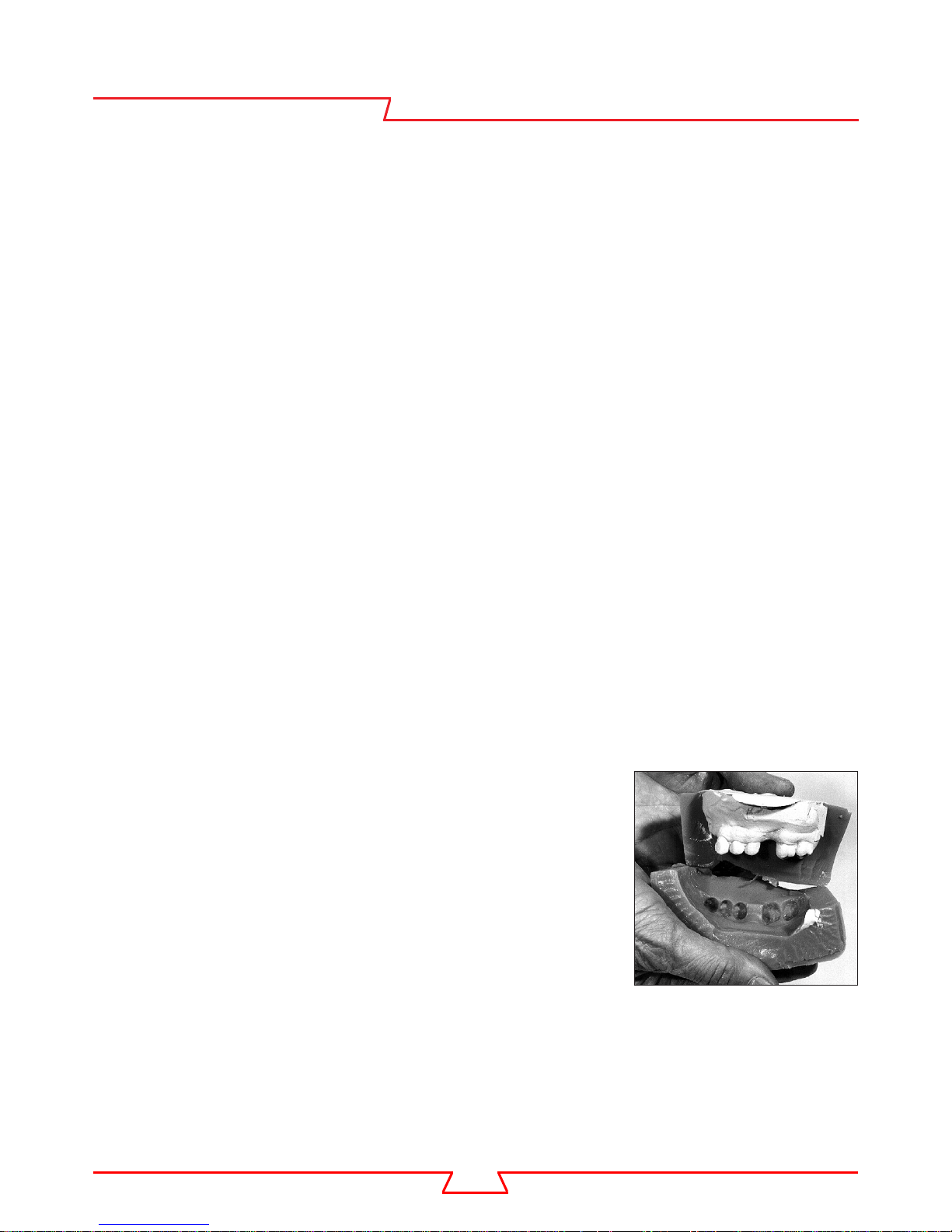

After designing,

surveying

(see figure 3) and

blocking-out of the

undercut areas,

relieve tissue

undercuts with

TICENE or WAX.

(see figure 4)

Remove TICENE

from model after

duplication and

store for reuse.

Choose the sprue

cone to be used

with each master

model. The sprue

cones are 7 mm high.

Correct placement on the lower cases should

be 7 mm from the lower part of the lingual bar.

Figure 3: SURVEYING

Figure 4: RELIEF

of unnecessary

undercuts and

sprue placement

For upper cases the sprue cone should be

placed approximately 4 mm from palatal

bars or from horseshoes. It is also important

that with uppers the criteria of placing the

sprue cone perpendicular to the occlusal

plane be followed.

A

Figure 5: MOUNTING

of “A” & “D” Sprue Cones

D

An easy way to place the cone in the correct

position is as follows:

1. Place the cone in a lying down position

so that the edge of the sprue cone touches the

design of the lingual bar.

2. Tilt back to vertical position and seal.

Always be sure that the cone is placed

perpendicular to the occlusal plane.

“A” Sprue Cone (#TD-1475A) is used for flat

surfaces.“D” Sprue Cone (#TD-1475D) for

inclined surfaces – (see figure 5) refer to Sprue

Cones on page 12. Secure sprue cones to the

master model with wax. If the case will not be

sprued through the investment model, no sprue

cone will be needed at the point.

3

TWO METHODS OF

DDUUPPLLIICCAATTIIOON

N

T

iconium Premium 100

SOAKING STONE MODELS

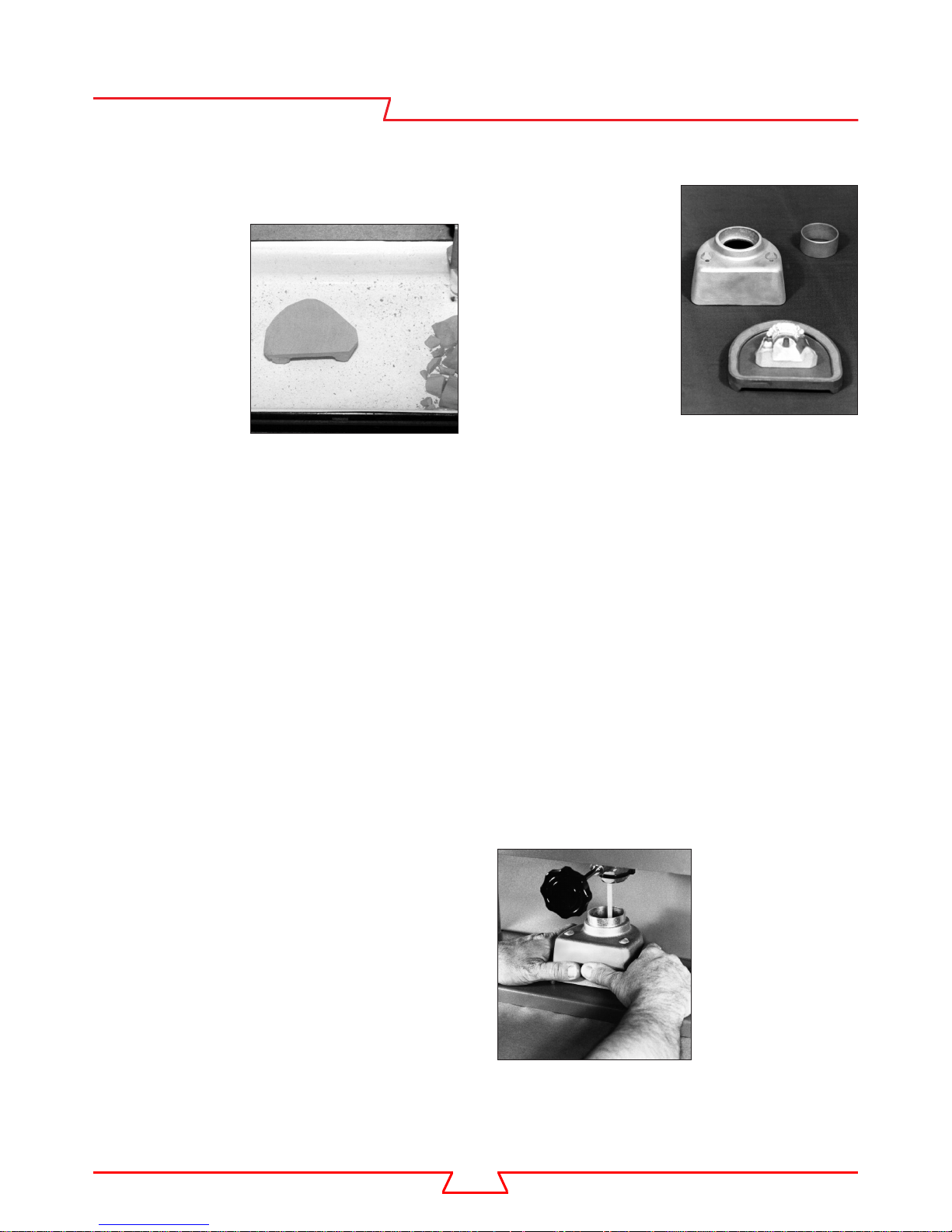

There are three parts to the duplicating flask:

(see figure 7)

1. Soak model

approximately

20 minutes in

tepid, slurry

water. (see figure

6) Slurry water is

the liquid resulting

from storing large

pieces of stone in

a bottle of water

and using the

resulting solution.

This solution will

Figure 6: SOAKING MODEL

to be duplicated in slurr y water

not etch the model

whereas tap water will. (If large areas of model

are relieved with sheet wax, soak model with

teeth pointed down.)

Some technicians prefer to use slurry water

from model trimmers. The idea is good,

although, special precautions must be taken.

The slurry water from model trimmers has a

milkish appearance and a large content of

powdered stone. Prior to using this slurry water

the container should be left aside for a couple

of days to allow the sediment to settle. Then,

the liquid should be filtered and transferred

to a new container. If this procedure is not

followed, a residue of stone will deposit on the

master model, including areas at the tips of the

clasps, and rest preparations, changing the

configuration of the master model, which will

result in a poor fitting casting.

2. Another method of soaking the model

is to stand the model in about 1/4” of water

and let the model soak by capillary action.

This is the preferred method, but will take

slightly longer.

After the model has been soaked, blow off

excess water and duplicate.

1. The base

2. The body

3. Pouring spout

Two flask sizes are

provided. Use the

one which provides

at least 1/2”

clearance between

the edge of the cast

Figure 7 :

DUPLICATING FLASK

and the rim of the

base. Place TICENE Blocking

Clay (#14) in the rim of the base.

This serves two important purposes:

1. It forms a seal between the base

and body so that there will be no leakage

of duplicating material during the duplication

process.

2. It will also act as an insulator when the

cooling process is begun.

Secure master cast to base of flask with

TICENE. Place flask body on the base and seat

firmly. Position a ball of TICENE behind each

venthole on the shoulder of body. Place pouring

spout into flask body.

Center duplicating

flask under pouring

spout. (see figure

8) Open valve

until the duplicating

material flows in a

stream about the

diameter of a lead

pencil. When the

duplicating material

reaches the level of

Figure 8: POURING

the 2 ventholes,

place the TICENE

over the vents and

continue filling the flask until at least 2/3 of

the pouring spout is full.

4

DDUUPPLLIICCAATTIIOON

N

Ticonium Premium 100

Place the flask in circulating tap water.

(see Figure 8) The temperature of the running

water used for chilling is directly related to the

temperature of the room in which the chilling is

being done. If the temperature of the water is

lower than the temperature of the room, a desirable pattern of cooling will result. Regulate depth

of water so it covers only the base of the flask.

The water should not be below 55°F (13° C).

30 minutes is

required to chill

small duplicating

flasks.

45 minutes is

required to chill

large duplicating

flasks.

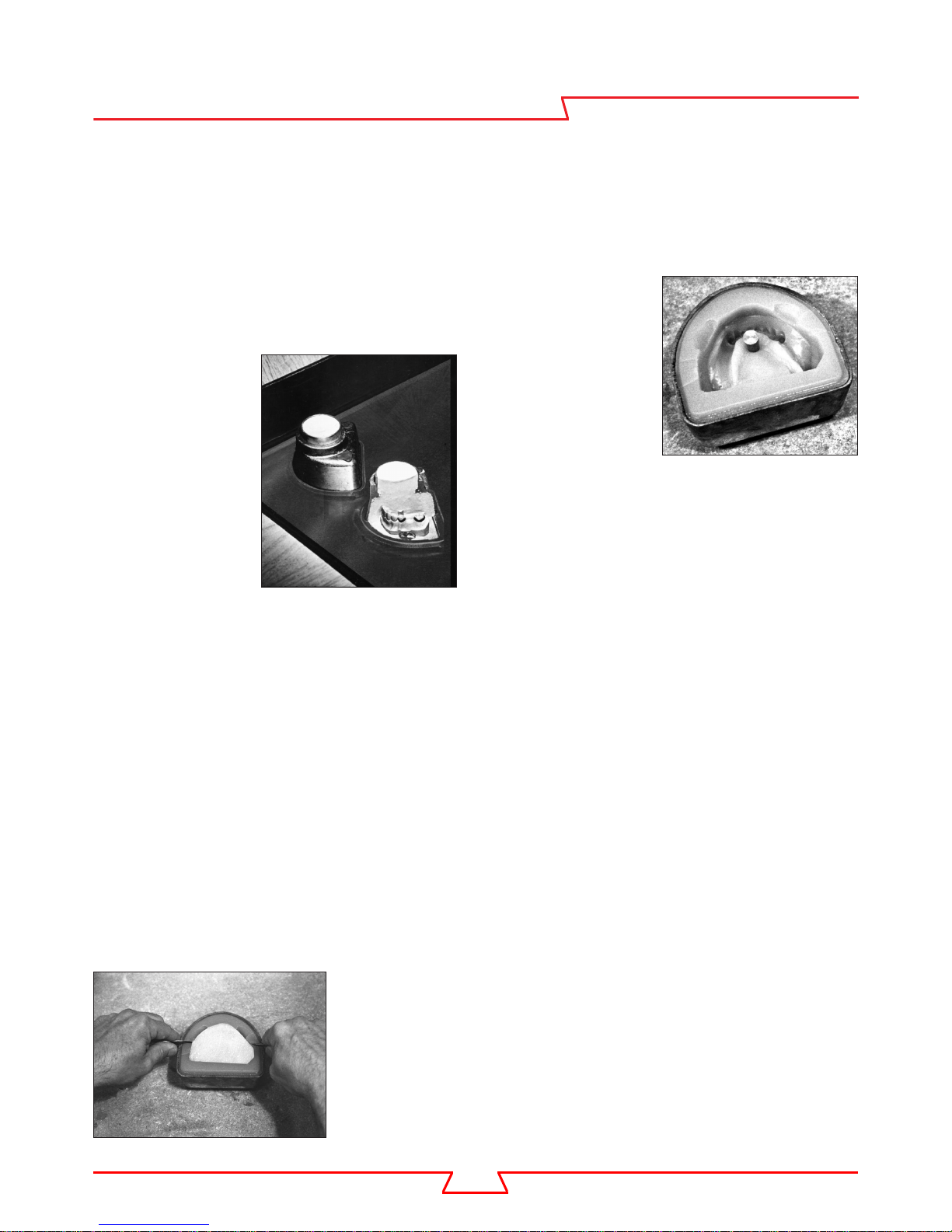

After proper

cooling time has

elapsed, you will

note a dimple in

Figure 9: CHILLING

DUPLICATING FLASK

the colloid in the

pouring spout. This indicates that colloid has

been pulled toward the chilling base, assuring

you that the duplicating material is fixed firmly

against the surface of the model inside the flask.

NOTE: DO NOT lift one side of model before

the other.

If sprue cone remains in duplicating material,

it can now be removed. (see figure 11)

Figure 11:

IMPRESSION

with sprue con

e

Use Ticonium

TM

INVESTIC

WARNING: INVESTIC

for refractory or investment models.

M

T

is harmful when inhaled

repeatedly over a long period of time. Care

should be taken to avoid breathing dust caused

by use of this product. This product contains a

blend of silica and plaster. Symptoms may not

appear until permanent lung injury (silicosis)

has occurred. Immediate clean-up of spills is

highly recommended.

EFFECT OF WATER

Remove the pouring spout by twisting it slightly.

Cut off excess duplicating material projecting

from the body of the flask. Remove the base by

prying with a knife between the base and body

of the flask.

Insert two knives in depression made by the dabs of

TICENE. The model is removed with a quick snap. Pry

up, using the walls of the body of the flask as a fulcrum.

(see figure 10)

Figure 10:

REMOVING

MASTER

MODEL

Most communities are chlorinating and/or

fluoridating the water supply. It is becoming

more and more essential to use distilled

water for mixing investment and duplicating

material. Laboratories have noticed a

pronounced difference in the behavior

both of the investment and duplicating

material during different seasons. Hence,

the recommendation is that only distilled

water be used in mixing both investment

and duplicating material.

The recommended proportion is 29 cc of

distilled water to 100 grams of Ticonium

investment. (Always use room temperature

water. Hot or cold water will accelerate or

retard setting time of investment.)

Use 28 cc of water to 100 grams of

investment for large horseshoe or full bases.

5

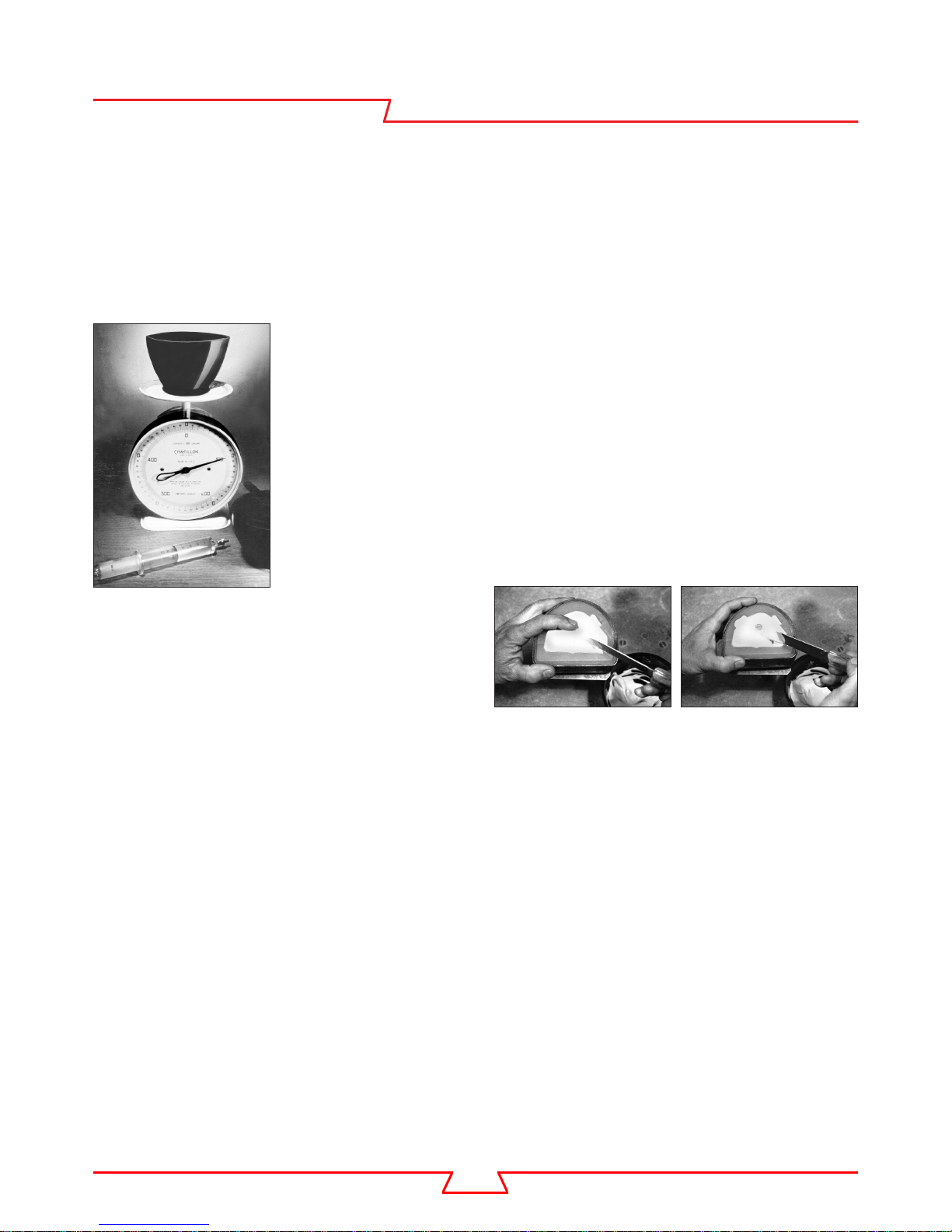

NOTE: Use an accurate scale and syringe

DDUUPPLLIICCAATTIIOON

N

Ticonium Premium 100

for measuring. (see figure 12)

The Dionizer Distiller (#61750) will eliminate

variables in water such as chlorination,

fluorination and deposits of mineral salts

in hard water. (see figure 1 on page 2)

Figure 12:

CAREFULLY WEIGH

inve stment and mea sure

wate r for accuracy

Before vibrating the investment into the

duplicating material, blow out any “free water”

left in the impression, after the master model is

removed from the colloid.

NOTE: The above recommendation is important

to avoid a powdery investment model.

Vibrate directly into the mold. Place a little

investment in the teeth and along the ridges

and vibrate to displace all trapped air. Then

add enough to fill the mold. DO NOT make

it flow around the mold as this may cause

inaccuracies where salts are removed from the

duplicating material by the flow of investment.

Vibrate a small amount of investment around

the sprue cone to form a seal. Now remaining

vibration can be accomplished without holding

sprue cone. (see figure 13)

Mechanical spatulation of a mix used for

models is highly desirable. The expansion

obtained with the investment when it has

been mechanically spatulated can be

controlled much more closely than is possible

with hand spatulation. The investment has been

compounded to provide a combined setting

and hygroscopic expansion of 0.7% when

mechanically spatulated for 30 seconds at a

water/powder ratio of 29 cc to 100 grams and

then poured into Ticonium duplicating material.

If the water/powder ratio is dropped to

26 cc to 100 grams, the combined setting and

hygro-scopic expansion can be forced upward

to 1.1%. Thus a very wide control range has

been built into the investment.

Excessive spatulation will tend to break down

the crystalline structure of the investment whereas

insufficient spatulation will cause a weak model.

If spatulation is by hand, 60 seconds is needed.

Figure 13: VIBRATION

NOTE: By vibrating investment around the steel

sprue cone, the sprue hole produced is smooth

and dense.

After pouring the refractory model the

duplicating flask should be placed in a

location which it will not be subjected to

continued vibration while other cases are

being poured.

Effect of Vibration

If the impressions are placed on the bench

alongside the vibrator as additional refractory

models are poured, the continued effect of

vibration will bring moisture to the interface

between the colloid and the model. This

water layer will result in a powdery surface

on the model.

DO NOT ALLOW TICONIUM INVESTMENT

6

DDUUPPLLIICCAATTIIOON

N

Ticonium Premium 100

TO EXTEND TO THE BODY OF THE FLASK

AS THIS WILL RESTRICT THE AMOUNT OF

SETTING-EXPANSION OBTAINED.

Allow investment model to set 60 minutes,

minimum, before separating from colloid.

SPECIAL NOTES

Occasionally it is a good idea to check your

operating procedures. Many minor deviations

can occur. These deviations add up and can

cause real difficulty.

The following is a list of the problems which

may occur and the errors that cause them.

M

T

1. STORAGE OF INVESTIC

Investment material will pick up moisture if

exposed to humid air. Therefore, it should

be kept in a tightly closed container and in

a cool, dry place.

Investic is doubly protected in a water

resistant carton and a polyethylene bag.

To prevent prolonged exposure after

the package is opened, the material is

packaged in 25 pound containers.

To get the maximum protection, we recommend

that after you have removed investment from the

polyethylene bag you squeeze the bag down

snugly against the surface of the investment,

thus squeezing out any air (see figure 14)

and preventing prolonged contact between

the investment and air.

:

Figure 14:

SQUEEZE AIR

out of investment

bag to prevent

cont amination

The 25 pound pack is a convenient unit to

use right at the bench and many labs now

use it instead of the wall mounted plaster

bin. However, if you are still working with

the plaster bin, check its location. In many

instances the bin is located alongside a

boil-out tank where steam is given off and

allowed to come in continual contact with

the investment. This will cause difficulty.

TM

2. PROPER HANDLING OF INVESTIC

:

Attention must be given not only to the

investment, but also to the materials used

in conjunction with it.

3. TESTING: Ticonium INVESTIC

TM

can absorb moisture from the air which

will affect accuracy. Investments may be

checked as follows:

When a new package of investment is opened,

mix 30 cc of distilled water with 100 grams

of investment for 30 seconds, mechanically, or

one minute by hand. Then check the time from

the start of spatulation until the surface of the

investment appears to be dry. To check the

batch later, repeat this operation to see if

the time corresponds. If moisture has been

absorbed, the setting time will have increased.

4. SLOW SETTING: Slow setting

investment can cause difficulty. Slow setting

is usually caused by severe hydration of

the investment. To avoid trouble, keep the

investment in a tightly sealed container.

RAPID SETTING CAN RESULT IF HYDRATED

7

NVESTMENT IS MIXED WITH NORMAL INVESTMENT.

DDUUPPLLIICCAATTIIOON

N

Ticonium Premium 100

I

INVE S TMENT MO D EL

The most common ways this may occur are:

A. Old investment clinging to the blades

of a mechanical spatulator.

B. Investment trapped in worn areas of

a plaster bowl.

C. Investment which has caked on the

weighing scoop.

Duplicating material which has been used

during the day should be:

A. Rinsed off in cool tap water.

(Preferably giving final rinse in distilled water.)

B. Cut into small pieces.

C. Returned to a cool air tight container

and covered with a damp towel.

PREPARATIO N

IMPORTANT

Always allow the investment to set in

the duplicating material for a 1 hour

minimum. Premature separation of the

refractory model is a potential cause

for loose, powdery investment deposits.

Look for a change in investment setting

time, particularly during the summer months

(when humidity is high), as hydration of

the investment may occur. Originally the

hydration will cause a speed up in the setting

time, but this will later reverse, and result in a

retarding action. If the normal setting time of

the investment, which is about 8 to 9 minutes

initial setting, starts to increase, the refractory

model may not be completely set and hard in

the normal one hour.

Usually the moisture that remains on the surface

of the colloid during rinsing is sufficient to

replace lost water in the duplicating process.

However, it may be necessary to add additional

water to maintain proper consistency.

NOTE: Never store duplicating material

by immersing in water. This will cause the

duplicating material to absorb water and

rapidly lose accuracy and strength.

Also, never store the colloid near a heat source,

such as sunny windows or boil-out tanks as this

may result in water loss.

Following these simple rules, Ticonium

Duplicating Material can be used effectively

and with the greatest degree of accuracy for

approximately 200 duplications or two to four

weeks of normal use.

TECHNICAL INFORMATION

Remove duplicating material from duplicating

flask and break duplicating material away from

investment model. (see figure 15)

Figure 15:

SEPARATE

inve stment mode l

from collo id

As soon as model is removed from mold,

outline with a pencil approximately 1/4”from

extremities of proposed pattern and trim with

knife or wet model trimmer. (see figure 16)

8

Keep fingers off of abutment teeth, regardless

MMOODDEELLPPRREEAARRAATTIIOON

N

Ticonium Premium 100

of how model is trimmed.

Figure 16:

WET GRIND

inve stment mode l

to outline

Immediately after trimming, the refractory model

should be carefully rinsed under running water

to rinse off any slurry adhering to it.

Dry model in the Ticonium Model Drying

Oven (#40551) for approximately one hour

at 190°-200° F (88°-93° C). (see figure 17)

Be sure to check the temperature of the Model

Drying Oven to prevent the temperature from

going above 190°-200° F (88°-93° C).

Over-drying the model will result in the

breakdown of the investment. It is best

not to exceed a temperature of 200° F (93° C).

It is important not to obstruct the vents on

the top of the unit, except the center one

where the thermometer should be placed.

Melt beeswax in a pan or

thermostatically-controlled pot.

Only refined beeswax should be used.

Check temperature of the wax occasionally

until 280°-300° F (138°-149° C) is reached.

If a thermometer is not available, you should

dip just as the beeswax begins to smoke.

Figure 18:

BEESWAX HEATER

#62133

Figure 17:

MODEL DRYING

OVEN #40551 with

a large drying area

Thermostatically-controlled pots, such as

Ticonium’s Beeswax Heater (#62133), are

available to prevent over-heating of the wax.

(see figure 18) These units are recommended to

maintain proper control of beeswax temperature.

NOTE: Temperature of the beeswax is

approximately 100° F (38° C) above the

temperature of the investment model.

9

When the beeswax has reached the proper

MMOODDEELLPPRREEAARRAATTIIOON

N

Ticonium Premium 100

temperature, immerse the dehydrated model.

After a few seconds, a foaming action will be

observed. The model should remain immersed

for 15 seconds after foaming starts. It should

then be removed and placed on a piece of

absorbent paper so excess beeswax will drain

off. (see figure 19) After a few seconds, move it

to another position on the absorbent paper so

that a pool is not allowed to collect at the base

of the model and solidify. Allow model to cool

and then begin waxing.

Figure 19:

MODEL DIPPED

in beeswax and

set to dry

Excessive heat during drying or immersing the

refractory model in the beeswax for too long

will alter the subsequent thermal expansion

of the investment.

SPECIAL NOTE

If you encounter difficulties with soft or powdery

investment surfaces, follow the special notes

described in the Duplication Chapter.

In order to use refractory models with

these symptoms, leave the case on the bench

over-night prior to drying and beeswax dipping.

This overnight setting will allow the investment

to improve in surface hardness.

The next day, place the refractory

models in the Model Drying Oven and dry at

190°-200° F (88°-93° C) for 45 minutes. This

drying process is fifteen minutes less than the

normal recommended procedure because a

large percentage of the water has already

evaporated during the overnight setting and

the model will be much easier to dry.

Next, dip in beeswax per normal

recommendations in this manual.

Some advantages of beeswax

dip over spraying are:

SPECIAL CARE IS NEEDED IN THIS STEP!

Contaminated Beeswax

After extensive use, the beeswax can pick up

an appreciable amount of investment residue.

Unless the beeswax is cleaned periodically, this

residue may attach itself to the surface of the

model during the beeswax operation.

PURE TICONIUM

BEESWAX #65

1. Eliminates soaking investment

model prior to applying the painting

layer of investment.

2. Assures a smooth, dense surface on

which to wax.

3. The action of the beeswax during

dipping drives out any excess moisture in

the model. Transfer the design from the master

cast to the investment model with a wax crayon

pencil. Use of a graphite pencil may cause pits

in the final casting.

10

WAXING

SSPPRRUUIINNG

G

Ticonium Premium 100

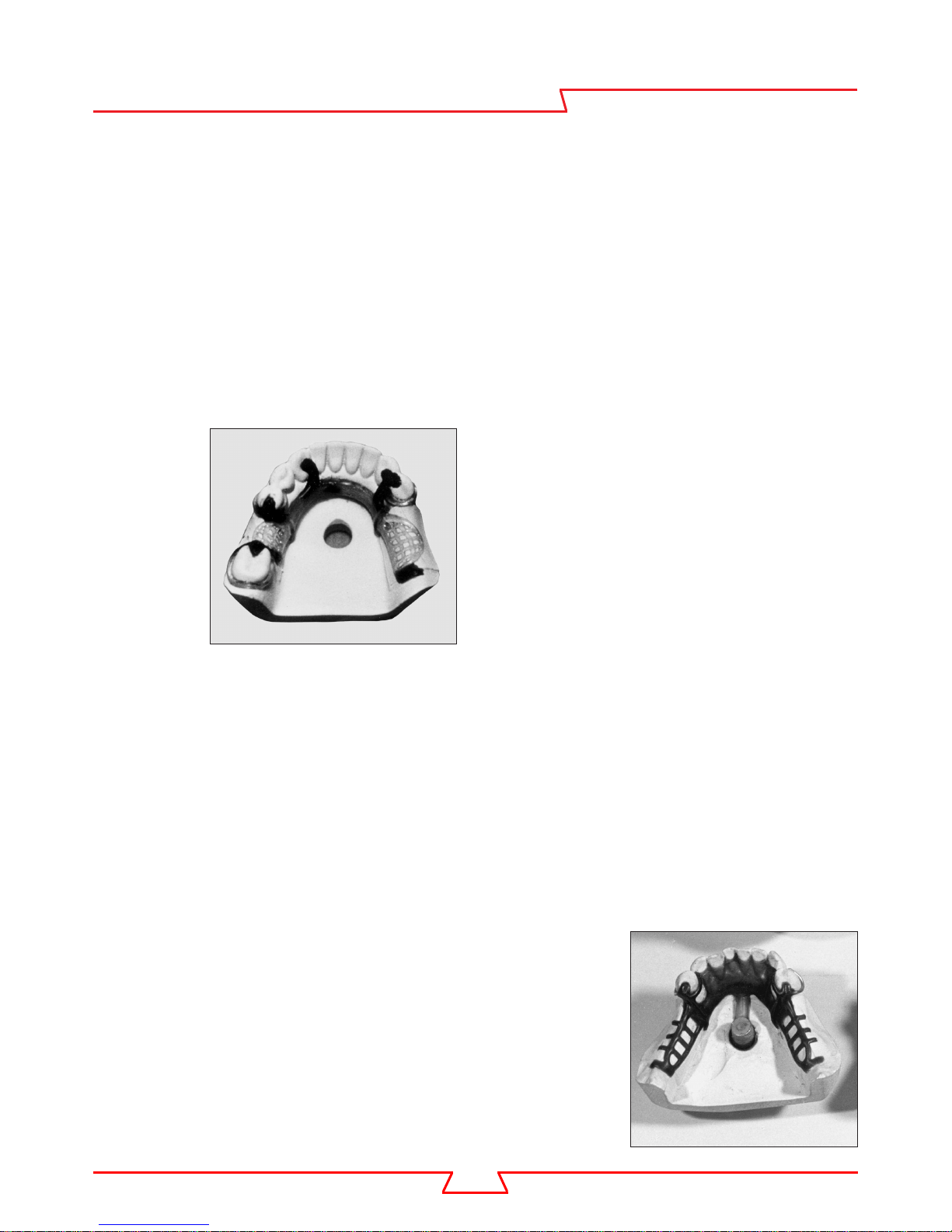

One of the most important considerations in

being an effective waxer is: ALWAYS USE WAX

OF KNOWN GAUGE OR THICKNESS.

Clean wax is essential. Wax containing debris

will certainly result in pits in the finished case.

Use preform plastic patterns to aid you further

in waxing uniformity. This will give your finished

case maximum strength and minimum bulk.

TYPICAL

TICONIUM

WAX-UP

SPRU I NG

SPRUE PIN CLEANLINESS

If the sprue pins are not kept perfectly clean,

the remaining investment will harden to the

surface and can become bonded to the new

investment. This will then loosely attach to the

surface of the mold. If sodium citrate solution

is used to soften the old investment and keep

the pins clean, it is essential that they be

thoroughly washed and rinsed before use.

Since the sodium citrate solution is a drastic

retarder, it will prevent the investment coming

in contact with the pin, coated with sodium

citrate, from setting.

First it is necessary to establish some basic facts

on spruing.

1. All metals shrink during solidification.

We cannot eliminate this shrinkage. We can,

however, compensate for the shrinkage

of Ticonium.

The following gauges are suggested for either

sheet wax or plastic stipple sheet:

1. Full upper palates – 26 gauge.

2. Narrow upper horseshoes – 24 gauge.

3. Broad upper horseshoes – 24 gauge.

4. Lower lingual plates – 24 or 26 gauge.

5. Saddle relief – 24 gauge.

6. Lingual bar relief – 28 to 30 gauge.

NOTE: Stippled TI-FORM patterns are

suggested for simulating tissue detail.

2. Never feed a thick section through

a thin section – ALWAYS SPRUE TO THE BULKY

SECTION OF YOUR PATTERN.

The ideal casting is one that gets progressively

smaller in volume from the point of attachment

of the sprue to the extremities of the casting.

(see figure 20) It is impossible, however, to

maintain this ideal situation since all dental

castings vary.

Figu re 20 :

TY PI CA L S IN GL E

SP RU IN G f ro m

bulk y to small er

volu me ar ea s

11

Loading...

Loading...